A kind of insulation structure of isobutane dehydrogenation device

An isobutane and dehydrogenation technology, which is applied in thermal insulation, pipeline protection, pipeline protection through thermal insulation, etc., can solve the problems of hydrogen leakage, waste of thermal insulation materials, hidden dangers, etc., to prevent hidden dangers, facilitate maintenance work, The effect of saving insulation material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

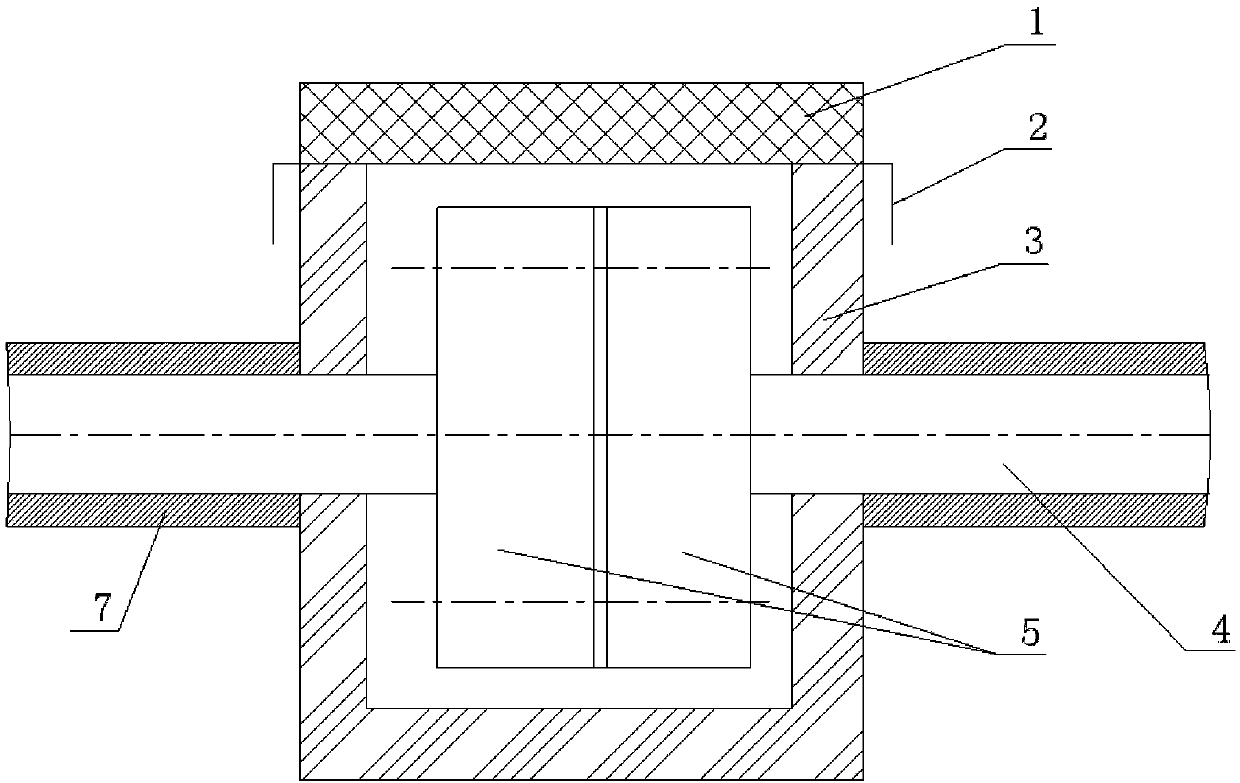

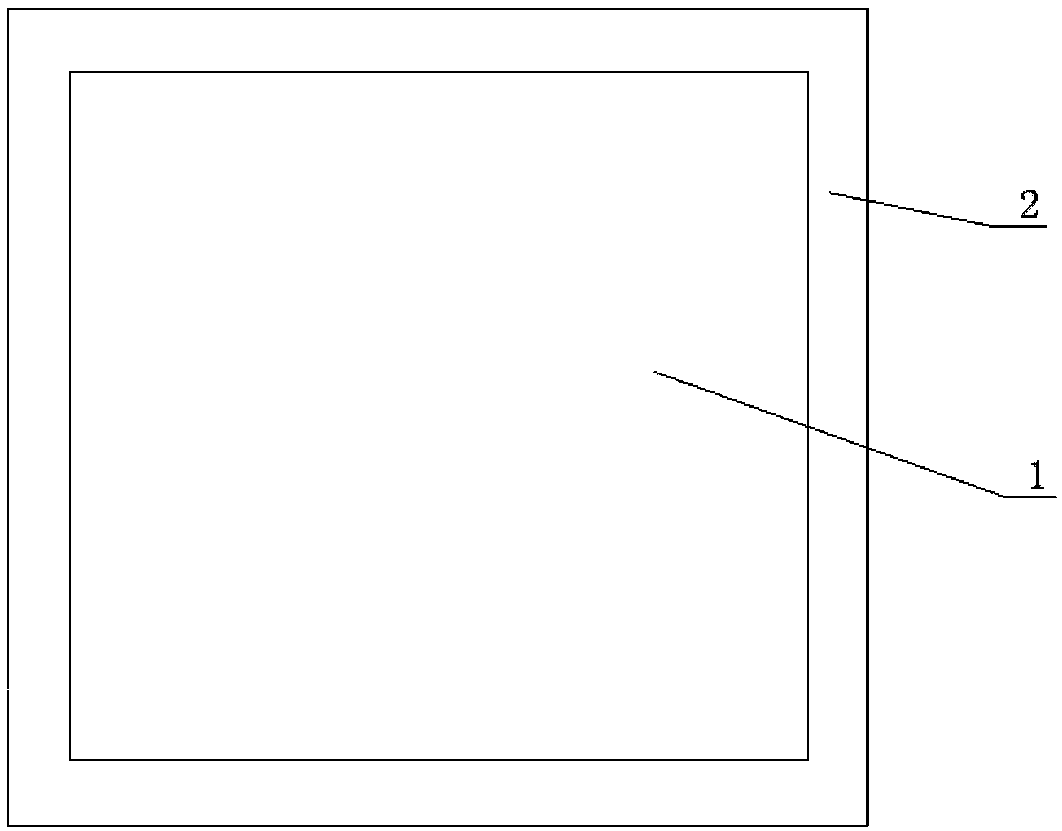

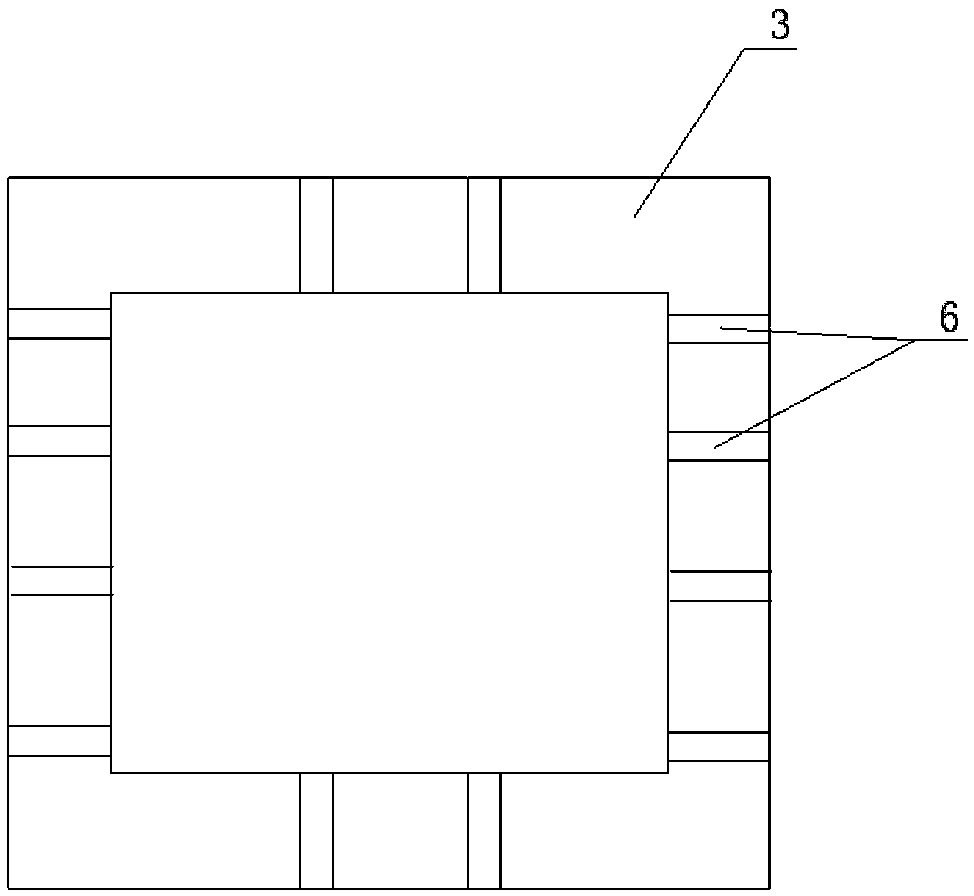

[0015] As shown in the accompanying drawings, a thermal insulation structure of an isobutane dehydrogenation device includes a pipeline 4 connected by a flange 5, and an insulation layer 7 is arranged on the outside of the pipeline 4, which is characterized in that: the pipeline The outside of the flange 5 on the 4 is provided with an insulated chamber that surrounds the flange 5 inside, and the insulated chamber includes a lower insulated chamber 3 and an insulated upper cover 1 that can surround the flange 5 in the interior, and the lower insulated chamber 3. The upper part is open, and the heat preservation upper cover 1 is closed on the opening of the lower heat preservation chamber 3. The upper port of the lower heat preservation chamber 3 is provided with a plurality of grooves 6 that pass through the heat preservation chamber. The grooves 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com