Micropore insulation baked brick and manufacturing method thereof

A production method and technology of sintered bricks, applied in building materials, building components, buildings, etc., can solve the problems of poor thermal insulation effect and low compressive strength, and achieve the effect of reducing density, high strength, and saving thermal insulation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

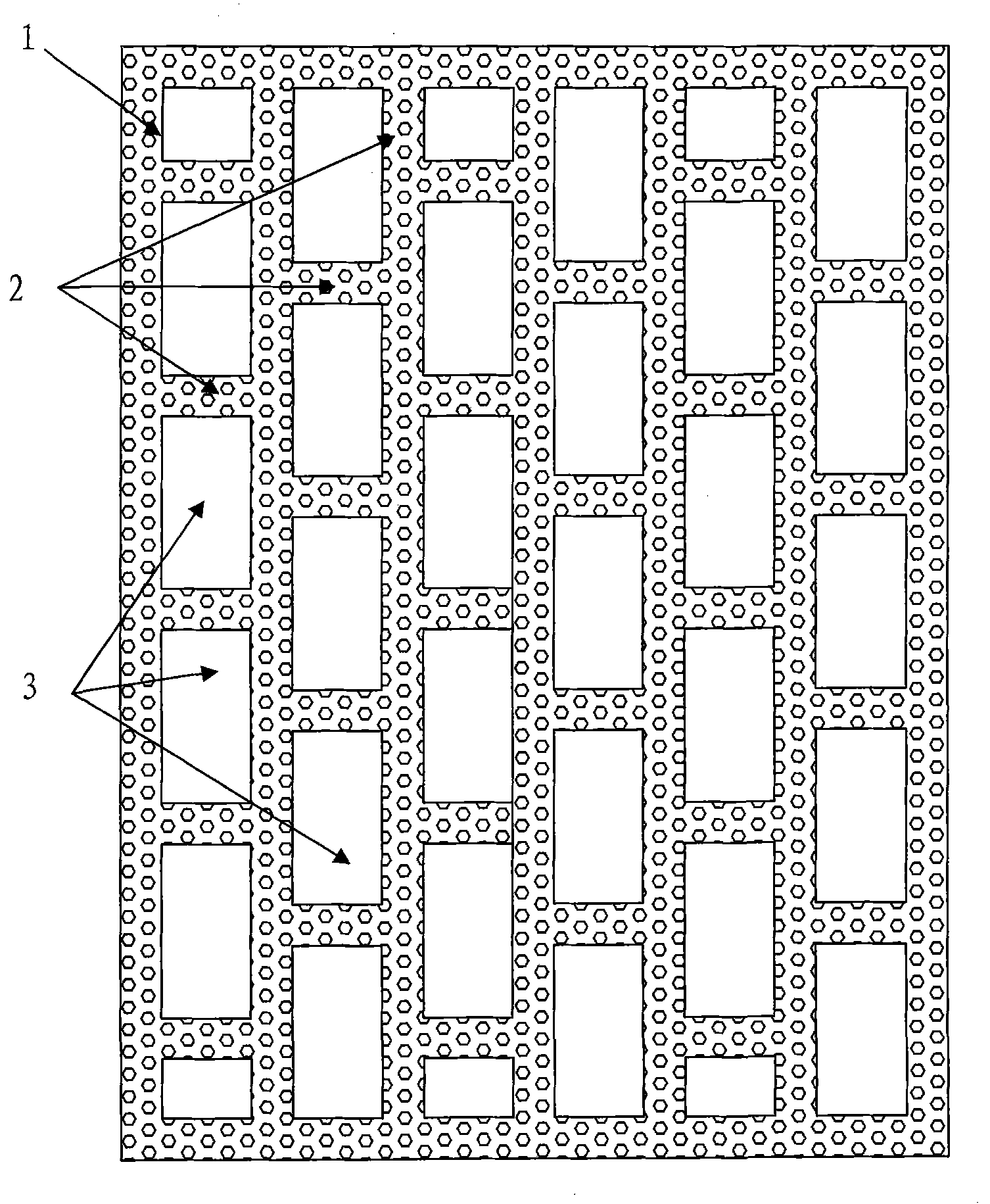

[0031] A microporous sintered brick, which is composed of a brick wall 1, a brick rib 2, and a brick hole 3. The brick rib 2 is located in a cavity surrounded by the brick wall 1 and is connected with the brick wall 1 or brick rib 2. In the raw material of making brick wall 1 and brick rib 2, adding volume accounts for 40% and has 2Mpa intensity, and diameter is the combustible organic particle of 1-2 millimeter, makes brick wall 1 and brick wall 2 have about 1-2 millimeter microporous.

Embodiment 2

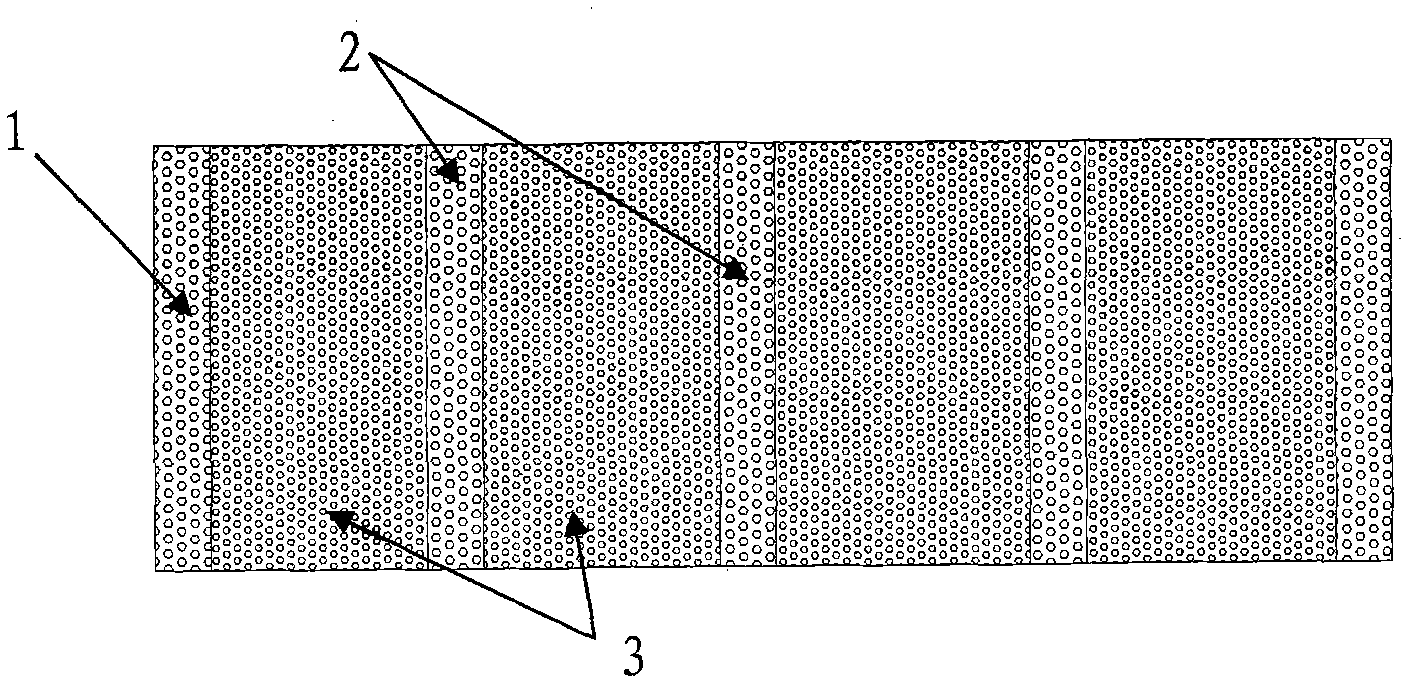

[0033] A microporous sintered brick, which is composed of a brick wall 1, a brick rib 2, and a brick hole 3. The brick rib 2 is located in a cavity surrounded by the brick wall 1 and is connected with the brick wall 1 or brick rib 2. In the raw materials for making brick wall 1 and brick rib 2, organic matter particles with a volume accounting for 30% and a strength ≥ 2Mpa and a diameter of about 3 mm are added to form micropores of about 2-3 mm on the brick wall 1 and brick rib 2 .

Embodiment 3

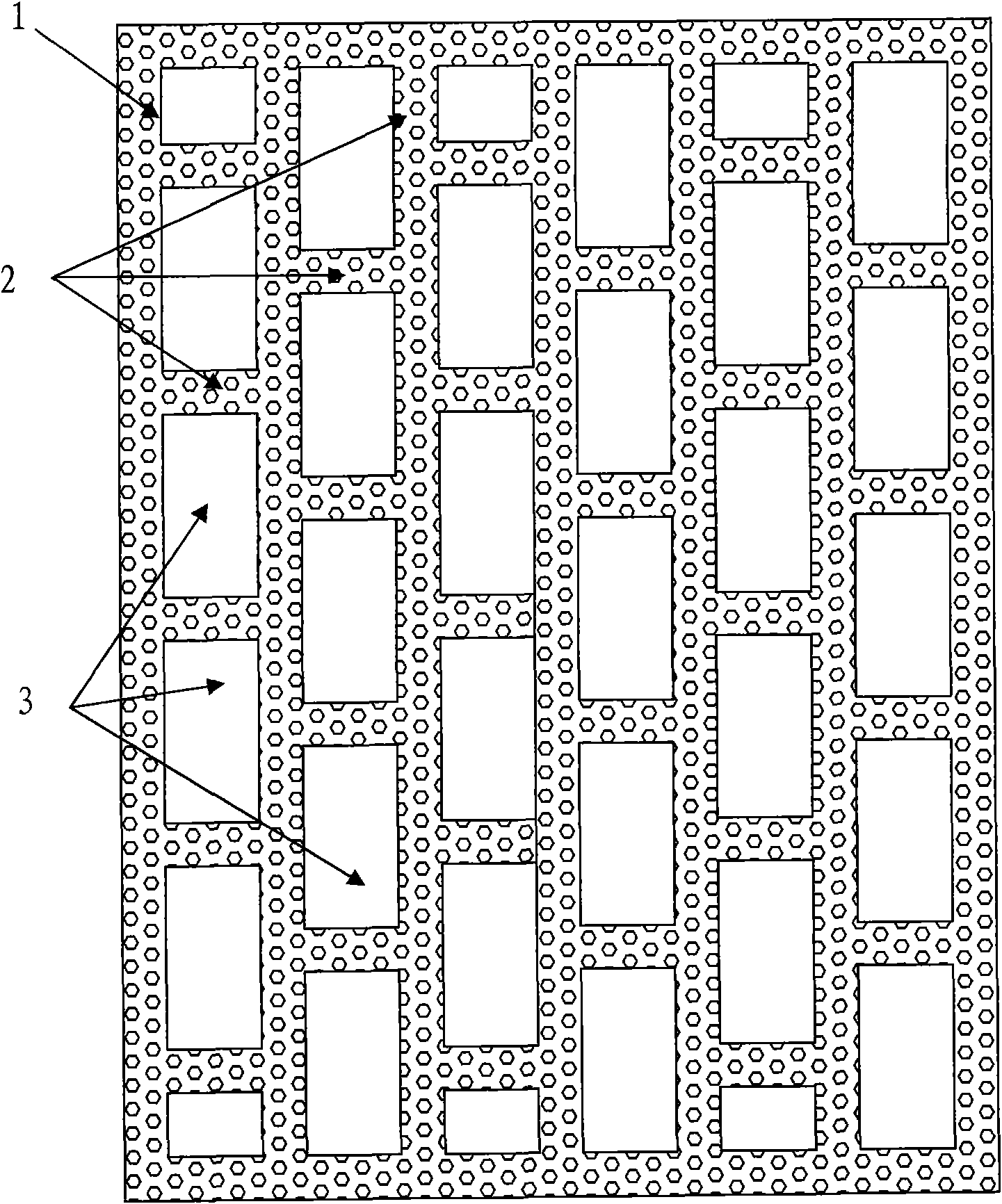

[0035] A microporous sintered brick, consisting of a brick wall 1, a brick rib 2, and a brick hole 3, the brick rib 2 is located in a cavity surrounded by the brick wall 1, and is connected with the brick wall 1, and the brick wall 1 is made Adding polystyrene particles with a diameter of about 3 mm and a volume of 30% to the raw material of the brick rib 2 forms micropores of about 3 mm on the brick wall 1 and the brick rib 2 . Insulation materials are filled in the brick holes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com