Work vehicle

A technology for operating vehicles and operating devices, which is applied to motor vehicles, servo motors, mechanically driven excavators/dredgers, etc., can solve problems such as engine application and engine flameout, and achieve the effect of suppressing engine flameout, clear structure and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

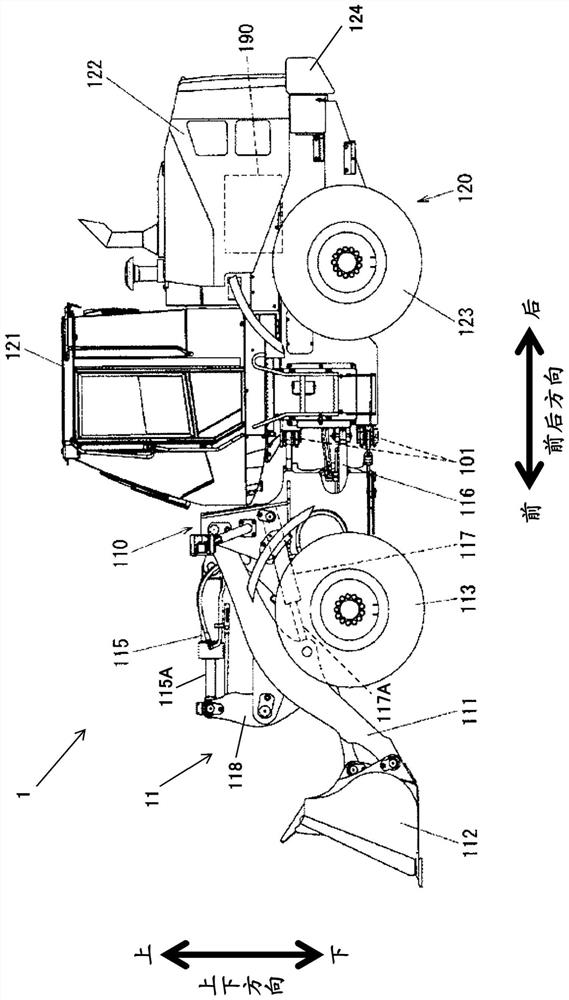

[0022] Hereinafter, as one form of the work vehicle according to the embodiment of the present invention, for example, a wheel loader that performs loading and unloading operations of excavating sand and minerals in an open pit mine and loading them onto a dump truck or the like will be described.

[0023]

[0024] First, refer to figure 1 The overall structure of the wheel loader 1 will be described.

[0025] figure 1 It is an external appearance side view showing a configuration example of the wheel loader 1 according to the embodiment of the present invention.

[0026] The wheel loader 1 is an articulated work vehicle whose body is folded in the center near the center to steer. Specifically, the front frame 110 serving as the front part of the vehicle body and the rear frame 120 serving as the rear part of the vehicle body are connected so as to be rotatable in the left and right directions by the center pin 101, and the rod of the steering cylinder 116 expands and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com