Patents

Literature

67 results about "Stall (engine)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A stall is the slowing or stopping of a process and in the case of an engine refers to a sudden stopping of the engine turning, usually brought about accidentally. It is commonly applied to the phenomenon whereby an engine abruptly ceases operating and stops turning. It might be due to not getting enough air, energy, fuel, or electric spark, fuel starvation, a mechanical failure, or in response to a sudden increase in engine load. This increase in engine load is common in vehicles with a manual transmission when the clutch is released too suddenly.

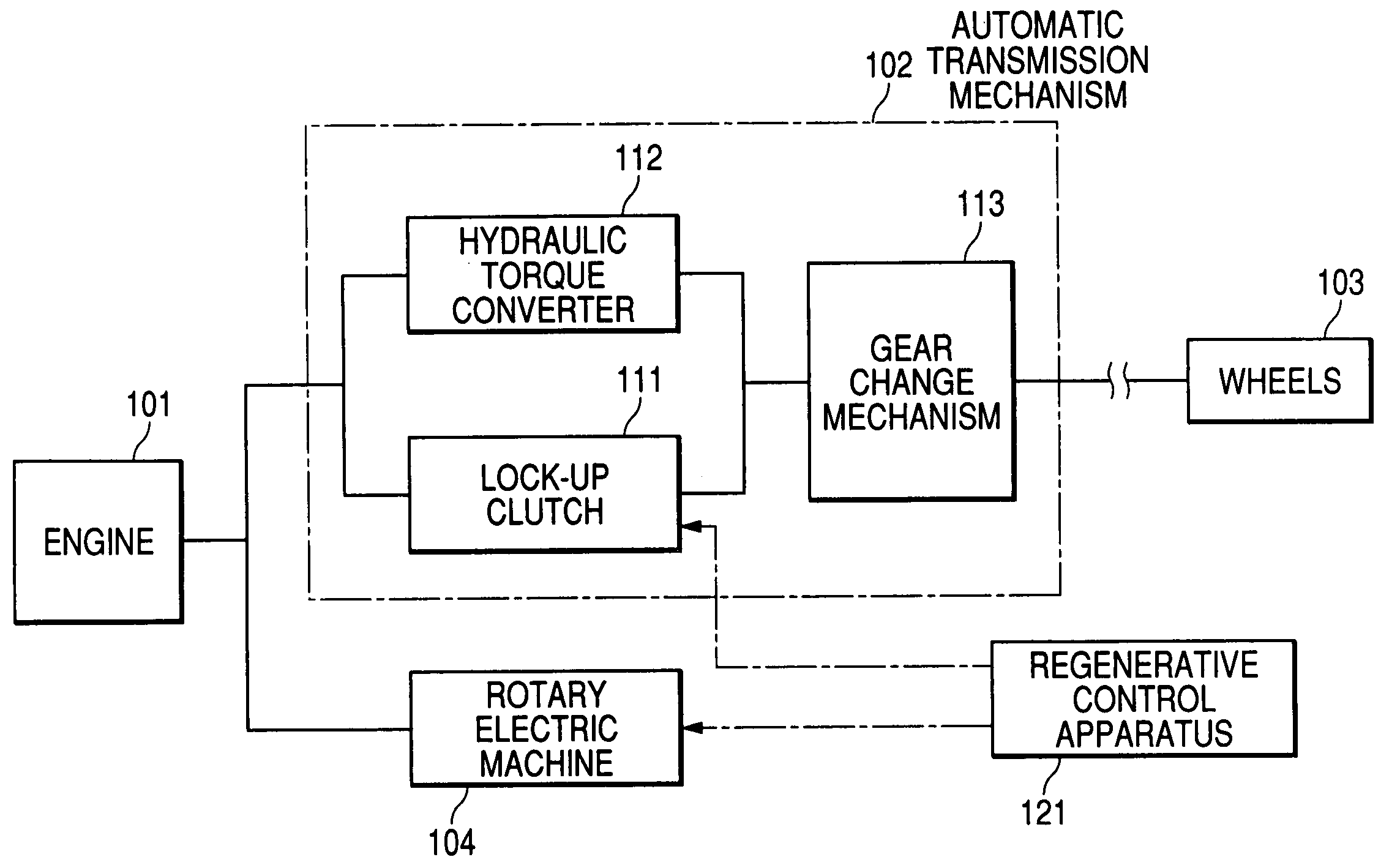

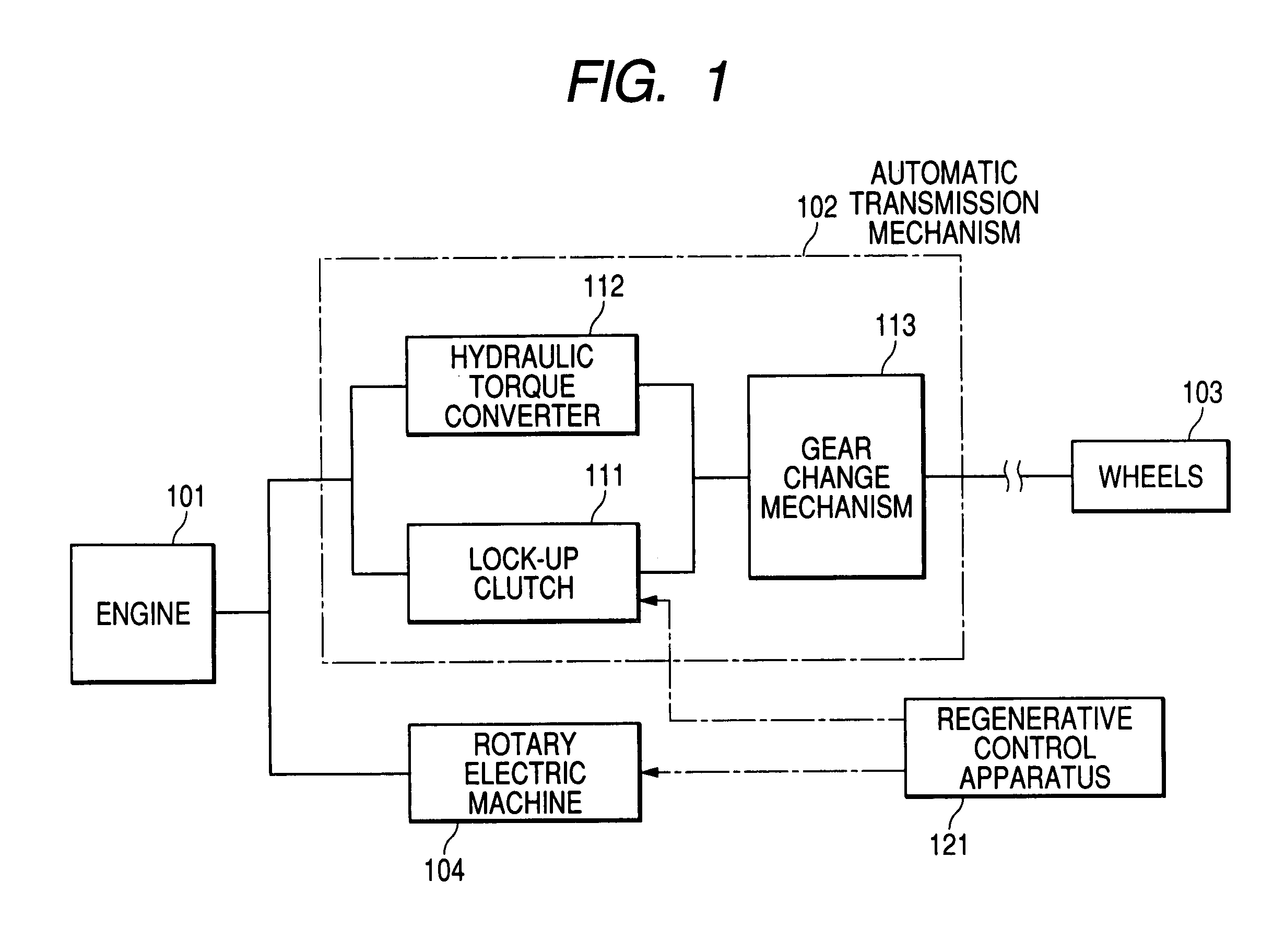

Regenerative control apparatus for vehicles equipped with a lock-up clutch

ActiveUS7329204B2Improve efficiencySuppressing engine stallHybrid vehiclesElectrodynamic brake systemsStall (engine)Regenerative brake

Owner:DENSO CORP

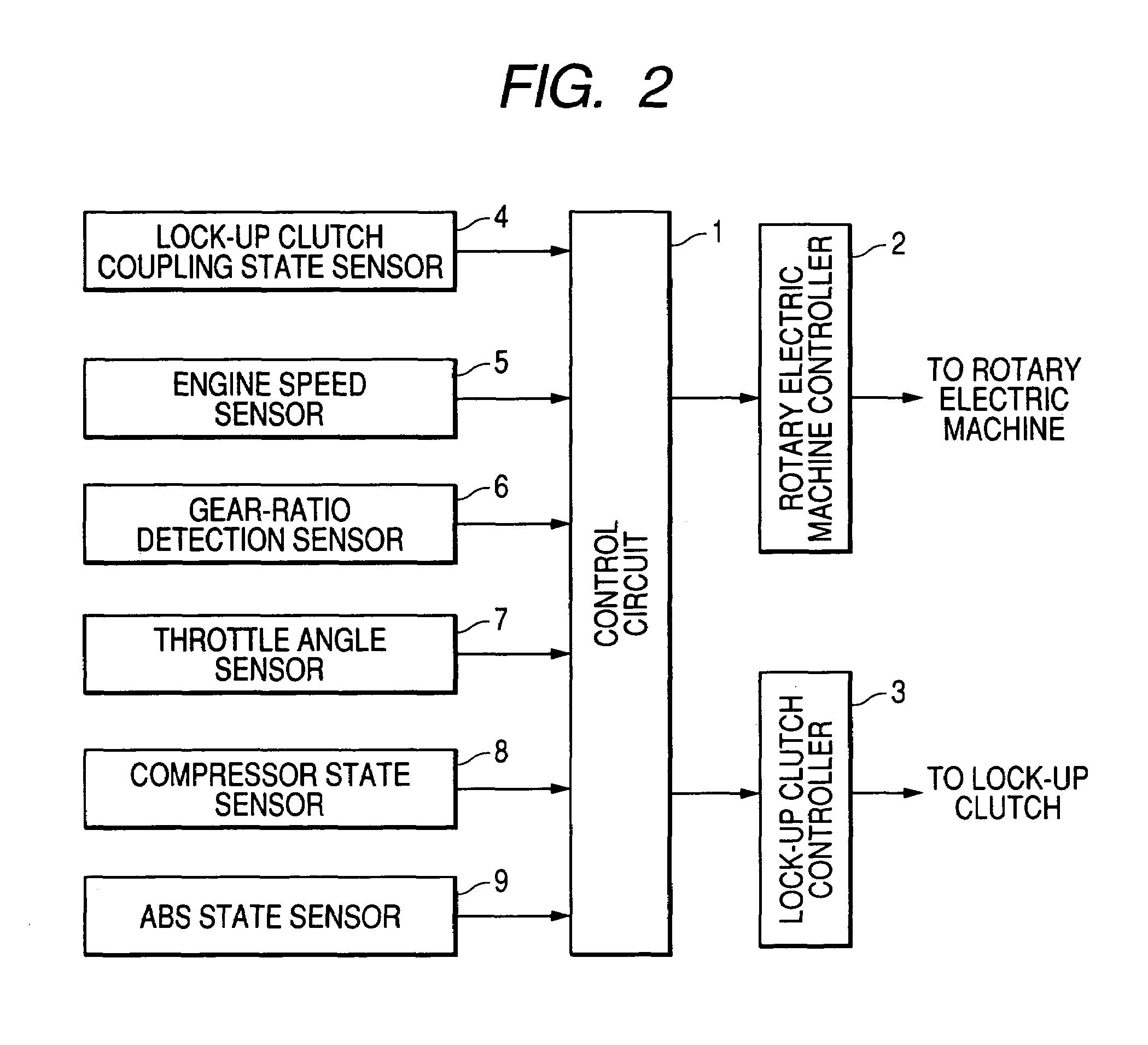

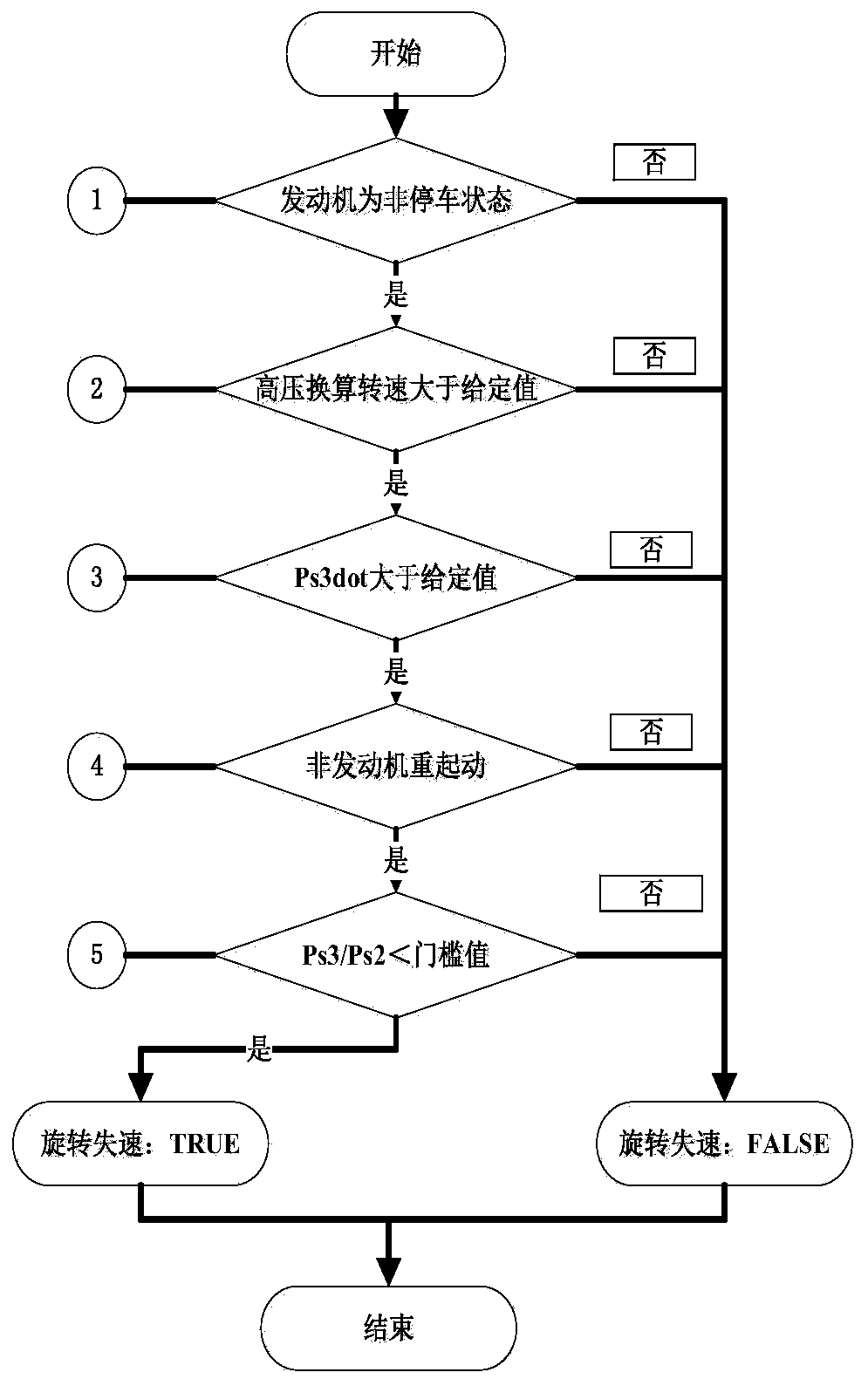

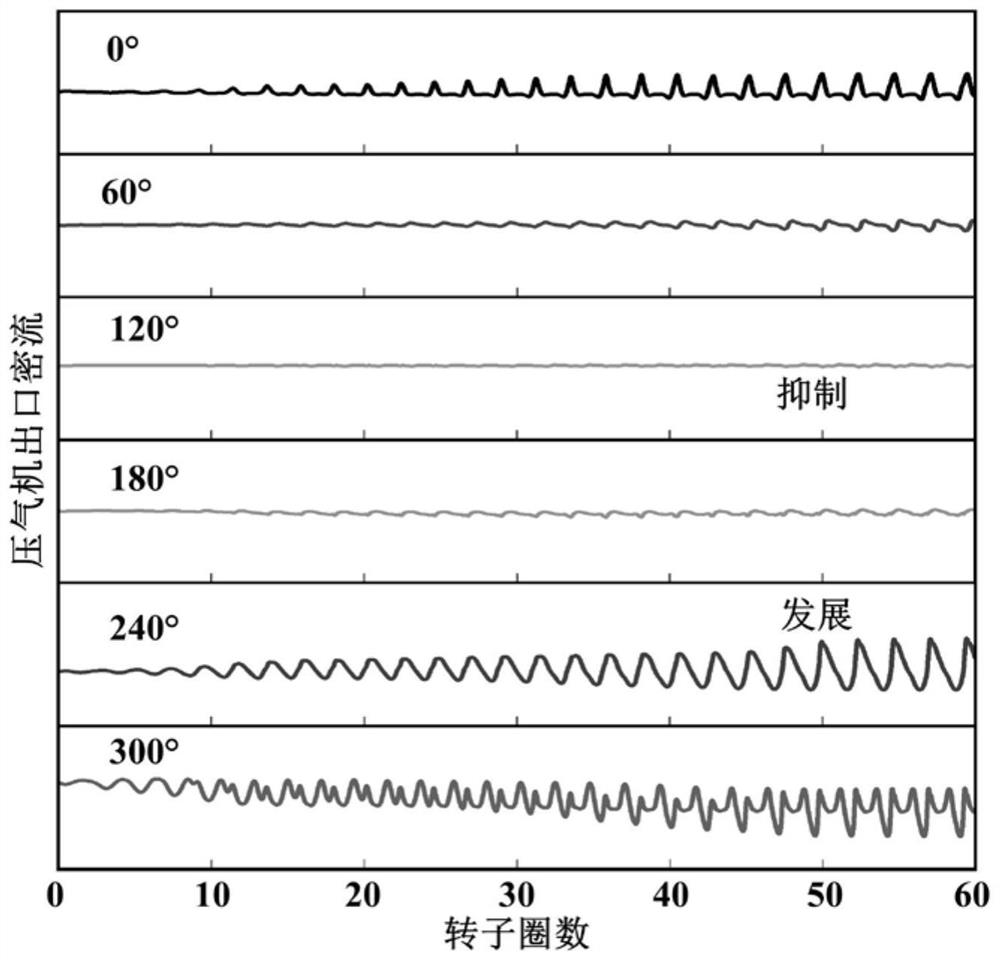

Method and device for judging rotating stall of aero-gas turbine engine

ActiveCN110735669ASolve the technical problem that the rotating stall cannot be judgedImprove stabilityGas turbine plantsSafety/regulatory devicesStall (engine)Gas compressor

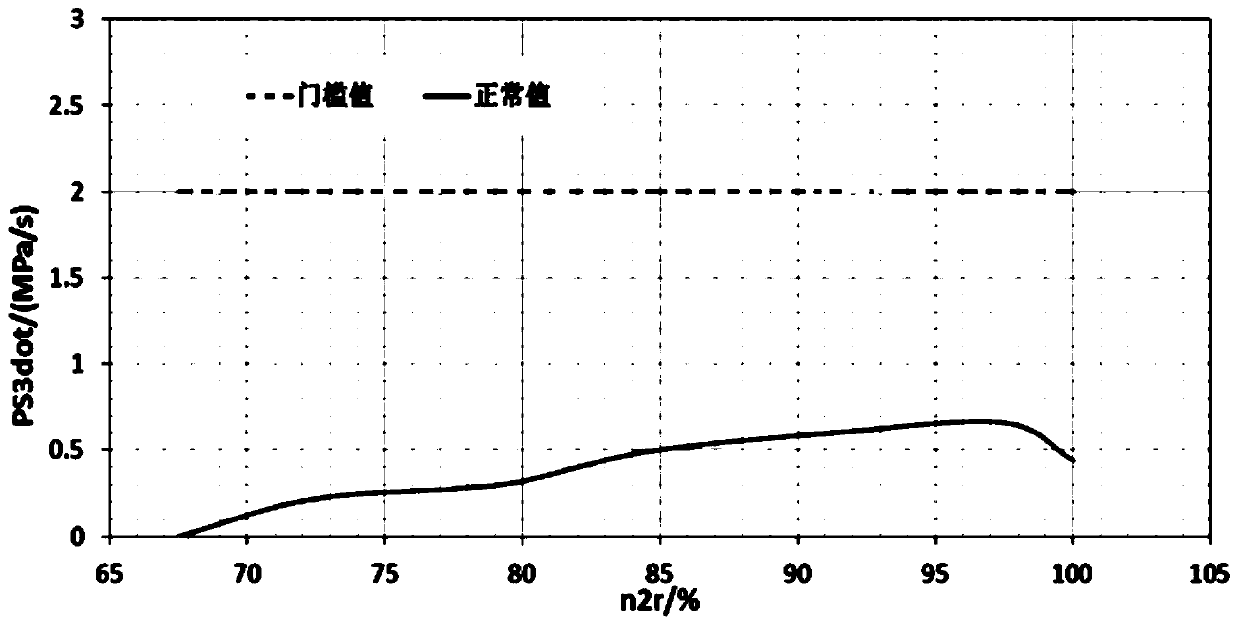

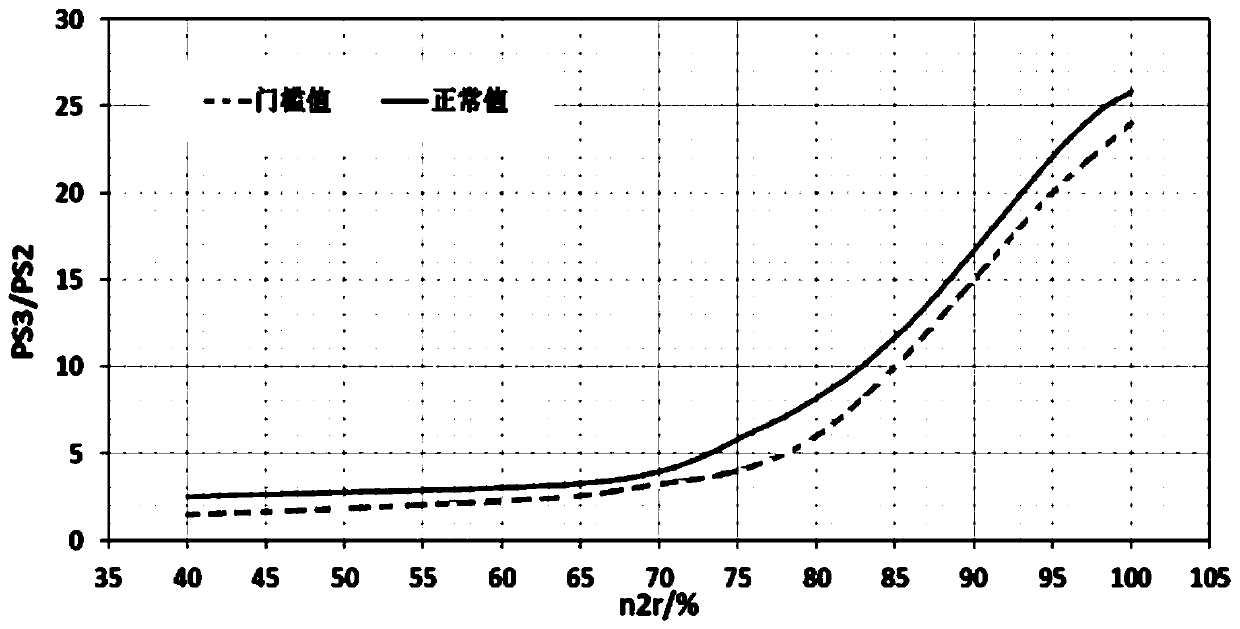

The invention belongs to the technical field of aero-engine control, and particularly relates to a method and device for judging rotating stall of an aero-gas turbine engine. The method comprises thesteps that whether the engine is in a stopped state or not is obtained; if the engine is in a non-stopped state, the high-pressure conversion rotating speed of the engine is obtained; if the high-pressure conversion rotating speed is larger than a first set value, the outlet static pressure of a gas compressor is obtained, and the change rate of the outlet static pressure of the gas compressor iscalculated; if the change rate of the outlet static pressure of the gas compressor is larger than a second set value, whether the engine is in a restarted state or not is determined; if the engine isin a non-restarted state, the inlet static pressure of a fan is obtained; and the ratio of the outlet static pressure of the gas compressor to the inlet static pressure of the fan is calculated, and if the ratio is smaller than a third set value, that the engine is in a rotating stall state is determined. According to the method and device, the technical problem that the rotating stall cannot be judged in the working process of the engine is solved, the risk of surge is reduced, and the aerodynamic stability and reliability of the engine are improved.

Owner:AECC SHENYANG ENGINE RES INST

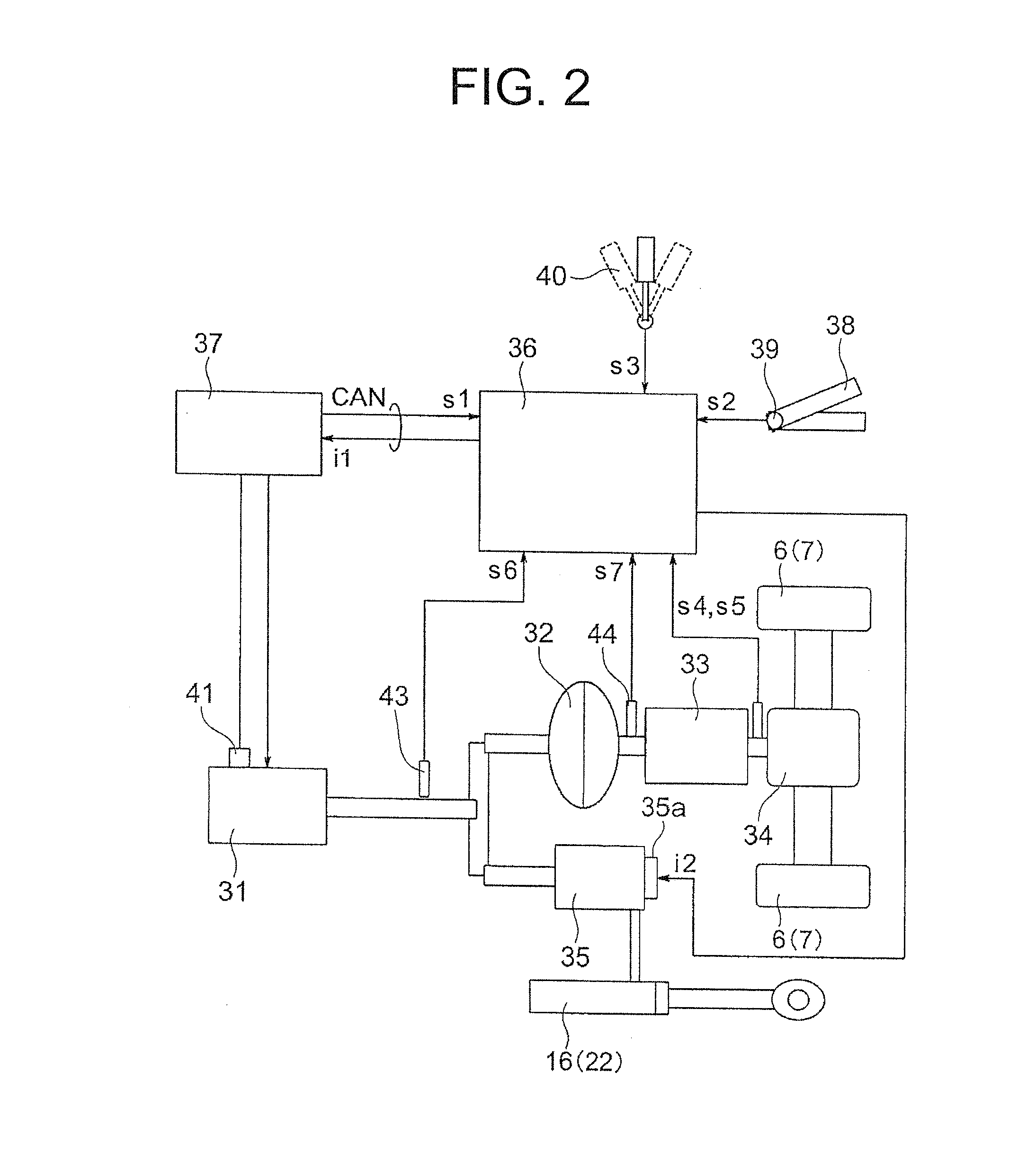

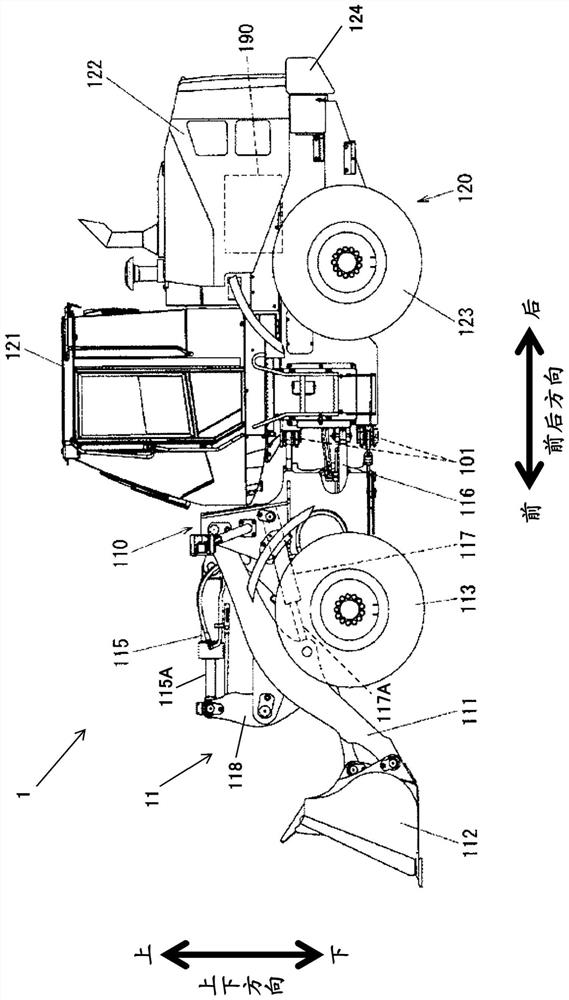

Drive Control Device for Work Vehicle

ActiveUS20140005900A1Maintain engine torque greatMinimize torqueAnalogue computers for trafficSoil-shifting machines/dredgersAutomotive engineeringControl system

To provide a drive control system for a working vehicle, which can prevent engine stall with certainty even when a large load suddenly acts on a vehicle-mounted engine and which is also excellent in environment friendly performance.When a vehicle speed of a wheel loader (1) is determined to be not higher than a reference value (Yes) in step S4 and a forward / reverse command means (40) is determined to have been switchingly operated (Yes) in step S5, the routine advances to step S6 where an increment ΔN of engine speed according to an engine load factor is determined. In step S7, the increment ΔN of engine speed is then added to a target engine speed Na corresponding to a depression stroke of an accelerator pedal (38), the thus-determined Na=Na+ΔN is set as a new target engine speed Na, and a target engine speed command i1 is sent to an engine controller (37).

Owner:HITACHI CONSTR MASCH CO LTD

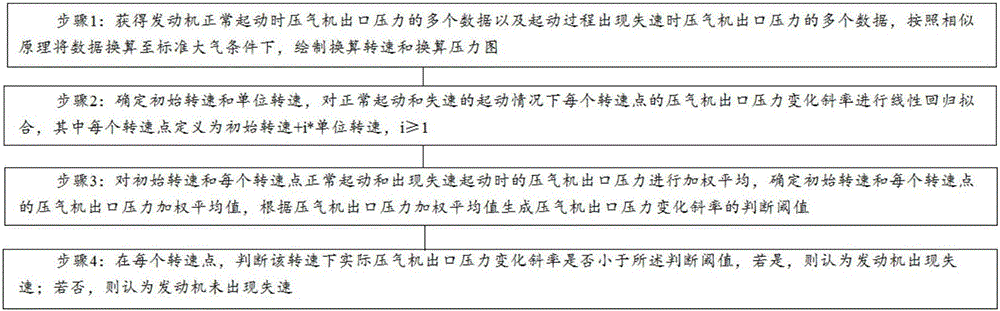

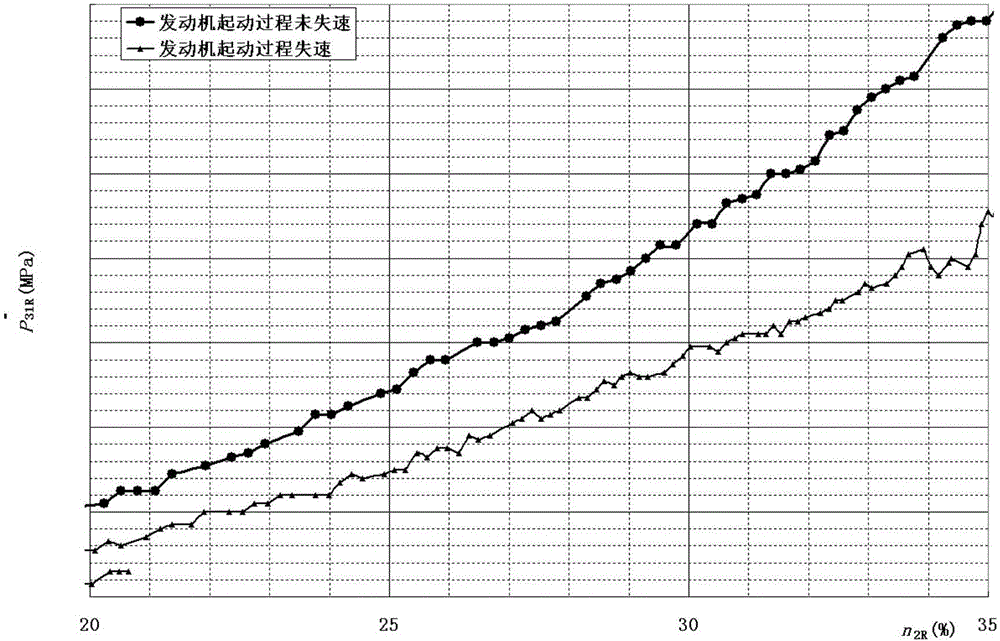

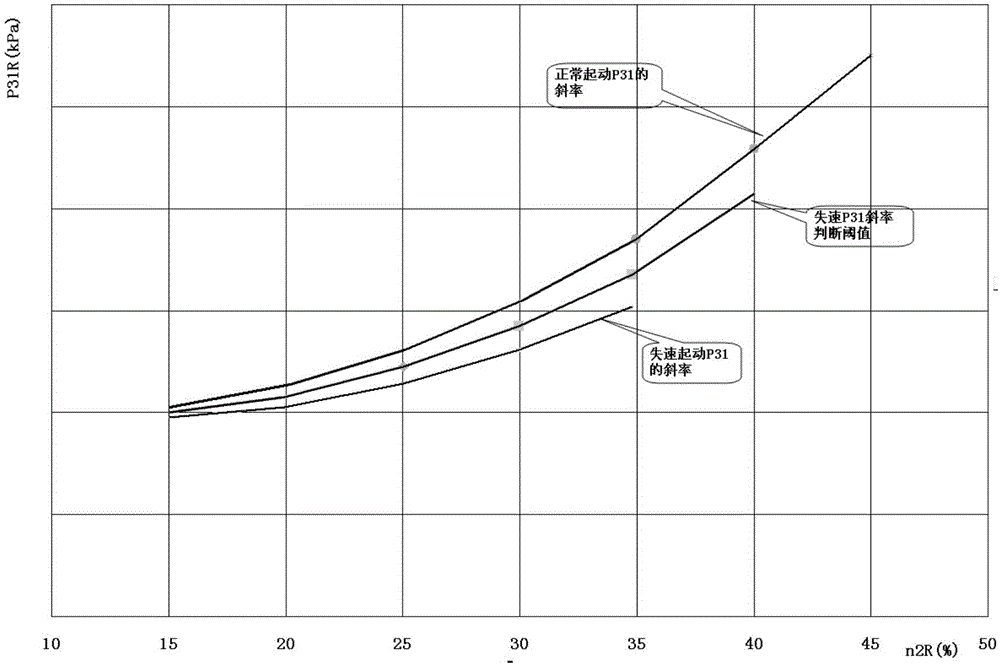

Method for judging stall during aero-engine starting

The invention discloses a method for judging stall during aero-engine starting. The method includes the steps of firstly, drawing corrected speed and corrected pressure graphs; secondly, determining initial speed and unit speed, and performing linear regression fitting; thirdly, performing weighted averaging on compressor discharge pressure of the initial speed and each speed point during normal starting and stall starting, and generating the judging threshold of a compressor discharge pressure change slope; fourthly, judging whether compressor discharge pressure change slope of the speed is smaller than the judging threshold or not, and if so, determining that engine stall occurs; if not, determining that engine stall does not occur. The method has the advantages that the method is designed according to the other feature, namely compressor discharge pressure lowering, of engine starting stall, and theoretically the stall can be distinguished once the stall occurs.

Owner:AECC SHENYANG ENGINE RES INST

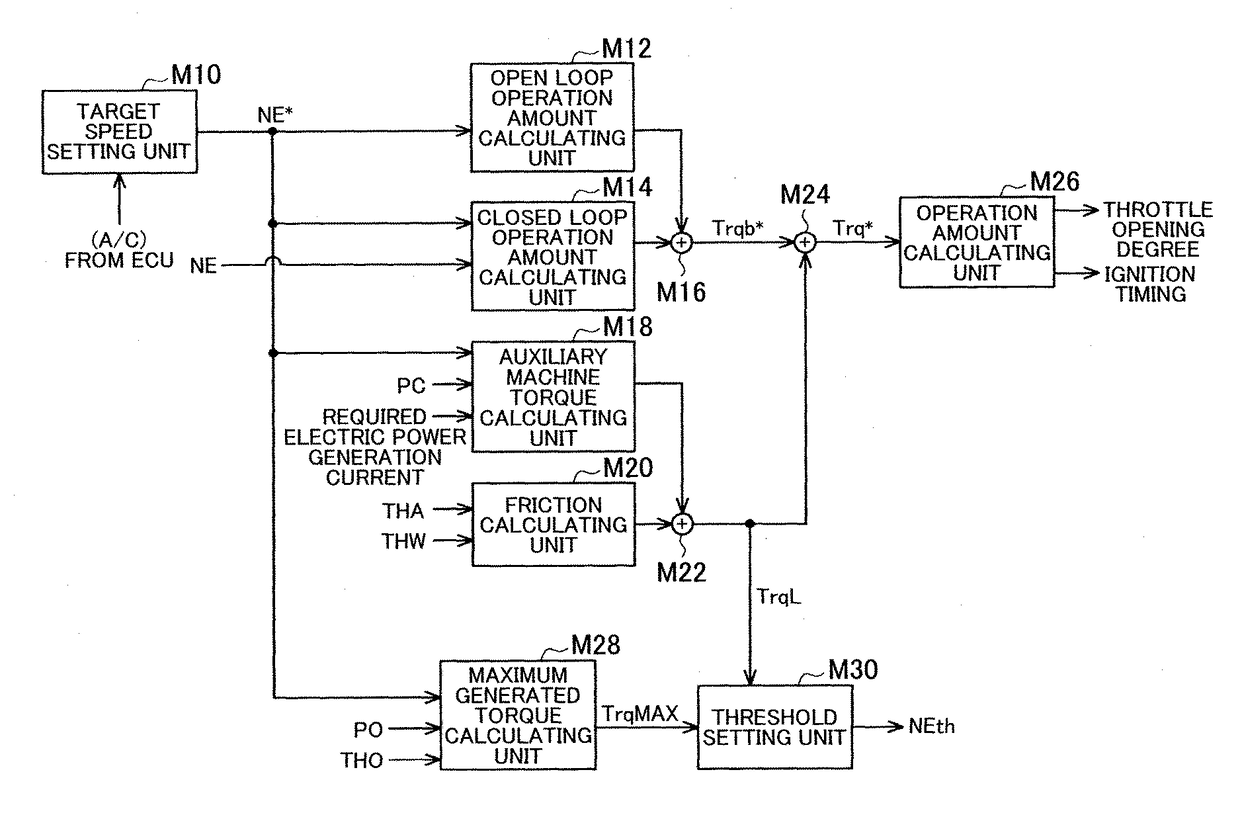

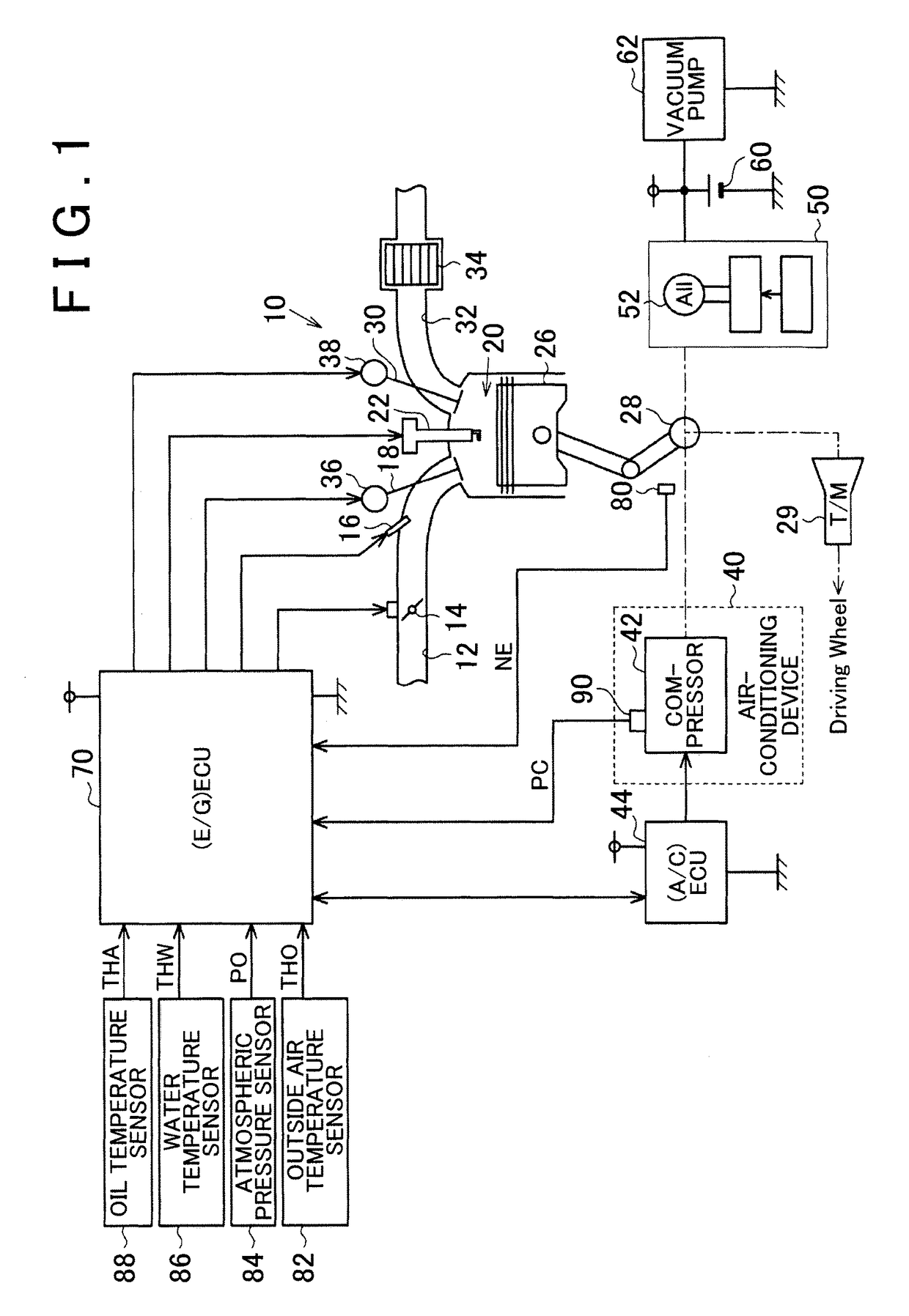

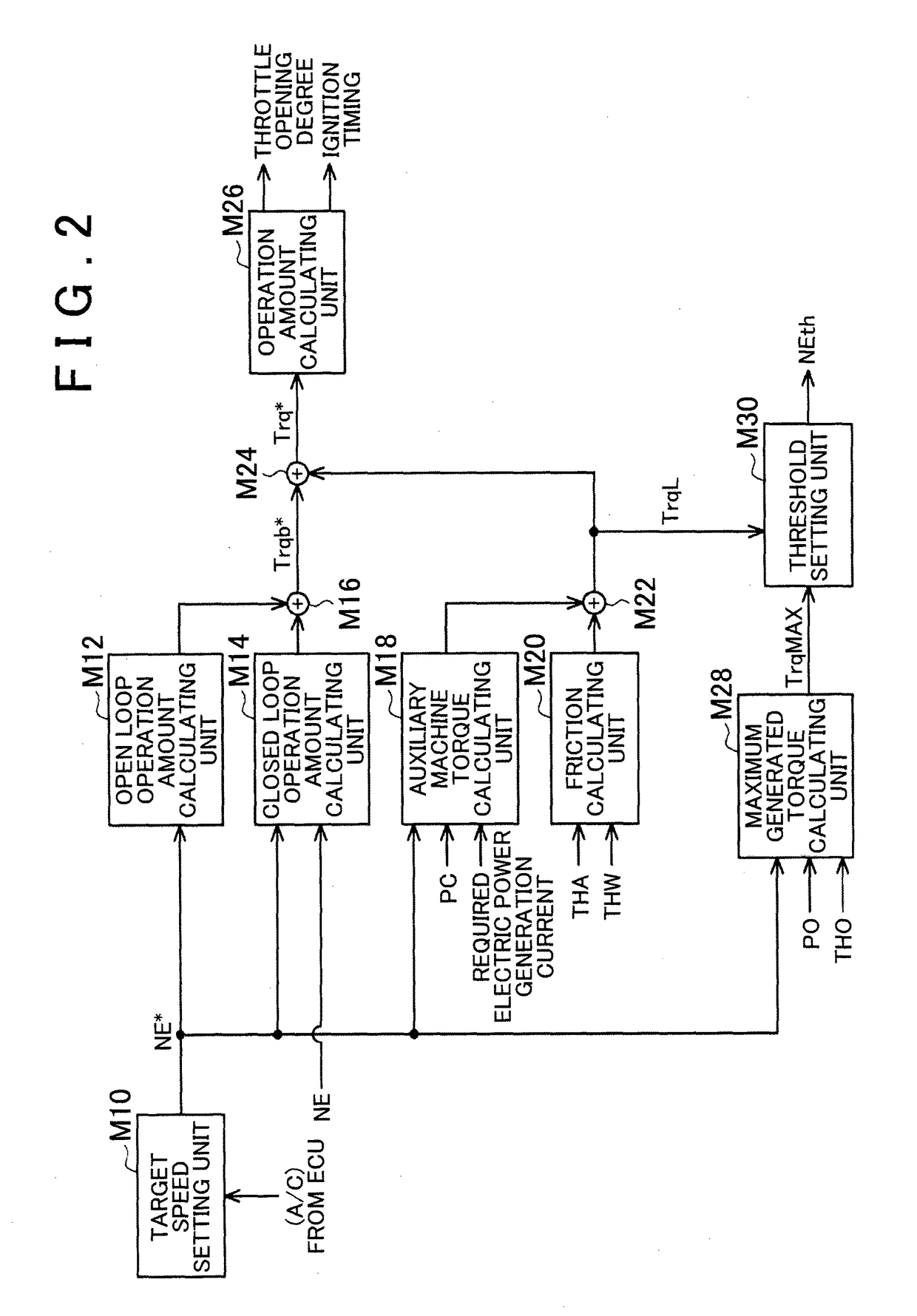

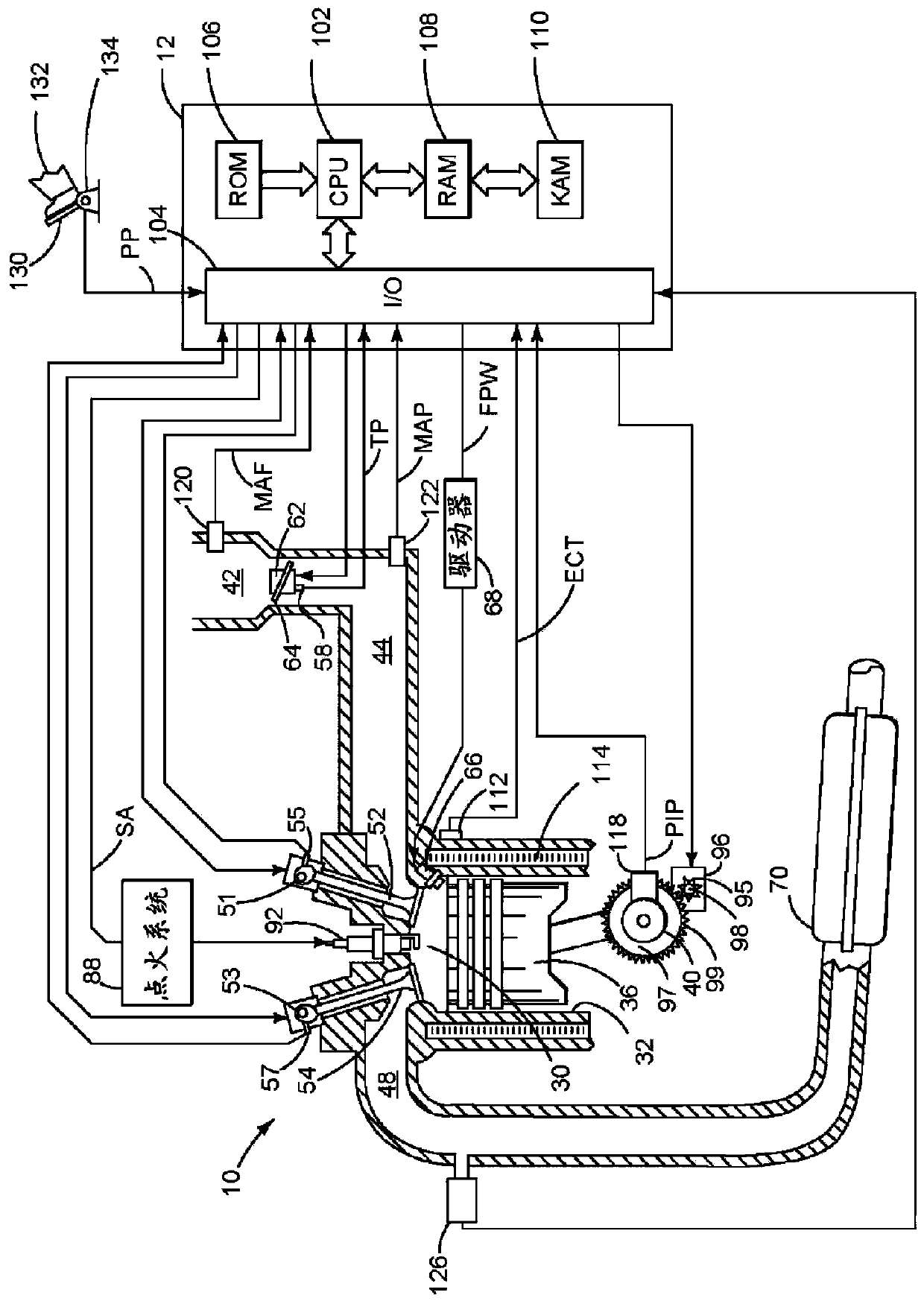

Control device for internal combustion engine

ActiveUS20170248090A1Accurate calculationElectrical controlVehicle heating/cooling devicesMaximum torqueAlternator

An ECU avoids engine stall by putting a compressor into a stationary state in a case where the rotation speed of a crankshaft is equal to or less than a predetermined speed during an idle operation of an internal combustion engine. During the idle operation, the ECU calculates a total load torque applied to the crankshaft by the compressor and an alternator. The ECU calculates the maximum torque of the internal combustion engine during the idle operation based on a target speed during the idle operation. Then, the ECU raises the predetermined speed in a case where the value obtained by subtracting the load torque from the maximum torque is equal to or less than a predetermined value.

Owner:TOYOTA JIDOSHA KK

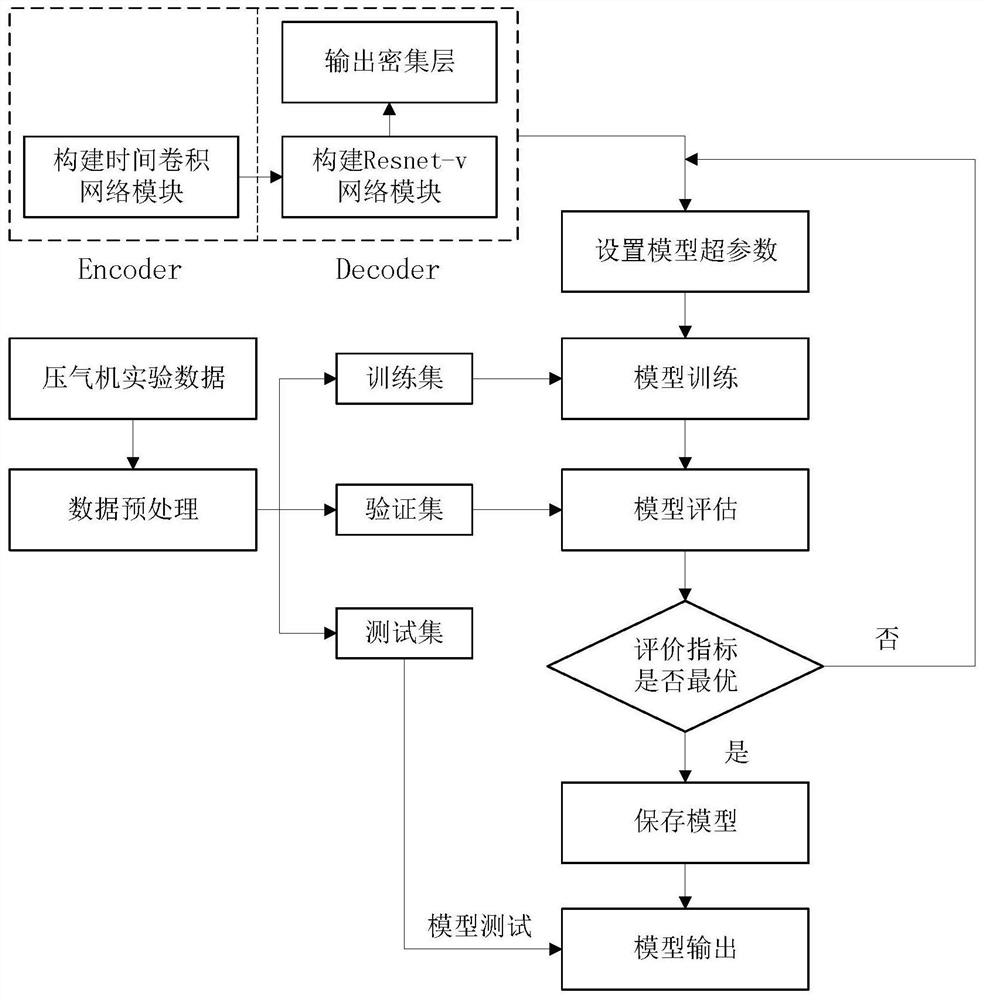

Gas compressor rotation stall early warning method based on time expansion convolutional network

ActiveCN113569338AImprove the performance of active controlImprove forecast accuracyGeometric CADSustainable transportationData setGas compressor

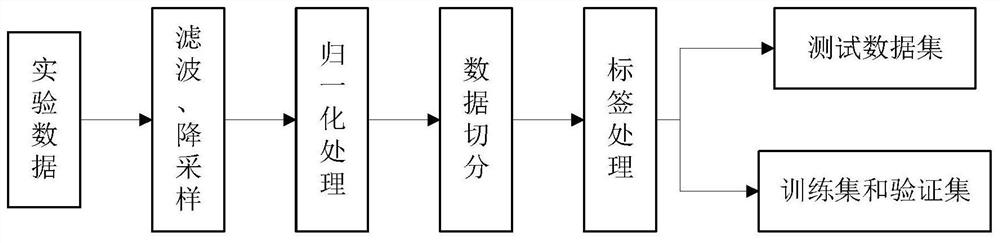

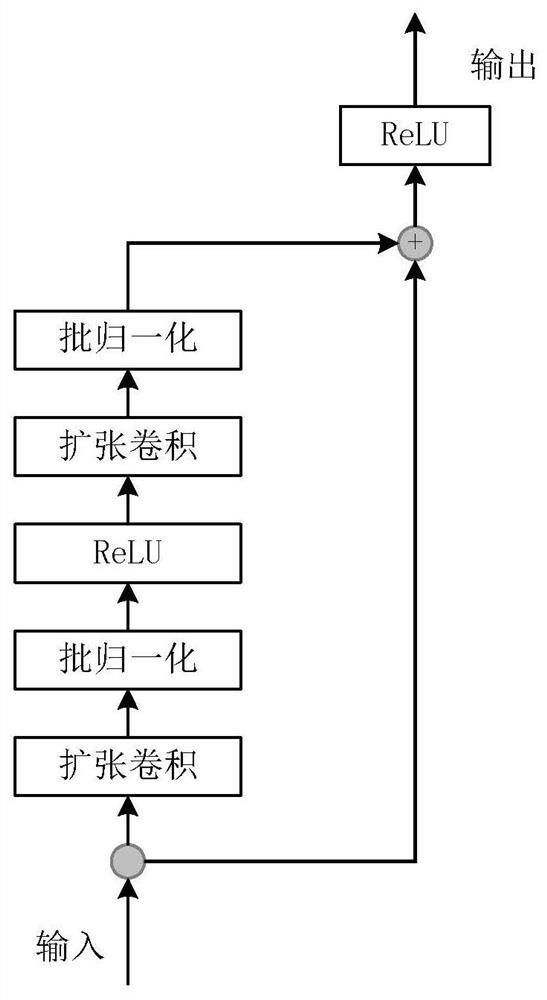

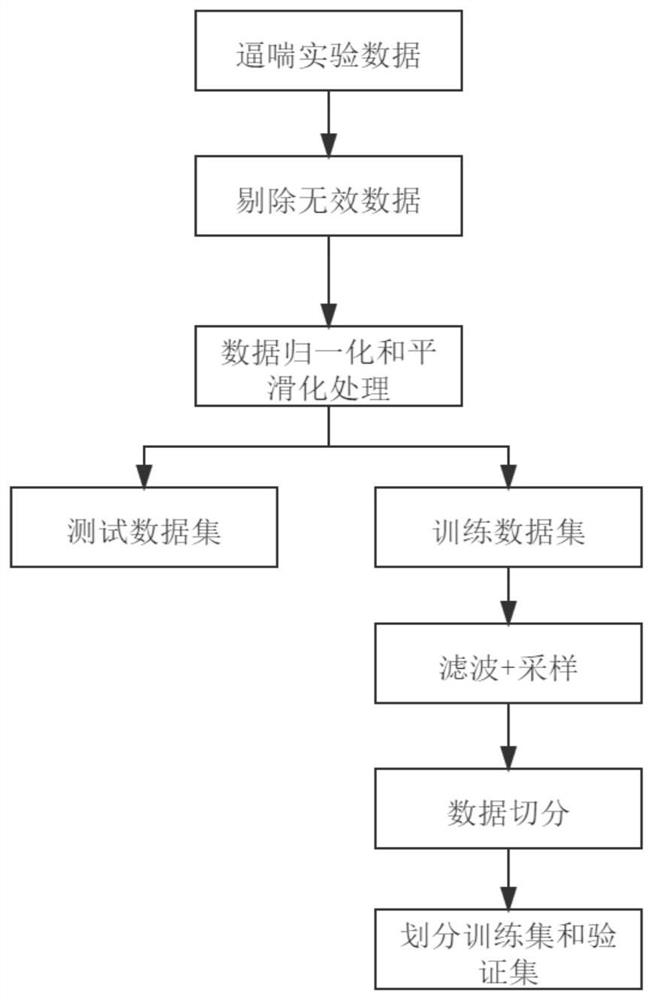

A gas compressor rotation stall early warning method based on a time expansion convolutional network comprises the following steps: firstly, preprocessing dynamic pressure data of an aero-engine, and dividing a test data set and a training data set from experimental data; secondly, sequentially constructing a time convolutional network module, constructing a Resnet-v network module, constructing a time expansion convolutional network prediction model, and storing an optimal prediction model; finally, performing real-time prediction on the test data: firstly, adjusting the data dimension of the test set according to the input requirement of the time convolutional network prediction model; according to a time sequence, calculating a surge prediction probability of each sample through a time expansion convolutional network prediction model; and calculating the real-time surge probability of a pair of samples containing covariables and not containing covariables through a time expansion convolutional network prediction model, and observing the improvement effect of the covariables on the model prediction effect. The time domain statistical characteristics and the change trend are integrated, and the prediction precision is improved; and the active control performance of the engine can be improved, and certain universality is achieved.

Owner:DALIAN UNIV OF TECH

Wind engine stall protection device

InactiveCN112302866AControl power offReduce speedRotational speed controlWind motor controlStall (engine)Dielectric plate

The invention relates to the technical field of wind engine stall protection, and discloses a wind engine stall protection device which comprises a shell. A power shaft is movably connected to the middle of the shell, a brake pad is fixedly connected to the outer side of the power shaft, a brake cavity is formed in the inner wall of the middle of the shell, and reset springs are fixedly connectedto the inner wall of the middle of the brake pad. Centrifugal blocks are fixedly connected to the outer sides of the reset springs, and dielectric plates are fixedly connected to the middle inner walls of the centrifugal blocks. According to the wind engine stall protection device, the power shaft drives the brake pad to rotate, the brake pad drives the centrifugal blocks to rotate, and then positive plates, negative plates and the dielectric plates are used in cooperation, so that the effect of controlling on-off of electromagnets is achieved, the dielectric plates in the middles of the centrifugal blocks move along with the centrifugal blocks, the relative area of the positive plates and the negative plates is changed, the voltage between every two pole plates rises, the working voltageof a piezoresistor is reached, and the electromagnets are electrified to generate magnetic force repelling magnetic blocks.

Owner:孙海东

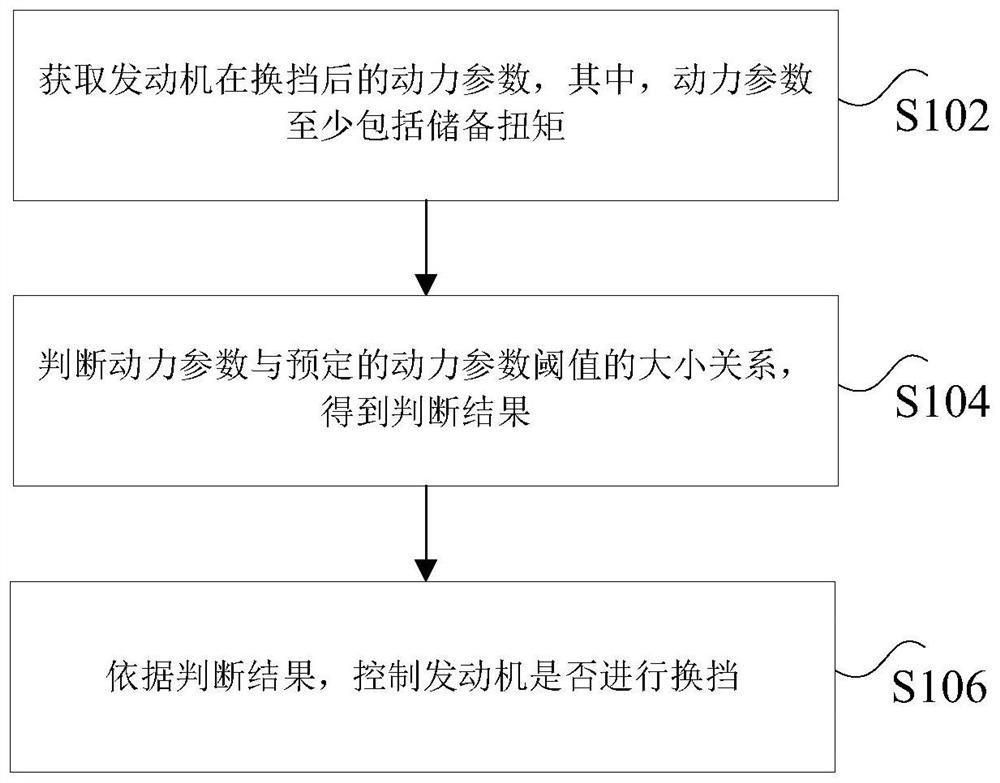

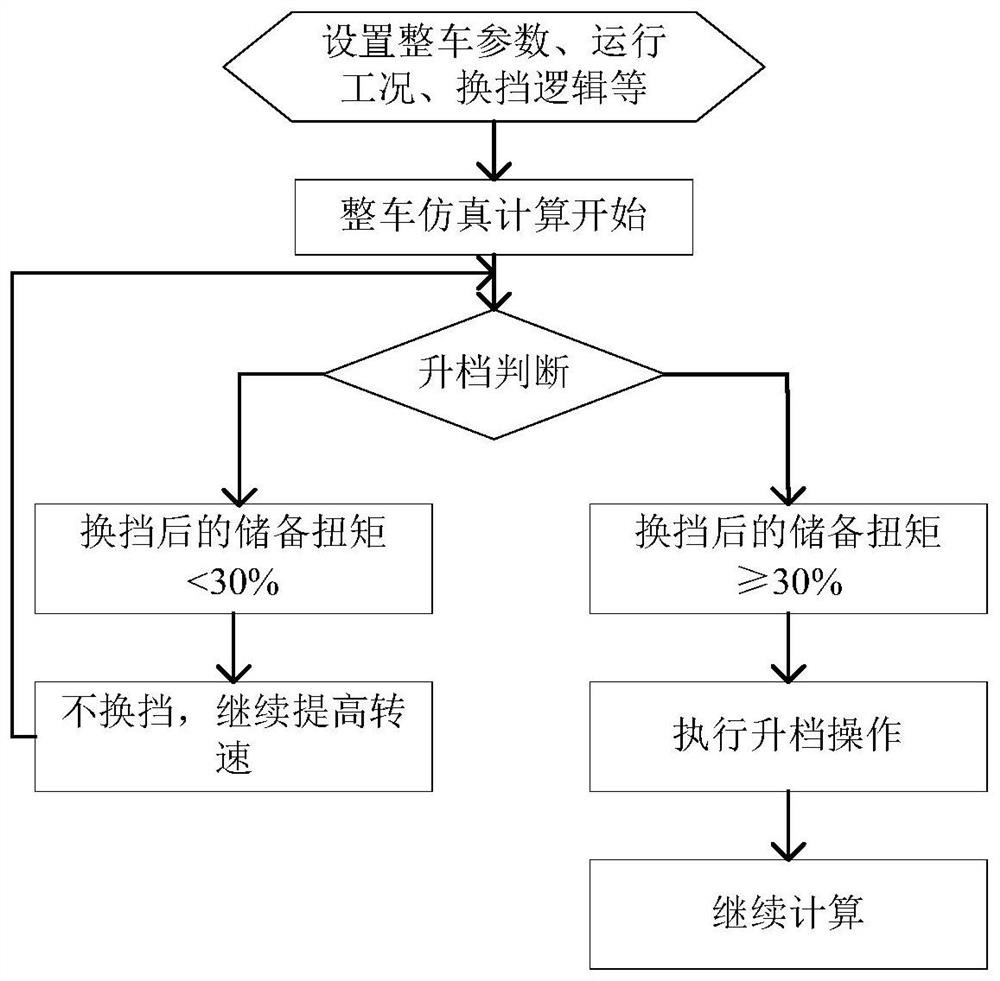

Control method and device for engine gear-shifting and heavy truck tractor

ActiveCN111692331AImprove shift smoothnessReduce lack of motivationGearing controlStall (engine)Control theory

The invention discloses a control method and device for engine gear-shifting and a heavy truck tractor. The control method includes the steps that power parameters of an engine after gear shifting areobtained, wherein the power parameters at least include reserve torque; the size relationship between the power parameters and a predetermined power parameter threshold value is judged to obtain a judgment result; and according to the judgment result, the engine is controlled to perform gear shifting or not. The technical problems in the related art that the engine rotating speed drops below theidle speed or even stalls caused by uneven gear shifting and insufficient power due to the engine gear shifting time in a low-rotating-speed zone ahead of time are solved.

Owner:WEICHAI POWER CO LTD

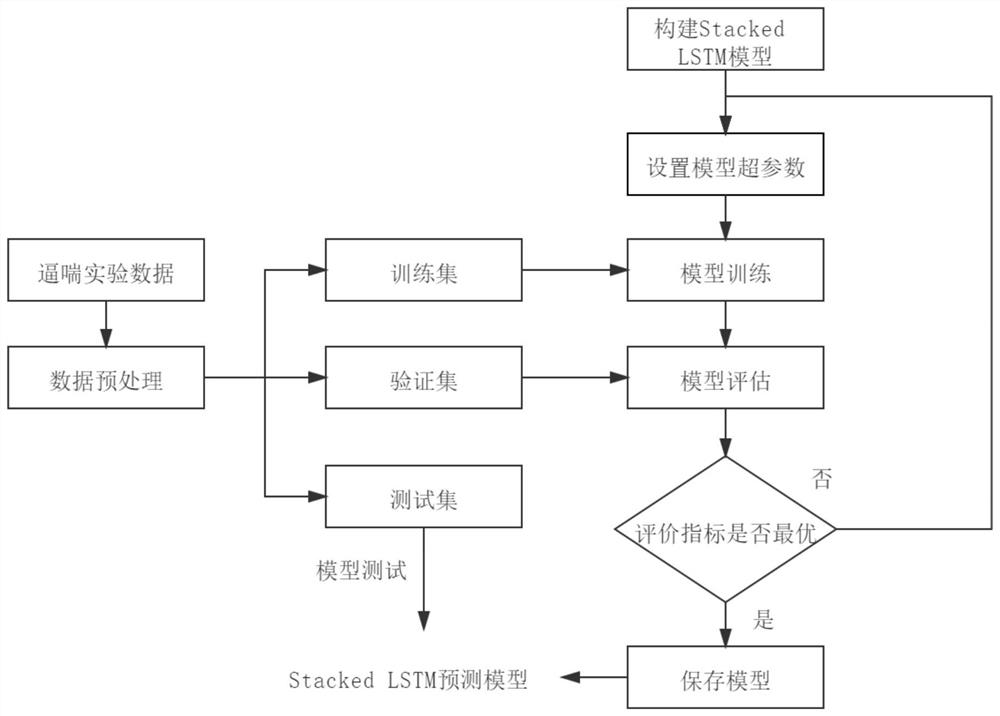

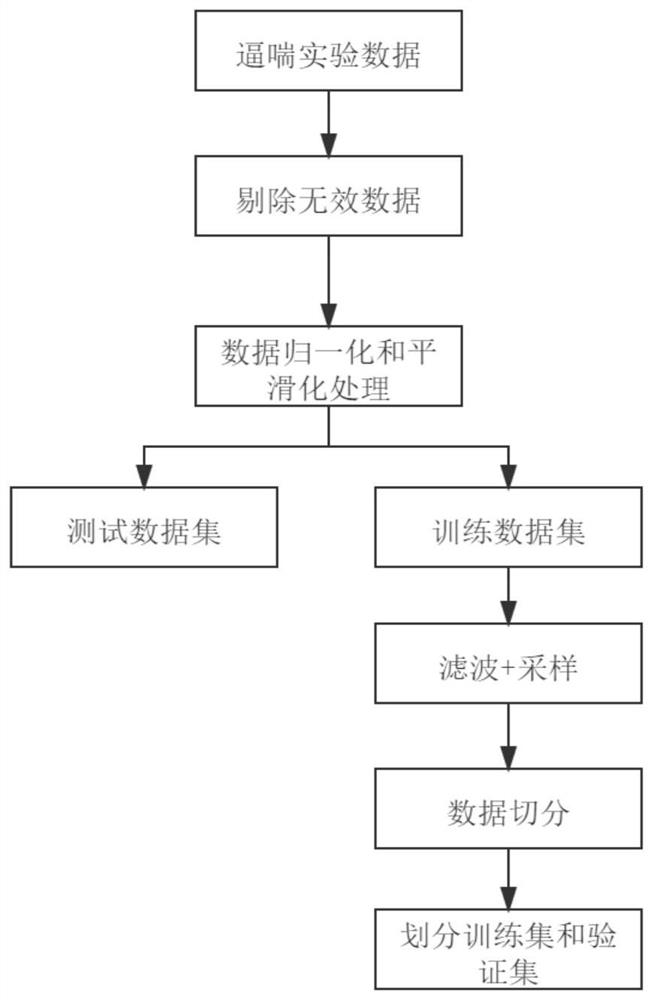

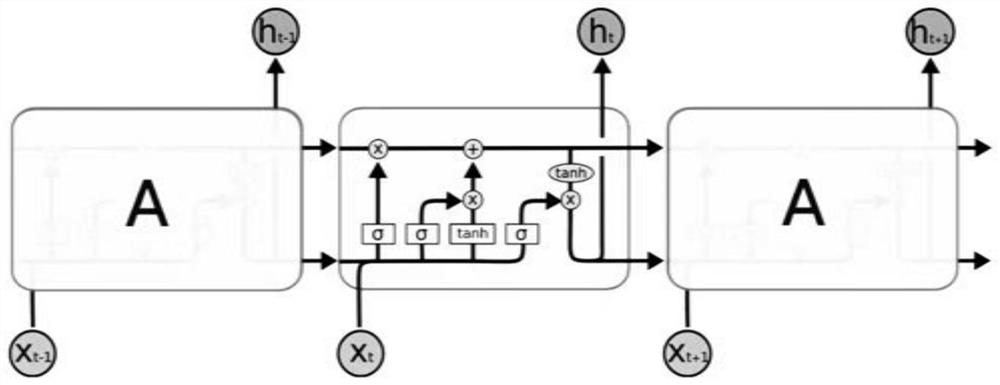

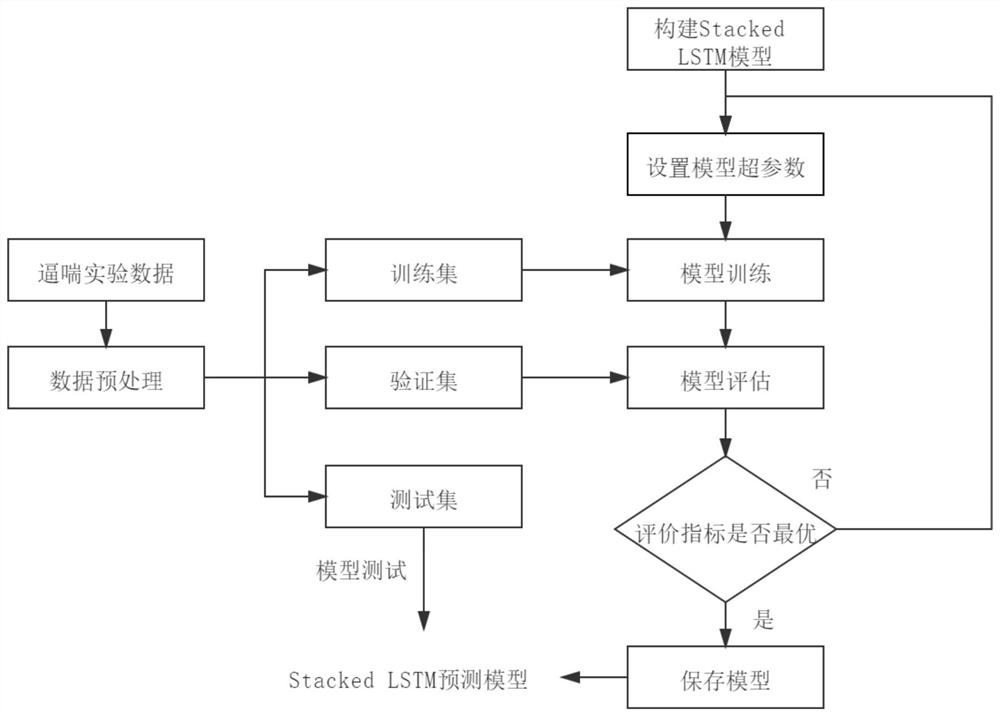

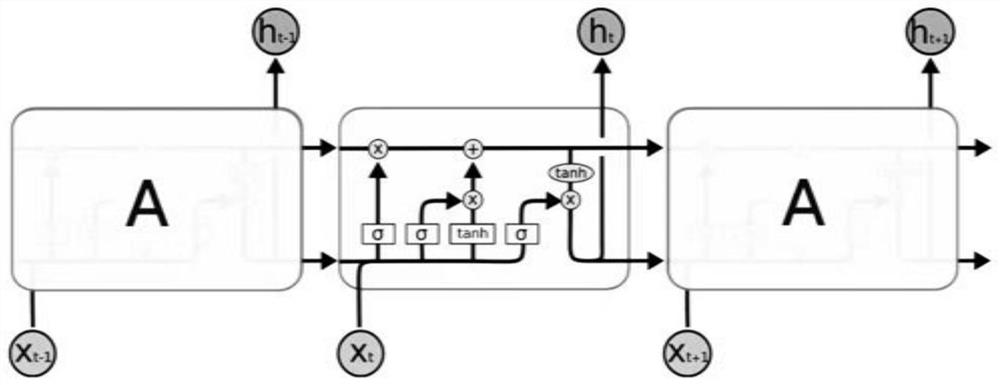

Stacked long short-term memory network-based axial flow compressor rotation stall prediction method

ActiveCN113836817AAdjust the running statusAchieve forecastDesign optimisation/simulationNeural architecturesShort-term memoryAlgorithm

The invention provides an axial flow compressor rotation stall prediction method based on a stacked long short-term memory network, and belongs to the technical field of aero-engine modeling and simulation. The method comprises the following steps: firstly, selecting and preprocessing surge experiment data of a certain type of aero-engine, and dividing the data into a training set and a test set; secondly, building and training a Stacked LSTM model, carrying out the real-time prediction on a test set by utilizing the finally trained model, and giving model loss and evaluation indexes; finally, carrying out real-time prediction on the test data by adopting a Stacked LSTM prediction model, and giving a change trend of the surge probability along with time according to a time sequence. According to the method, the time domain statistical characteristics and the change trend are integrated, and the prediction precision is improved; and the active control performance of the engine can be improved, and certain universality is achieved.

Owner:DALIAN UNIV OF TECH

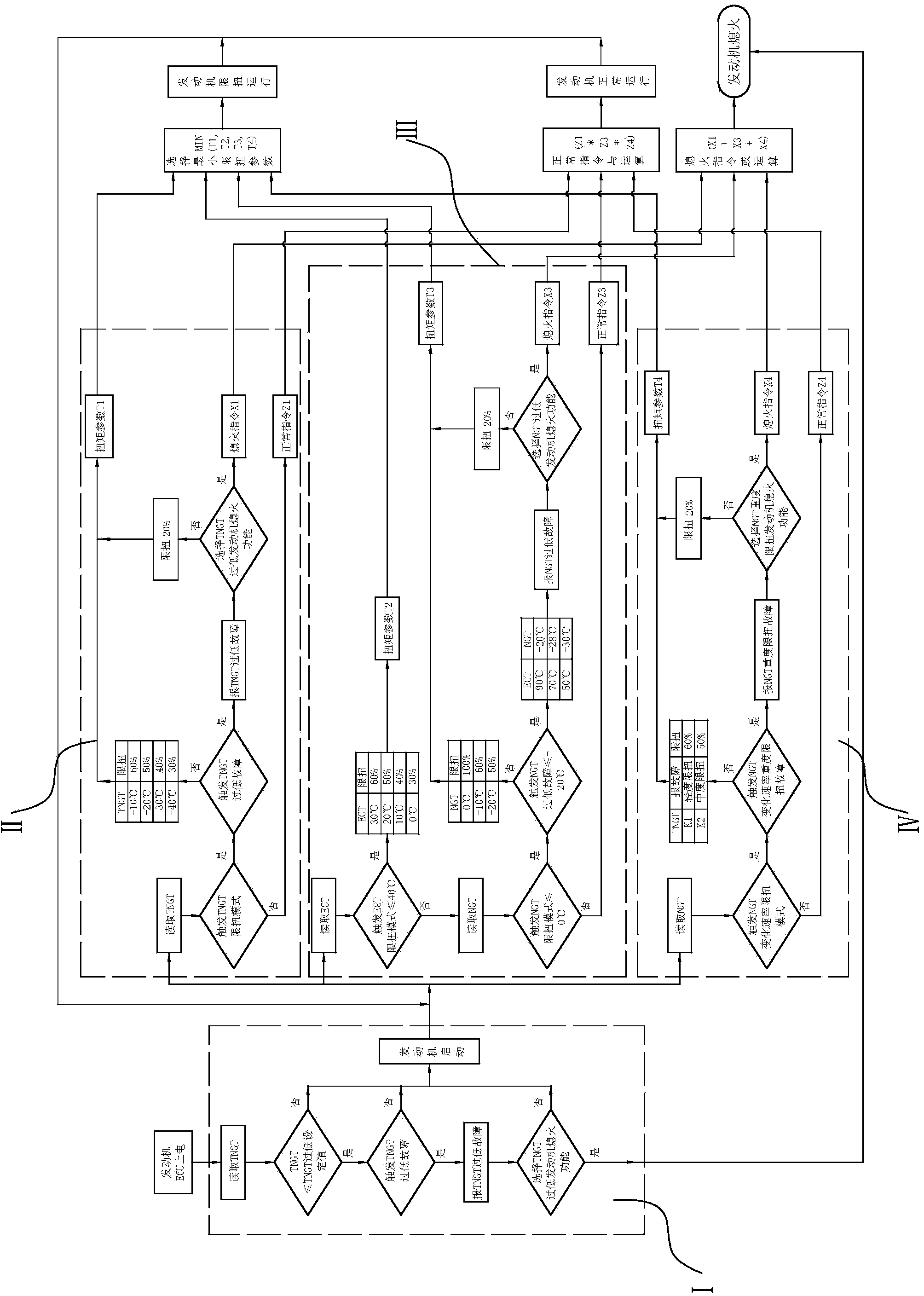

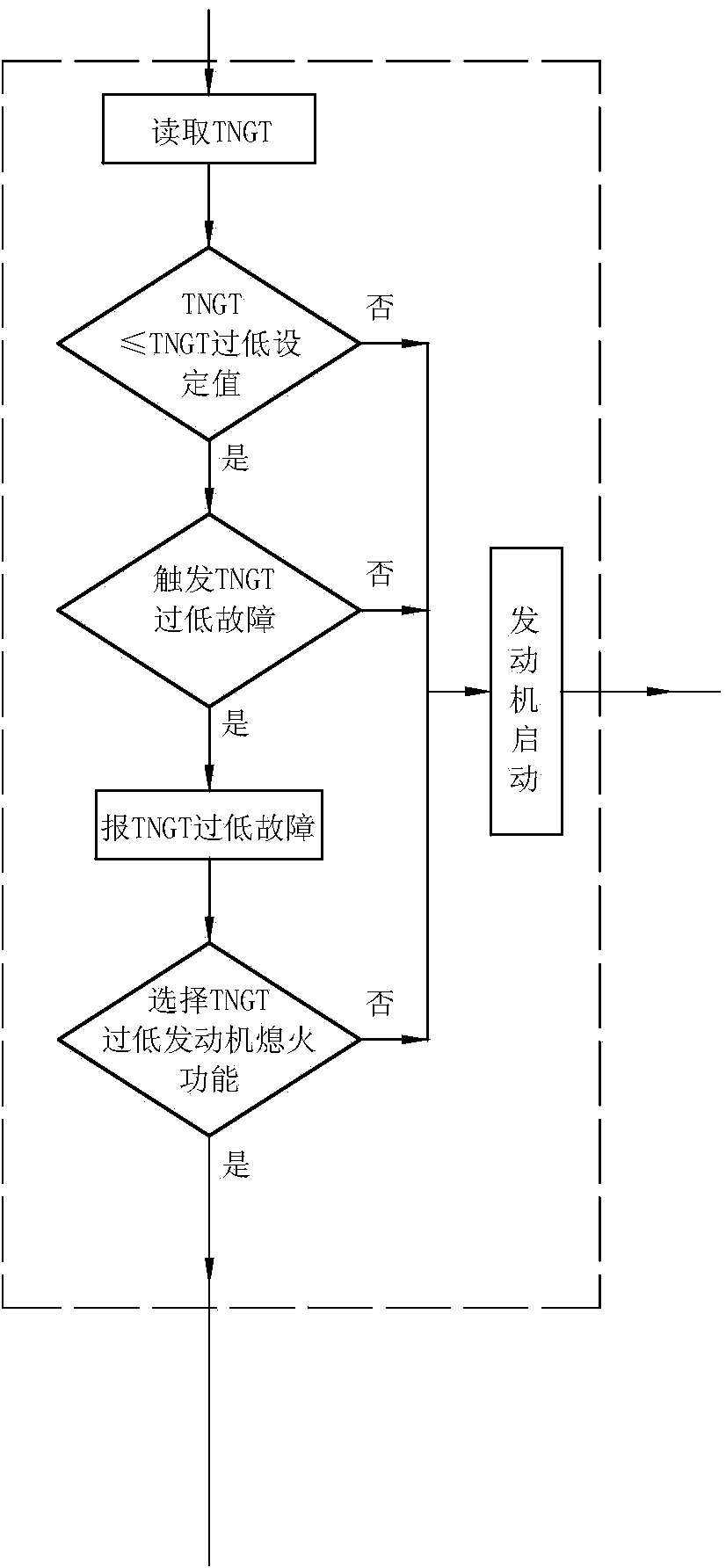

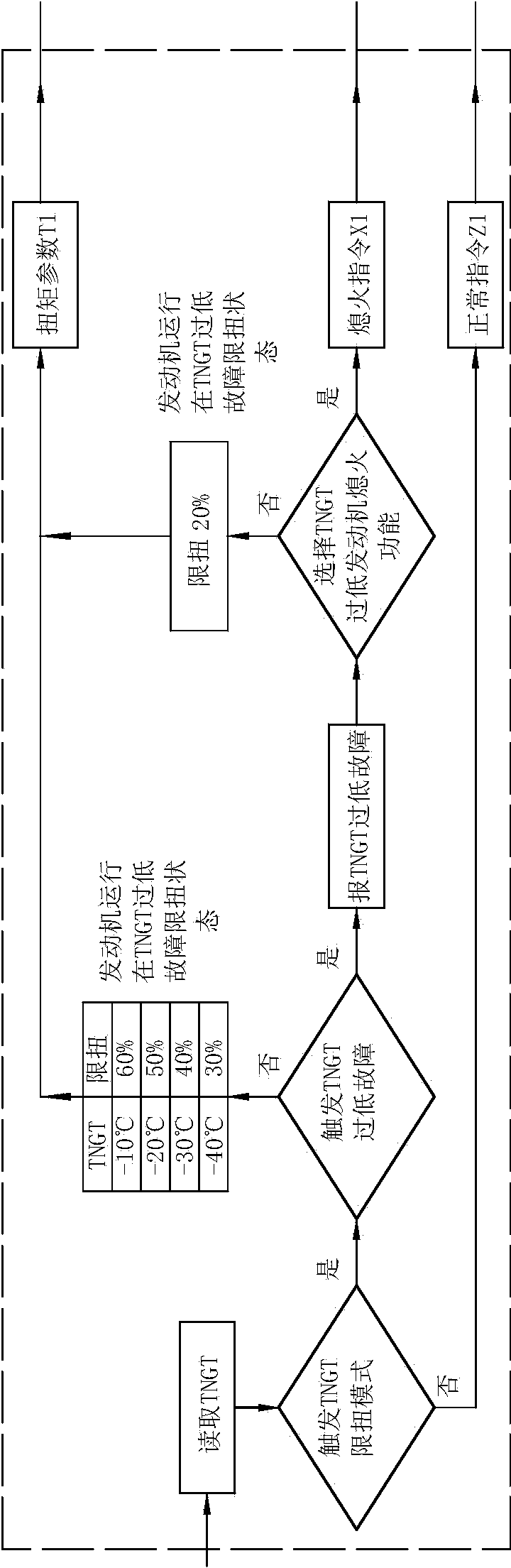

Ultralow-temperature fuel gas temperature protection method for LNG (liquefied natural gas) engine

ActiveCN103835827AAvoid personal safetyAvoid economic lossPower operated startersElectrical controlStall (engine)Control theory

The invention discloses an ultralow-temperature fuel gas temperature protection method for an LNG (liquefied natural gas) engine. The method includes the following steps: step 1, mounting temperature sensors at an outlet of a vaporizer, an inlet of a fuel gas metering valve and a water outlet of the engine in advance respectively, correspondingly collecting temperature TNGT of the outlet of the vaporizer, temperature NGT of the inlet of the fuel gas metering valve and temperature ECT of the water outlet of the engine respectively, and presetting TNGT control parameters, NGT control parameters and ECT control parameters respectively; step 2, after an engine ECU (electronic control unit) is power-on, performing engine start protection through judgment on the TNGT; step 3, reading the TNGT, the NGT and the ECT, and through logical operation, judging to perform torsion-limited engine operation, normal engine operation or engine stall; step 4, if the torsion-limited engine operation or the normal engine operation is performed in the step 3, repeating the step 3. By the ultralow-temperature fuel gas temperature protection method, reliable low-temperature protection to a fuel gas supply system of the LNG engine is realized, so that personal injuries and economic losses both caused by low temperature during use of the LNG engine are avoided.

Owner:WEICHAI XIGANG NEW ENERGY POWER

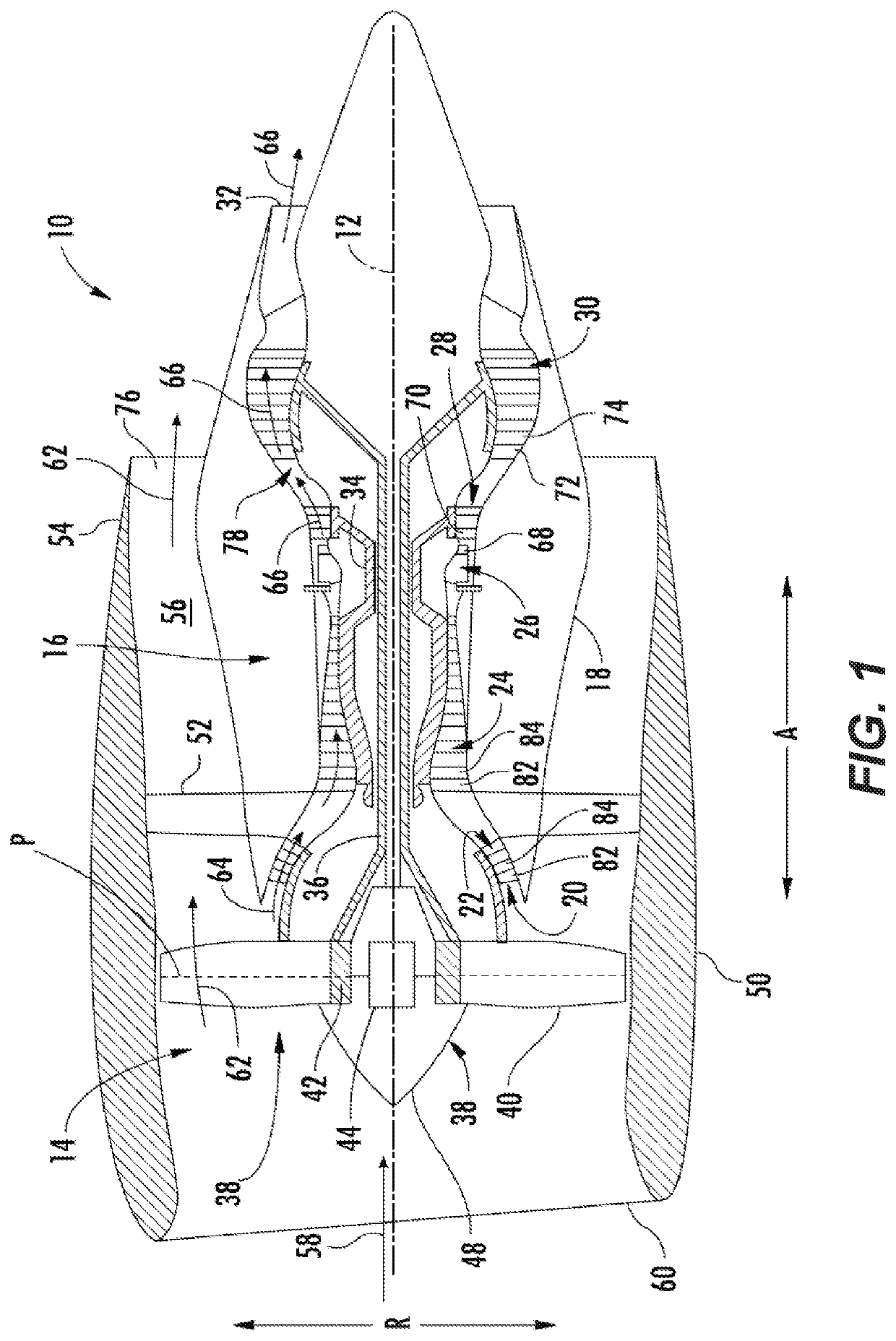

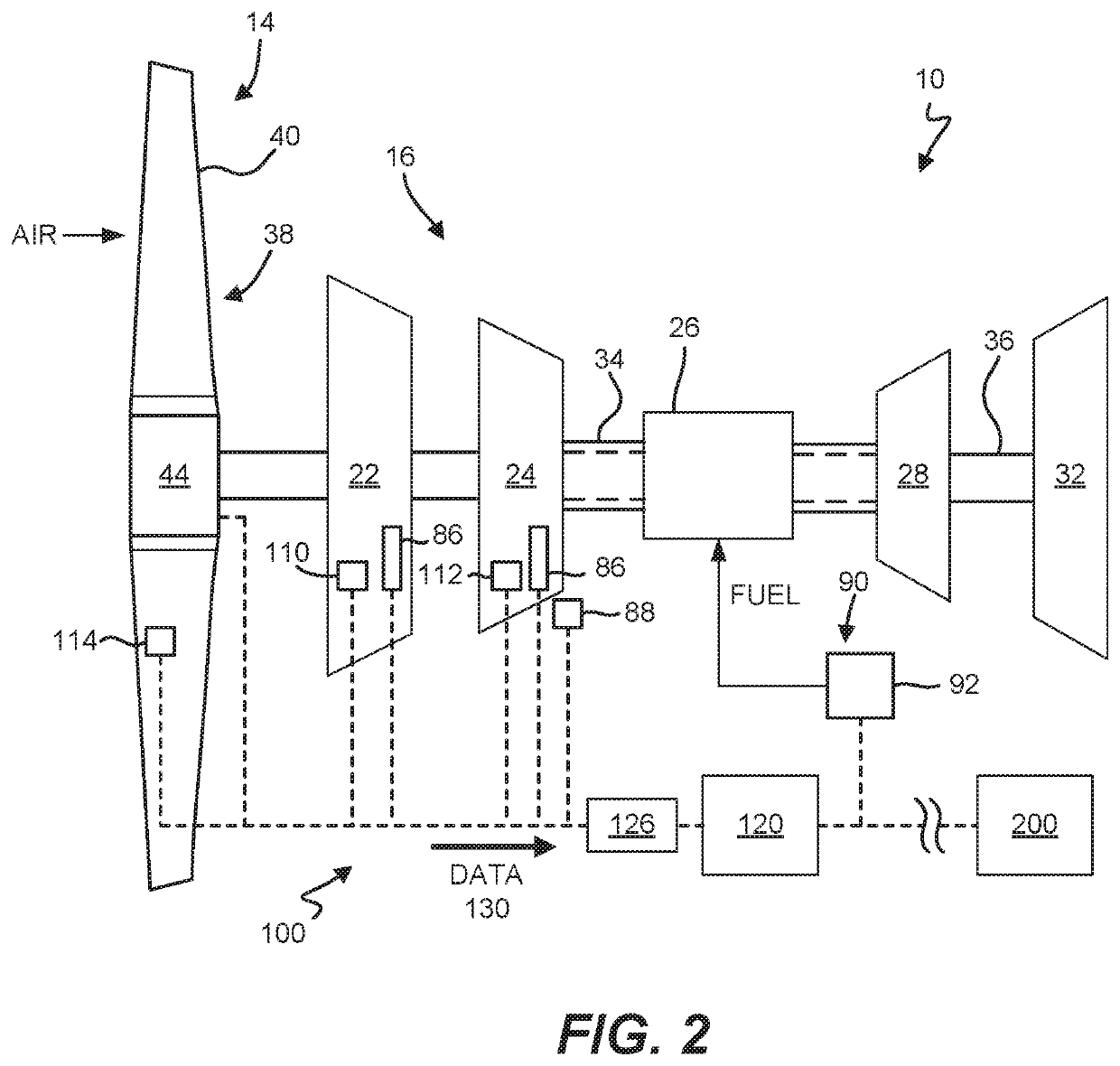

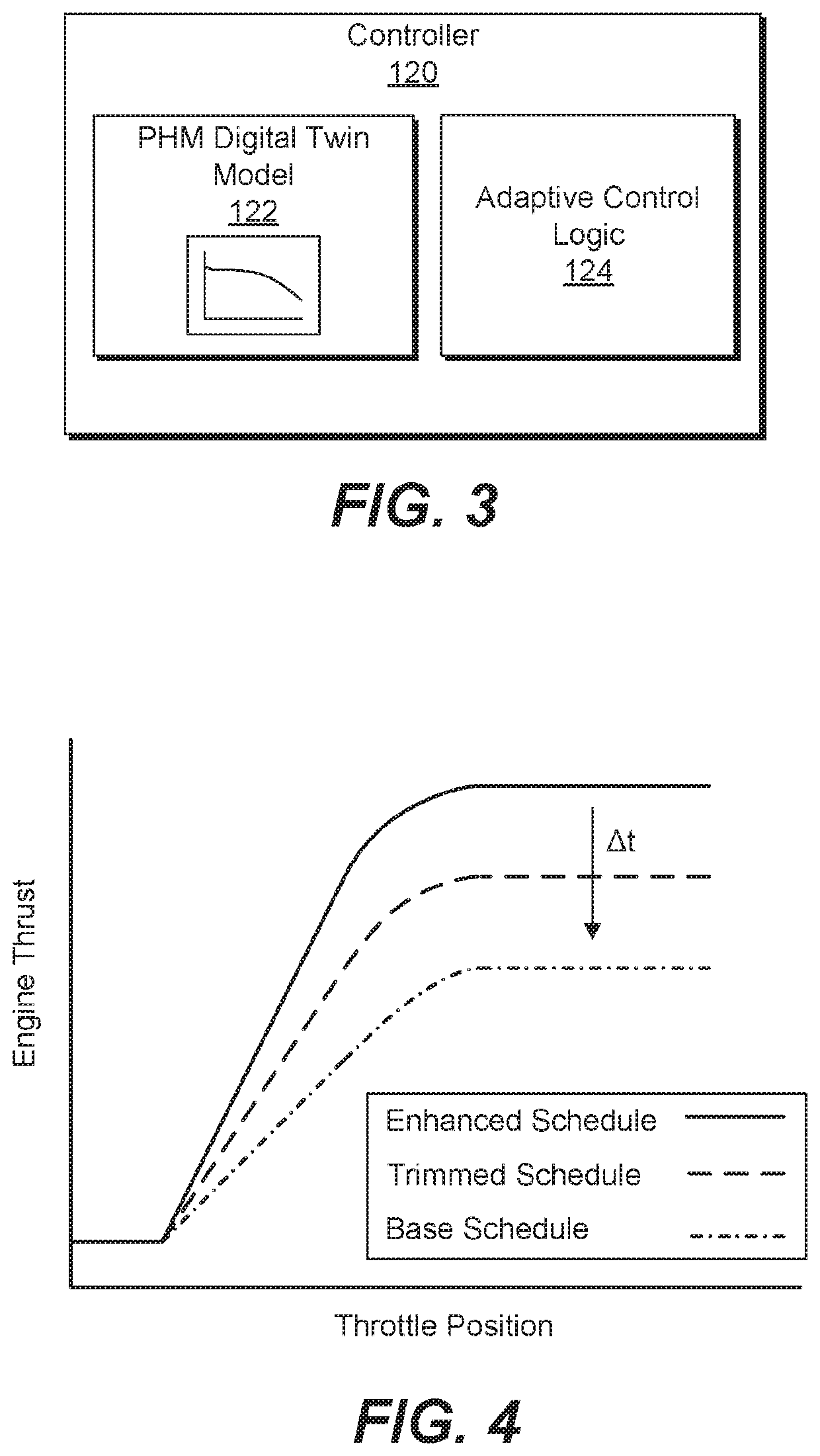

Prognostic Health Management Control for Adaptive Operability Recovery for Turbine Engines

The subject matter of the present disclosure is directed to a turbine engine having an adaptive prognostic health management control system that passively monitors stall margin reductions and applies corrective trims to a power management schedule of the engine to recover operability over time whilst maintaining a sufficient level of stall margin over the life cycle of the engine. The control system can adjust the power management schedule as needed to sustain a target stall margin, which allows for a more optimized and gradual performance to operability trade-off.

Owner:GENERAL ELECTRIC CO

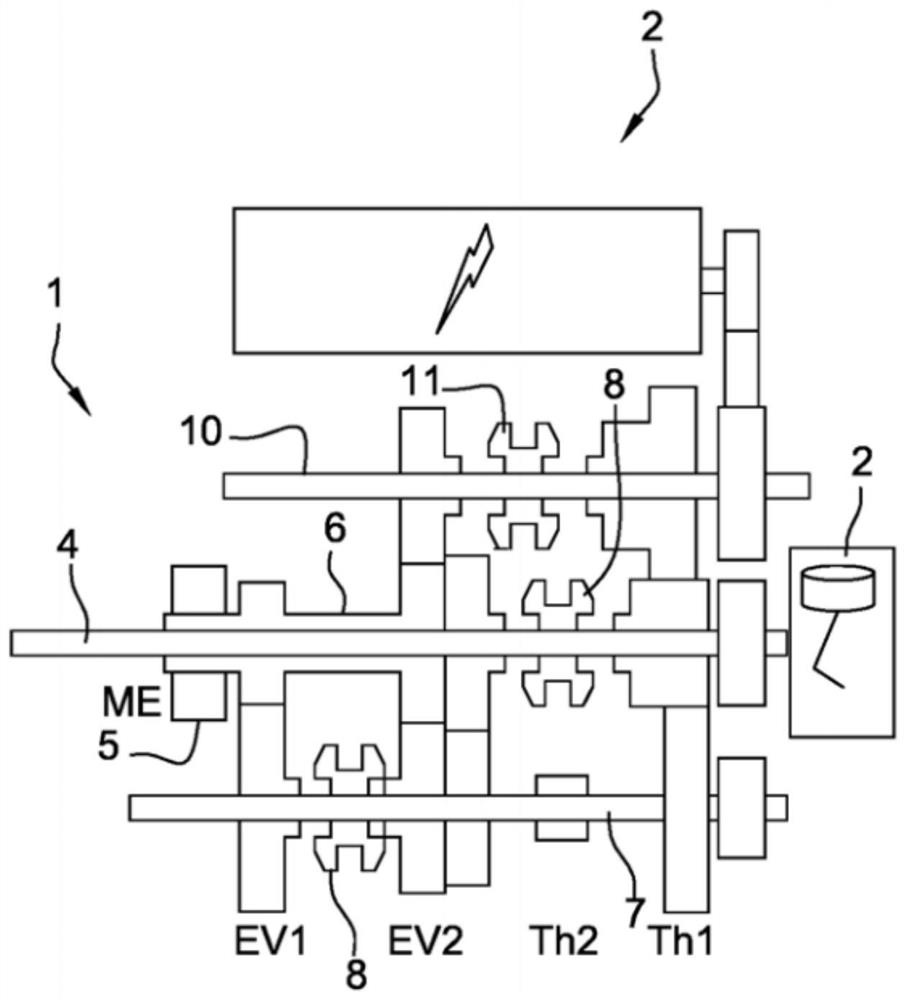

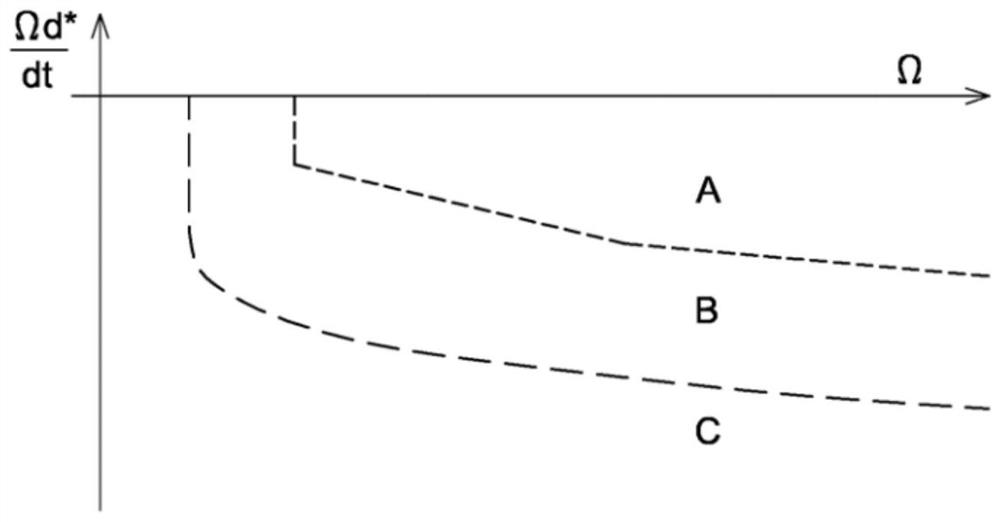

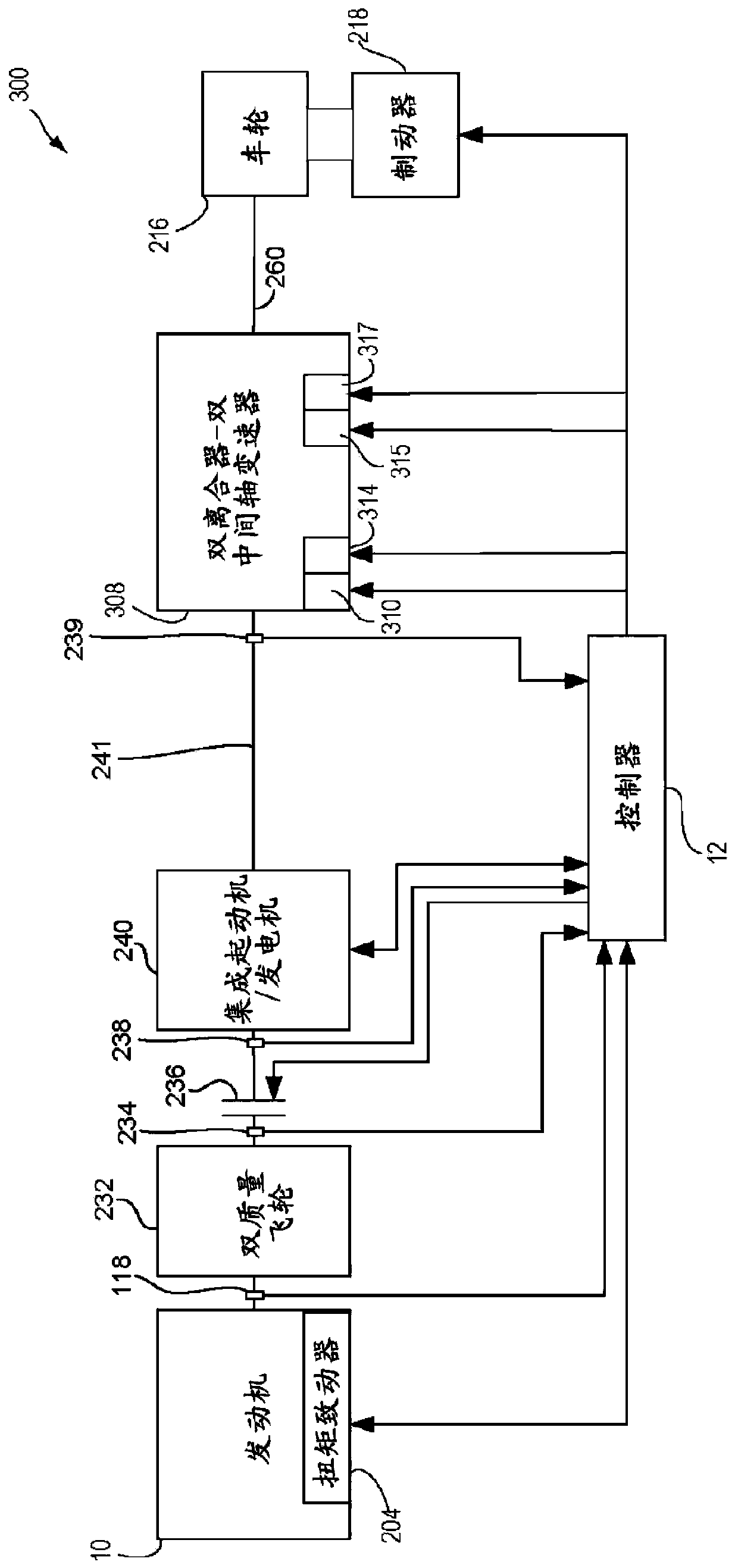

Method for controlling the release of internal couplers of gear wheels on transmission shafts, transmission and power train

PendingCN111615467AManage jettingHybrid vehiclesGas pressure propulsion mountingStall (engine)Gear wheel

A method for controlling the release of the teeth of an internal transmission coupler (8, 12) controlled by a gearshift actuator (16) for applying or canceling a transmission ratio to or from the torque provided by a heat engine connected to the input of the transmission without a disconnect clutch, characterized in that when the heat engine enters a critical situation in which there is a risk ofstalling during deceleration in an engaged gear, a first critical zone is determined in accordance with the speed of the heat engine (omega), in which first critical zone the actuator (16) is urged torelease the engaged gear in order to prevent stalling, and a second critical zone is determined in accordance with the engine speed and the deceleration of the engine, in which second critical zone the engine stall is controlled by preventing the injection of fuel.

Owner:RENAULT SA

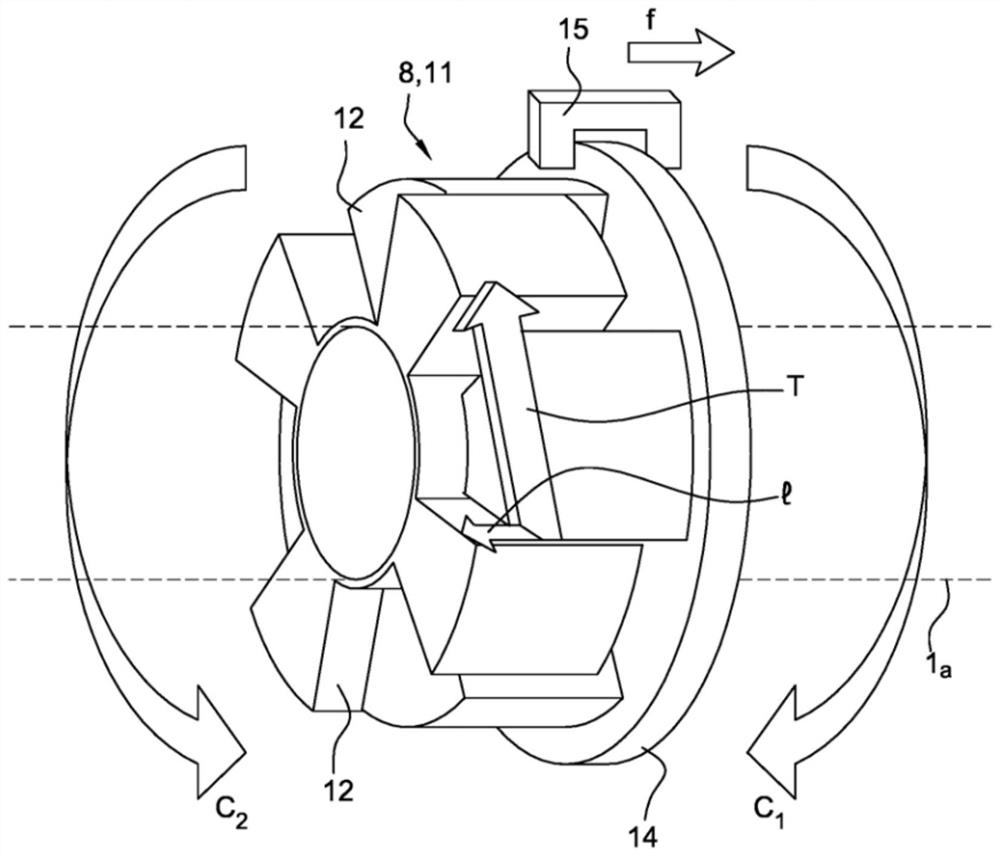

Green Cycle Heat Pump Engine

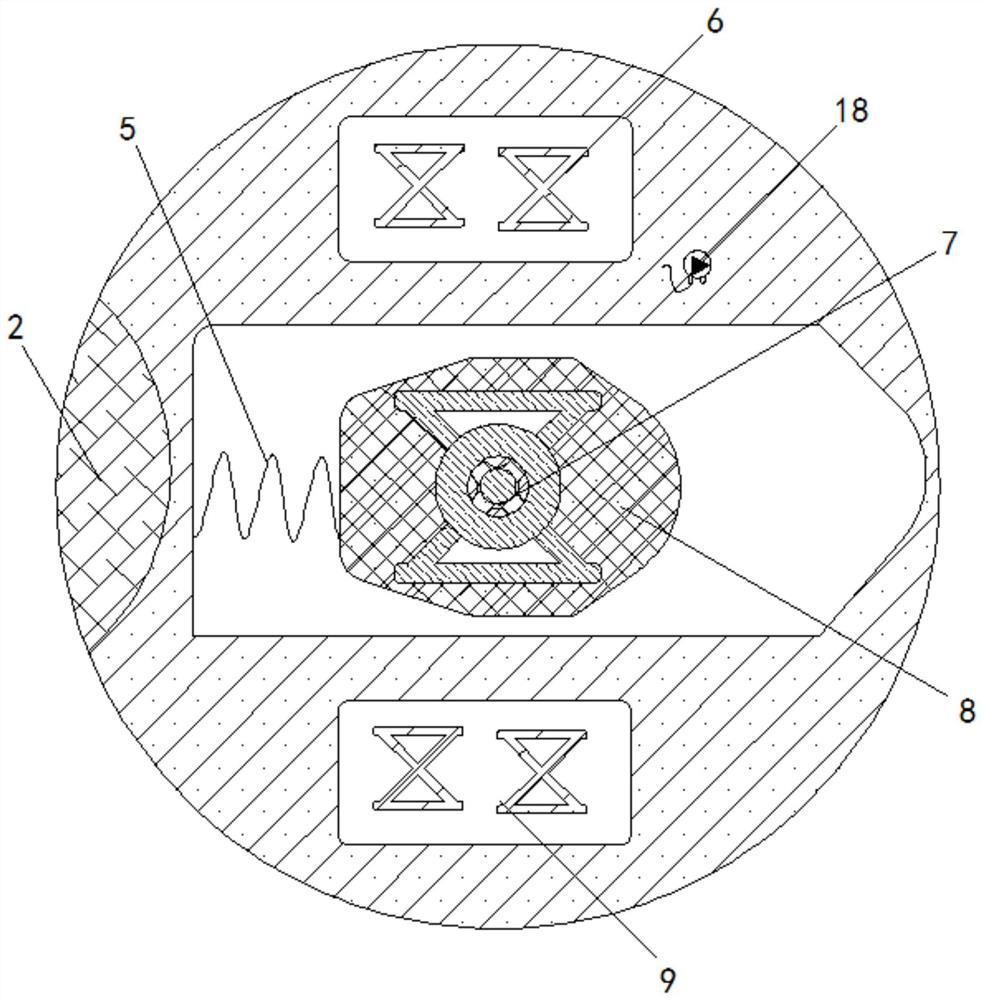

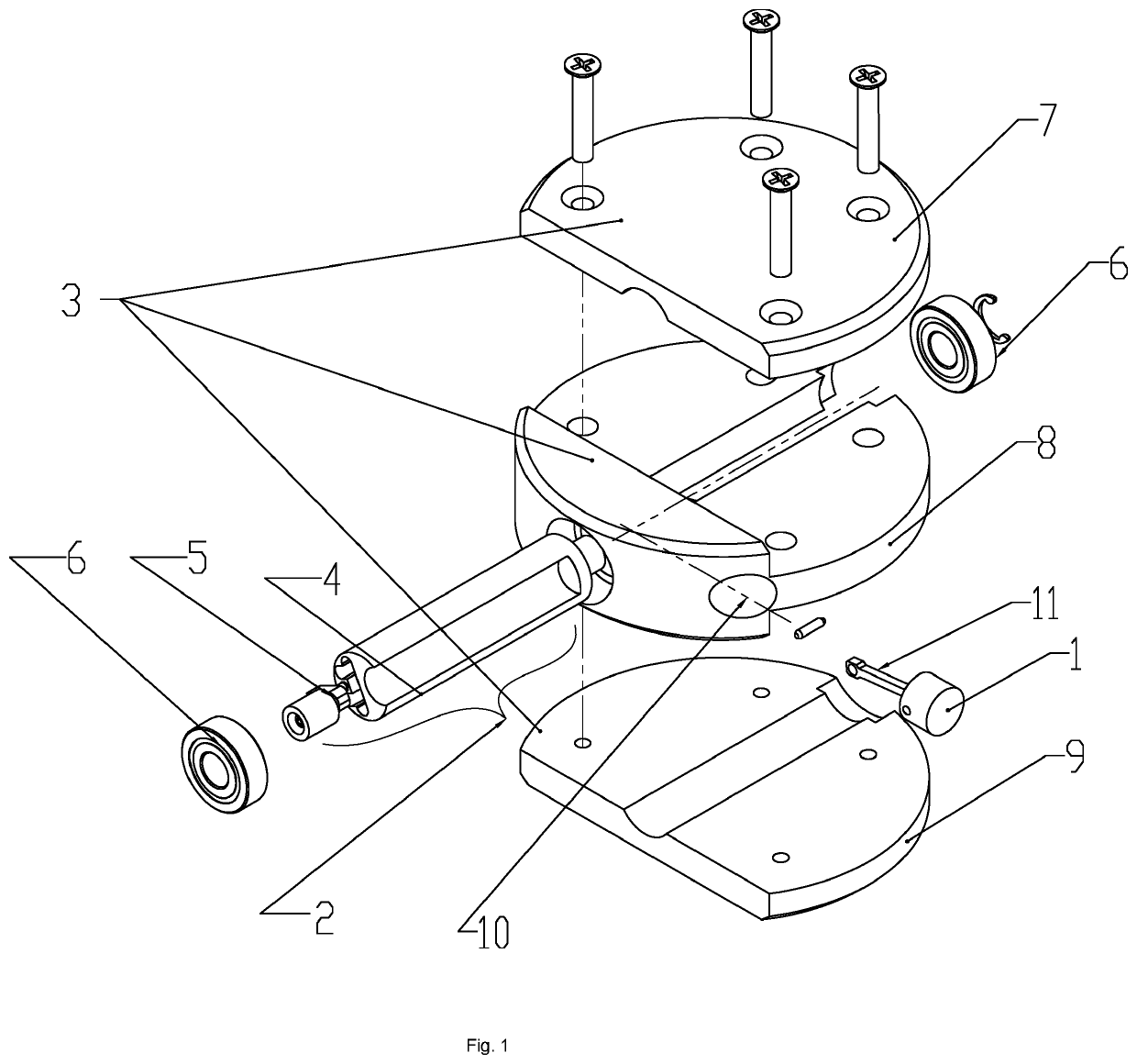

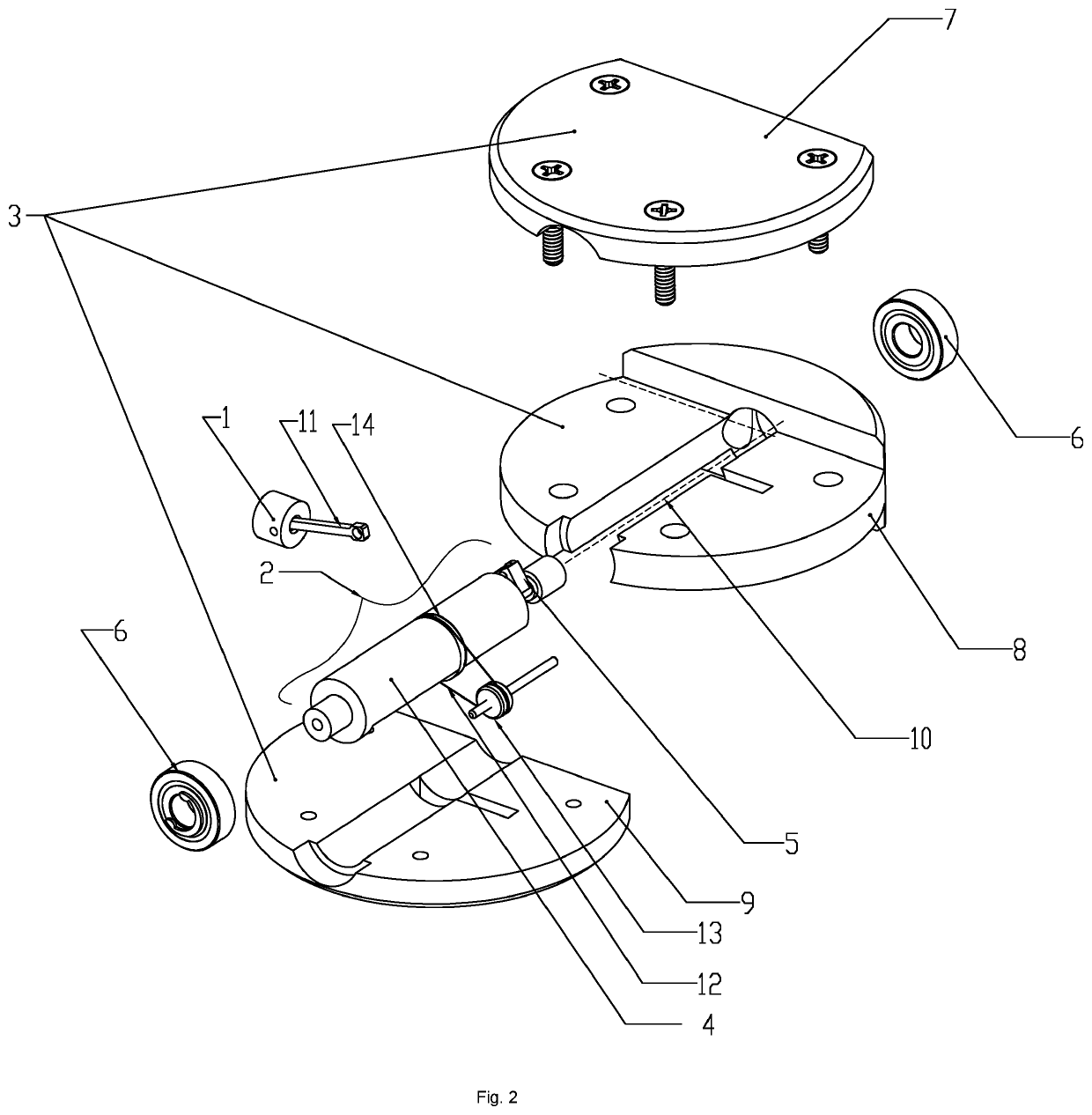

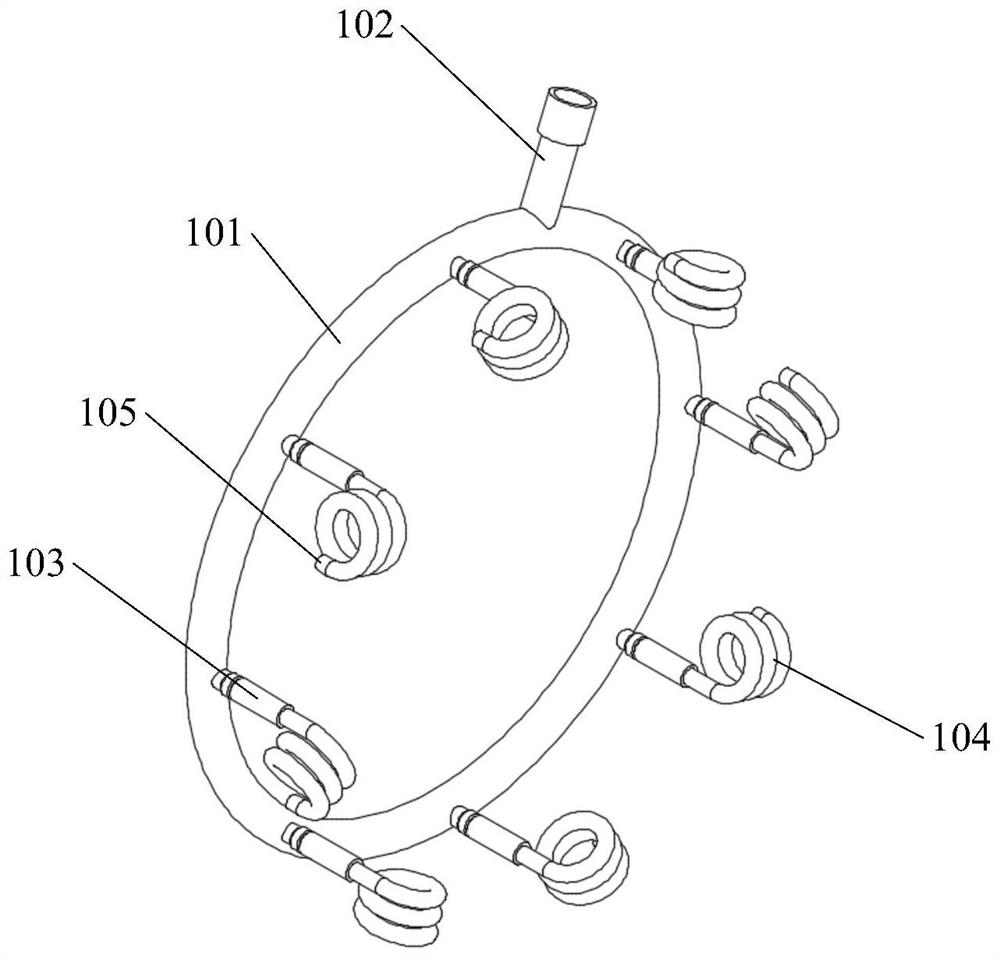

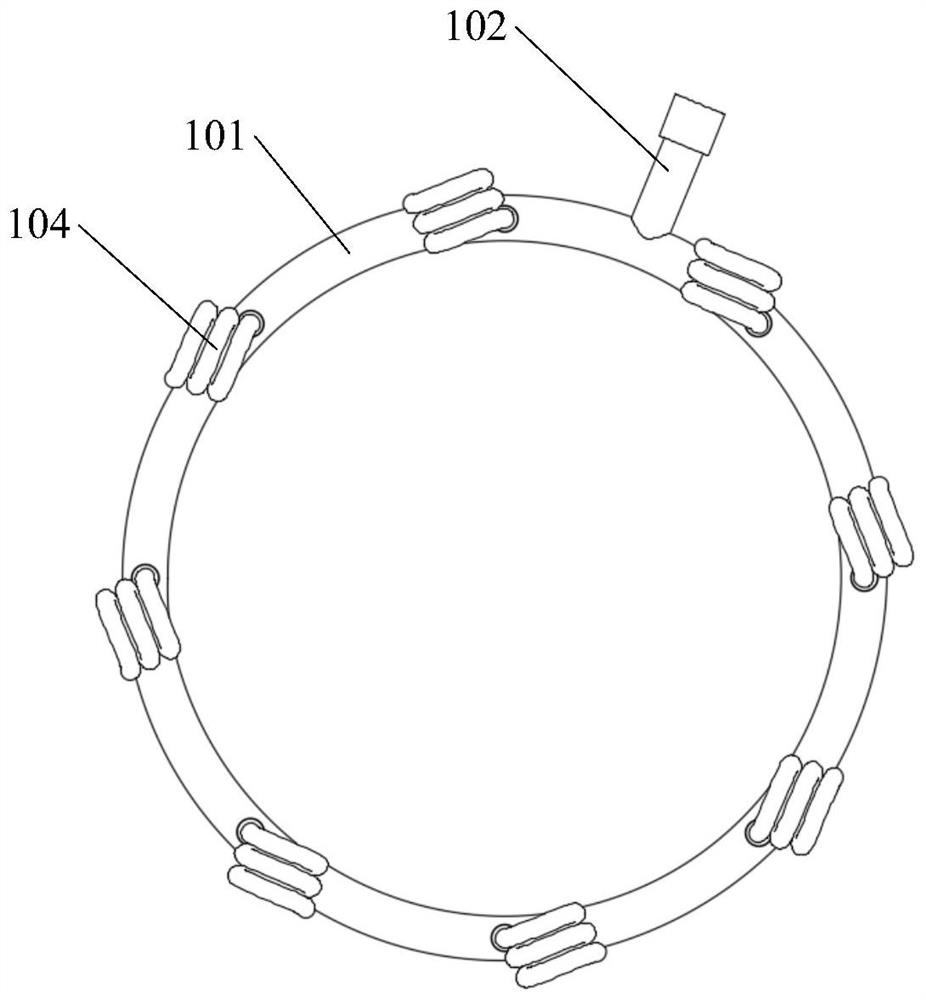

A single piston (1), rotary displacer (2), heat cycle / transfer engine, using a fixed volume of working fluid, in a single L shape tubular chambered (10), three zone (7)(8)(9), sealed housing (3). The rotary displacer (2) consists of a displacer cam (4) and a crank shaft (5) supported by a variable number of rotary bearings (6), the number and type of which depends on the size and rotational speed of the completed unit. The sealed housing (3), consisting of three zones, where one faces a heat source side (7), one acts an insulating barrier (8) and one acts as a heat sink (9). Movement of the rotary displacer (2) transports the contained working fluid to the exposed surfaces of the heat source side (7) and the heat sink (9) sequentially, while the incorporated crank shaft (5) drives the single piston (1), via a connecting rod (11), which allows for the manipulation of the corresponding expansion and contraction of the working fluid. The engine can use the transfer of heat, the Carnot Heat Cycle, to generate rotational (or linear) power or act as a heat pump / refrigeration unit. When used to produce rotational power, the initial rotational energy may be provided by a loop of Nitinol (12) or similar shape memory alloy to avoid a stall caused by the working fluid being exposed to the heat source side and heat sink side equally. The Nitinol loop (12) may ride on a second shape memory alloy ring (14), which allows it to disengage at higher temperatures and rotational speeds, effectively acting as a clutching mechanism. The invention is scalable to include nano-devices and micro electromechanical systems (MEMS), through large scale heat recovery systems.

Owner:GREEN JR DARRELL HENRY +2

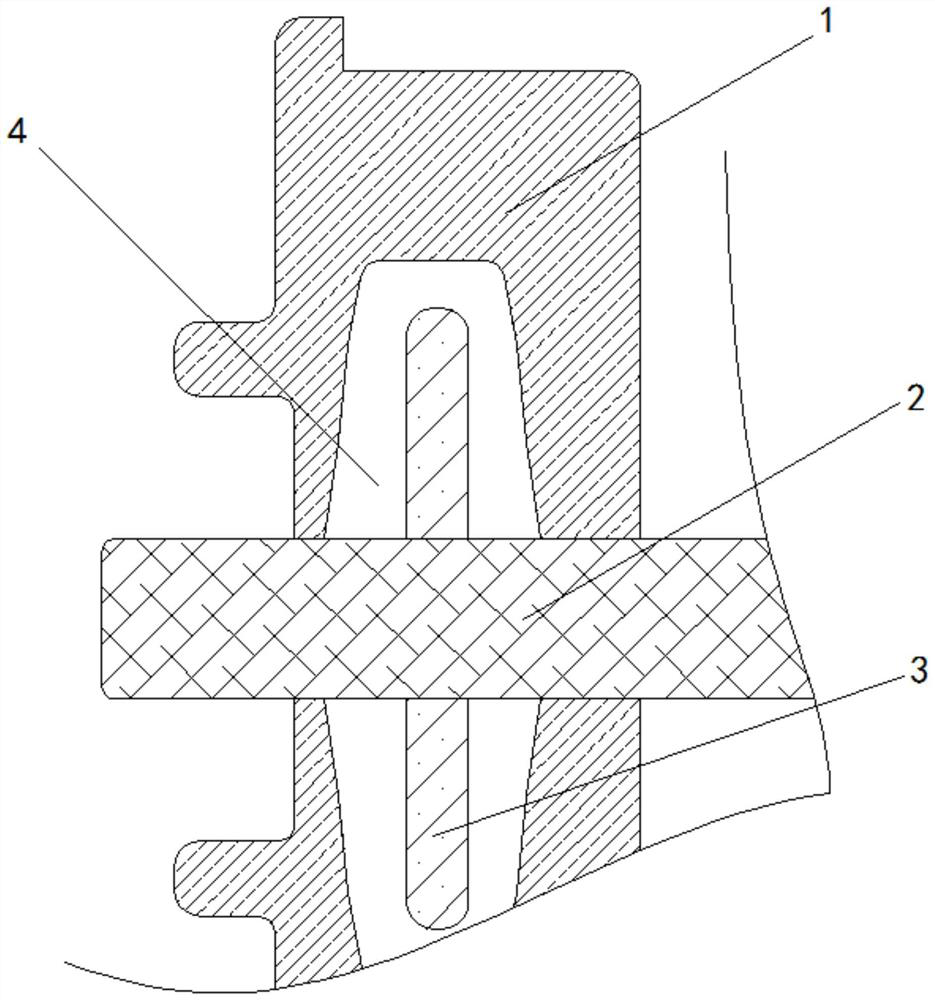

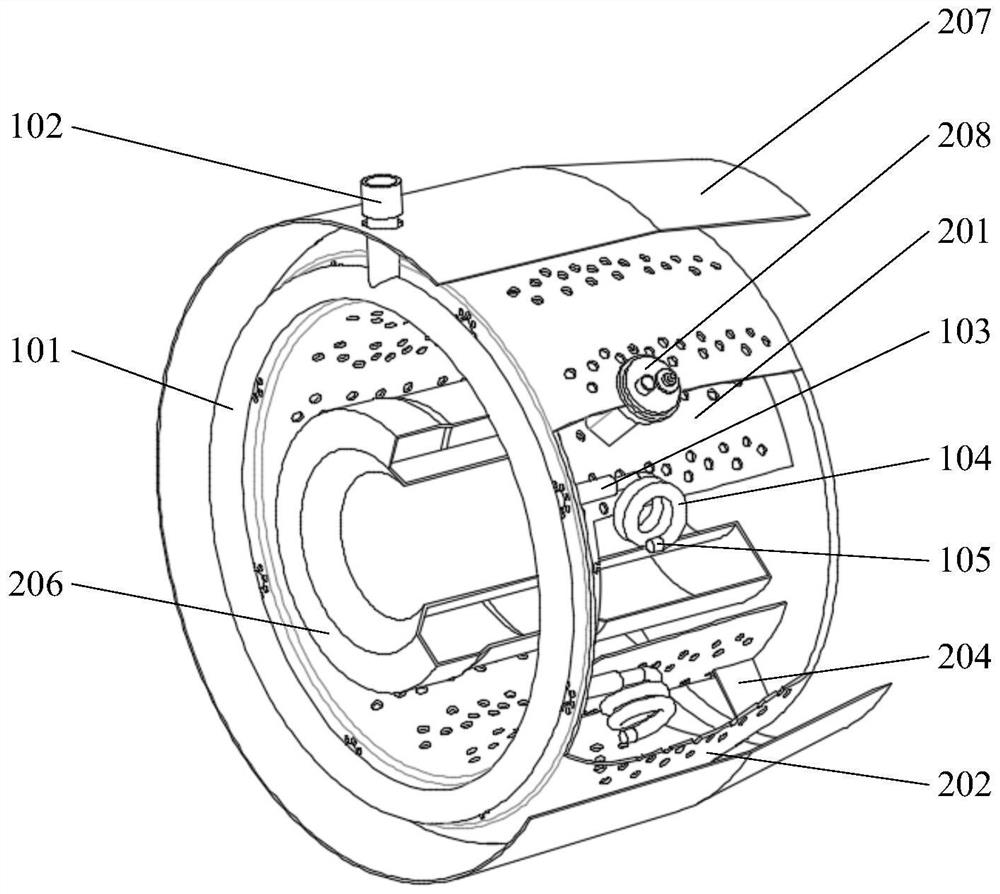

Oil supply atomization device, combustion chamber device and micro jet engine

PendingCN114110660ALess prone to surgeNot prone to situationsContinuous combustion chamberTurbine/propulsion fuel heatingStall (engine)Combustion chamber

The invention discloses an oil supply atomization device, a combustion chamber device and a micro jet engine, and the oil supply atomization device comprises an oil supply ring connected with an oil supply header pipe; and the evaporation pipe comprises a preheating part and an evaporation part, one end of the preheating part is connected with the oil supply ring, the other end of the preheating part is connected with the evaporation part, and the periphery of the preheating part is wrapped with a heat conduction piece. During working, the oil supply main pipe supplies fuel to the oil supply ring, the fuel enters the evaporation pipe from the oil supply ring and firstly enters the preheating part, and the heat conduction piece can quickly transfer heat in the combustion chamber to the fuel entering the preheating part, so that the fuel enters the evaporation part after being quickly preheated and is sprayed out after further heat transfer by the evaporation part; according to the micro jet engine, fuel can be fully preheated before entering the combustion chamber, so that the fuel is fully evaporated, atomized fuel hot steam which is uniformly distributed is formed, the atomization degree of the fuel is high, combustion is more sufficient and stable, the combustion chamber is not prone to stall, and the micro jet engine is not prone to surging, stopping in the air and the like.

Owner:付柏山

Methods and systems of actuating a clutch of a manual transmission during autonomous braking

Systems and methods are provided for actuating a clutch of a manual transmission of a vehicle comprising. An automatic emergency braking (AEB) system is configured to automatically initiate an AEB event and a brake controller is configured to automatically actuate a braking system of the vehicle. A powertrain controller in is configured to monitor vehicle parameters and determine when an engine ofthe vehicle is nearing stall. A clutch control module is configured to actuate a clutch hydraulic master cylinder and actuate the clutch. A vehicle sensor network is configured to detect objects surrounding the vehicle. The AEB system is configured to initiate the AEB event based on detected objects surrounding the vehicle and, when the AEB event is initiated, instruct the brake controller to automatically actuate the braking system and instruct the clutch control module to actuate the clutch when the vehicle is nearing stall.

Owner:GM GLOBAL TECH OPERATIONS LLC

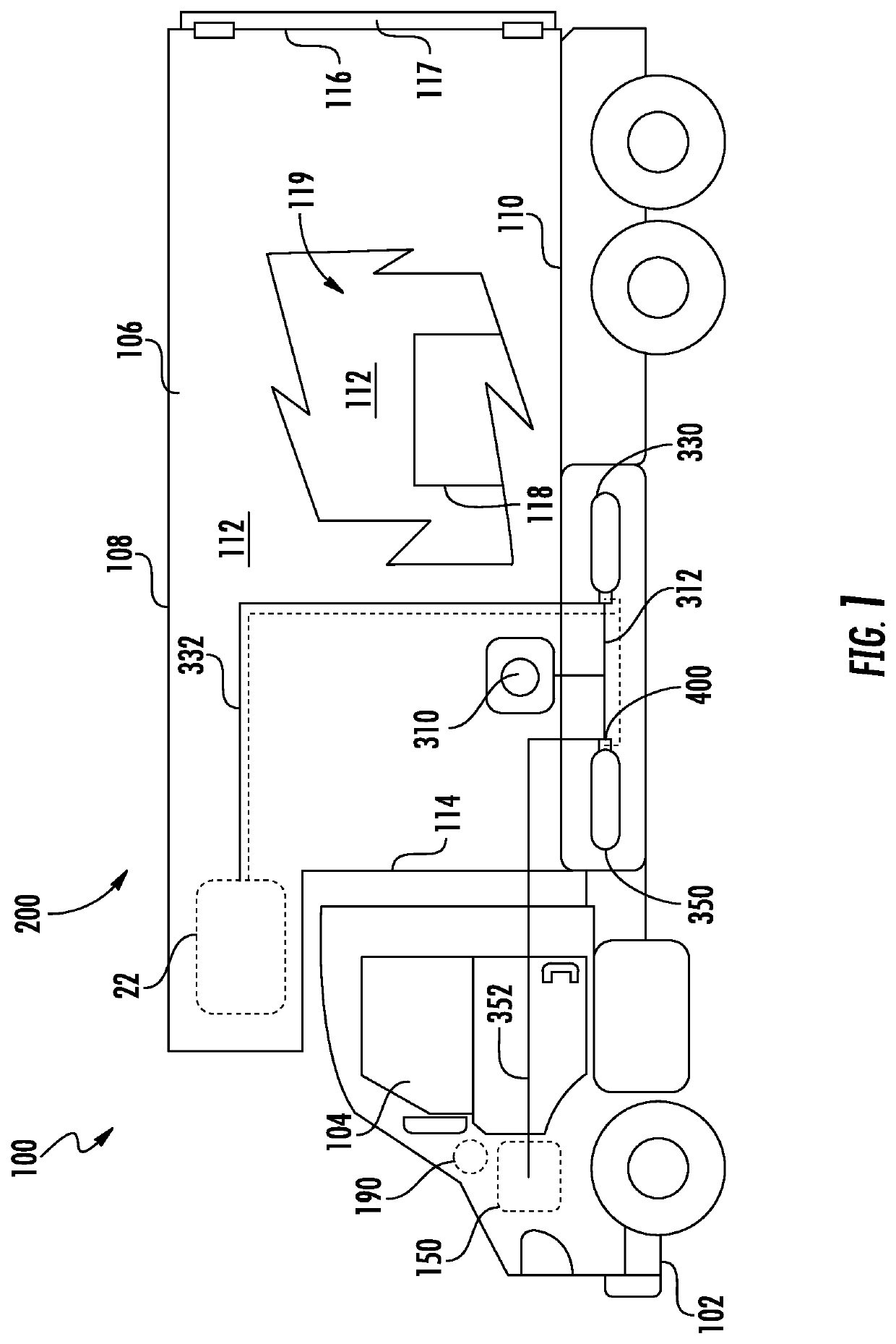

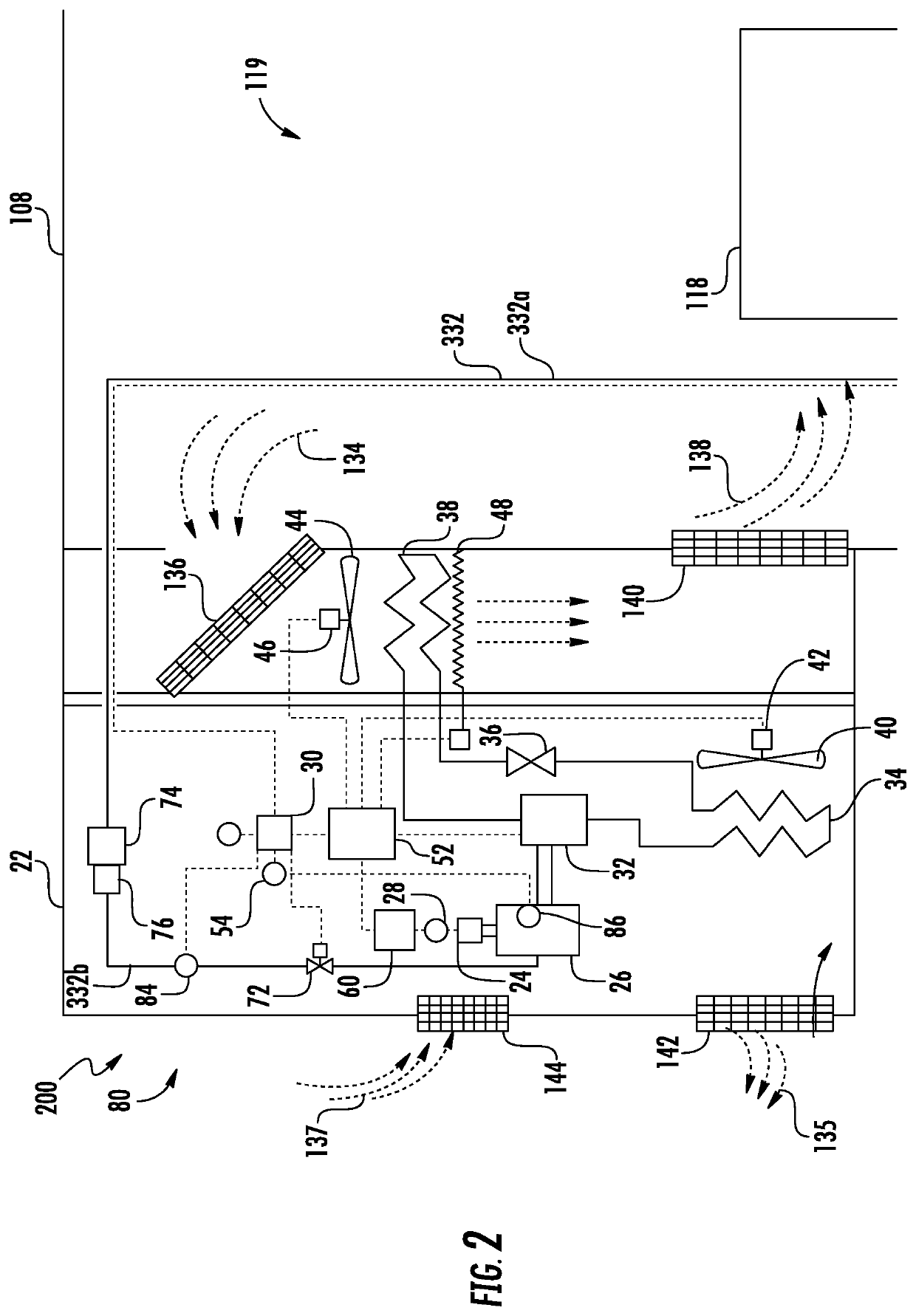

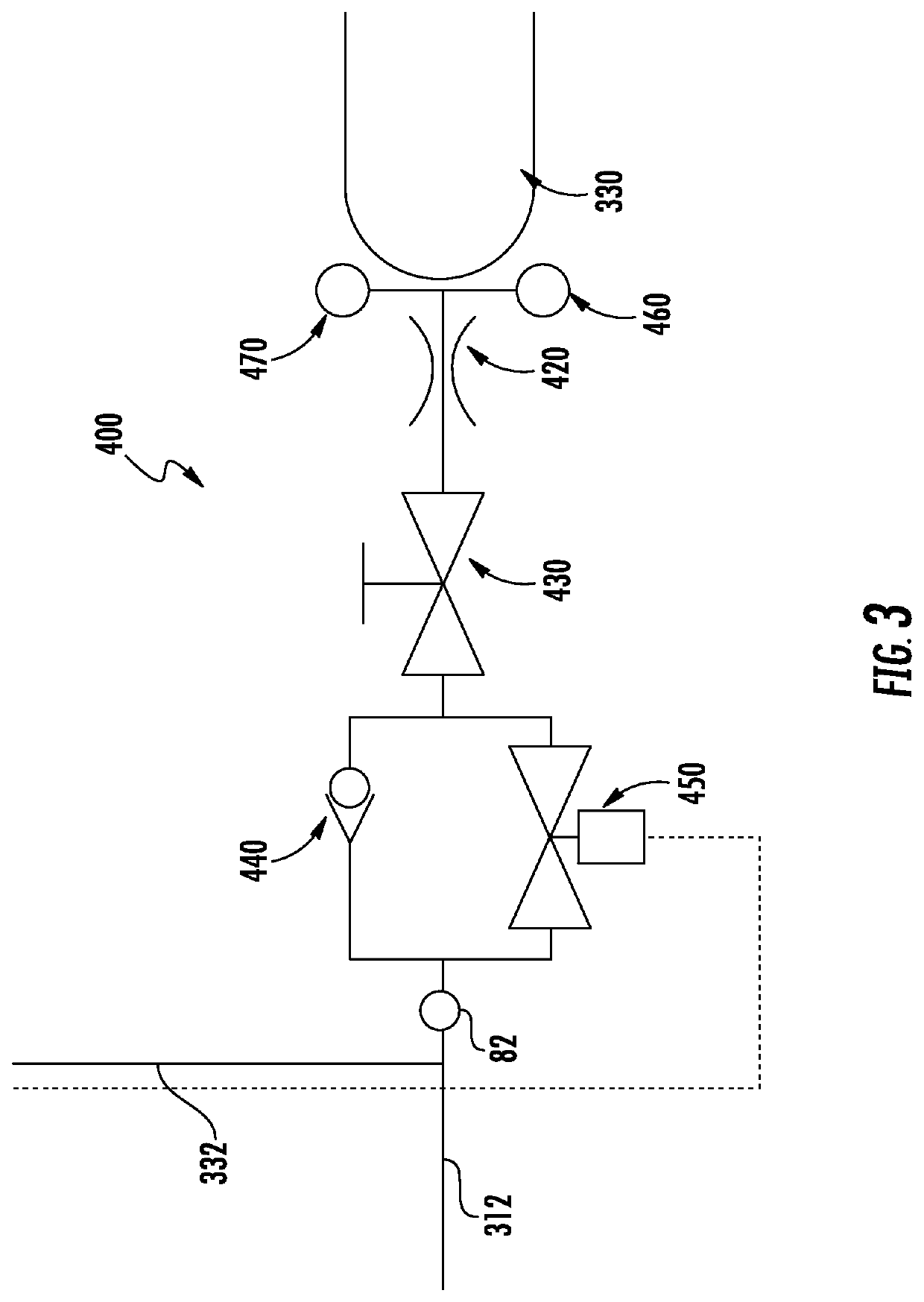

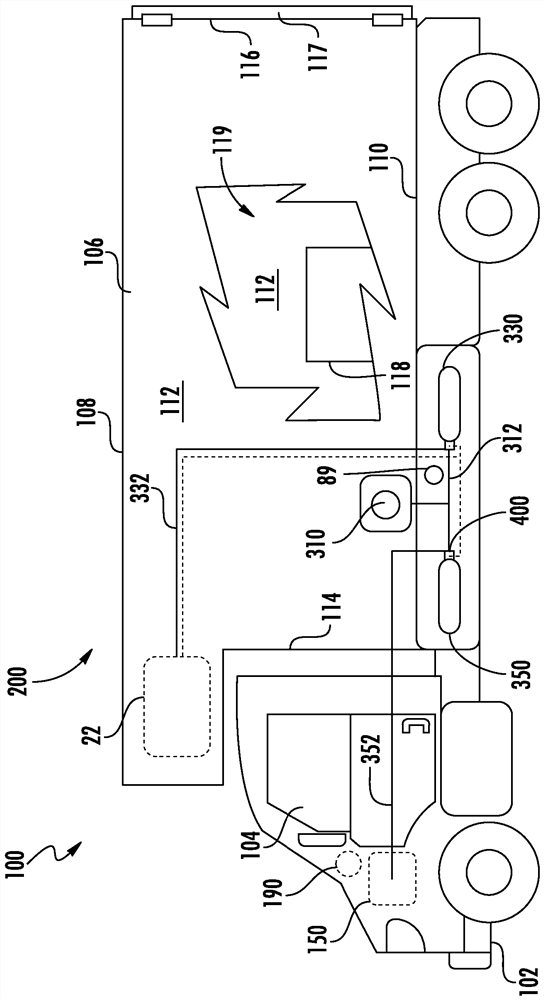

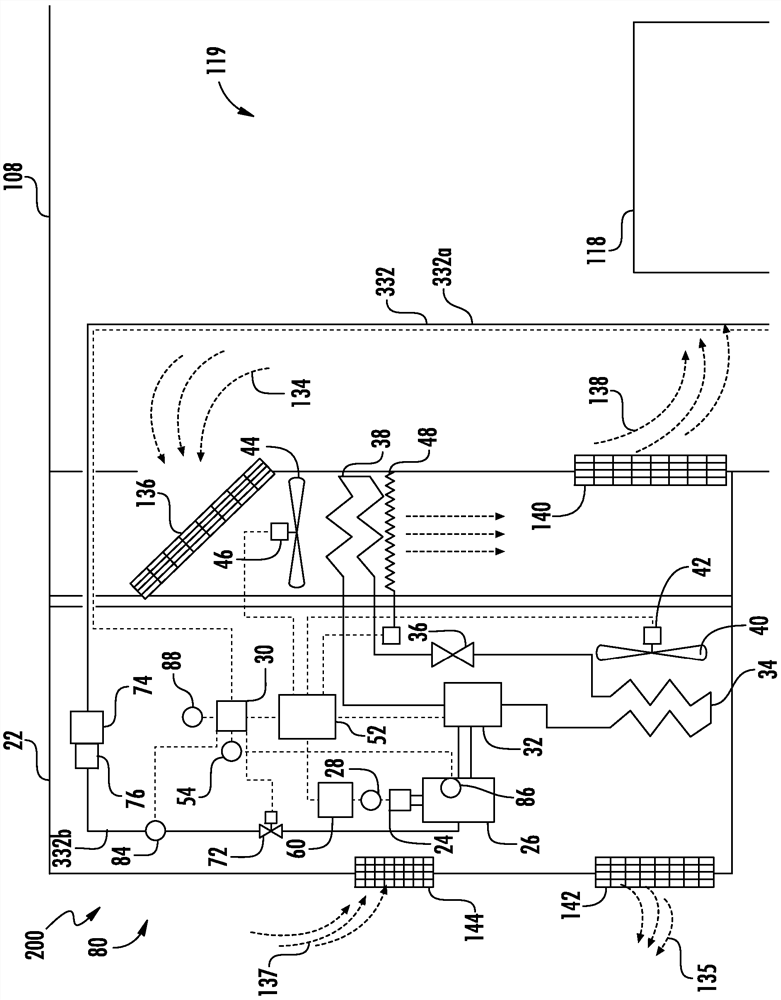

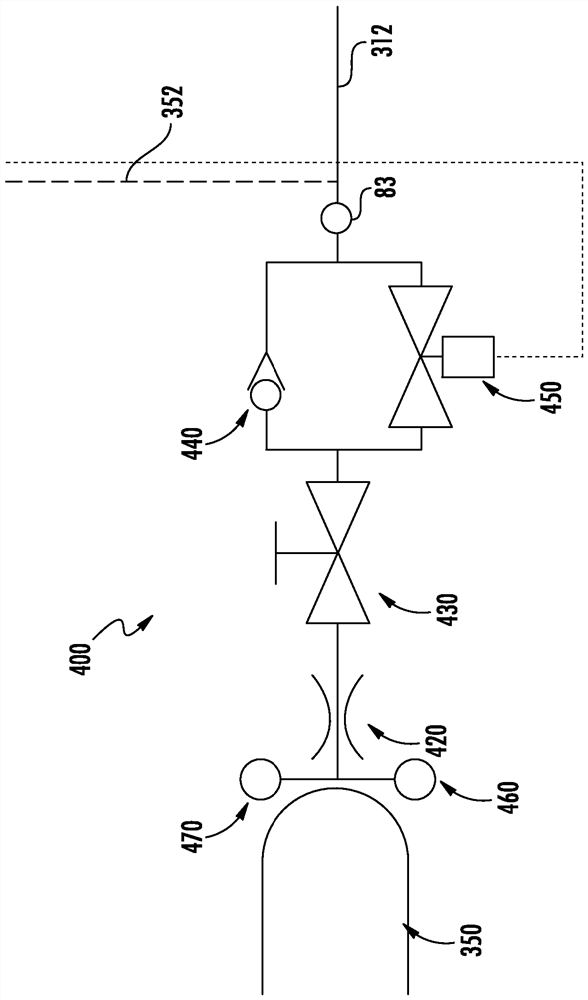

Fuel system control for refrigeration unit engine

A transport refrigeration system having: a first engine (26) configured to power a refrigeration unit (22); a first fuel tank (330) fluidly connected to the first engine through a first fuel line (332); a first shut off valve (450) located within the first fuel line proximate the first fuel tank; a second shut off valve (72) located within the first fuel line proximate the first engine; a sensor system (80) configured to detect at least one of a crash of the transport refrigeration system, a fuel leak in the first fuel line, and an engine stall in the first engine; and a controller (30) configured to close the first shutoff valve and the second shutoff valve when the sensor system detects at least one of a crash of the transport refrigeration system, a fuel leak in the first fuel line, and an engine stall in the first engine.

Owner:CARRIER CORP

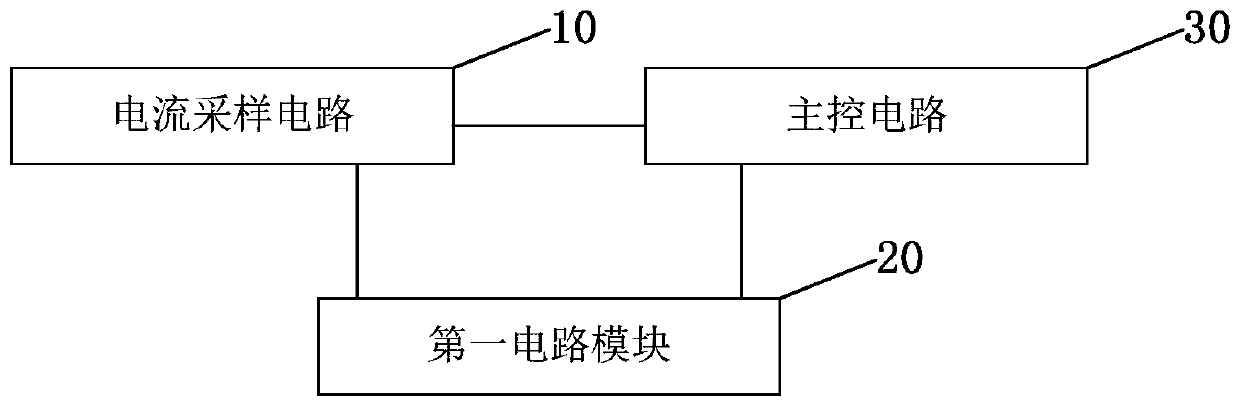

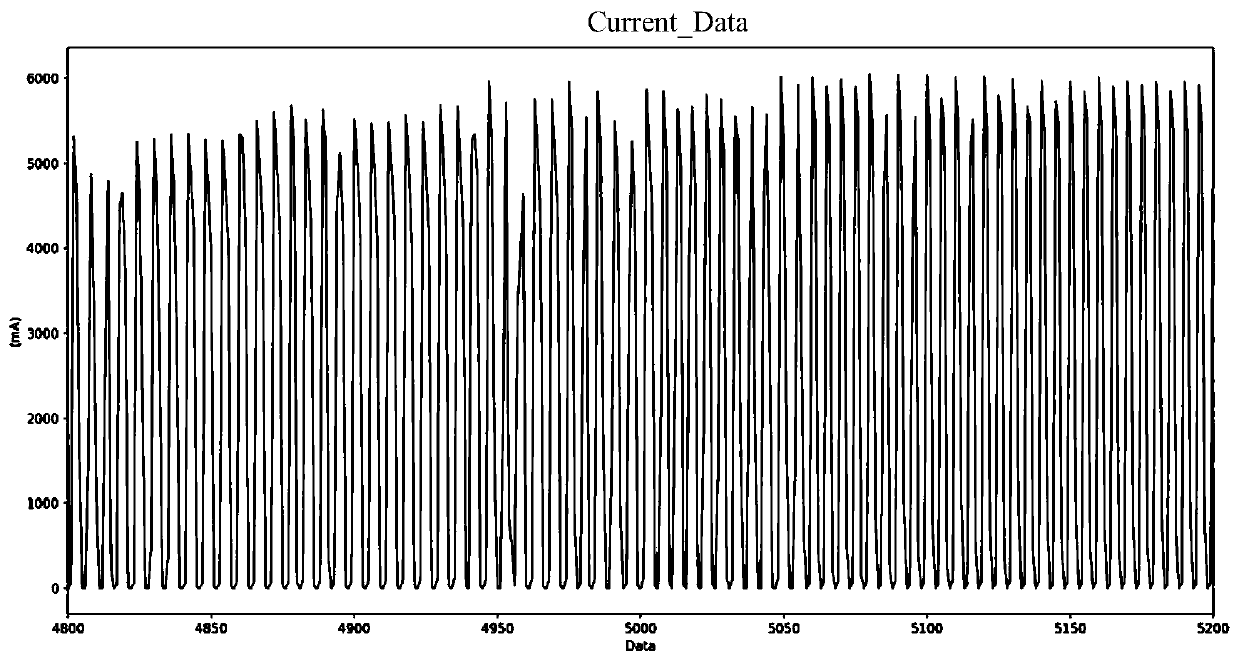

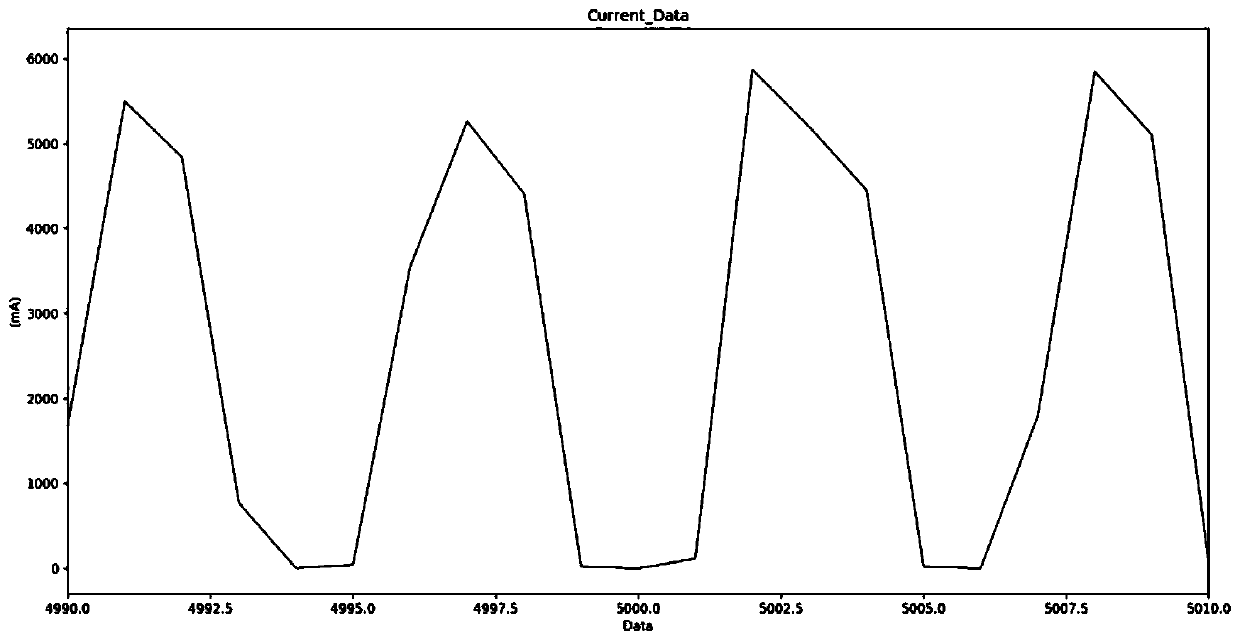

Detection device of machine equipment

InactiveCN111381159AStall monitoringDynamo-electric machine testingStall (engine)Control engineering

The embodiment of the invention discloses a detection device for machine equipment, and the detection device comprises: a current sampling circuit which is electrically connected with a first circuitmodule of the machine equipment, and is used for collecting a current signal of the first circuit module; and the main control circuit that is used for receiving the current signal of the first circuit module and judging that the first circuit module fails when detecting that the current value of the first circuit module exceeds a first set current value. According to the embodiment of the invention, the first circuit module is any one steering engine part of the robot; the detection device collects a current signal of the first circuit module through the current sampling circuit, and then detects the current signal through the main control circuit to judge whether the first circuit module fails or not, that is, whether the robot arm steering engine stalls or not is judged by detecting thecurrent signal of the first circuit module, so that monitoring of stalling abnormality of the arm steering engine is realized.

Owner:UBTECH ROBOTICS CORP LTD

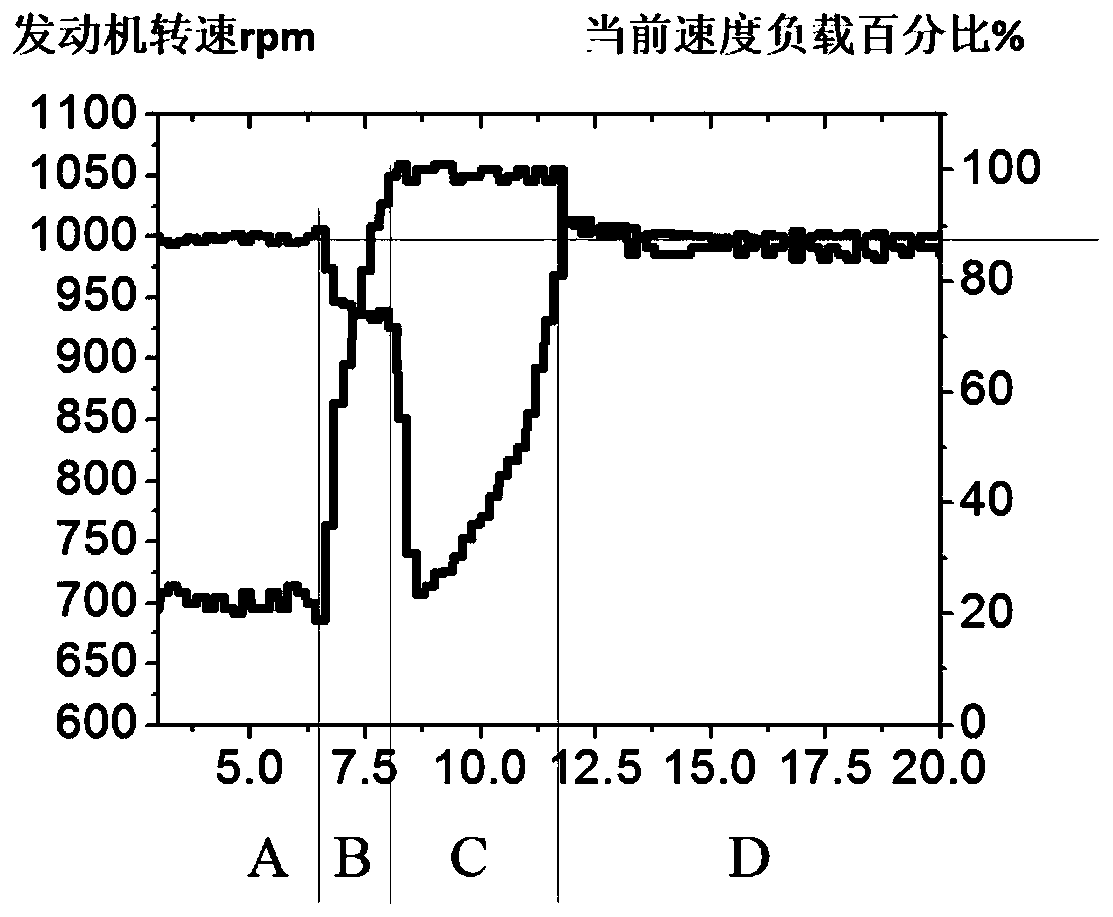

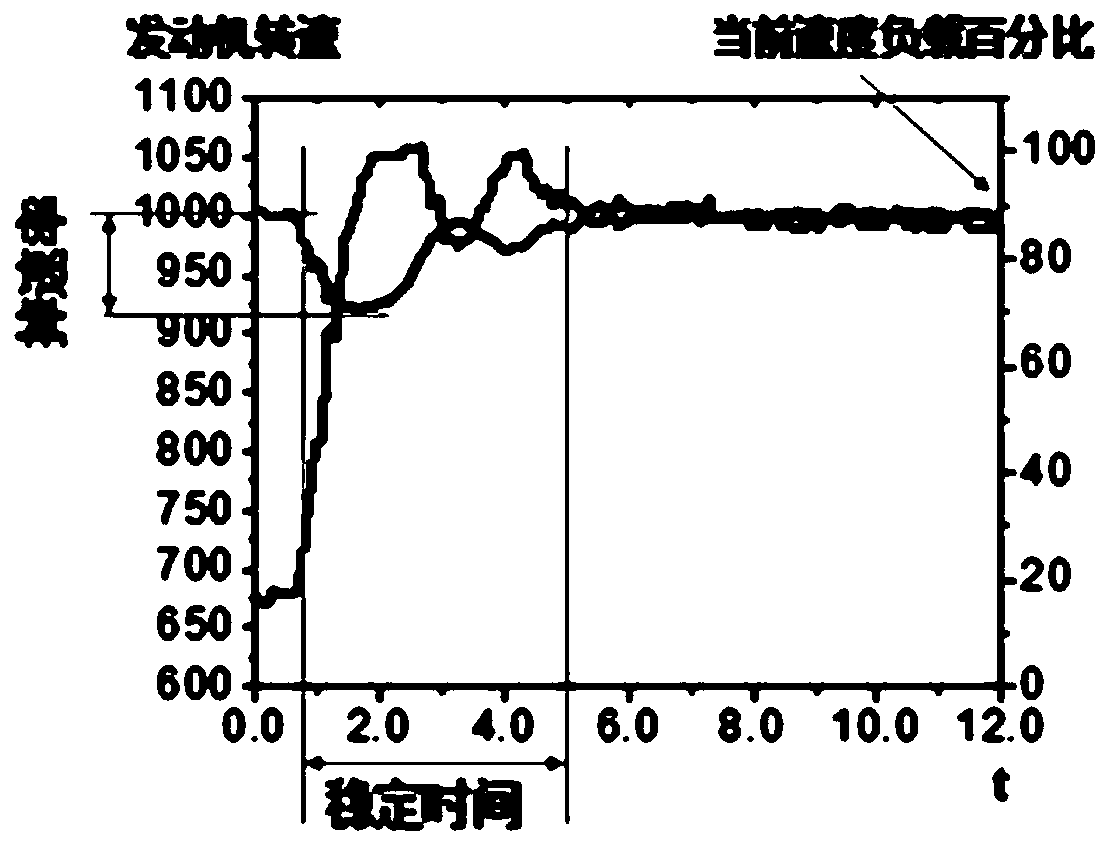

Method, controller and machine for controlling a hydraulic system

ActiveCN106647837BSolve the flameout problemAchieving Power MatchingSpeed/accelaration control using electric meansStall (engine)Control engineering

Owner:ZOOMLION HEAVY IND CO LTD

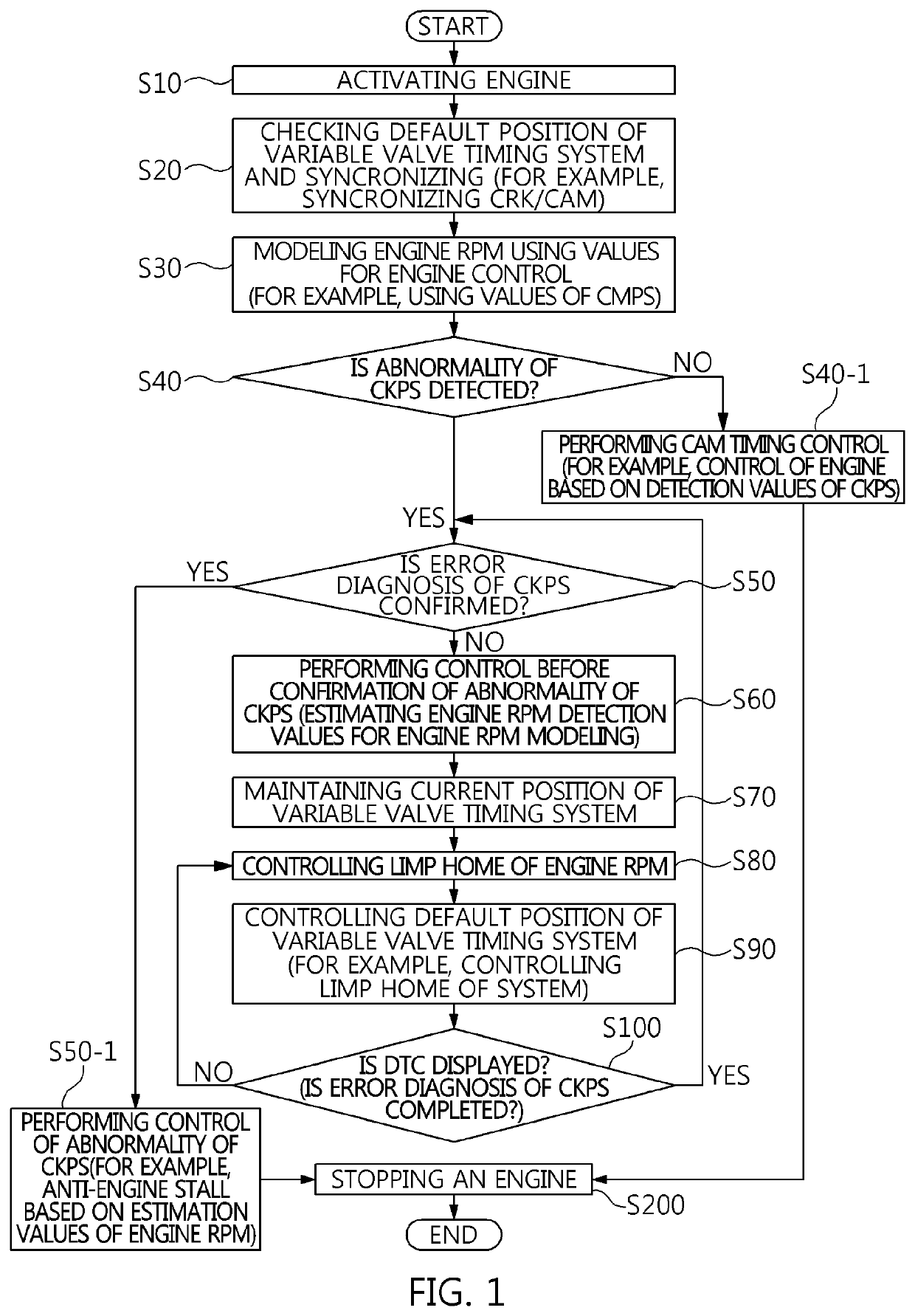

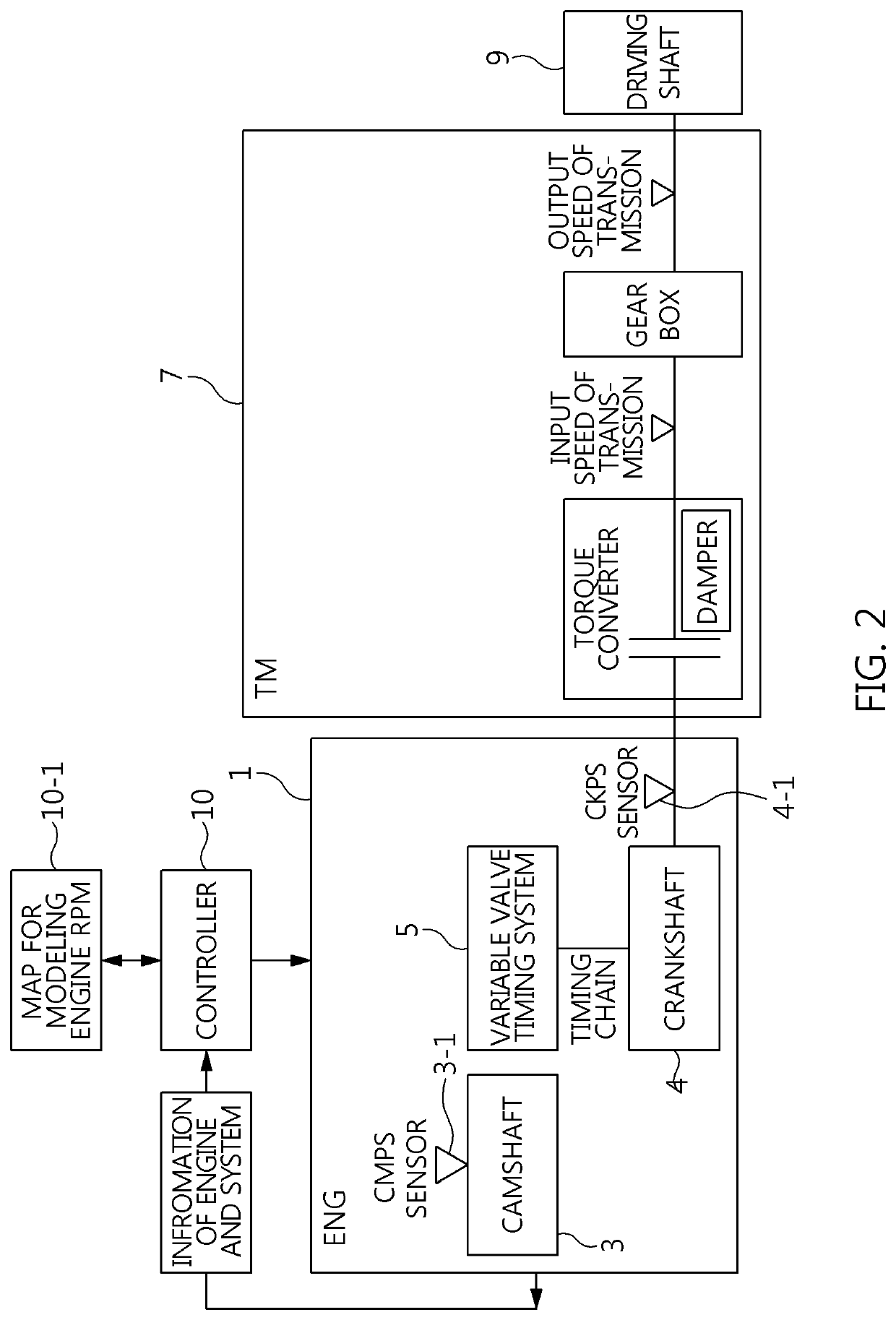

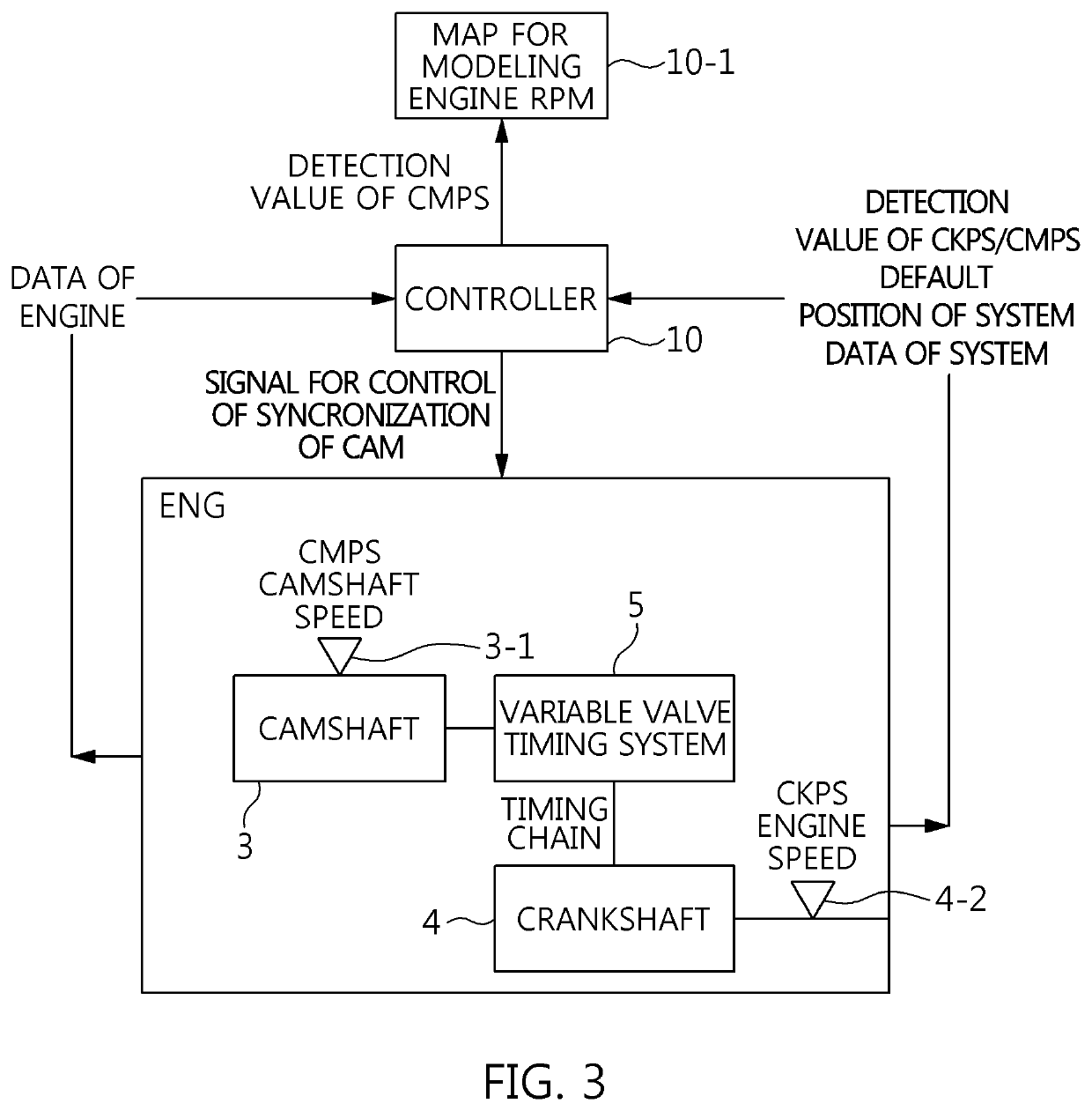

Method for reinforcing anti-engine stall and vehicle

ActiveUS10598103B2Avoid procrastinationInhibit deteriorationValve arrangementsElectrical controlStall (engine)Crank

A method for reinforcing anti-engine stall may include performing a cam timing control for measuring engine speed of an engine wherein when abnormality of a crank position detector is detected by a controller, engine speed of the engine is controlled to be higher than that at the time when the abnormality of crank position detector occurs while maintaining position for cam phase control operation of a variable timing system.

Owner:HYUNDAI MOTOR CO LTD +1

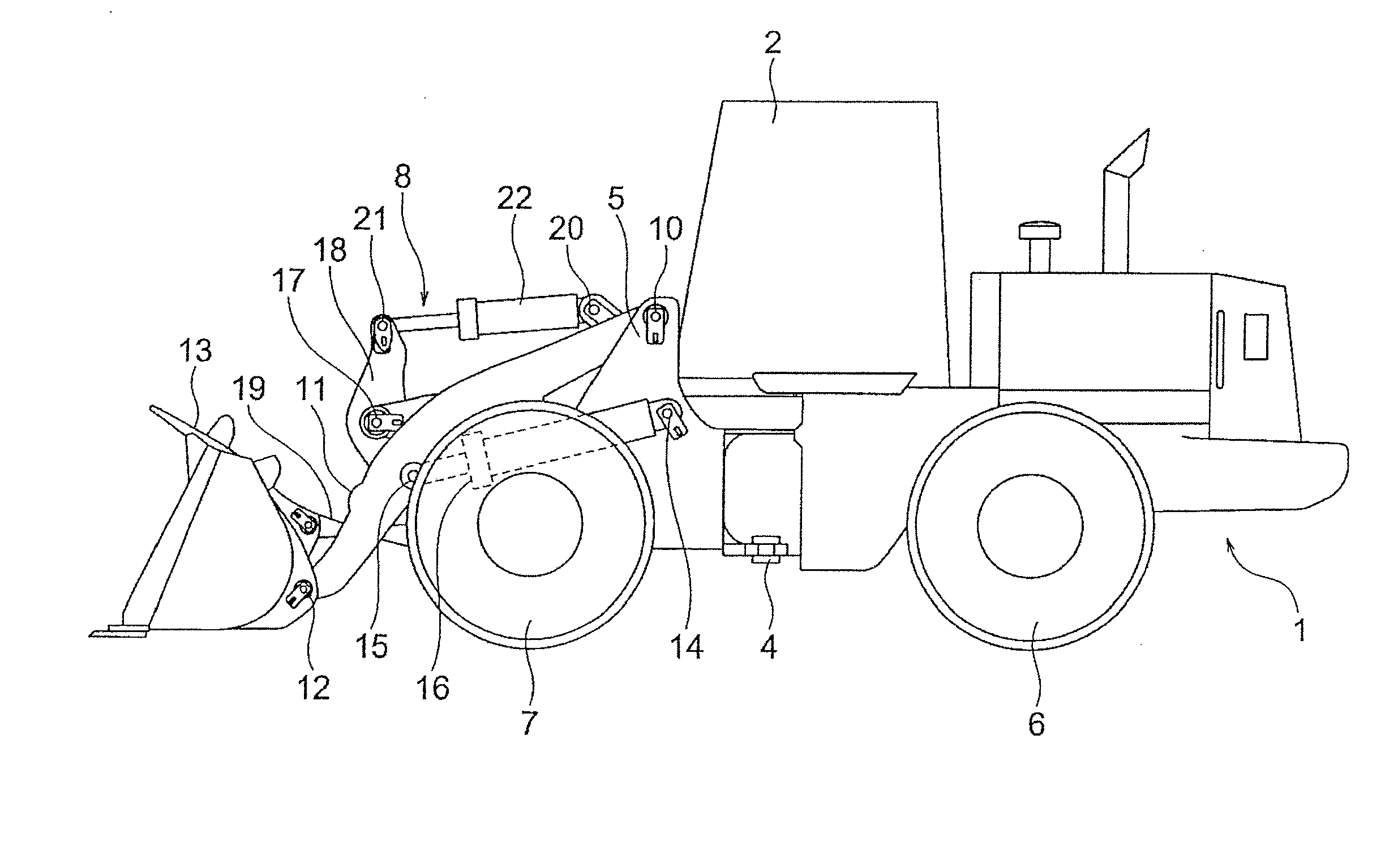

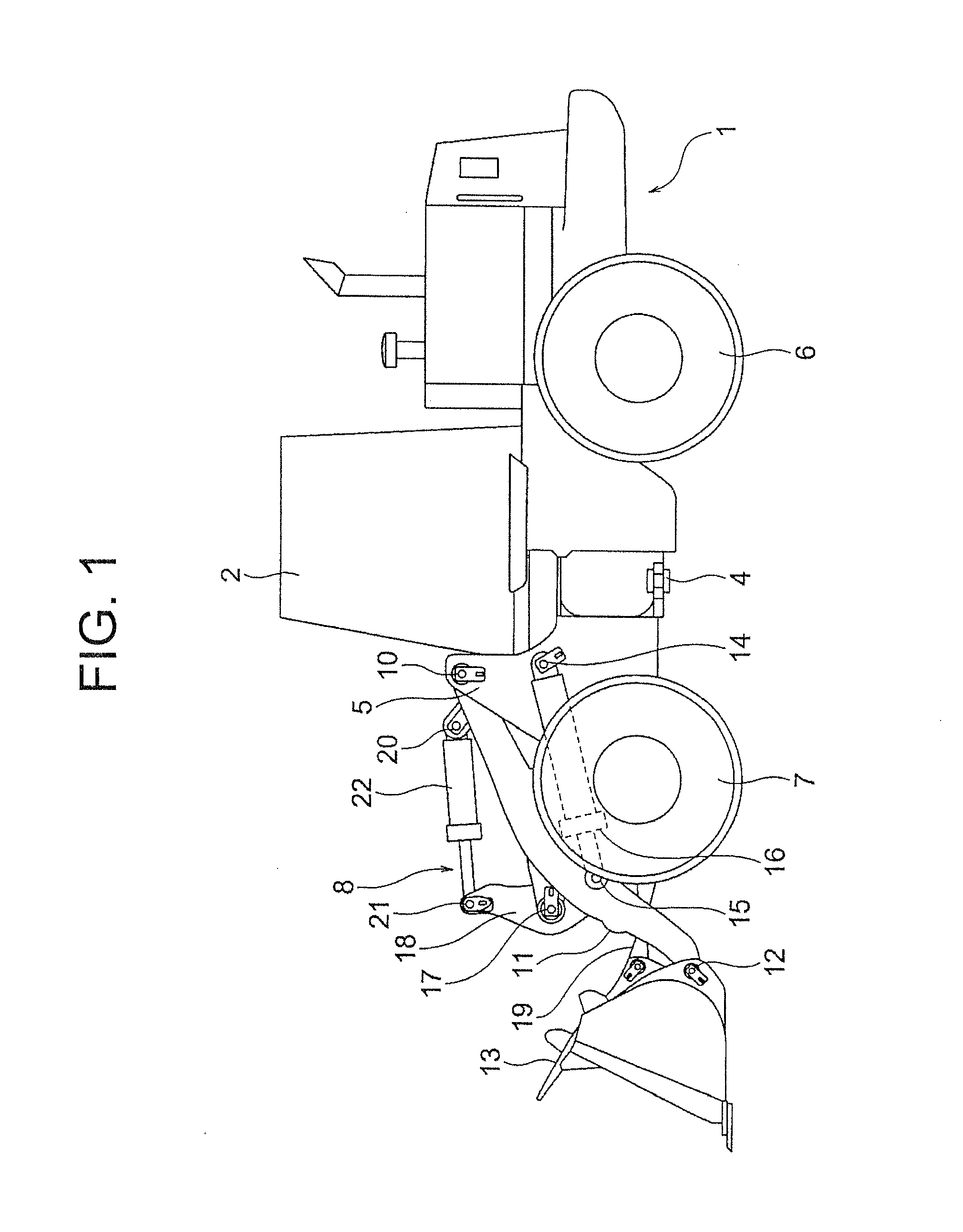

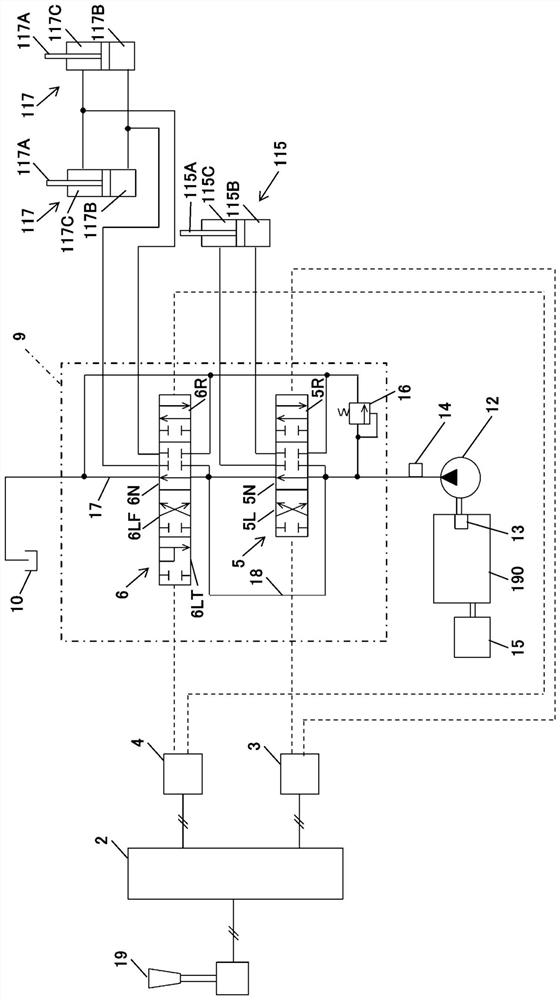

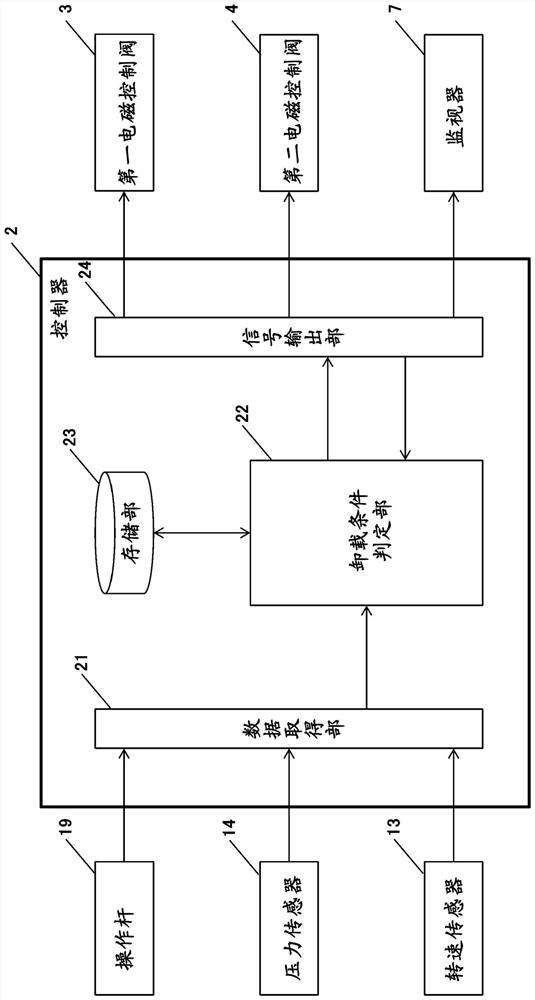

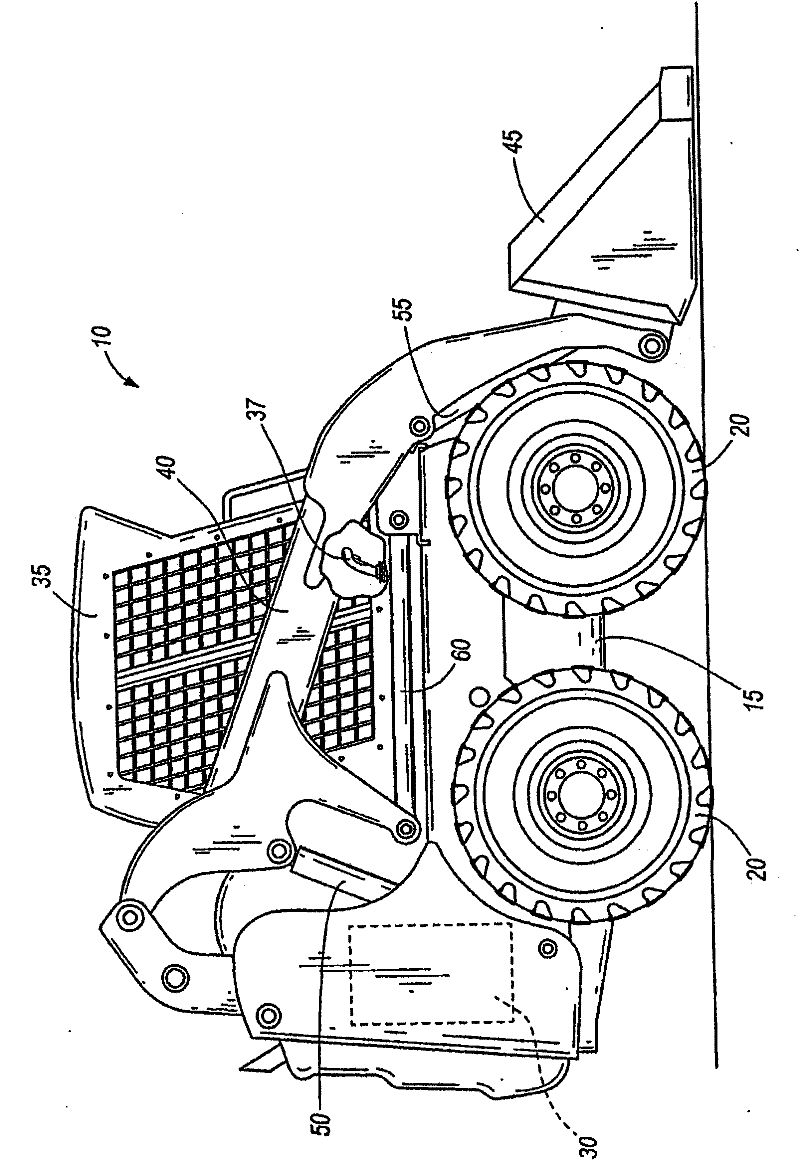

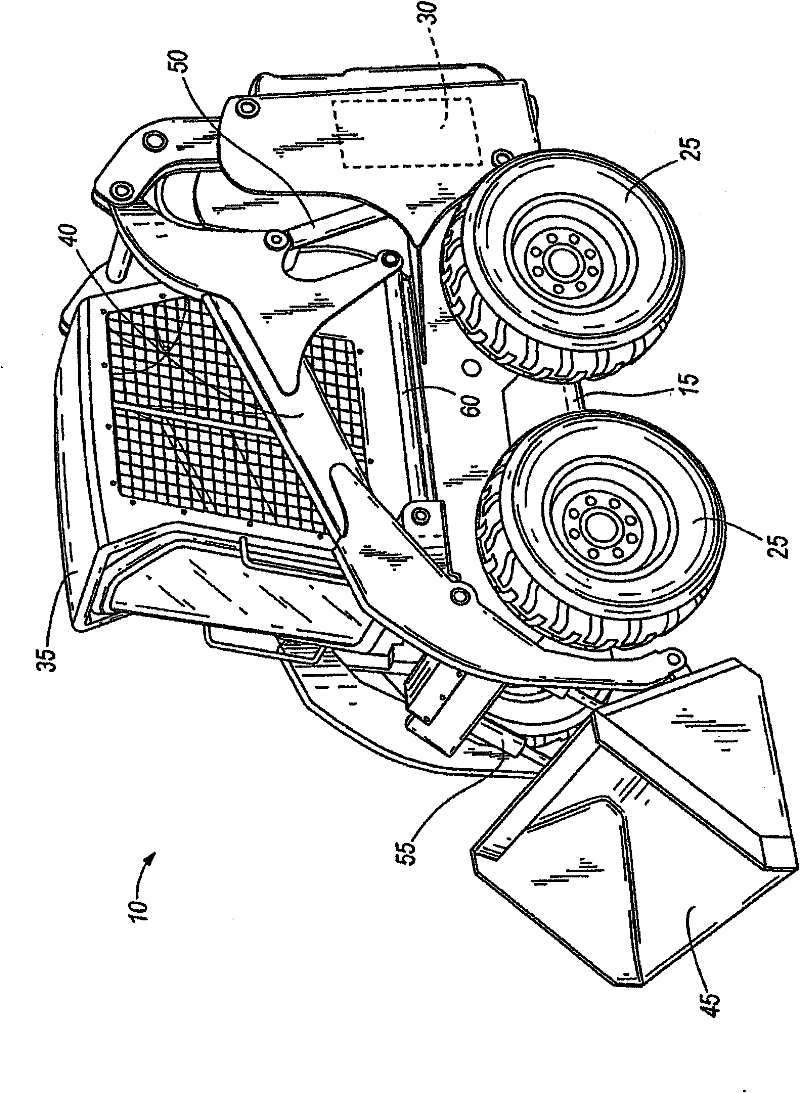

Work vehicle

ActiveCN114174600ASuppress flameoutClear structureServomotor componentsMechanical machines/dredgersStall (engine)Control signal

In a work vehicle in which a loading / unloading work device is operated by an electric operating lever, the occurrence of engine stall is suppressed regardless of the type of system mounted on the vehicle body. In a wheel loader (1) provided with a loading / unloading work device (11) operated by an electric operating lever (19), a first directional control valve (5) and a second directional control valve (6) include neutral positions (5N, 6N) at which hydraulic oil discharged from a hydraulic pump (12) is returned to a hydraulic oil tank (10), and when the discharge pressure (P) of the hydraulic pump (12) is at least a main overflow pressure (Pr) and the engine rotation speed (N) is lower than a low idle rotation speed (NL), the hydraulic oil is returned to the neutral positions (5N, 6N). The controller (2, 2A) limits the output of control signals to the first solenoid control valve (3) and the second solenoid control valve (4) such that the first directional control valve (5) and the second directional control valve (6) are switched to neutral positions (5N, 6N).

Owner:NIHON KENKI CO LTD

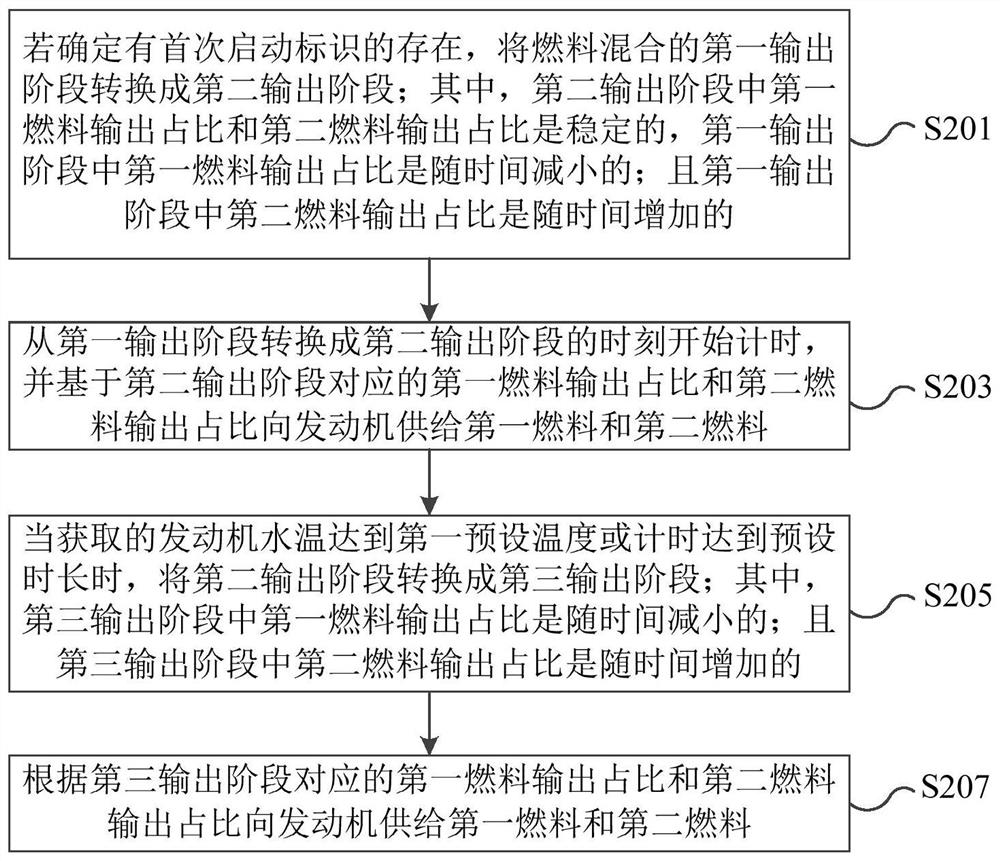

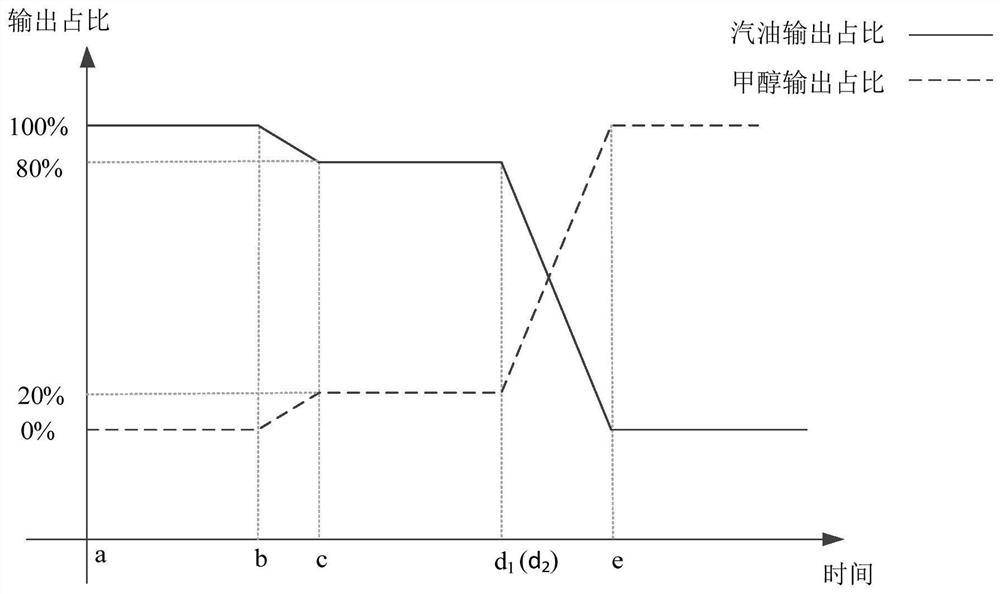

A fuel supply method, device, electronic device and storage medium

ActiveCN111749796BSolve the flameout problemInternal combustion piston enginesEngine controllersStall (engine)Thermodynamics

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

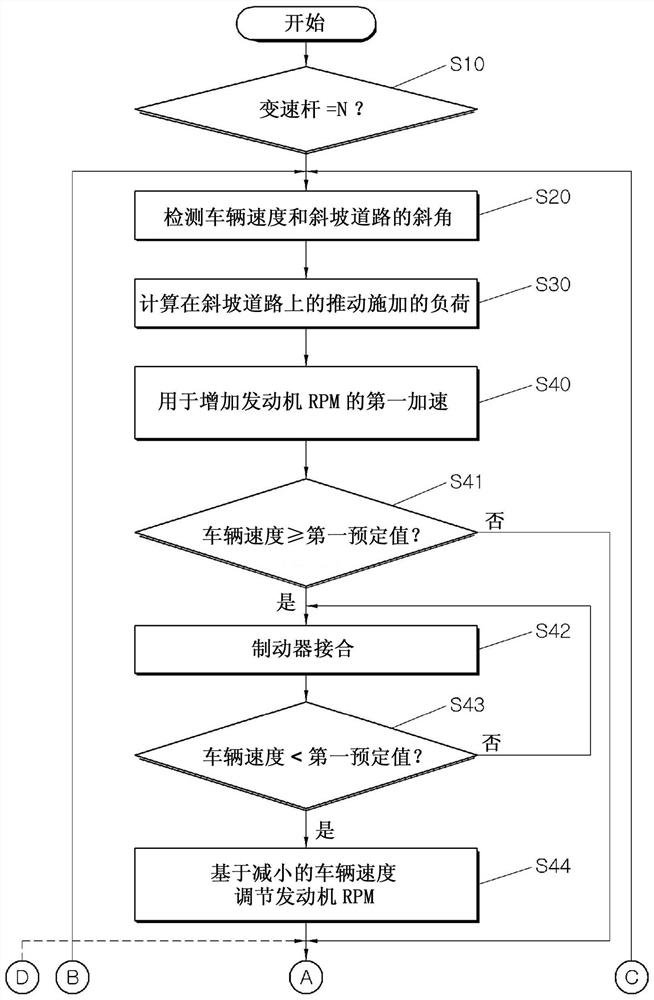

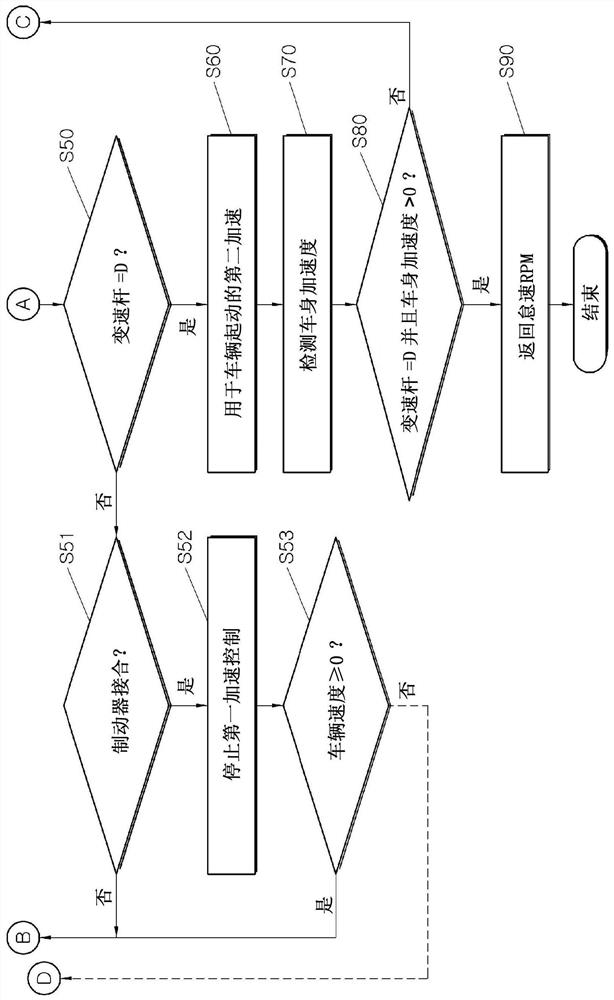

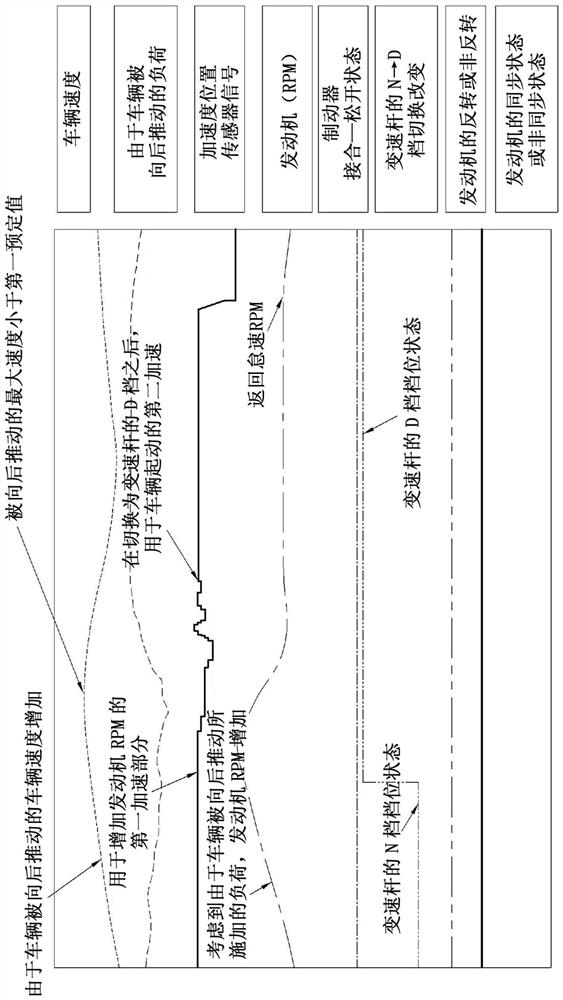

Engine control method for preventing engine stall of vehicle on sloped road

ActiveCN106948953BAvoid stallingImprove experienceEngine controllersMachines/enginesStall (engine)Control theory

The present application discloses an engine control method for preventing an engine stall of a vehicle on a sloped road, which includes the steps of: detecting whether a shift lever is in a neutral stage (N gear); measuring the vehicle speed and the slope angle of the slope road, and calculating the effect on the The load of the vehicle body on the slope road; the first acceleration of the engine to increase the engine RPM so that the engine torque is greater than the load; and the second acceleration of the engine to move the vehicle when the shift lever is moved into the drive gear stage (D range).

Owner:HYUNDAI MOTOR CO LTD

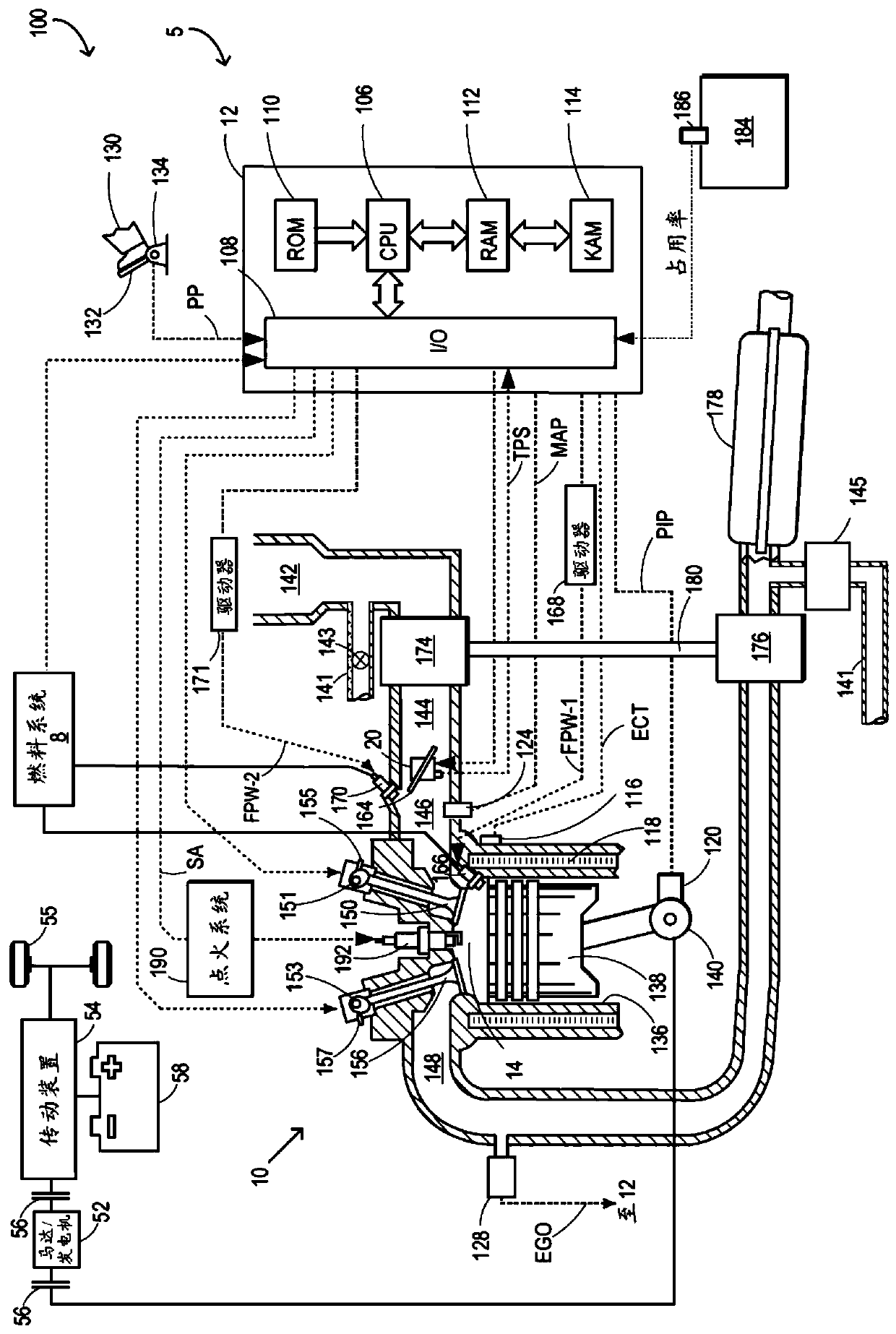

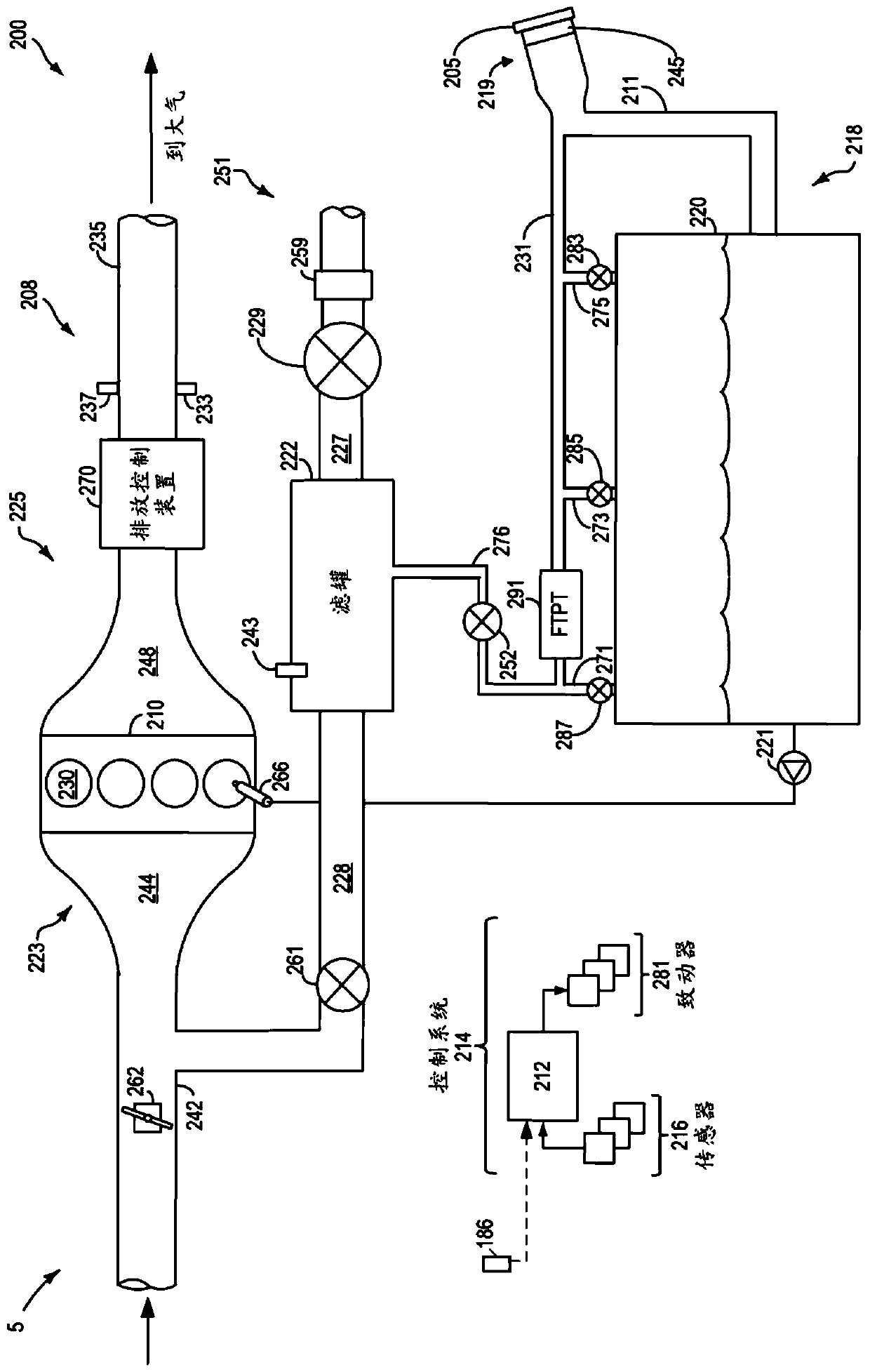

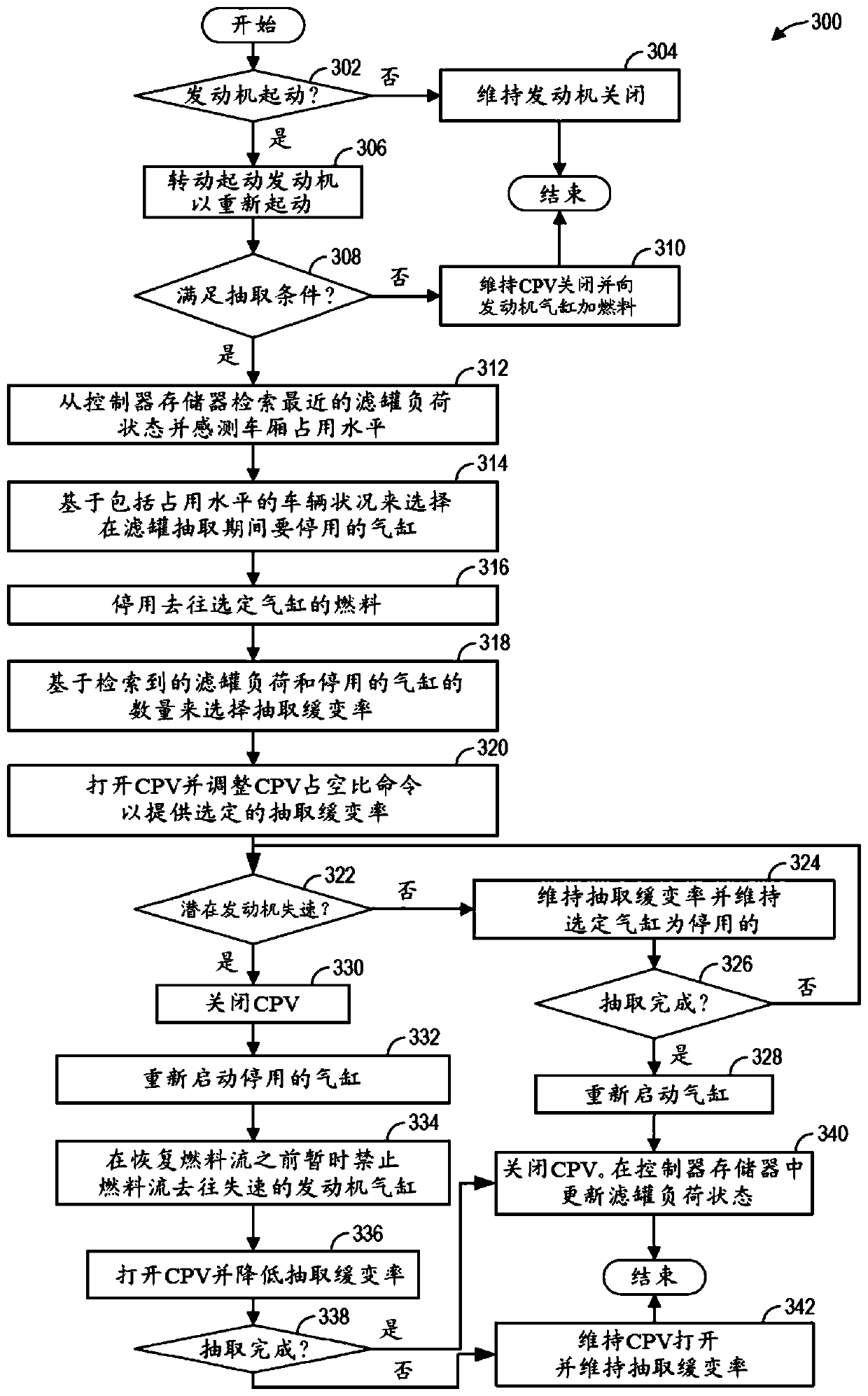

Method and system for purge control

PendingCN111550316AAvoid stallingClean completelyElectrical controlNon-fuel substance addition to fuelStall (engine)Thermodynamics

The disclosure provides a method and a system for purge control. Methods and systems are provided for reducing engine stall incidence during canister purging. A fuel vapor canister is purged at a higher purge ramp rate to an engine with one or more cylinders selectively deactivated. In response to an indication of potential or partial engine stall, the deactivated cylinders are reactivated and thecanister purge ramp rate is lowered.

Owner:FORD GLOBAL TECH LLC

Crash detection system for transport refrigeration units

A transport refrigeration system (200) including: a first engine (26) configured to power a refrigeration unit (22); a first fuel tank (330) fluidly connected to the first engine (26) through a firstfuel line (332); a first shut off valve (450) located within the first fuel line (332) proximate the first fuel tank (330); a second shut off valve (72) located within the first fuel line (332) proximate the first engine (26); a sensor system (80) configured to detect at least one of a crash of the transport refrigeration system (200), a crash of the first fuel tank (330), a fuel leak in the firstfuel line (332), and an engine stall in the first engine (26); and a controller (30) configured to close the first shutoff valve (450) and second shutoff valve (72) when at least one of a crash of the transport refrigeration system (200), a crash of the first fuel tank (330), a fuel leak in the first fuel line (332), and an engine stall in first engine (26) is detected.

Owner:CARRIER CORP

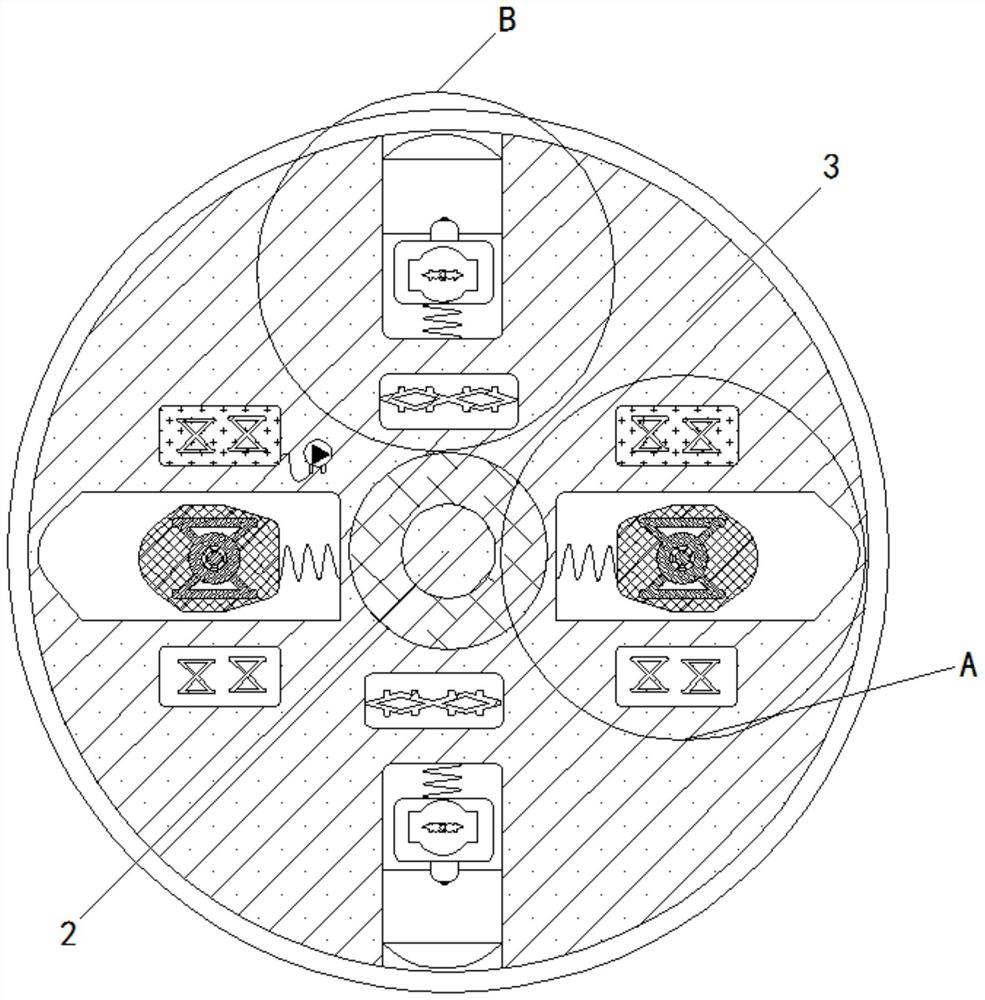

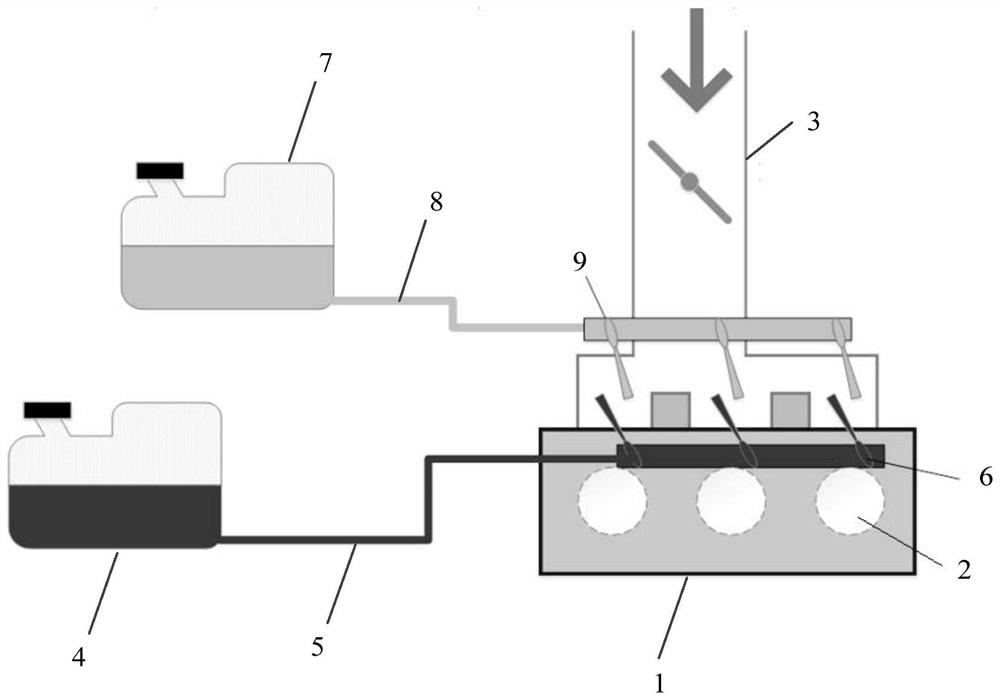

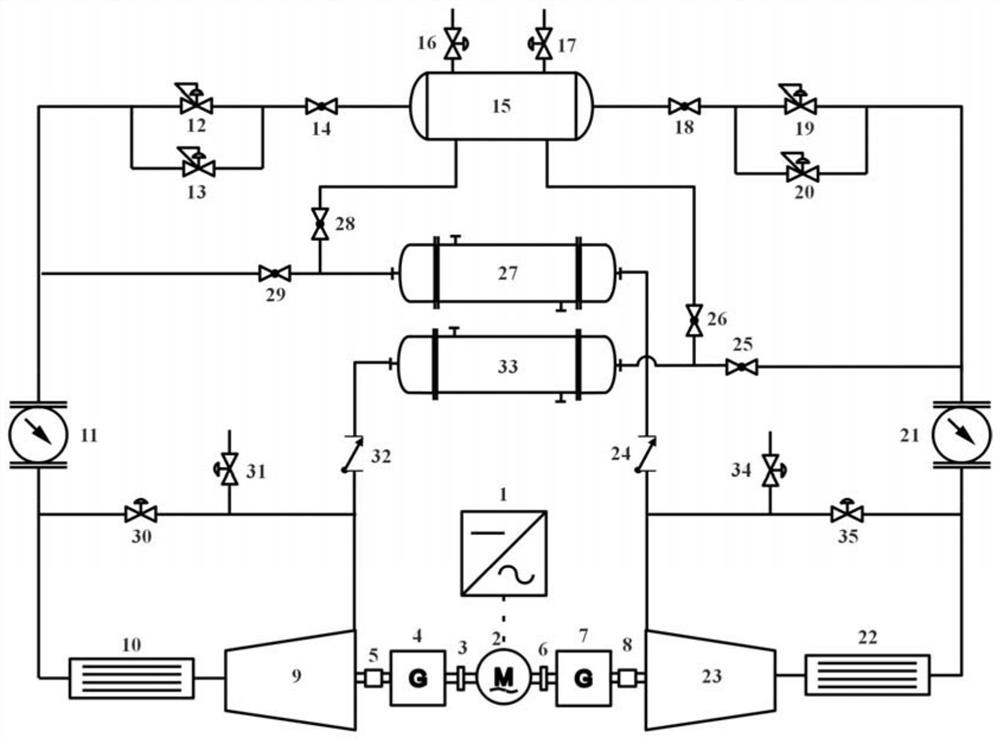

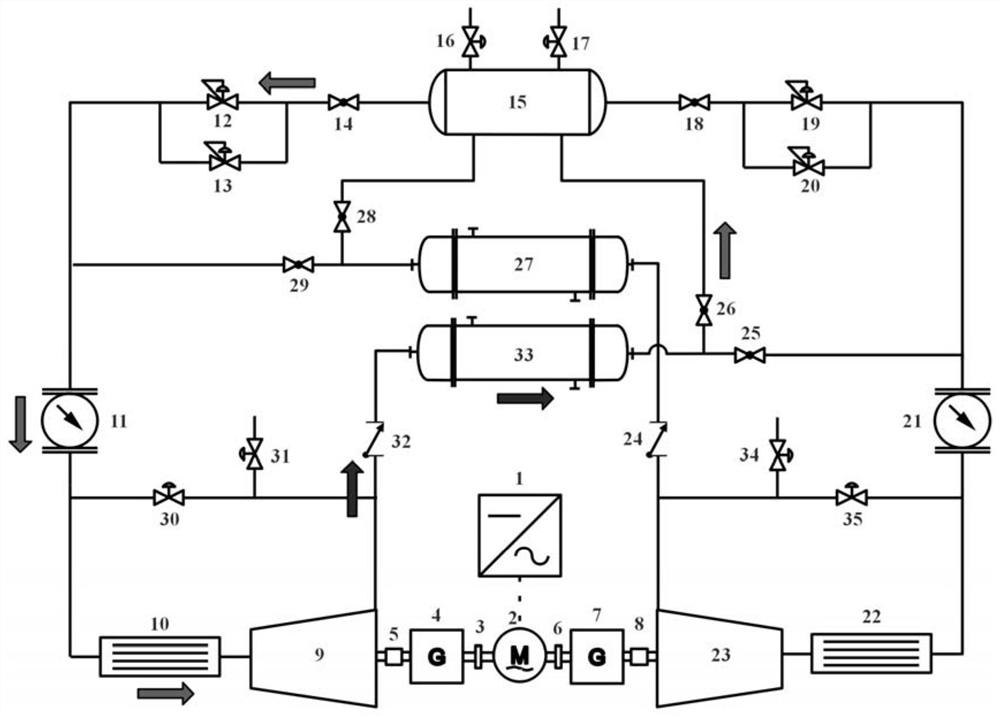

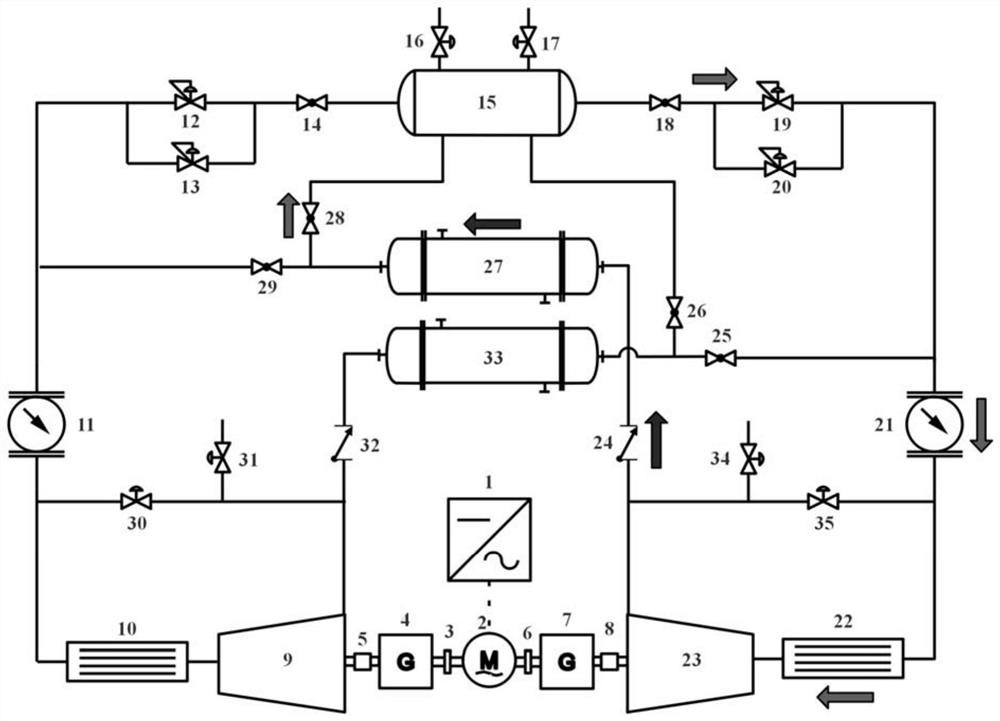

A double-closed intercooler compressor experimental system

ActiveCN110793802BExpand the scope of testingMeet the requirements of intake parametersStructural/machines measurementStall (engine)Engineering

The invention discloses a double-closed intercooling compressor experiment system, which comprises two compressors to be tested, a rectification and voltage stabilization unit, an air charging and deflation unit, a surge experiment unit and the like. The experimental system is capable of testing single-stage compressors or double-stage intercooled compressors, and is suitable for performance experiments on compressors with stable media such as air, carbon dioxide, and nitrogen, effectively expanding the test range of the test bench; The requirements of the air inlet parameters of the cold compressor, especially the demand for high inlet pressure, so as to truly simulate the flow state of the intercooler compressor and reveal its internal flow-heat transfer coupling mechanism; the experimental system has the ability to perform surge experiments and can carry out compression Research on the mechanism of engine stall and surge, with the ability to test from normal pressure to high pressure.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

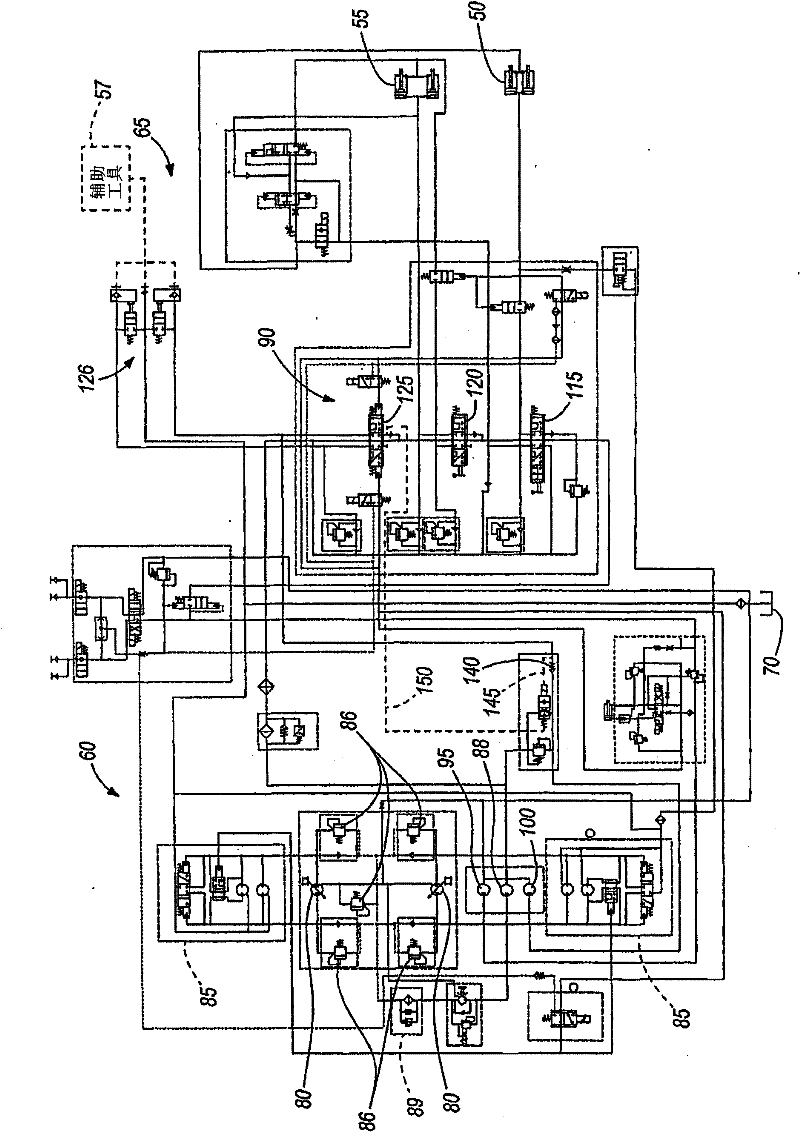

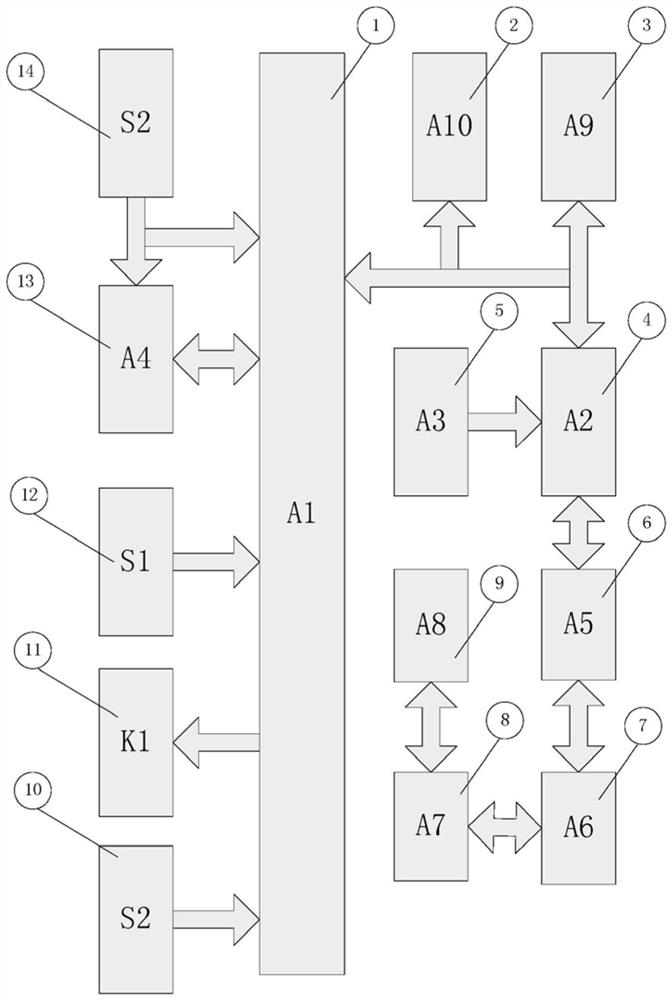

Hydraulic power management system

Owner:CLARK EQUIP CO INC

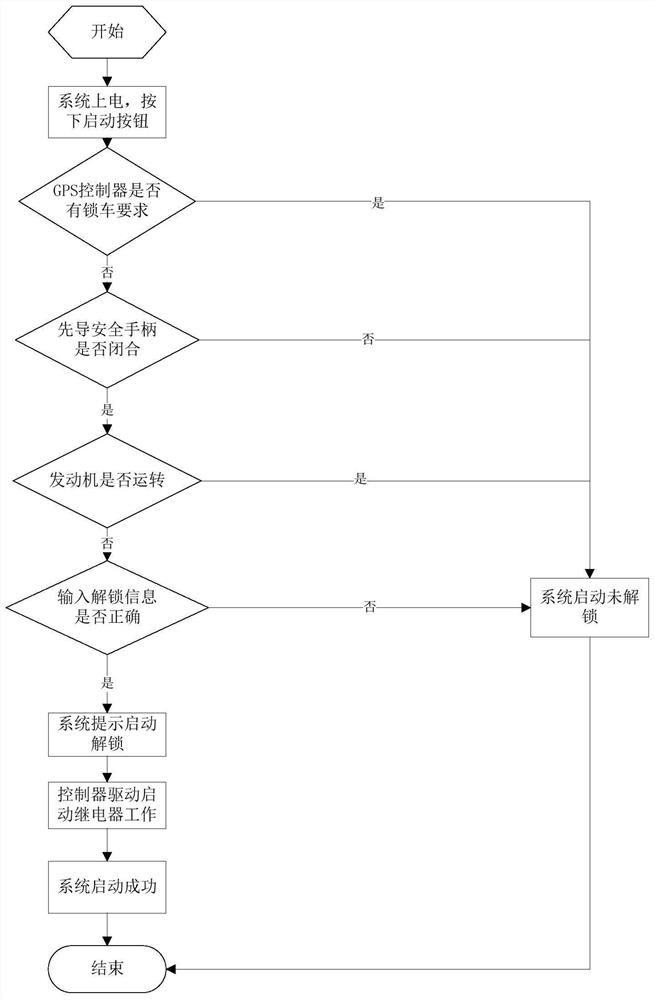

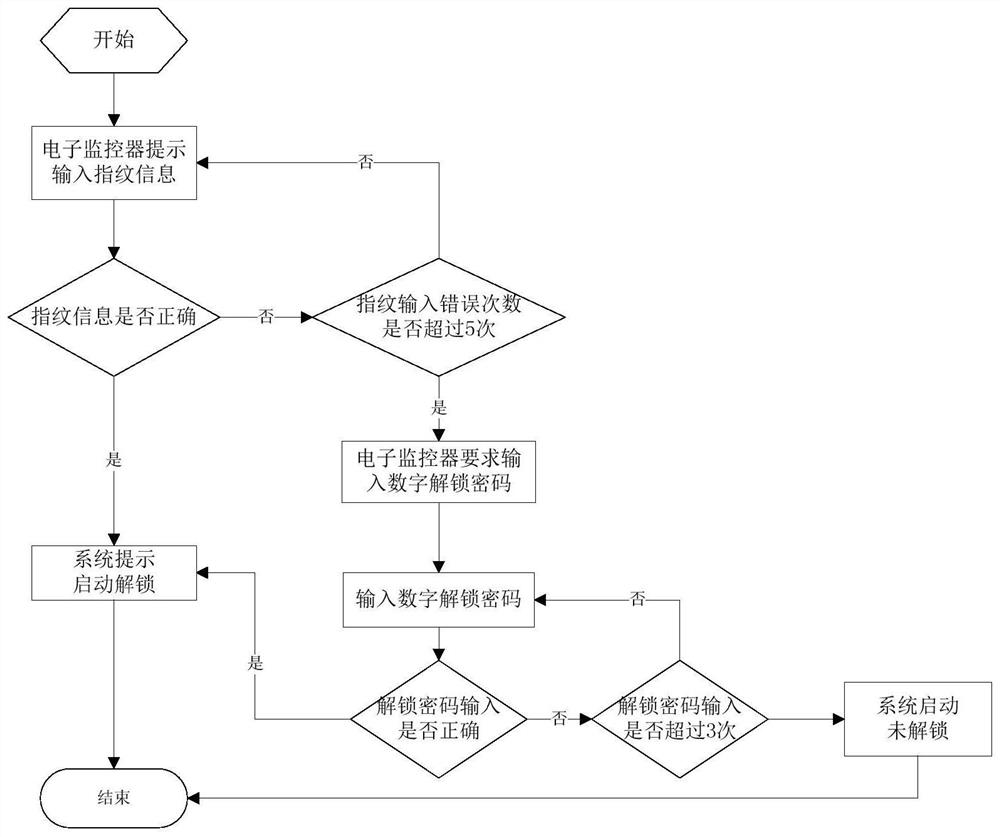

One-button start control device and control method for excavator

ActiveCN108583507BStrengthen security managementImplement rights managementAnti-theft devicesRadio frequencyExcavator

The invention provides an excavator one-key start control device and method. The control device comprises a master controller, a guide handle, a guide pedal, an electronic monitor, a fingerprint identification module, a GPS controller, a GPS management platform, a mobile communication platform, a mobile phone client side, a one-key start module, a start relay, a guide safety handle, an engine controller and an emergency stop switch. A start key conventionally adopted in the prior art is saved through simplification, auxiliary start devices such as radio frequency are not needed, the inconvenience factor caused by the fact that a user forgets to carry an induction device is avoided, meanwhile, a one-vehicle one-key purpose is convenient to achieve, authorization control of a start system can be guaranteed under the condition that the one-vehicle one-key condition is guaranteed, start and operation authority management of excavator equipment can be achieved through combination with the latest fingerprint identification technology, the safety management level of a machine is improved, potential safety hazards generated by non-active control such as a secondary start and a mistaken stall are effectively prevented, and the operability and safety of the machine are effectively improved.

Owner:XCMG EXCAVATOR MACHINERY

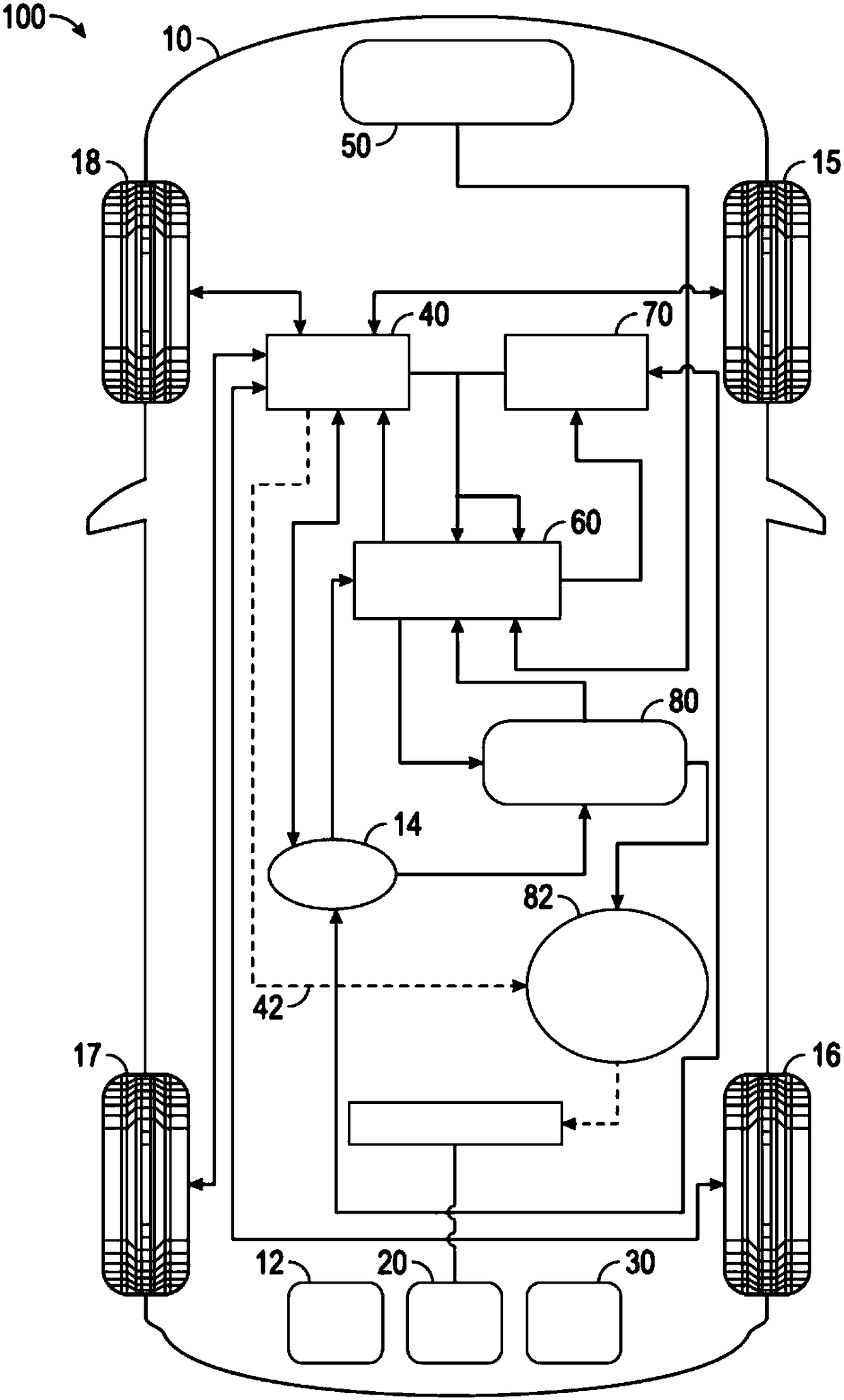

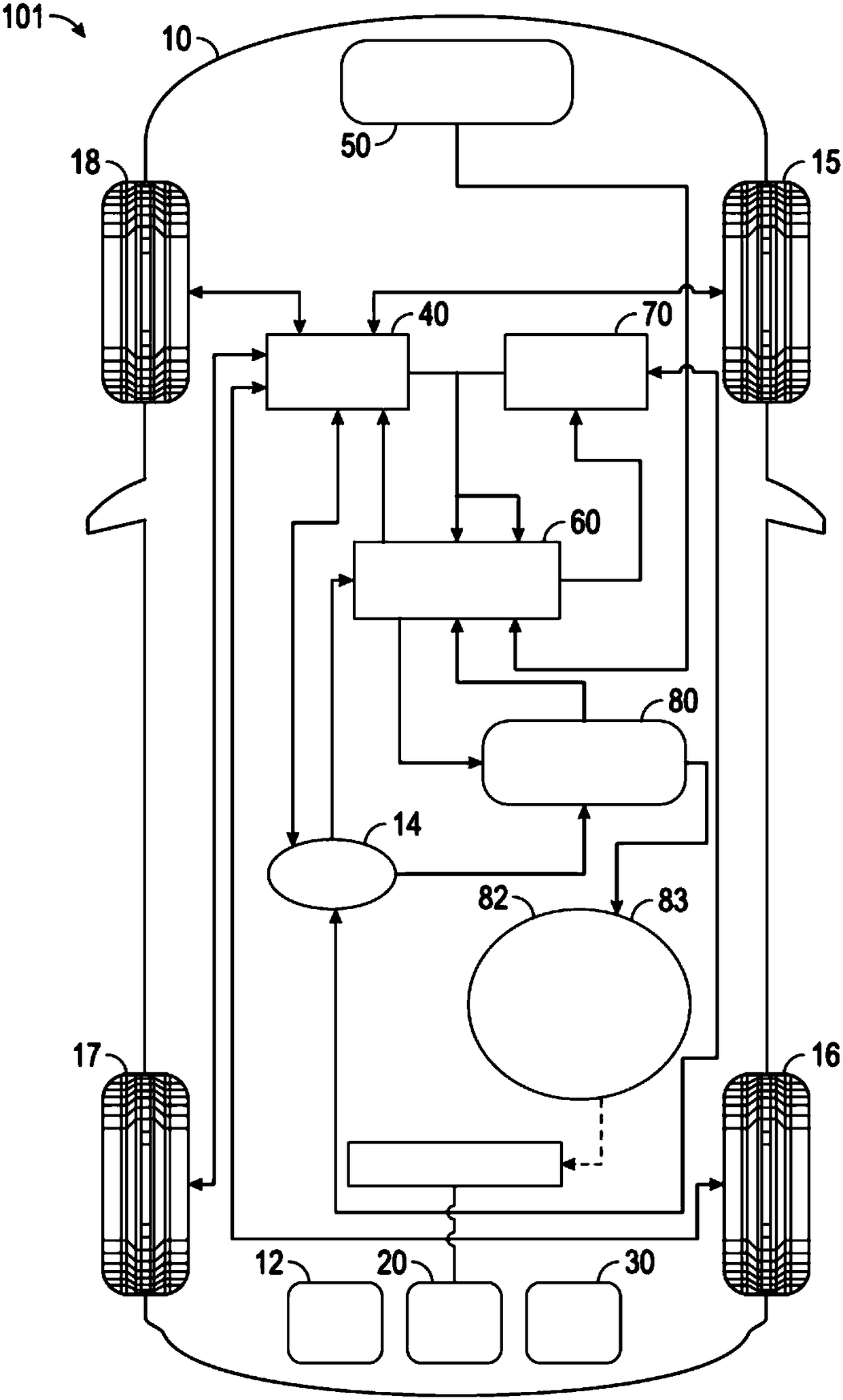

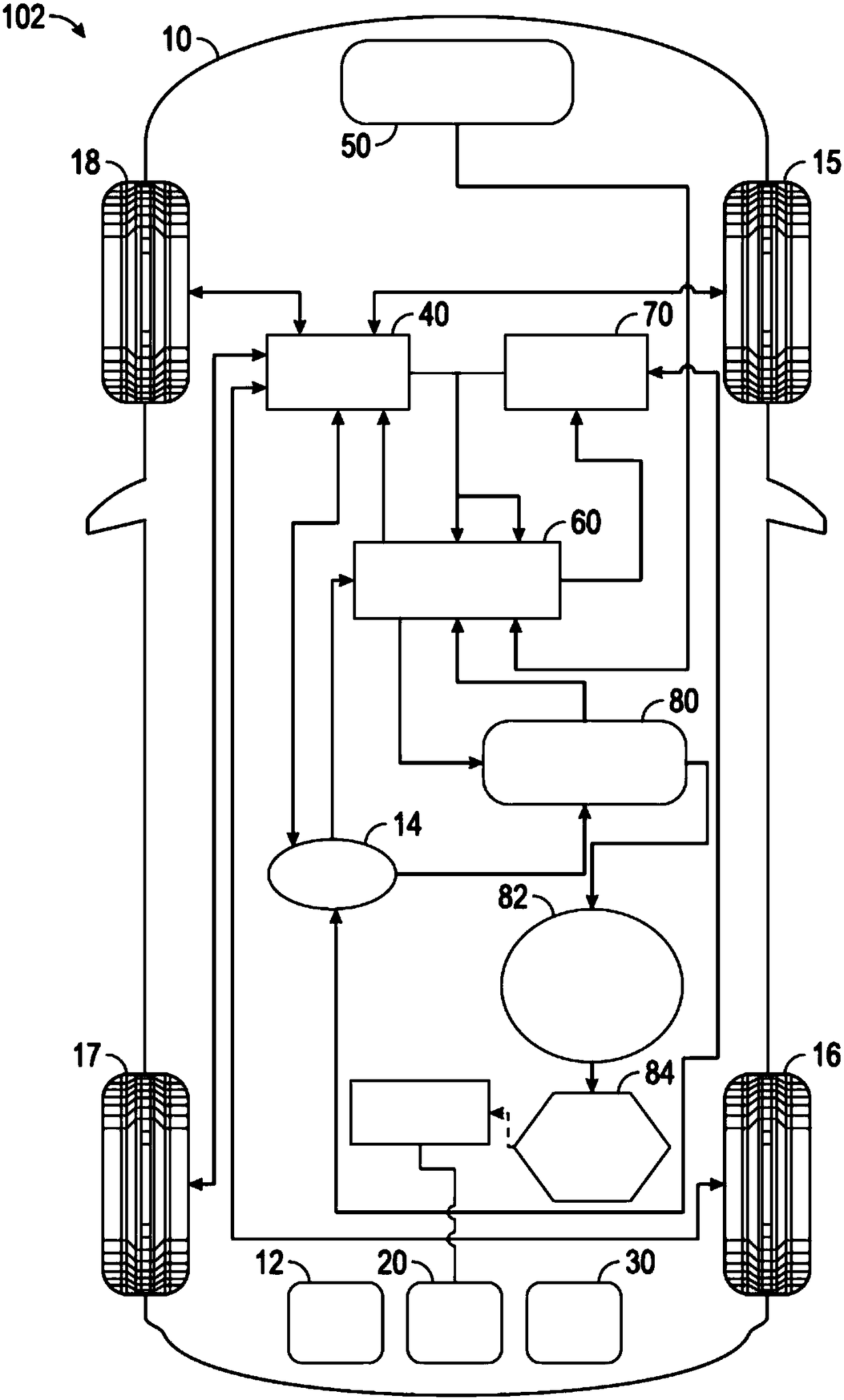

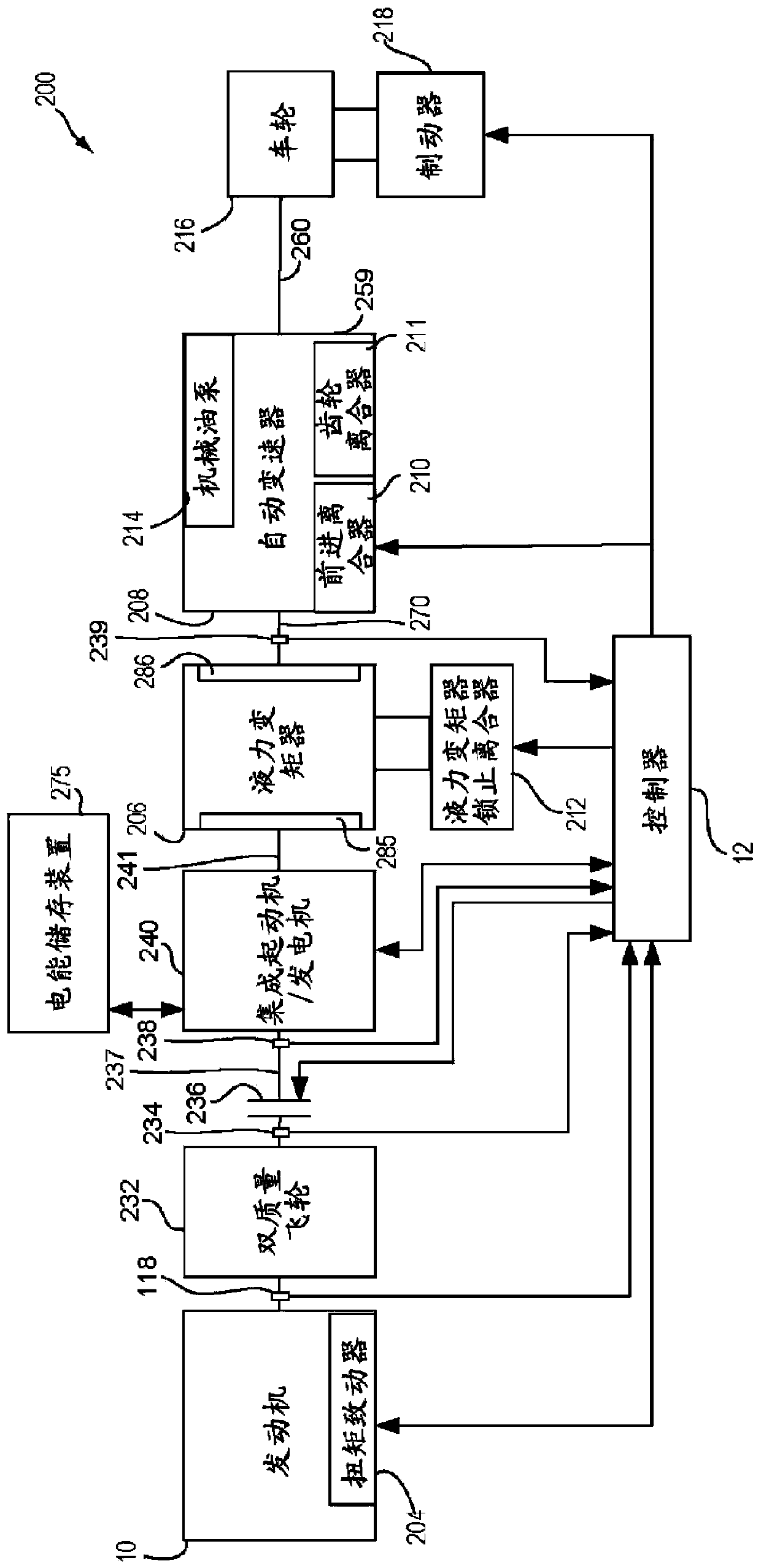

Method and system for hybrid electric vehicle

InactiveCN103381815BReduce estimation errorImproved Torque DisturbanceHybrid vehiclesControl devicesStall (engine)Electric machinery

Owner:FORD GLOBAL TECH LLC

A Rotating Stall Prediction Method of Axial Compressor Based on Stacked Long Short-Term Memory Network

ActiveCN113836817BAdjust the running statusAchieve forecastDesign optimisation/simulationNeural architecturesAlgorithmEngineering

The invention provides a method for predicting the rotational stall of an axial flow compressor based on a stacked long-term and short-term memory network, which belongs to the technical field of aero-engine modeling and simulation. First, using a certain type of aero-engine surge experimental data, the data is selected and preprocessed, and the data is divided into training set and test set. Secondly, build a Stacked LSTM model and train it, use the final trained model to perform real-time prediction on the test set, and give the model loss and evaluation indicators. Finally, the StackedLSTM prediction model is used to predict the test data in real time, and the trend of surge probability over time is given in time sequence. The invention synthesizes the time-domain statistical features and changing trends, improves the prediction accuracy, is beneficial to improving the performance of the active control of the engine, and has certain universality.

Owner:DALIAN UNIV OF TECH

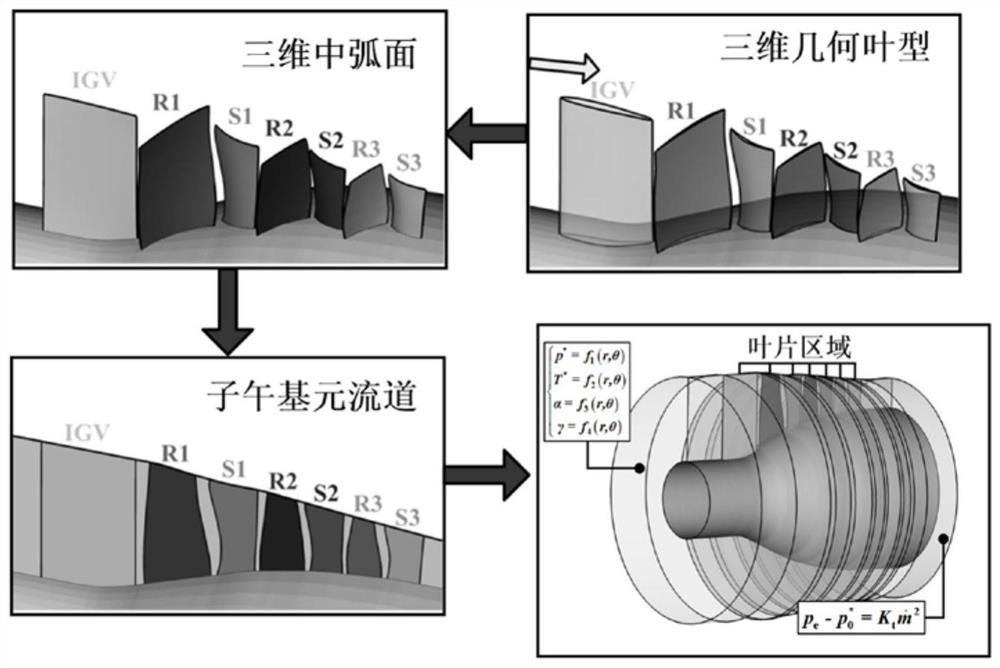

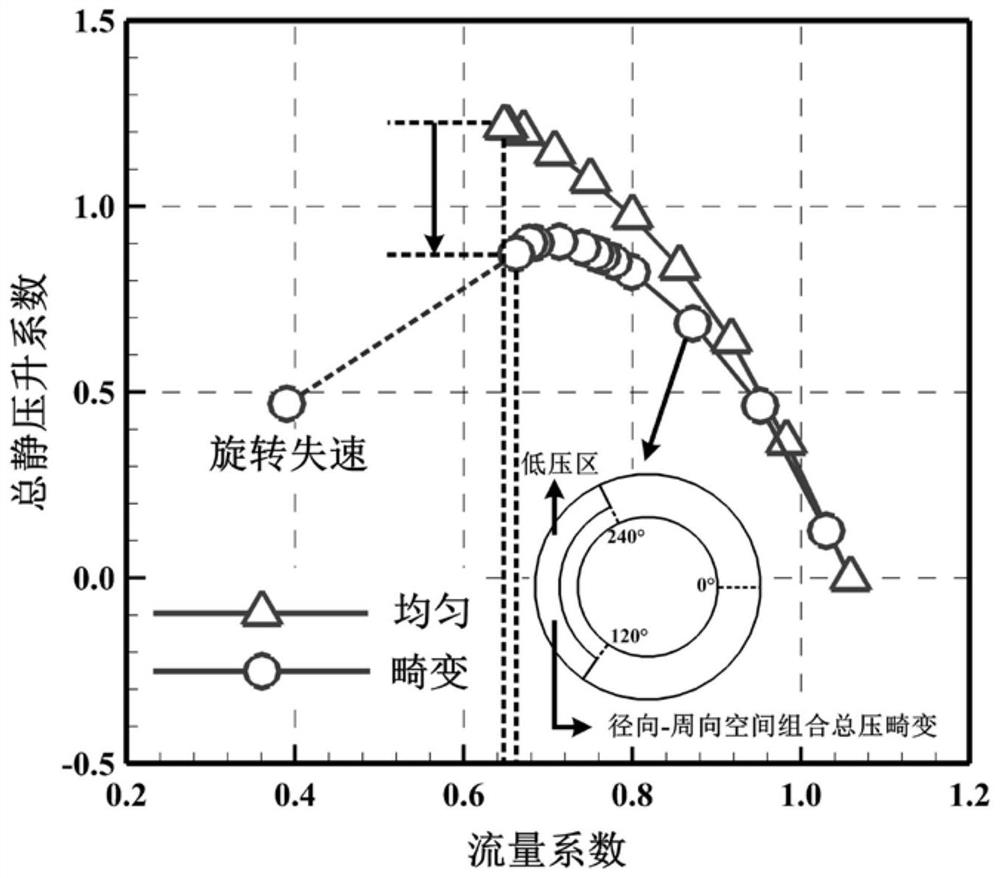

Prediction method for dynamic stall process of aviation axial flow compressor under complex inlet distortion

ActiveCN112943668BEffectively reflect the characteristics of aerodynamic instabilityPump controlNon-positive displacement fluid enginesAxial compressorAviation

The invention discloses a method for predicting the dynamic stall process of an aviation axial flow compressor under complex intake distortion. The method describes the wall-solid effect of the blade through a distributed force source, and effectively constructs the force source of the flow path of the local blade element based on the concept of loss coefficient and lagging angle. The dynamic correlation with air flow parameters has the ability to quantitatively describe the dynamic stall evolution process of multi-stage axial flow compressors under complex intake distortion. Compared with the traditional two-dimensional calculation method and the high-order three-dimensional CFD calculation method, this method can effectively reflect the complex air intake distortion disturbance including swirling flow and radial / circumferential spatial combination distortion characteristics while taking into account the calculation efficiency. The characteristics of the aerodynamic instability of the flow compressor provide technical support for the high-fidelity aerodynamic stability design of advanced aero-engines.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com