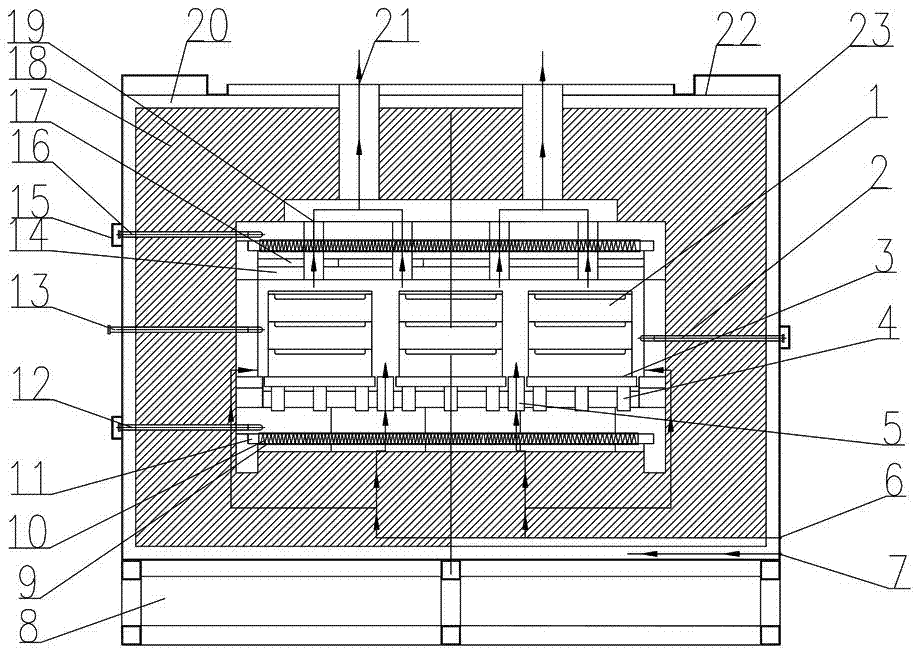

Furnace body of atmosphere protection three-pushed-slab kiln

A three-push plate kiln and furnace body technology, which is applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve problems such as easy arching, uneven gas and temperature, uneven sintering of materials, etc., and achieve improvement Effects of power utilization, space and material saving, and insulation material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] Such as figure 1 As shown, a furnace body of an atmosphere-protected three-push pusher kiln of the present invention includes a furnace shell 20, a base 8, a refractory material masonry 18 and a heating device, wherein the refractory material masonry 18 includes a furnace body for placing and moving Push plate 3 and guide rail 4 and guide block 5 of sagger 1. The guide rail 4 and the guide block 5 run through the kiln cavity and extend to the outside of the kiln cavity, and the three rows of push plates 3 at the same horizontal position are separated from each other by the guide block 5 . Due to the guiding function of the guide block 5, it is possible to avoid the arching phenomenon of the push plate 3 and the sagger 1 during the moving process and block the kiln body, thus ensuring the smooth transmission process throughout,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com