Method for controlling the release of internal couplers of gear wheels on transmission shafts, transmission and power train

A control method and transmission technology, which are applied in the arrangement of multiple different prime movers of general power plants, the starting of engines, and the starting of motors for engines, etc., and can solve problems such as vibration, impact on vehicles, and bumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

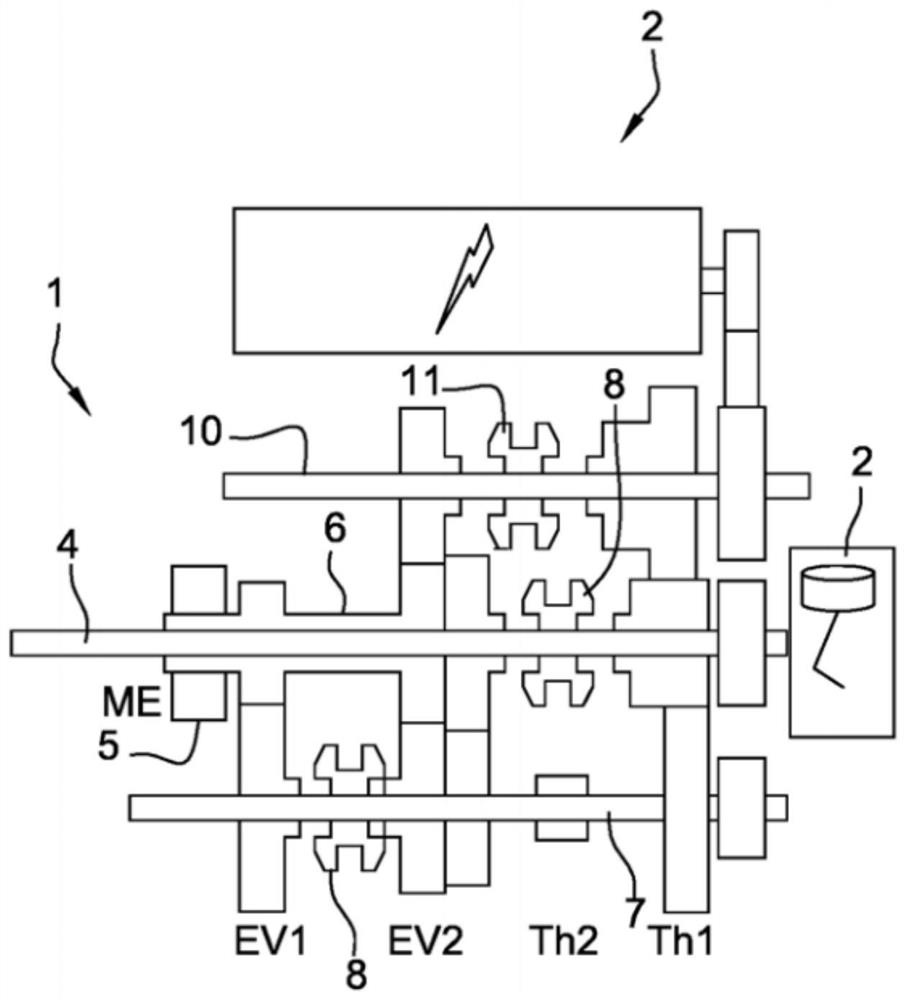

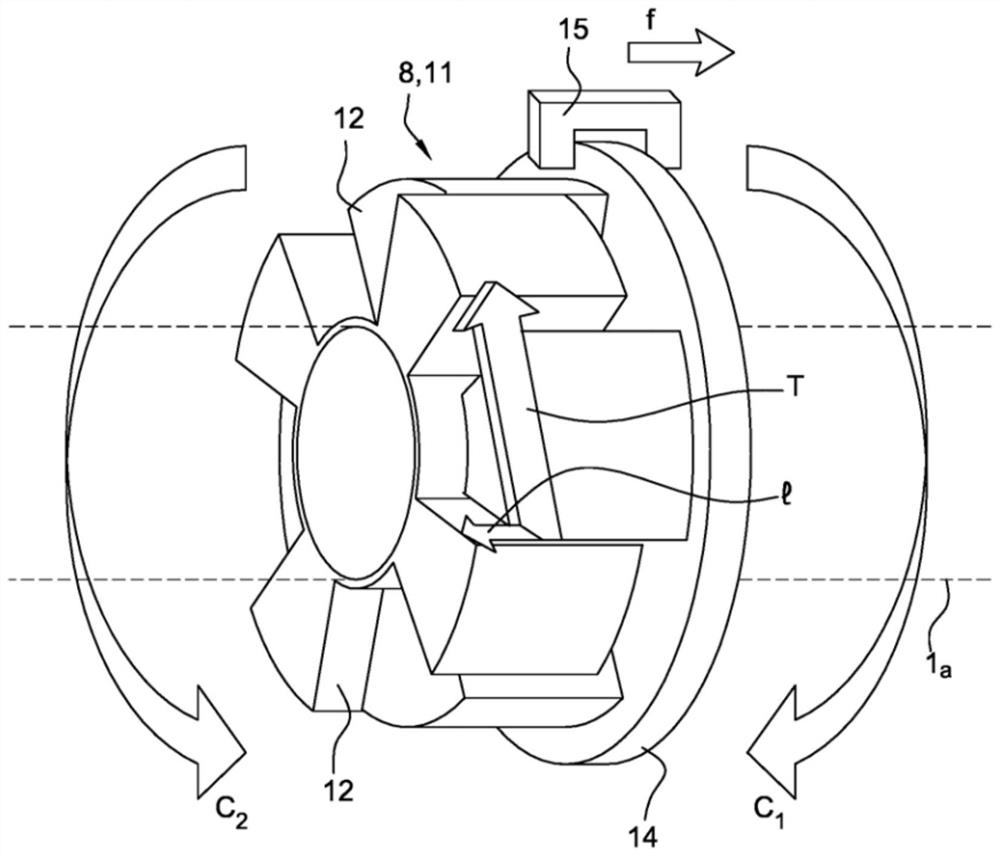

[0022] figure 1 The gearbox 1 is for example of the "semi-automatic" type. Its operation is that of a manual transmission, but the shifting is automatic. The diagram depicts an electric machine known as HSG (Hybrid Starter Generator Machine) 2 , a combustion engine 3 on a solid main shaft 4 . Mounted on the hollow main shaft 6 is another electric machine 5, called ME, more powerful than the first one. The layshaft 7 of the gearbox is connected to a differential (not depicted) and then to the wheels of the vehicle.

[0023] A first coupling 8 with sliding gear and pawl located on the layshaft 7 makes it possible to vary the gear ratio of the electric machine ME 5 independently of the rest of the gearbox, so as to have two available electric gear ratios EV1 and EV2. A second coupling 9 with sliding gears and pawls located on the solid main shaft 4 makes it possible to modify the gear ratio of the combustion engine 3 separately from the motor gear ratio in order to establish t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com