Slope roof thermal insulation, ventilation and energy-saving dry structure and its construction method

A sloping roof and dry method technology, applied in the field of sloping roof structure and its construction, can solve the problems of uneven tile laying, large roof load, and poor heat insulation effect, and achieve excellent heat insulation capacity, good heat preservation and energy saving performance, The effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

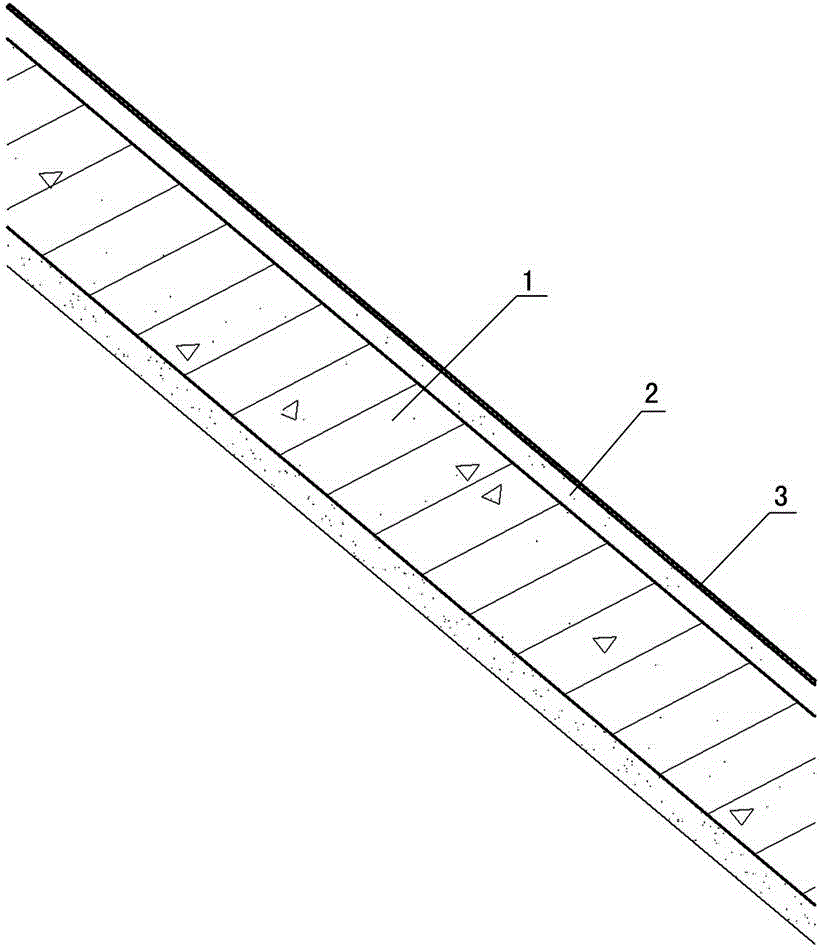

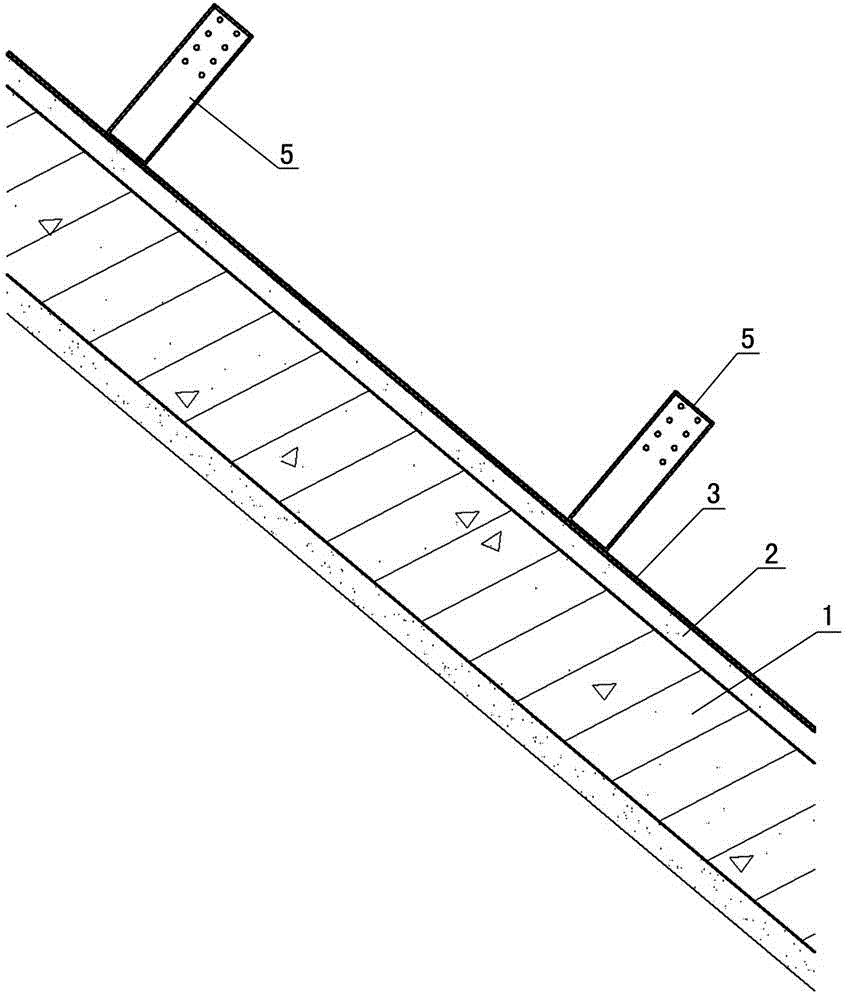

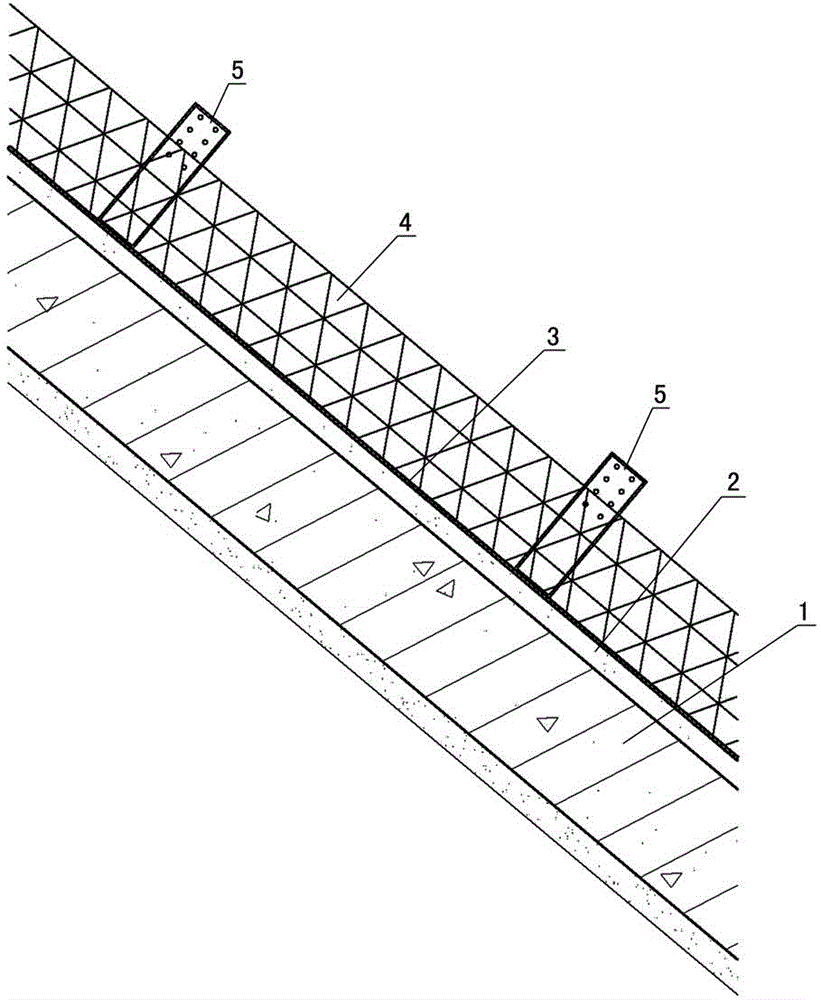

[0032] Examples see Figure 7 , Figure 8 As shown, this sloping roof thermal insulation, ventilation and energy-saving dry structure includes a cement mortar leveling layer 2 laid on the concrete base 1, a waterproof cushion layer 3 laid on the cement mortar leveling layer 2, and a waterproof cushion layer laid on the waterproof cushion layer 3. The thermal insulation and drainage layer, the horizontal tile-hanging wooden strips 8 laid on the thermal insulation and drainage layer, and the roof tiles 9 hung on the horizontal tile-hanging wooden strips 8.

[0033] The thermal insulation and drainage layer is composed of thermal insulation board 4 , backing bracket 5 , longitudinal wooden strips 6 and aluminum foil coiled material 7 .

[0034] The backing bracket 5 is arranged on the waterproof cushion 3, and the backing bracket 5 is fixedly connected with the cement mortar leveling layer 2 through nails. In this embodiment, the backing bracket 5 is an L-shaped backing bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com