Shaped wire stranded cable conductor and production method thereof

A stranded cable, special-shaped technology, applied in cable/conductor manufacturing, conductors, non-insulated conductors, etc., can solve the problems of high voltage breakdown probability, high conductor resistance increase, and many single wires, etc., to save cables. materials and auxiliary materials, the reduction of the outer diameter of the conductor, and the small gap between the single wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

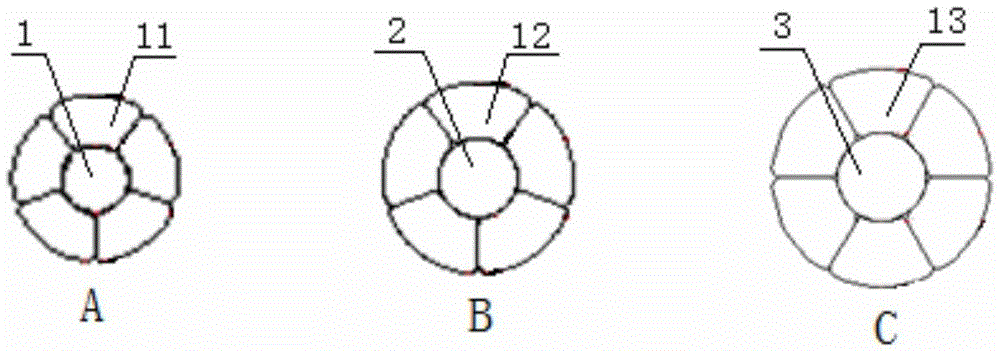

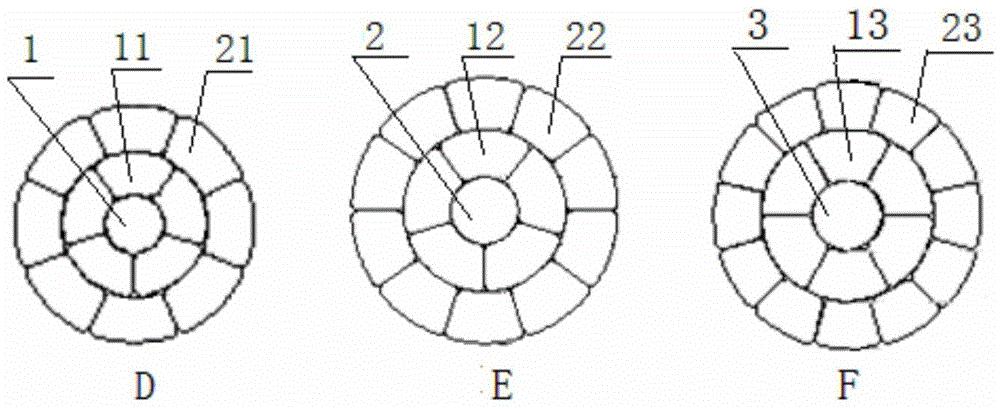

[0056] Embodiment 1: The present invention provides a special-shaped wire twisted cable conductor, and the cross-section of the special-shaped single wire is tile-shaped; the conductor in this embodiment is made of aluminum alloy. The product series numbers are A, B, C, D, E, F, G, I, J, L, N, O and P, and there are 13 specifications in total. The special-shaped wire stranded cable conductor of the present invention includes a single wire with a circular cross-section in the center layer, and at least 5 to 72 single wires with a special-shaped cross-section. 2 .

[0057] see figure 1 , the one-layer special-shaped single wire has three kinds of products numbered A, B, and C, and the diameters of the corresponding center layer round single wire are 2.40mm, 2.86mm, and 3.32mm respectively, and the special-shaped single wire with one layer is respectively There are 5, 5, and 6 wires, and the radians corresponding to each tile-shaped conductor are 72°, 72°, and 60° respectively....

Embodiment 2

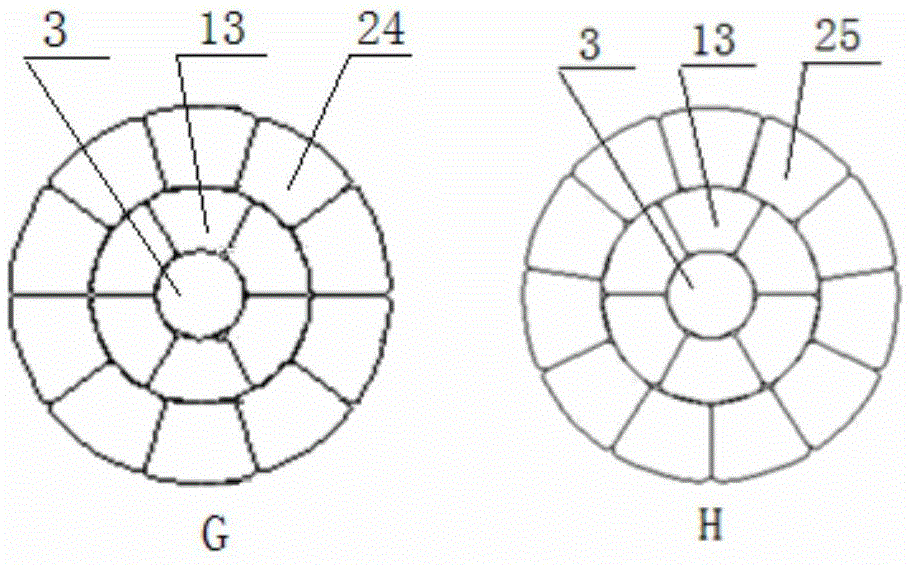

[0066] Embodiment 2: The present invention provides a special-shaped wire stranded cable conductor made of copper material, and the product series numbers are A, B, C, D, E, F, H, I, K, M, N, O and P, There are 13 specifications. The product includes a circular cross-section single wire in the center layer, and at least 5 to 72 special-shaped single wires. The special-shaped single wire has 1 to 5 layers, and the nominal cross-section of the stranded conductor is 25 to 630mm. 2 ; The profiled single-line cross-section is tile-shaped; the structure of numbers A, B, C, D, E, F, I, N, O and P in the series of products is the same as the aluminum alloy material structure of embodiment 1, only wherein Numbering is H, K, M product structure is different from embodiment 1.

[0067] see image 3 , the product number is H. The product structure is: 2 layers of special-shaped wires, including a central circular wire 3 with a diameter of 3.22mm; 6 special-shaped wires 13 with an outer ...

Embodiment 3

[0070] Embodiment 3: The present invention provides a method for producing special-shaped wire stranded cable conductors. This embodiment takes the production of an aluminum alloy product with number N as an example. Equipment needs to be prepared before production, including 13-mode sliding wire drawing machine, and raw materials: preparation 9.5mm aluminum alloy rod; then follow the steps below:

[0071] ⑴, due to the specific special-shaped wire stranding structure size and special-shaped single wire size design of the number N aluminum alloy product cable conductor each layer specification that has been completed in embodiment 1; and the conductor cross-sectional area is calculated to meet the national standard resistance value requirements; also calculated The width-to-height ratio of the special-shaped wires of each twisted layer of each specification is guaranteed to ensure that the special-shaped wires do not turn over during the drawing and twisting process.

[0072...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com