Method and system for purge control

A technology of controller and extraction valve, applied in electrical control, charging system, engine control, etc., can solve problems such as engine stall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

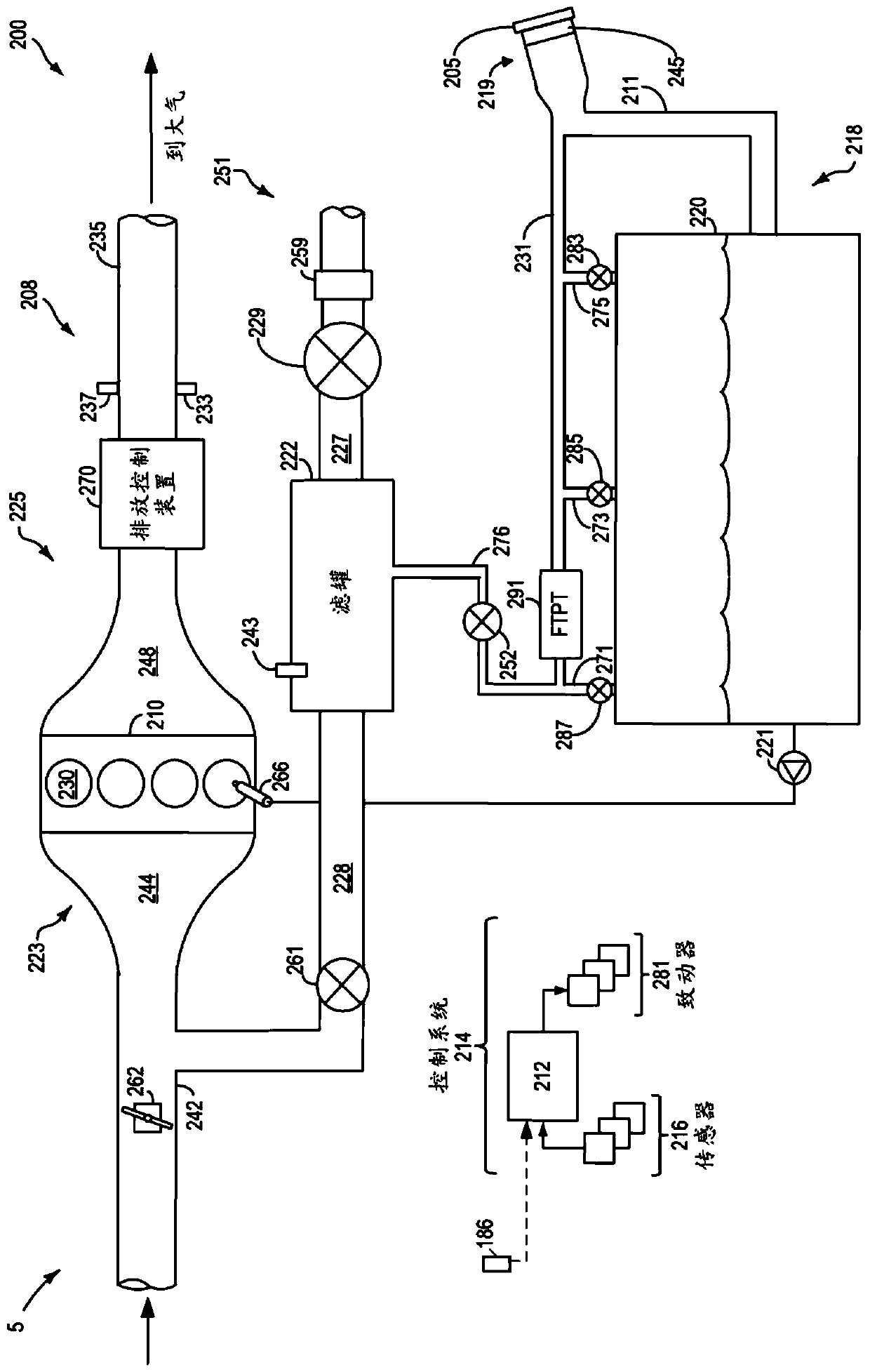

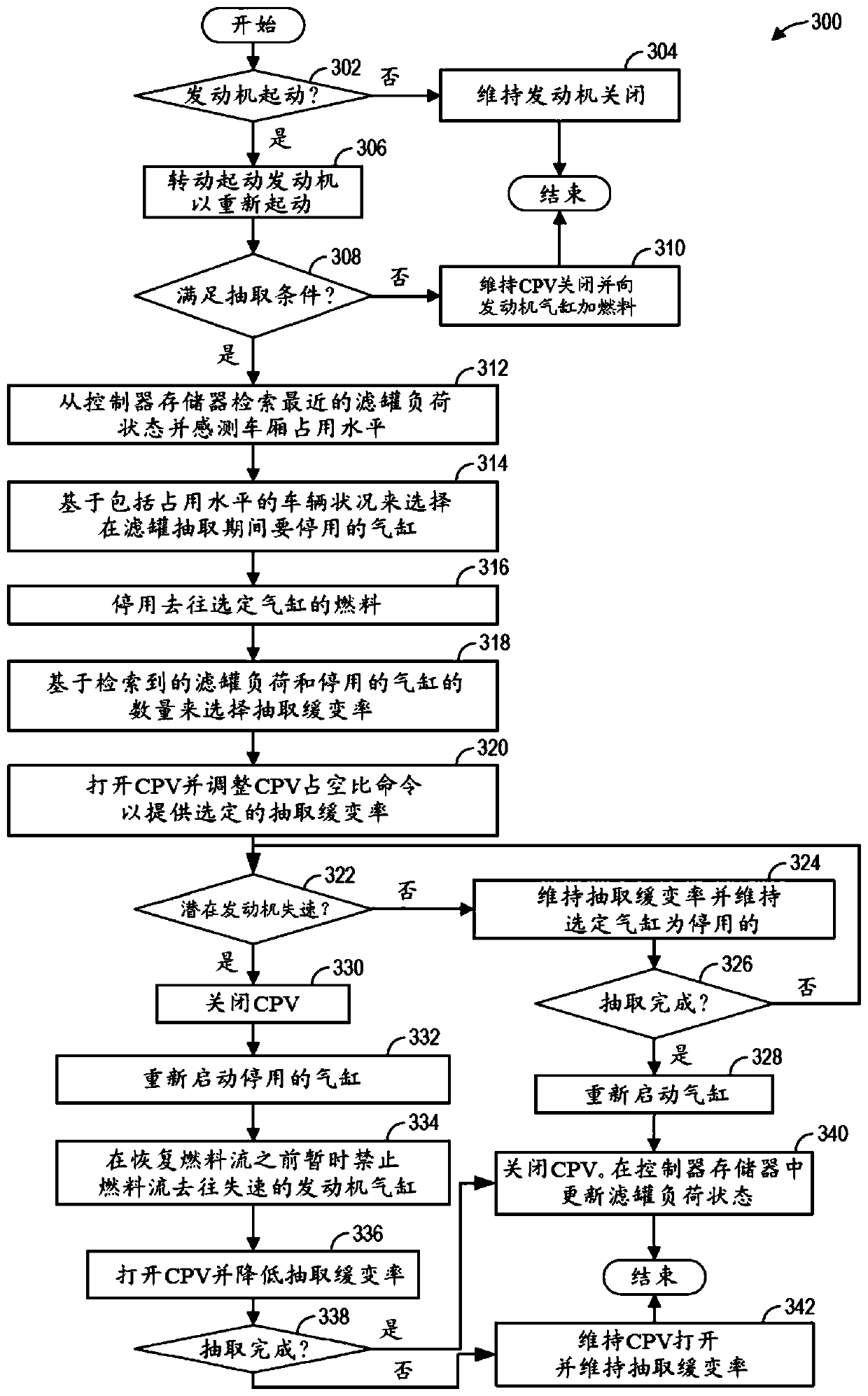

[0014] The following descriptions refer to methods used to reduce joins in figure 1 fuel system canisters in engine systems (such as in figure 2 Systems and methods for engine stall during purging of a fuel vapor recovery system). The controller can be configured to execute control routines such as image 3 An exemplary routine for purging a canister at a higher purge rate to an engine with one or more cylinders selectively deactivated. In response to an indication of a potential engine stall, deactivated cylinders may be reactivated and the purging rate may be reduced.

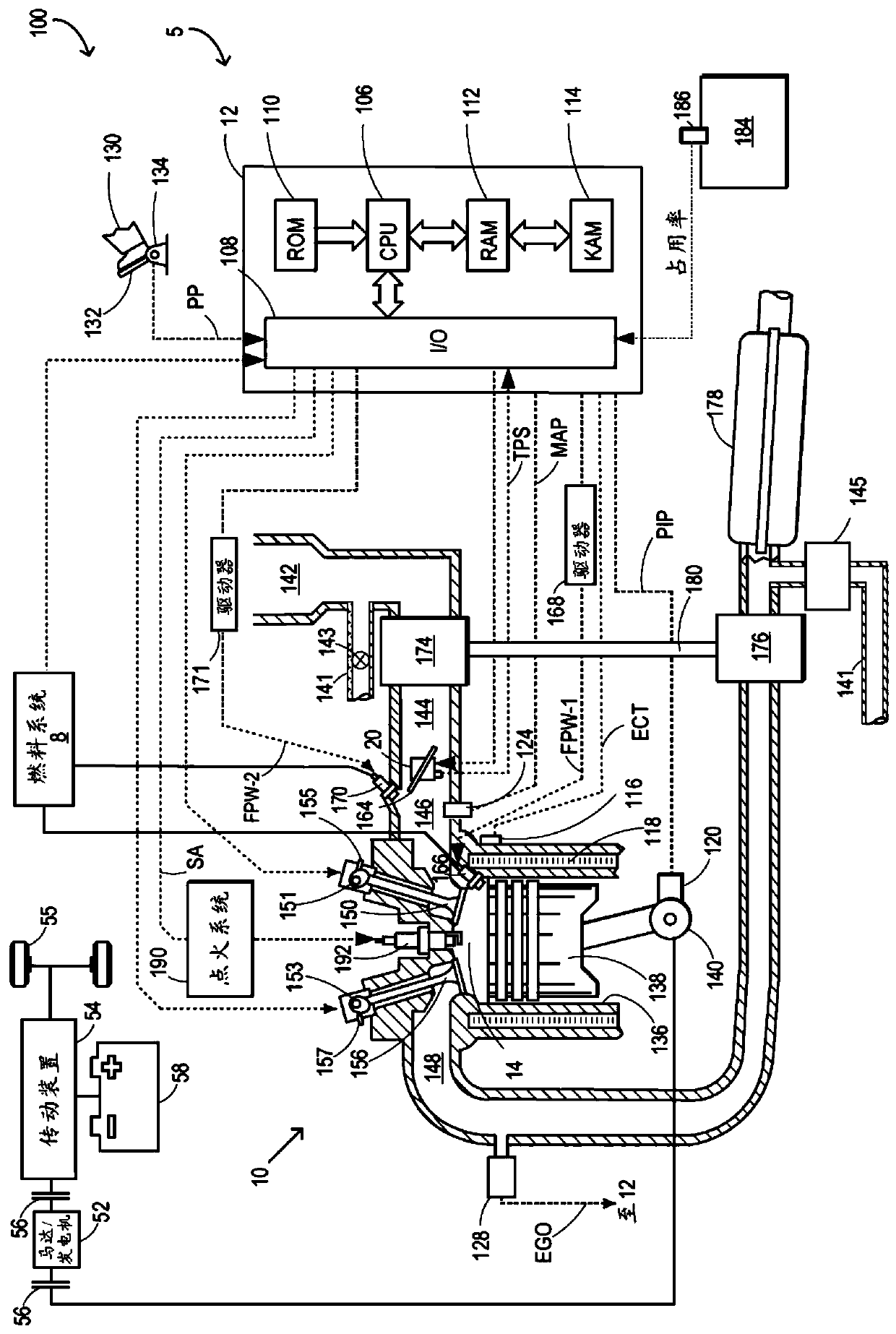

[0015] now turn figure 1 , illustrates an exemplary embodiment 100 of a combustion chamber or cylinder of an internal combustion engine 10 . Engine 10 may be coupled to a propulsion system, such as vehicle system 5 configured for on-road travel. Engine 10 may receive control parameters from a control system including controller 12 and input from a vehicle operator 130 via an input device 132 . In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com