Combustor fire cover

A burner and fire cover technology, which is applied to burners, burners, gas fuel burners, etc., can solve the problems of difficult to clean, turn off the flame, block the flame stabilization groove, etc. The effect of pressure elimination in the mixing chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

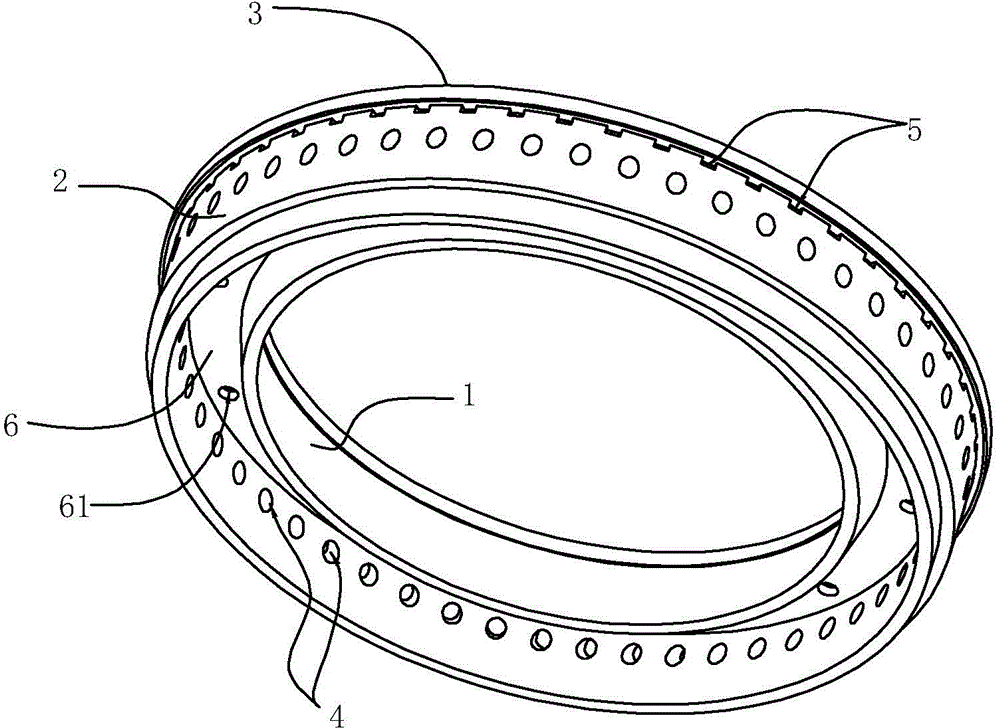

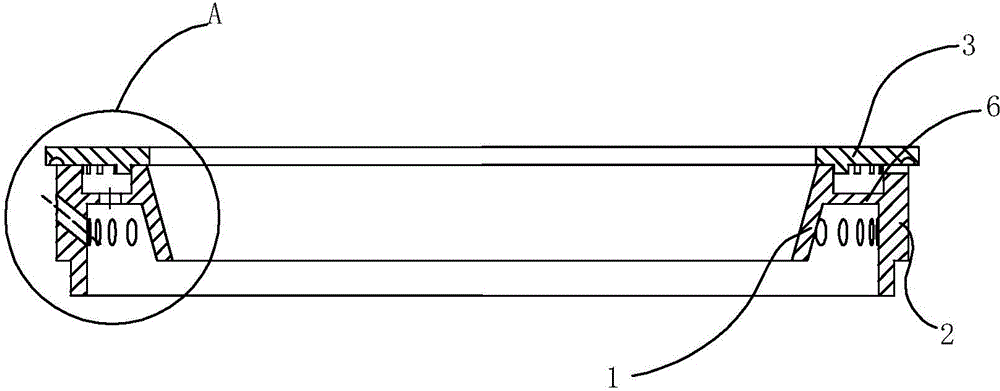

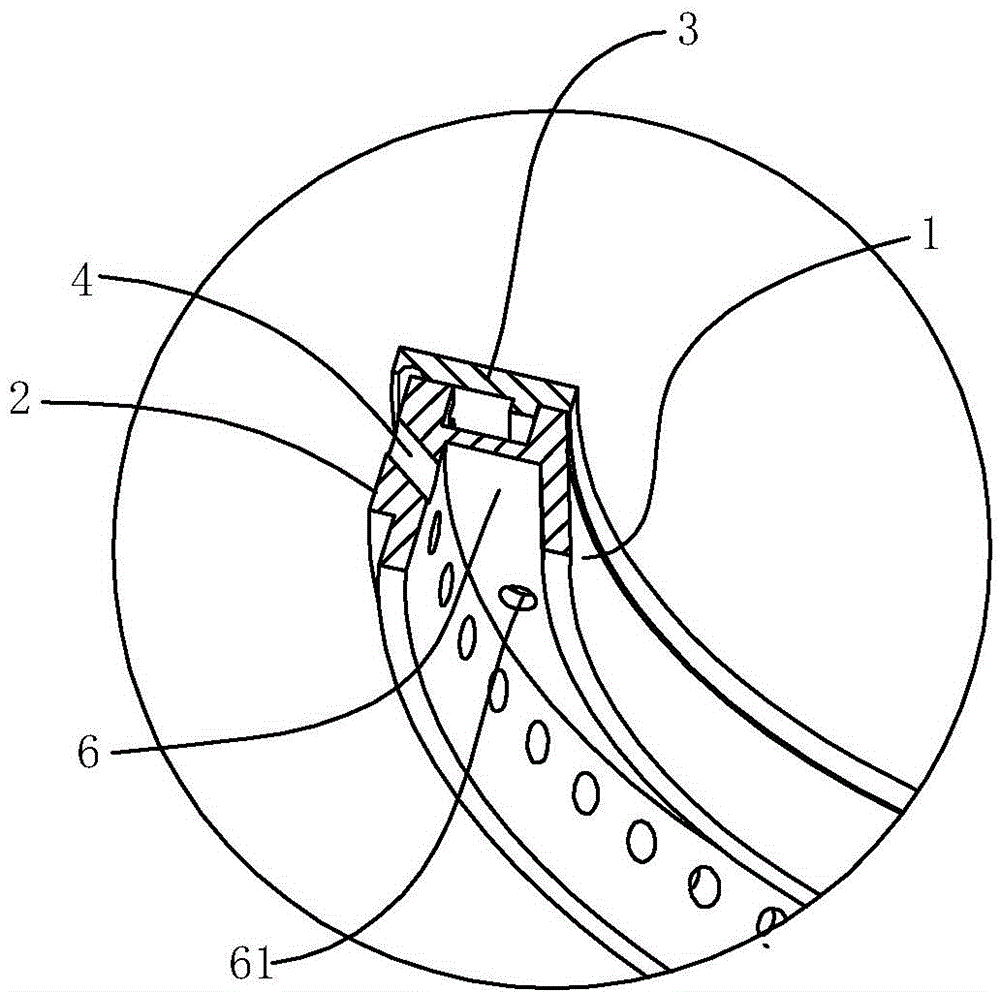

[0025] like Figure 1-4 Shown is the schematic diagram of the burner cap of the embodiment of the present invention. The fire cover includes an inner ring wall 1 and an outer ring wall 2 that are annular and concentrically arranged at intervals, and a cover body 3 located above the inner and outer wall surfaces. The fire cover is placed above the gas mixing chamber for combustion. The device forms a flame.

[0026] The outer ring wall 2 of the fire cover has a circle of fire holes 4 that run through its thickness direction and are evenly spaced along the circumference of the outer ring wall 2, such as figure 2 As shown, the axial direction of the fire hole 4 is at an angle to the horizontal direction, and the fire hole 4 extends obliquely upward from the outer ring wall 2 from inside to outside. The top of the outer ring wall surface 2 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com