Method, controller and machine for controlling a hydraulic system

A hydraulic system and controller technology, applied in the direction of electric speed/acceleration control, etc., can solve the problem of poor control effect, inability to accurately reflect the engine load state, and the speed load percentage cannot accurately reflect the demand torque and the actual torque everywhere. Differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

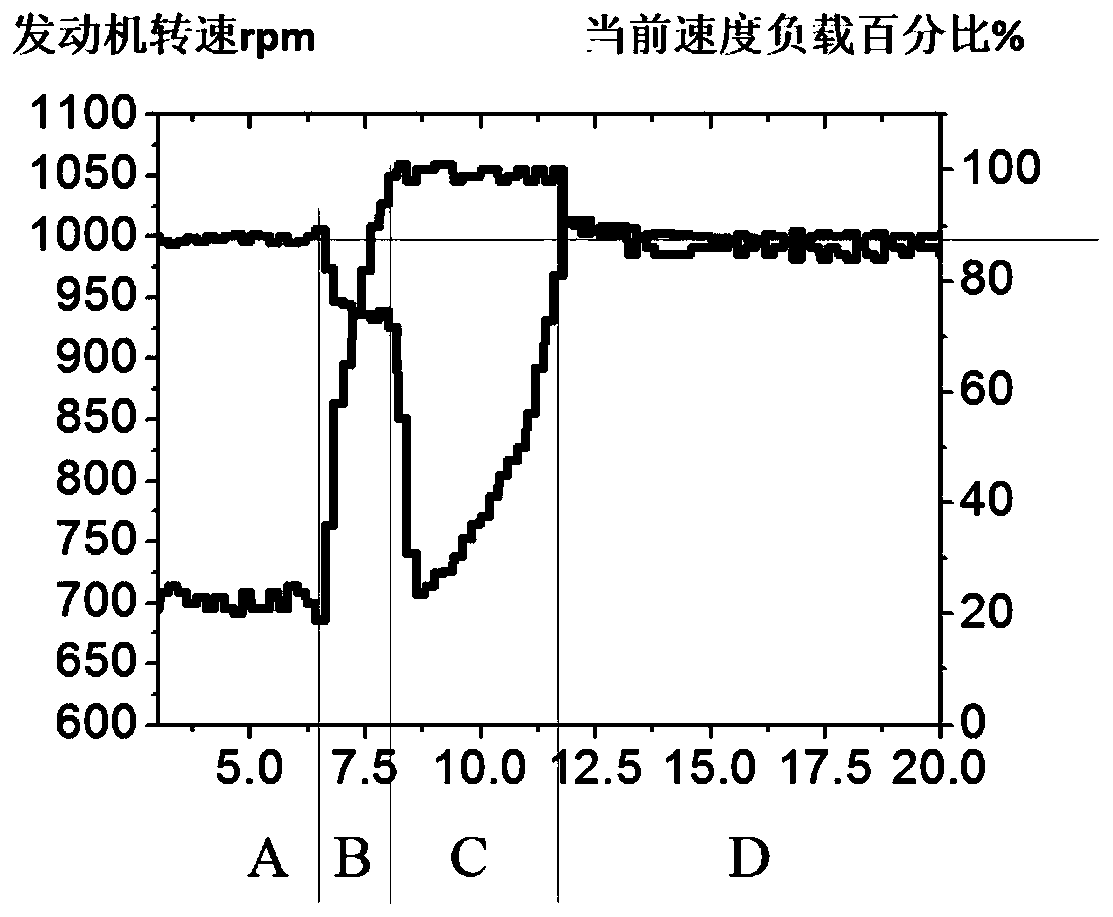

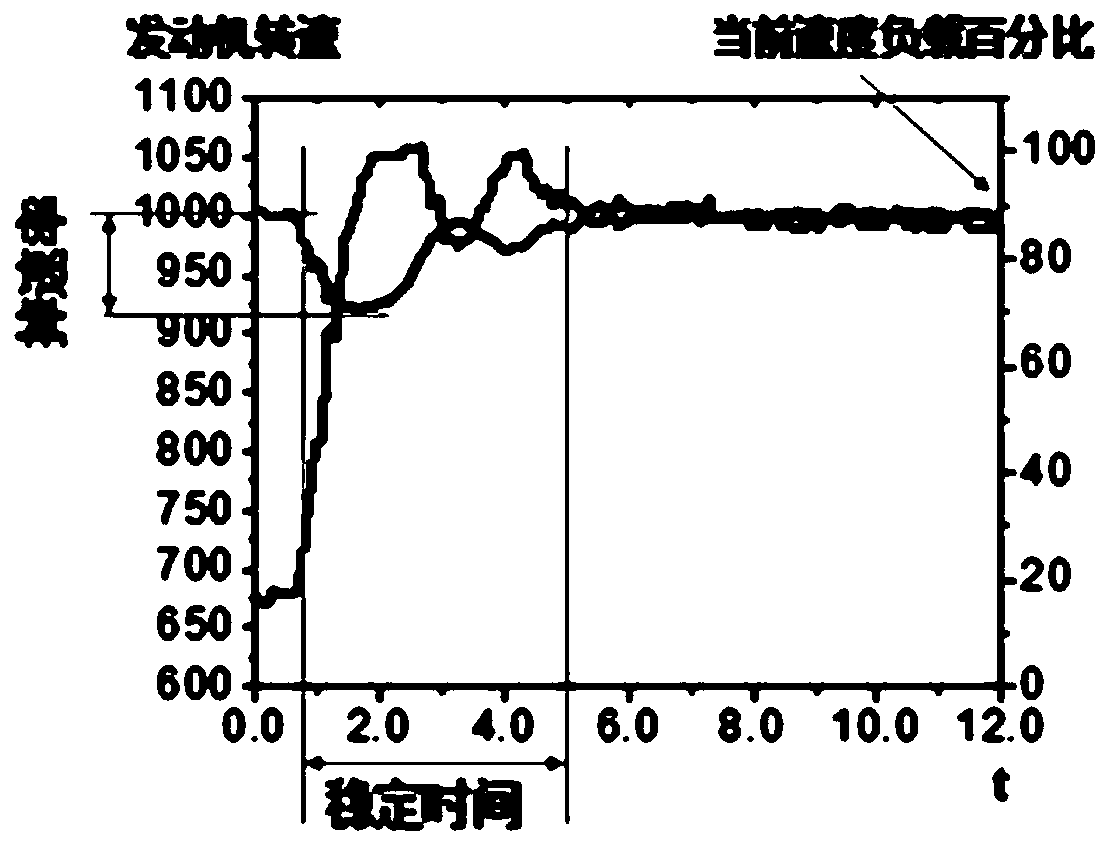

[0056] The term "drop rate" mentioned in this application refers to the percentage of the ratio of the difference between the maximum rotational speed (or minimum rotational speed) of the engine under a sudden load change and the rated rotational speed before the load sudden change to the rated rotational speed.

[0057] The term "current speed load percentage" referred to in this application refers to the ratio of the actual engine torque (indicated torque) to the maximum effective indicated torque at the current engine speed.

[0058] The term "stabilization time" mentioned in this application refers to a period of time from the sudden change of the engine spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com