Steam direct pressure type drying device of veneer materials

A drying device and steam technology, applied in the direction of static material dryer, drying gas arrangement, local stirring dryer, etc., can solve the problems of high energy consumption and expensive equipment, and achieve less heat loss, fast drying speed and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

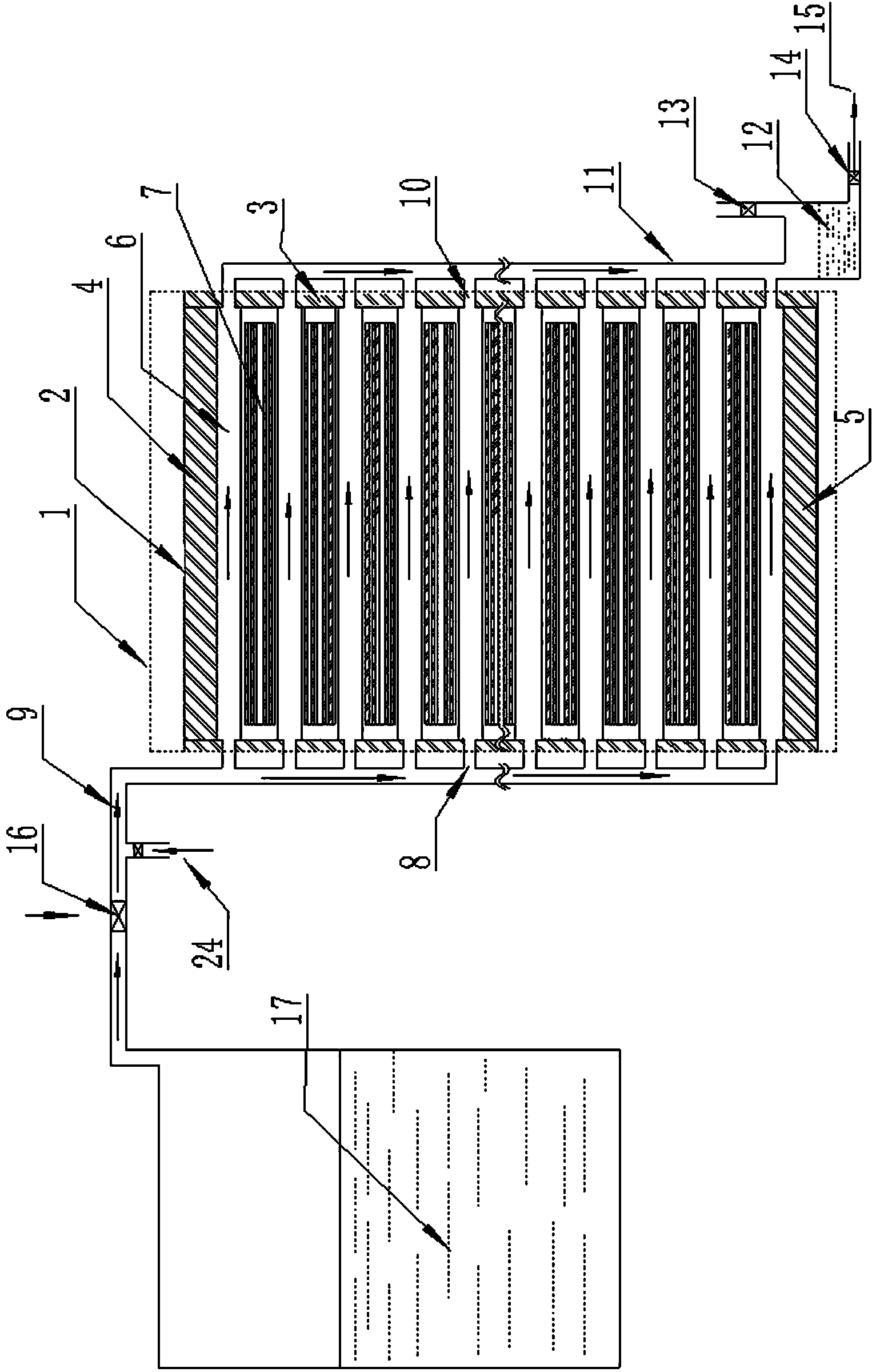

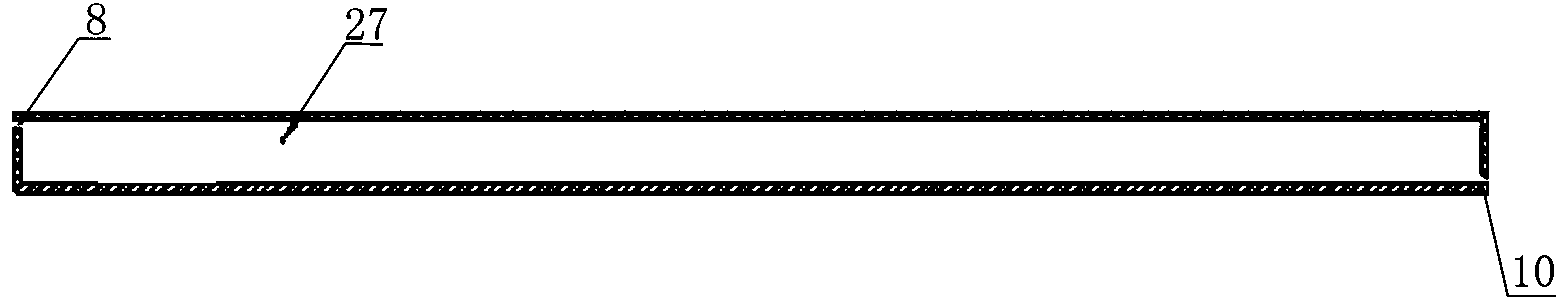

[0028] refer to figure 1 , figure 2 and image 3 , a steam direct pressure type veneer material drying device, comprising a drying box 1, a steam boiler, a steam supply pipe 9 connecting the drying box 1 and the steam boiler and a valve 16 arranged on the steam supply pipe 9, the periphery of the drying box 1 There is a heat insulation layer, and a drying rack 2 is arranged in the drying box 1. The drying rack 2 is placed horizontally in the drying box 1. The top and bottom layers of the drying rack 2 are the upper pressure limit plate 4 and the lower bearing made of steel plates. The pressure limiting plate 5 is fixedly connected with the connecting rod 3 arranged between the upper and lower pressure limiting plates, and the same stainless steel plate is arranged in parallel at equal intervals to make the surrounding closed. Hollow heating plate 6, the side of heating plate 6 of each layer is fixedly connected with connecting rod 3, is provided with steam inlet 8 on the sa...

Embodiment 2

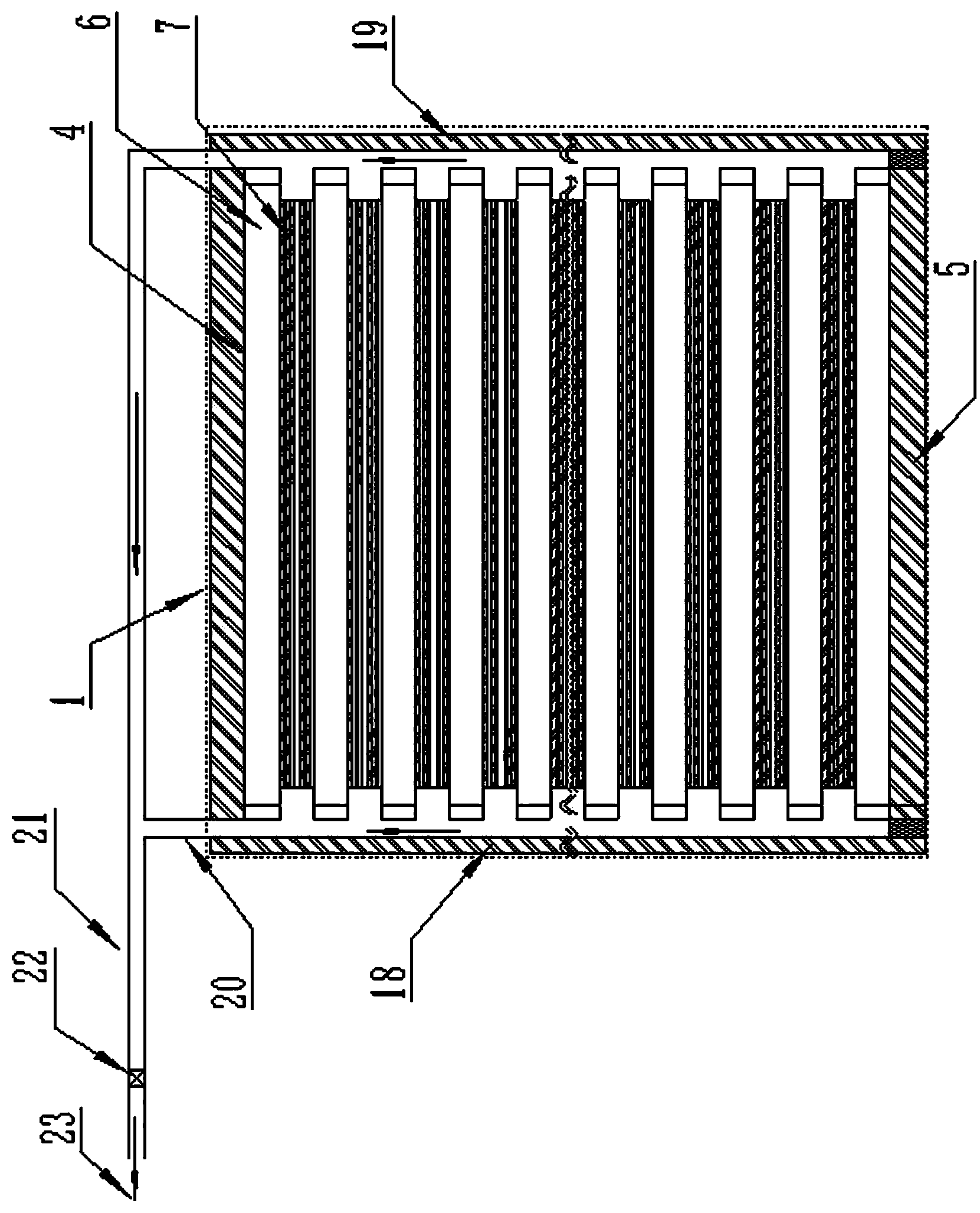

[0035] refer to image 3 , Figure 4 and Figure 5, a steam direct pressure type veneer material drying device, the difference from embodiment 1 is: the drying rack 2 is vertically placed in the drying box 1, and the left and right sides are left pressure limiting plates 25 made of steel plates With the right pressure limiting plate 26, the connecting rod 3 is fixedly connected between the left and right pressure limiting plates, and the same spacing is arranged in parallel between the left and right pressure limiting plates. Hollow heating plates 6 closed all around, the upper and lower sides of each heating plate 6 are fixedly connected with the connecting rod 3, and the upper end surface of each heating plate 6 is provided with a steam inlet 8, and the connecting pipe of the steam inlet 8 communicates with the boiler steam supply pipe 9 , steam can pass into the heating plate inner cavity 27, and the lower end surface of each heating plate 6 is provided with a gas-liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com