Heat preservation interlayer and heat preservation tool

A thermal insulation interlayer and tool technology, applied in the field of thermal insulation interlayer, can solve the problems of product quality degradation, insufficient cold preservation effect of fresh food, etc., and achieve the effect of improving performance, ensuring product quality, and saving thermal insulation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

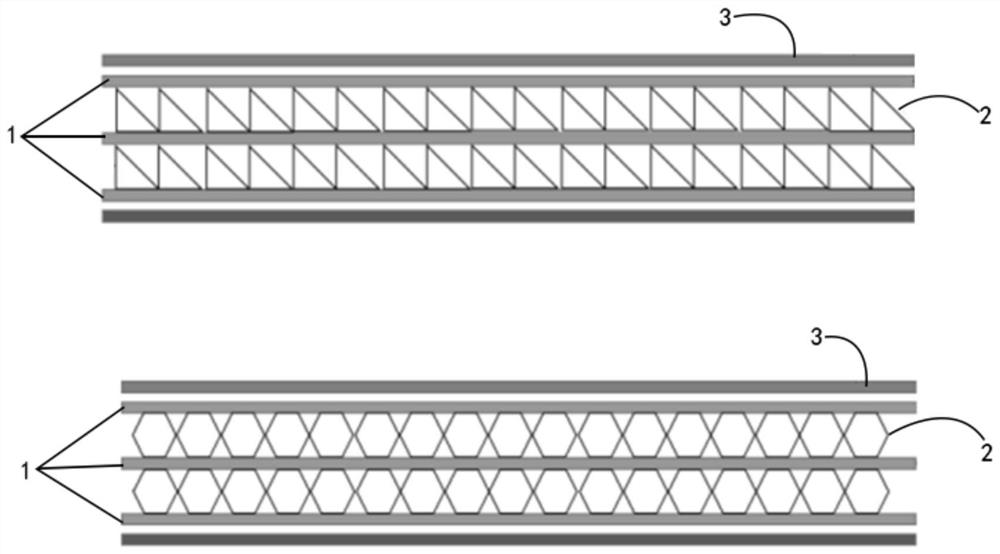

[0037] like figure 1 As shown, the embodiment of the present invention provides a thermal insulation interlayer, which includes: a first thermal insulation layer 1 and a second thermal insulation layer 2 .

[0038] Specifically, in the embodiment of the present invention, a plurality of first heat insulation layers 1 are provided at intervals, and a gap is provided between two adjacent first heat insulation layers 1 . Further, the first heat insulation layer 1 may be made of airgel material, and the first heat insulation layer has a planar structure. A second heat-insulating layer 2 is arranged in the gap, said second heat-insulating layer 2 also consisting of an airgel material. The airgel material may be a flexible aerogel or a rigid aerogel. In the embodiment of the present invention, the second heat insulation layer 2 is pressed and arranged in a three-dimensional pattern shape, and the three-dimensional pattern shape may be triangular or hexagonal. Specifically, it may...

Embodiment 2

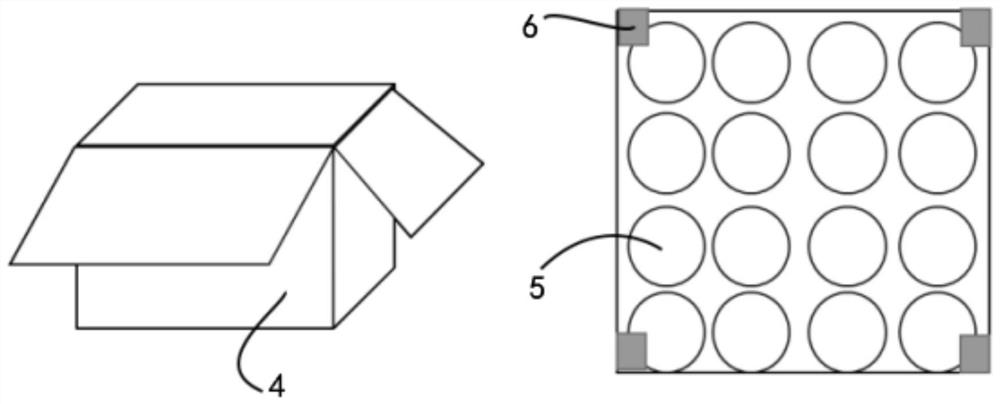

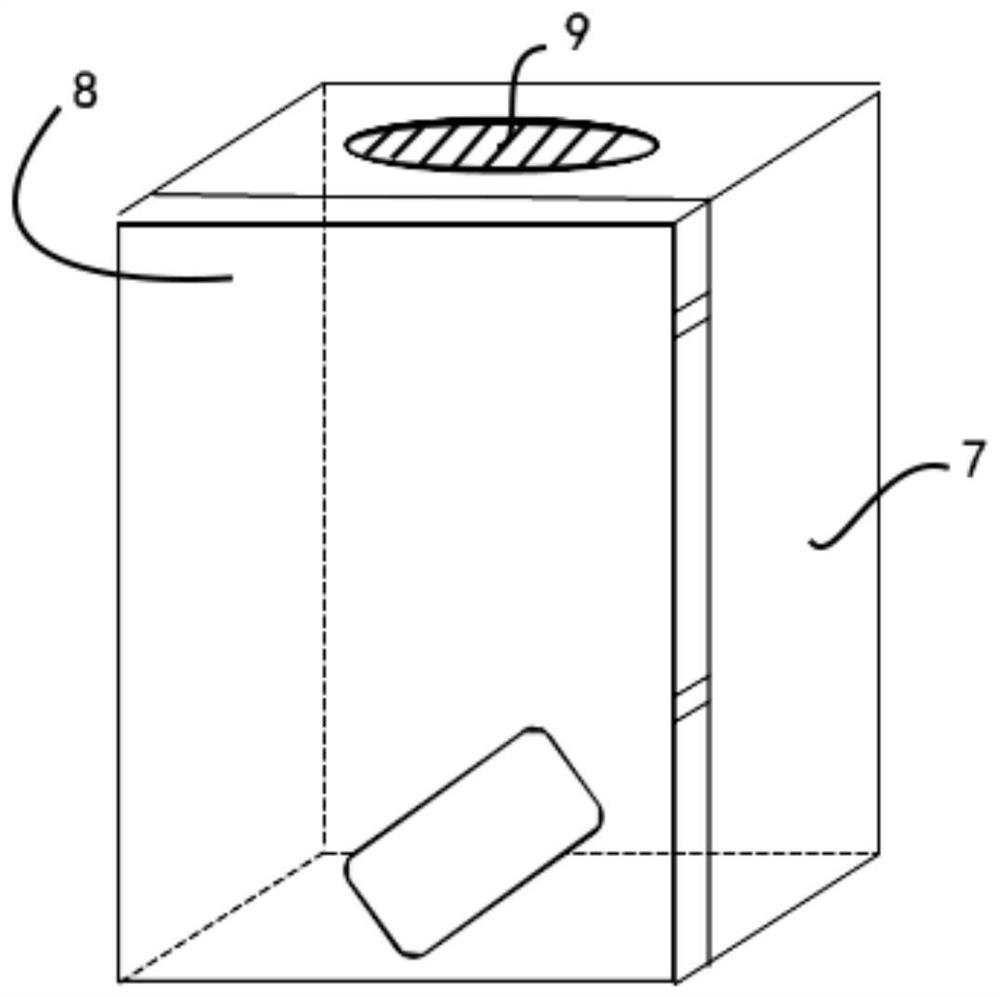

[0051] like Figure 2 to Figure 4 As shown, the embodiment of the present invention also provides a thermal insulation tool, which includes: the thermal insulation interlayer as described in any one of the above embodiments, and the thermal insulation tool is composed of the thermal insulation interlayer.

[0052] Specifically, in an optional embodiment of the present invention, the heat preservation tool can be a storage and transportation box 4, and a cold source 6 is arranged around the bottom of the storage and transportation box 4, and the cold source 6 is made of a phase change material. production. When the storage and transportation box 4 is a dairy product storage and transportation box 4, a product base 5 can be set at the bottom of the storage and transportation box 4, for example, it can be matched to a circular base, a square base or other shapes according to the actual nature of the product, in order to increase the overall For the cold storage effect of the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com