Indoor wheel rutting instrument

A rutting and horizontal technology, applied in the direction of material inspection products, etc., can solve the problem of large shearing effect, and achieve the effects of stable test temperature, shortened heating time, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

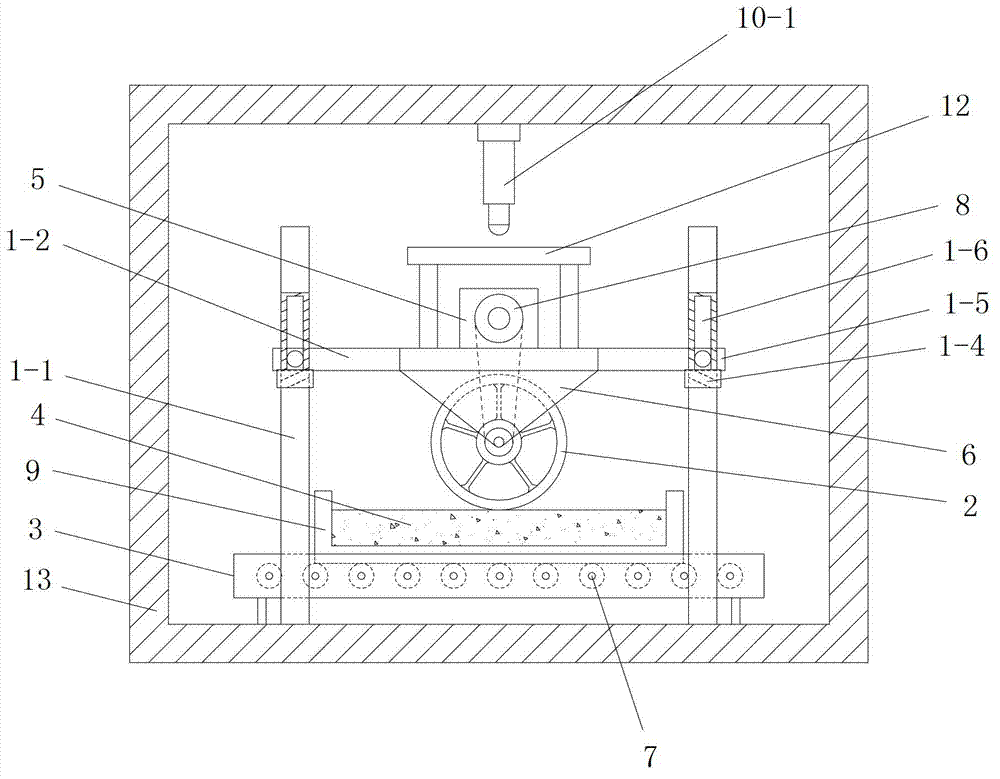

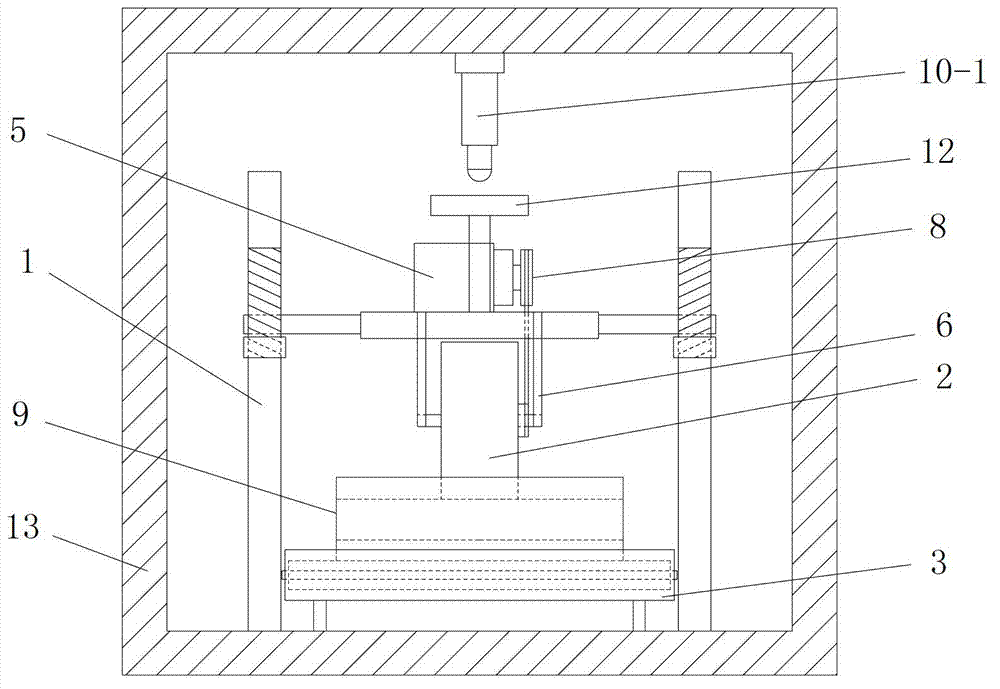

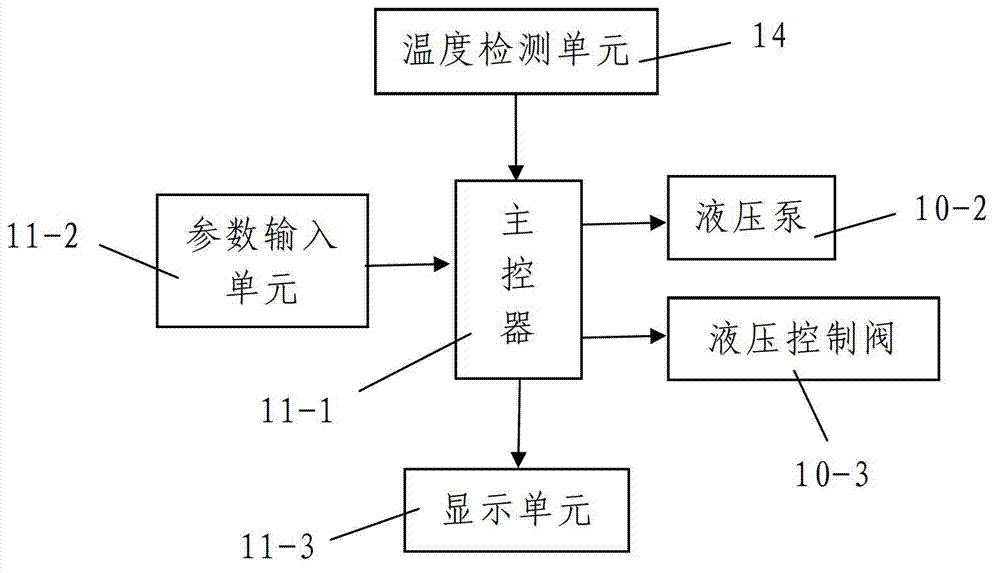

[0037] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a horizontal test bench 3, a rolling support device arranged on the horizontal test bench 3 and arranged horizontally, a test piece 4 for the rutting test is installed and can drive the test piece 4 to perform on the rolling support device The horizontal sliding part that moves back and forth, the test wheel bracket 1 with adjustable support height, the test wheel 2 supported on the test piece 4 at the bottom, and the drive motor 5 that drives the test wheel 2 to rotate continuously. The horizontal sliding part is placed horizontally on the rolling bearing device. The test wheel support 1 is provided with two left and right wheel frames 6 for the axles of the test wheel 2 to be mounted on, and the left and right ends of the wheel axle are mounted on the two wheel frames 6 through bearings respectively. The power output shaft of the driving motor 5 is connected to the wheel shaft throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com