Horizontal plate thermal bridge structure

A technology of horizontal plates and thermal bridges, applied in the direction of building components, heat preservation, etc., can solve the problem of not considering the relationship between the length of the heat preservation plate and the horizontal plate, and achieve the effect of saving heat preservation materials and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

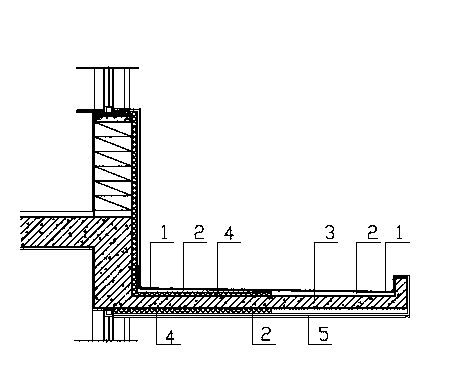

[0009] like figure 1 As shown, for the thermal bridge structure of the horizontal plate, within the range of the non-condensing thermal resistance length, use 1:3 cement mortar to level the unevenness of the horizontal plate, paste insulation materials, and press 4 mm polymer mortar on the insulation materials. Into the grid cloth, 20 mm waterproof mortar to find a 1% slope. Waterproof mortar returns 250 along the exterior wall. Paste thermal insulation material under the horizontal board, use 4 mm polymer mortar to press into the grid cloth under the thermal insulation material, and paint. Outside the length range of non-condensing thermal resistance, apply waterproof mortar on the horizontal board to find a 1% slope, and the thickness shall be in line with the place where there is insulation material. Under the horizontal board, apply 1:3 cement mortar and paint the finish layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com