Solid electric heat storage equipment

An electric heat storage and solid technology, which is applied in heat storage equipment, lighting and heating equipment, fluid heaters, etc., can solve problems such as unsatisfactory use effect and complex structure, and achieve simple structure, high efficiency, and saving insulation materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

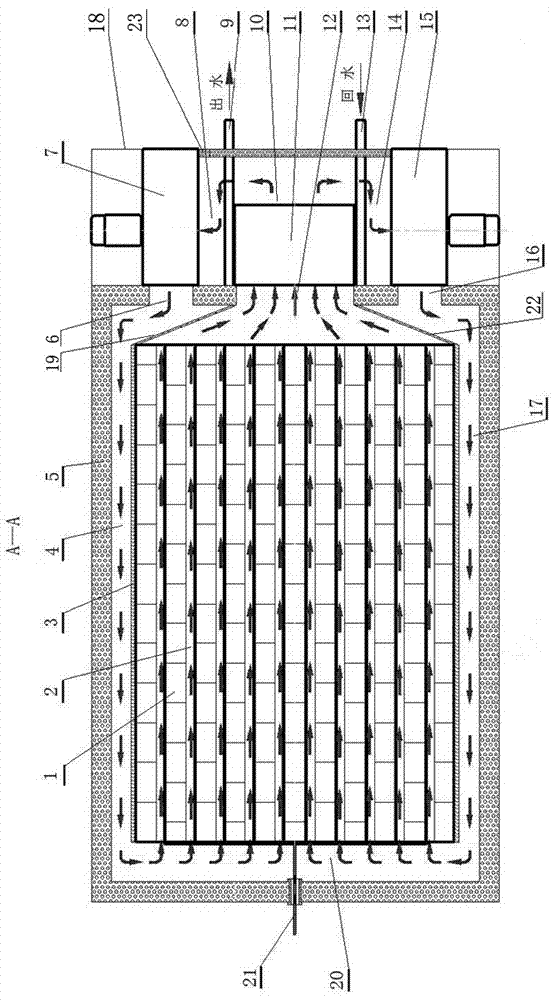

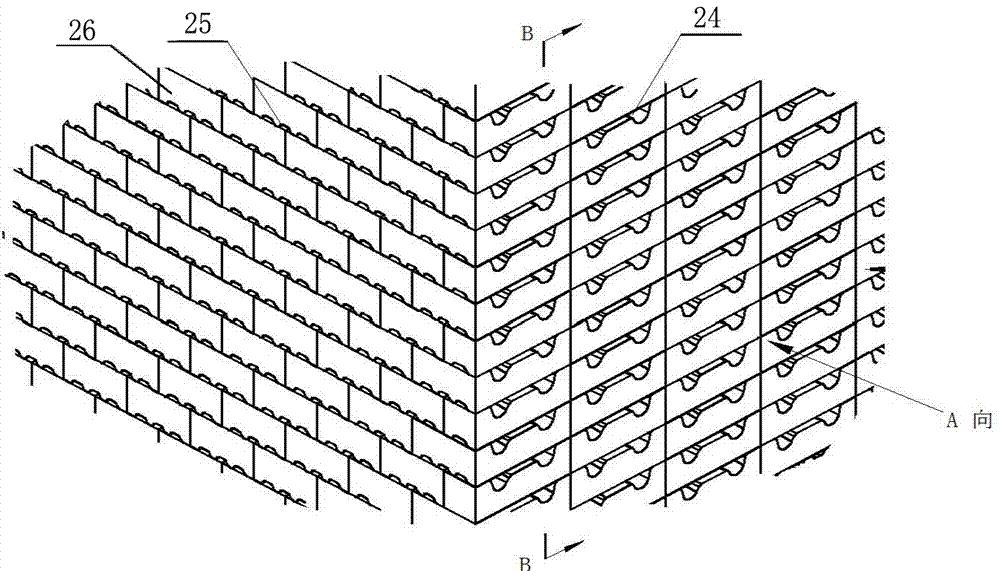

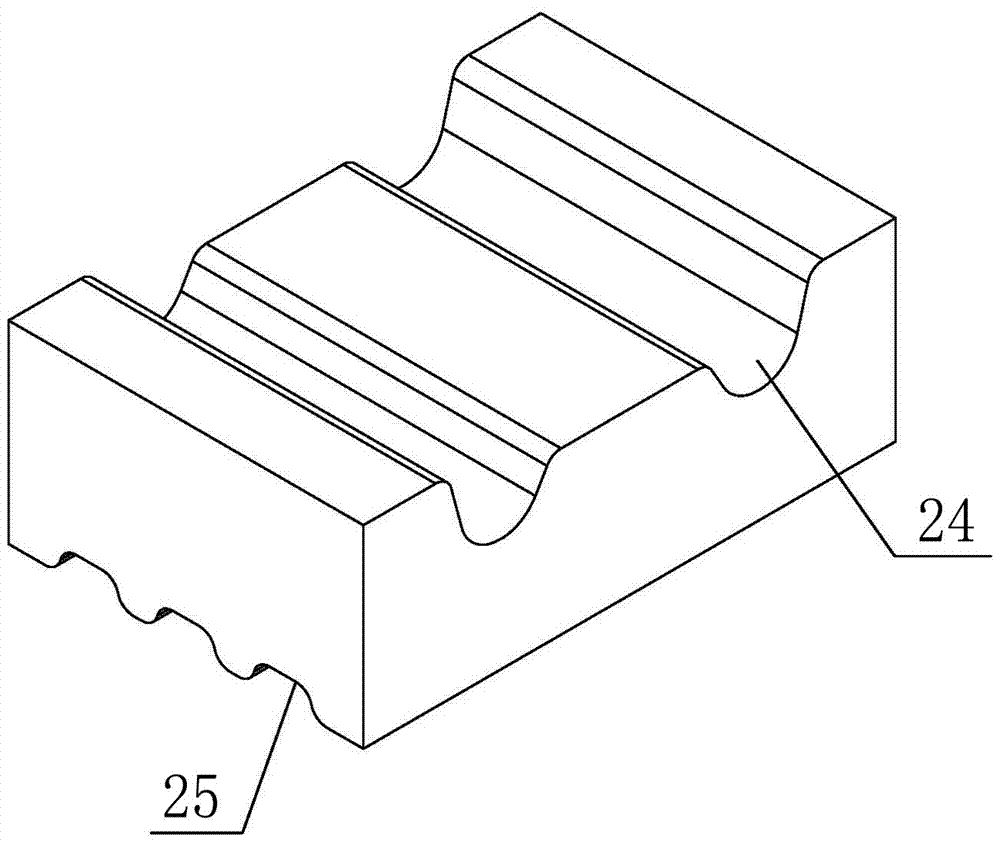

[0019] The solid electric heat storage device used in this embodiment includes a heat storage body 1, a fan 7, a fan 15, a heat exchanger 11 and a housing 18 with a power inlet 21, where the power inlet 21 can be used to connect Heating element. A shell insulation layer 5 is also provided on the inner wall of the shell 18, and a thermal storage body insulation layer 3 is also provided on the outside of the thermal storage body 1. The thermal storage body insulation layer 3 in this embodiment adopts a fire-blocking and thermal insulation board. A heat storage body ventilation duct 2 is provided between each heat storage brick layer in the body 1, and a return air duct is formed between the heat storage body heat preservation layer 3 and the shell heat preservation layer 5.

[0020] Between the inner wall of the shell insulation layer 5 located between the fan 7 and the heat exchanger 11 and the top end of the heat storage body insulation layer 3 is connected a fire prevention insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com