Mixed microwave sintering method of mullite composite material

A composite material and mixed microwave technology, which is applied in the field of mixed microwave sintering of mullite composite materials, can solve problems such as environmental pollution, large energy consumption, and long sintering time, and achieve broad application prospects, energy saving, and short cycle times. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

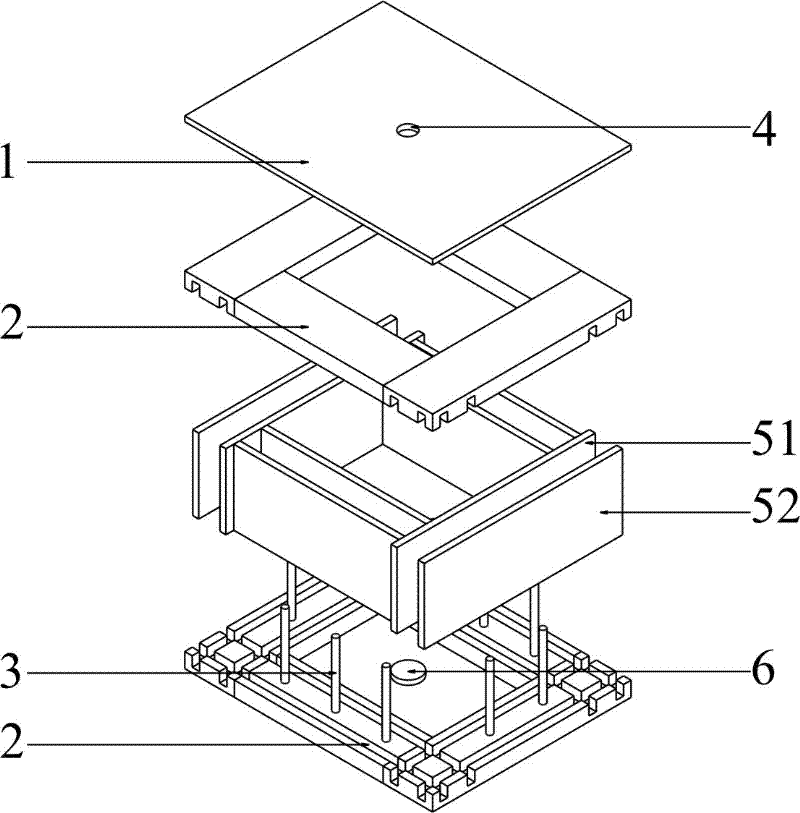

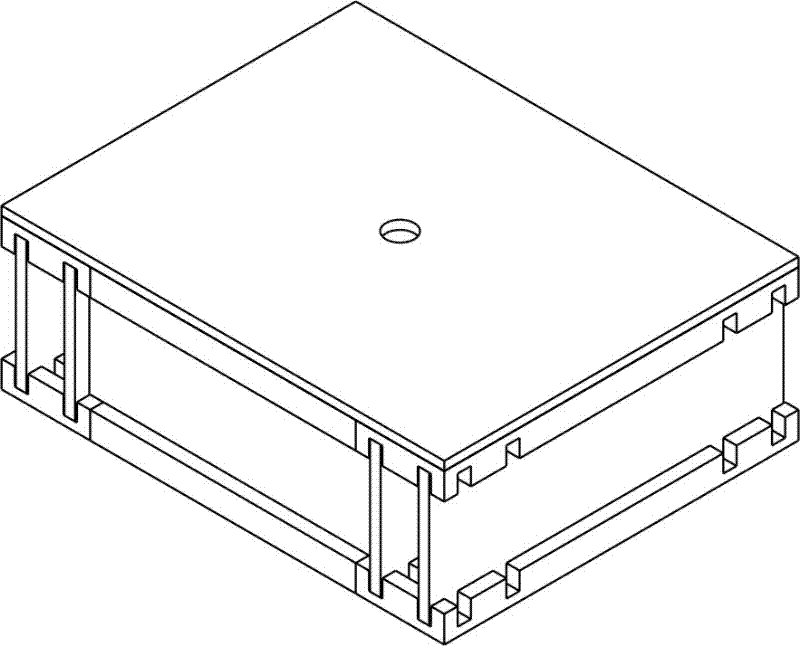

[0028] like figure 1 and figure 2 As shown, a combined auxiliary heating and heat preservation device, the device includes upper and lower mullite slots 2, inner and outer double mullite plates 51, 52 fixed between the upper and lower mullite slots 2, inner and outer double mullite plates The SiC heating rod 3 between the stone plates 51 and 52 and the mullite cover plate 1 set on the top of the device, the mullite cover plate 1 is provided with an infrared temperature measurement probe hole 4; the inner and outer double-layer mullite plates 51, 52 Fitted with a slot structure, the distance between the inner and outer double-layer mullite plates 51, 52 and the SiC heating rod 3, and between the inner layer mullite plate 51 and the center of the device (where the sample 6 is placed) is 0.4-0.6 cm.

[0029] The raw material is mullite refractory brick body (provided by Henan Dengfeng Hongchang Refractory Co., Ltd.), the main chemical composition is α-mullite, the size is 240mm...

Embodiment 2

[0032] Basically the same as Example 1, the difference is: when the reflected power is basically stable, the heating rate is maintained at 25±3°C / min, the temperature is raised to the sintering temperature of 1000°C at a uniform speed, and the holding time is 5min. The whole sintering process lasted 72min.

[0033] The compressive strength of the obtained mullite sample is 6.14MPa, which is 1.26 times that of the conventional sample; its porosity is 69.0%, water absorption is 82.8%, and the bulk density is 0.85g / cm 3 , which is similar to conventional samples and can meet the requirements of use.

Embodiment 3

[0035] Basically the same as Example 1, the difference is: when the reflected power is basically stable, the heating rate is maintained at 25±3°C / min, the temperature is raised to the sintering temperature at a uniform speed of 1200°C, and the holding time is 10 minutes. The whole sintering process lasted 85min.

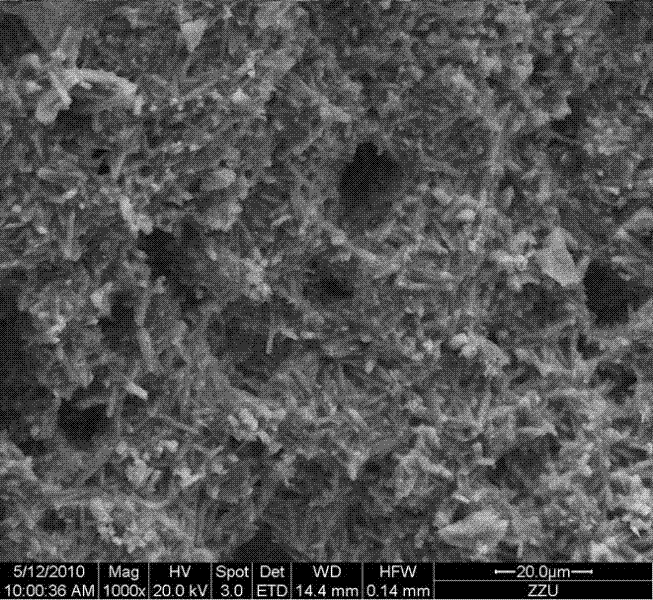

[0036] Get the SEM image of the section of the mullite sample magnified 4000 times, see Figure 5 As shown, its compressive strength is 6.53MPa, which is 1.34 times that of conventional samples; its porosity is 68.2%, water absorption is 81.9%, and the bulk density is 0.87g / cm 3 , which is similar to conventional samples and can meet the requirements of use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com