A double-closed intercooler compressor experimental system

An experimental system and compressor technology, which is applied in the field of compressor testing and compressor experimental systems, can solve the problems that cannot meet the experimental requirements of intercooled compressors used in compressed air energy storage systems, and achieve the effect of expanding the testing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

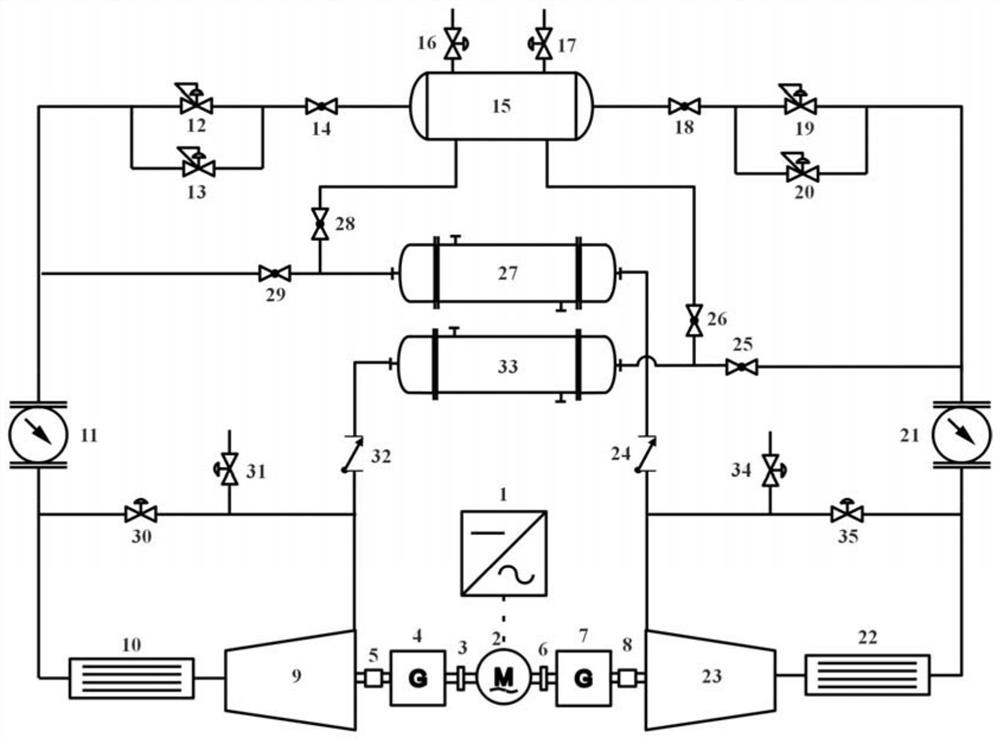

Image

Examples

Embodiment 1

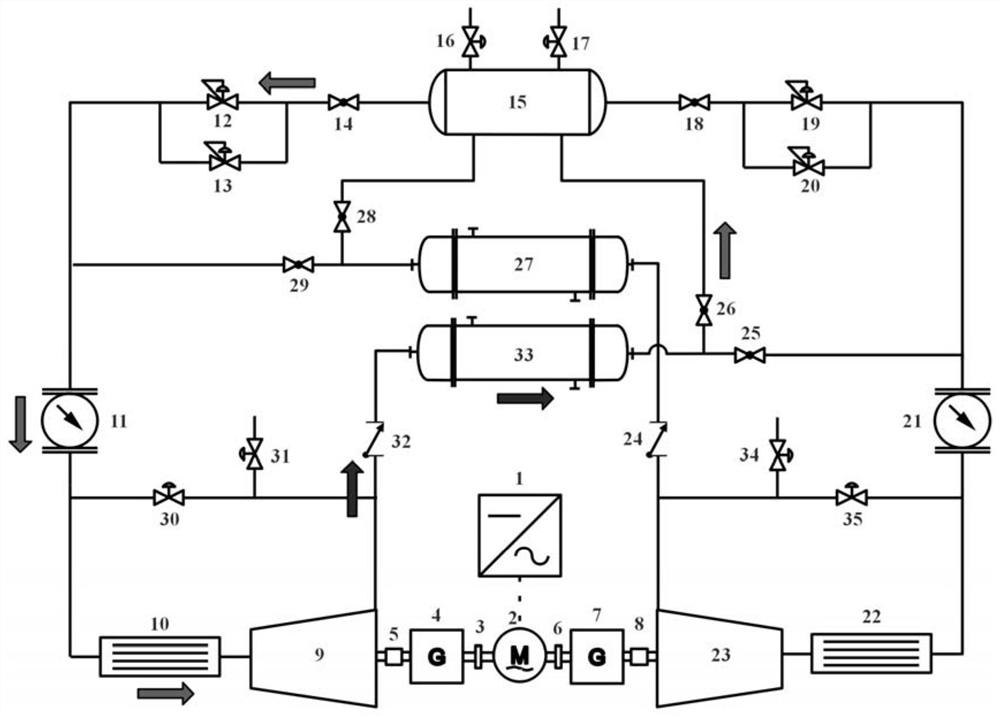

[0054] figure 2 The situation is shown when the first compressor under test 9 is in experimental test mode. Such as figure 2 As shown, when the experimental system carries out the experimental test of the first compressor under test 9, the first compressor under test 9 is started, the second compressor under test 23 is closed, and the intake pipeline of the second compressor under test 23 needs to be closed. And the shut-off valve on the exhaust pipeline and the shut-off valves 18, 25, 28 and 29 on each linkage communication pipeline, open the shut-off valves 14, 26 on the first tested compressor 9 intake pipeline and the exhaust pipeline. The gas passes through the flow meter 11, flows into the first compressor 9 to be tested for pressurization, then passes through the heat exchanger 33 to lower the temperature, then flows into the surge tank 15 to reduce the air flow pulsation, and finally passes through the main pressure regulator valve 12 and auxiliary pressure regulato...

Embodiment 2

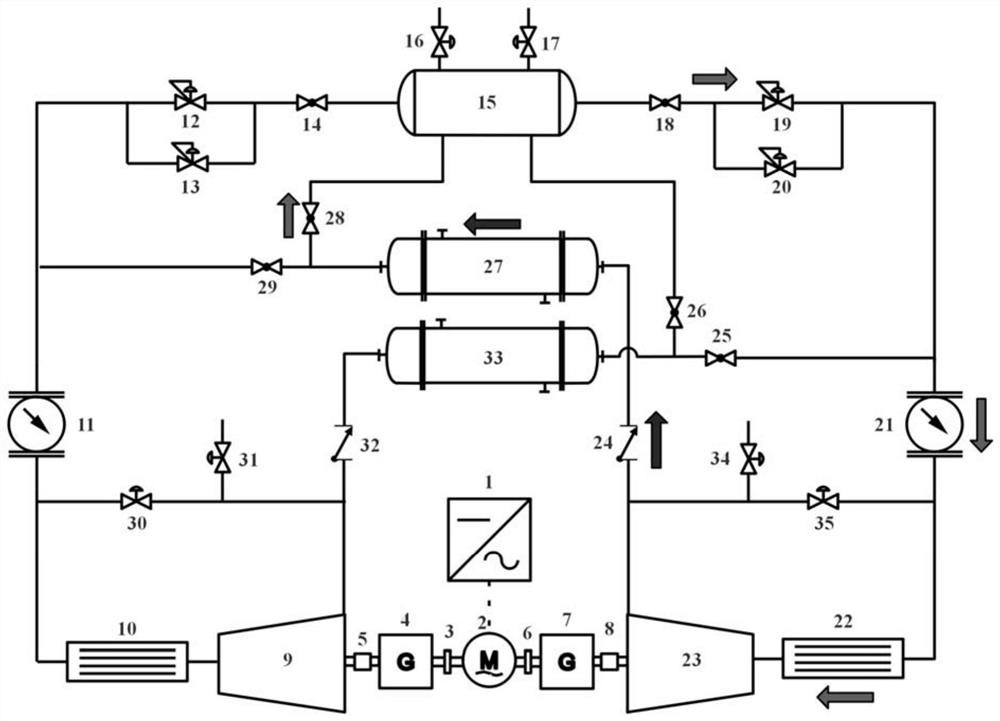

[0056] image 3 The situation is shown when the second compressor under test 23 is in experimental test mode. see image 3 , when the experimental system carries out the experimental test of the second compressor under test 23, it is necessary to close the stop valves 14, 25 on the intake and exhaust pipelines of the first compressor under test 9 and the stop valves on each linkage communication pipeline. , 26 and 29, open the shut-off valves 18, 28 on the intake pipeline and exhaust pipeline of the second compressor 23 under test. The gas passes through the flowmeter 21, flows into the second compressor under test 23 for pressurization, then passes through the heat exchanger 27 to lower the temperature, then flows into the surge tank 15 to reduce the air flow pulsation, and finally passes through the main pressure regulator valve 19 and auxiliary pressure regulator After the valve 20 lowers the pressure, it re-enters the second tested compressor 23 to complete the closed cy...

Embodiment 3

[0058] Figure 4 It shows the situation during the linkage experiment test of the tested compressor 9-23. see Figure 4 , when the experimental system carries out the linkage experimental test of the tested compressors 9-23, it is necessary to close the shut-off valves 18, 26 and 29, and open the shut-off valves 14, 25 and 28. The gas passes through the flowmeter 11, flows into the first compressor 9 to be tested for pressurization, then passes through the heat exchanger 33 to lower the temperature, then flows into the second compressor 23 under test for further pressure increase, and passes through the heat exchanger 27 to reduce the temperature , and finally reduce the air flow pulsation in the surge tank 15, and then re-enter the first compressor under test 9 after reducing the pressure through the main pressure regulator valve 12 and the auxiliary pressure regulator valve 13 to complete the closed cycle. During the experiment, by adjusting the opening of the main pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com