Thermal-insulation slurry and preparation method thereof, water-based insulating glass coating and preparation method thereof

A heat-insulating slurry and heat-insulating glass technology, applied in the field of coatings, can solve the problems of insufficient transparency, unsatisfactory heat insulation performance, poor heat insulation effect, etc., achieve simple process operation, maintain long-term stability and uniformity, and solve transparent The effect of insufficient sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

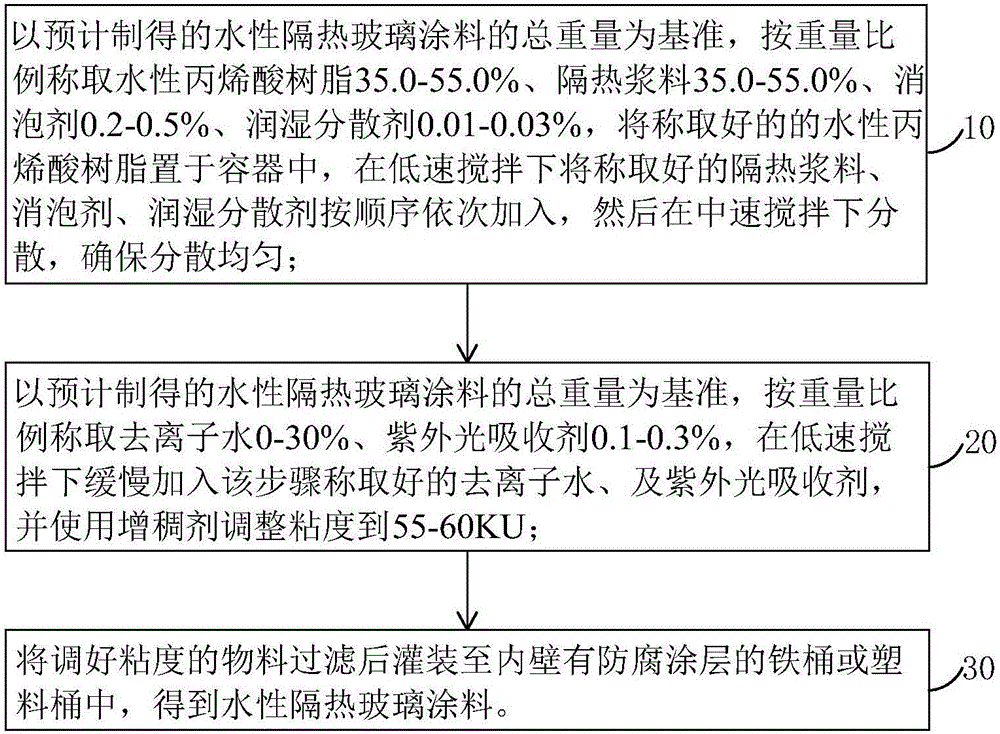

[0047] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

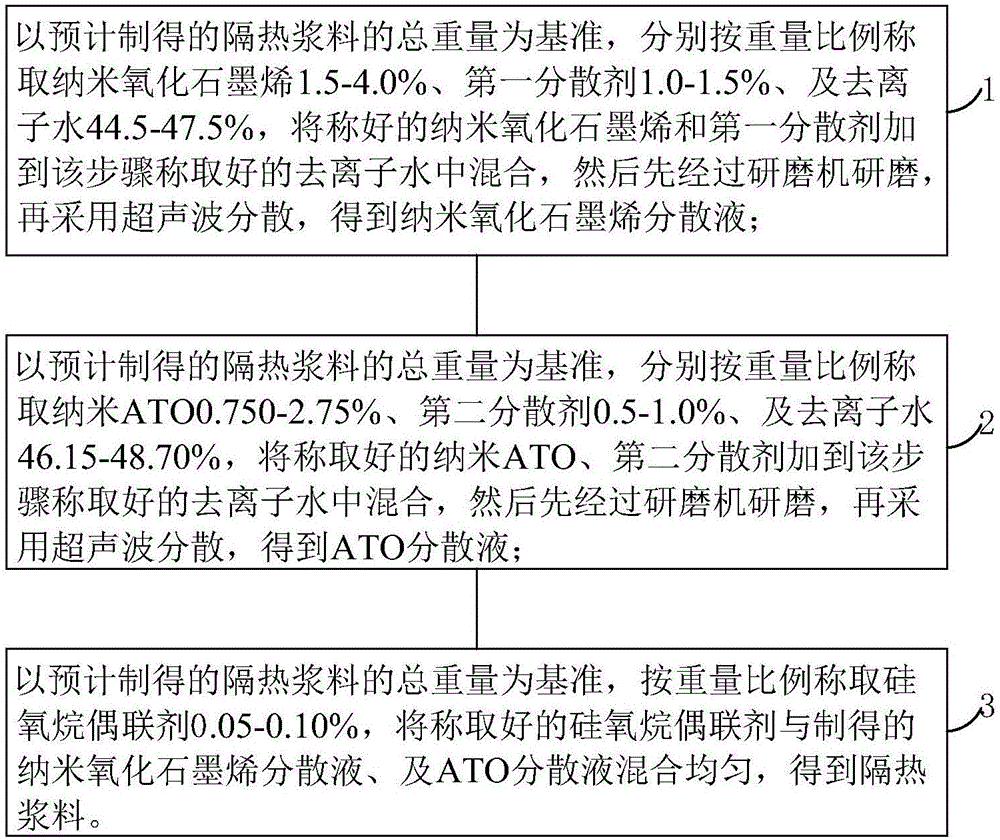

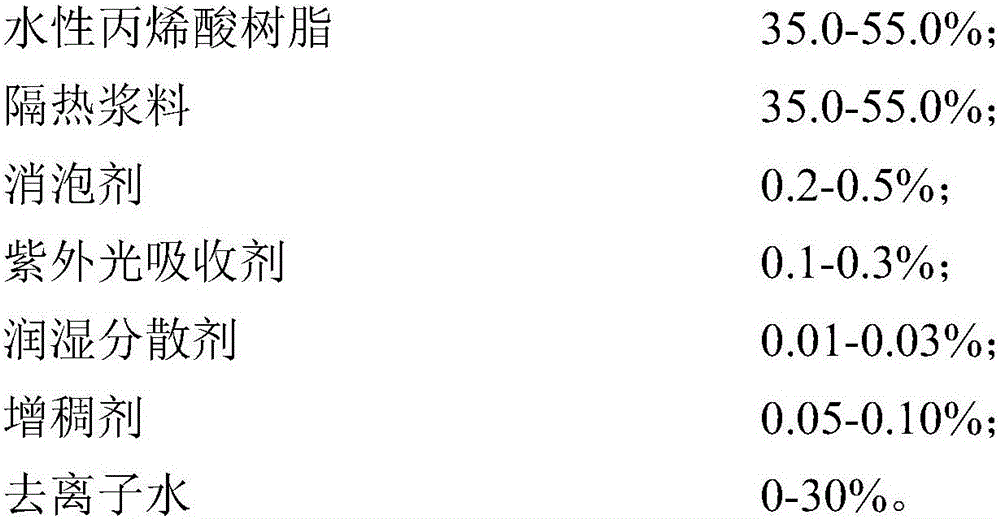

[0048] The present invention firstly provides a heat-insulating slurry, the components and weight percentages of which are included in the formula are as follows:

[0049] Nano graphene oxide dispersion 47-53%;

[0050] Nano ATO dispersion 47.4-52.45%;

[0051] Silicone coupling agent 0.05-0.10%;

[0052] Wherein, the nano-graphene oxide dispersion liquid includes nano-graphene oxide, the first dispersant, and deionized water, and the nano-graphene oxide, the first dispersant, and deionized water in the nano-graphene oxide dispersion liquid are The weight percentages in the heat insulating slurry are respectively 1.5-4.0%, 1.0-1.5%, 44.5-47.5%;

[0053] The nano-ATO dispersion includes nano-ATO, the second dispersant and deionized water, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com