Anchoring method of flat cross section of carbon fiber composite reinforcement material

A technology of composite materials and anchoring methods, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of unfavorable anchoring, raising, and small thickness of rib protrusions, etc., so as to avoid inconsistency of perfusion, high anchoring efficiency, and reduce small length effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

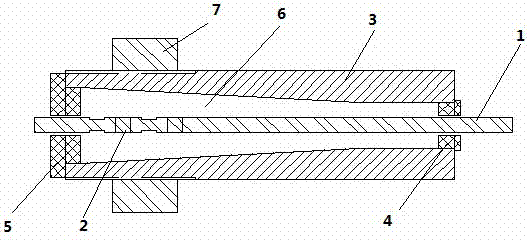

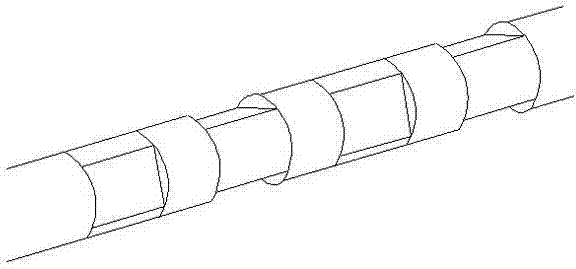

[0017] see figure 1 with figure 2 , figure 1 It is a longitudinal section structure drawing of the bonded anchoring scheme of the present invention. figure 2 It is a partial enlarged view of the three-dimensional entity of the rolled part of the carbon fiber composite material bar of the present invention. Depend on figure 1 with figure 2 It can be seen from the figure that the carbon fiber composite reinforcement is locally heated and softened near the end of the anchorage. When it is close to the curing temperature of the reinforcement, the heated part is rolled with a tool, and the rolled part becomes flat. A total of one reinforcement Carry out four times of rolling, alternately rolling twice in the orthogonal and vertical directions, and after cooling, the rolled parts are solidified again.

[0018] After passing the reinforcement through the positioning hole of the end plug and the cover, place the anchor vertically, remove the end plug, pour the prepared epoxy r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com