Self-adaption decompression type grouting anchor rod

A self-adaptive technology for grouting bolts, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems that the bolt reinforcement capacity needs to be improved, so as to improve the anchoring efficiency, enhance the anchoring effect, and increase the anchoring force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

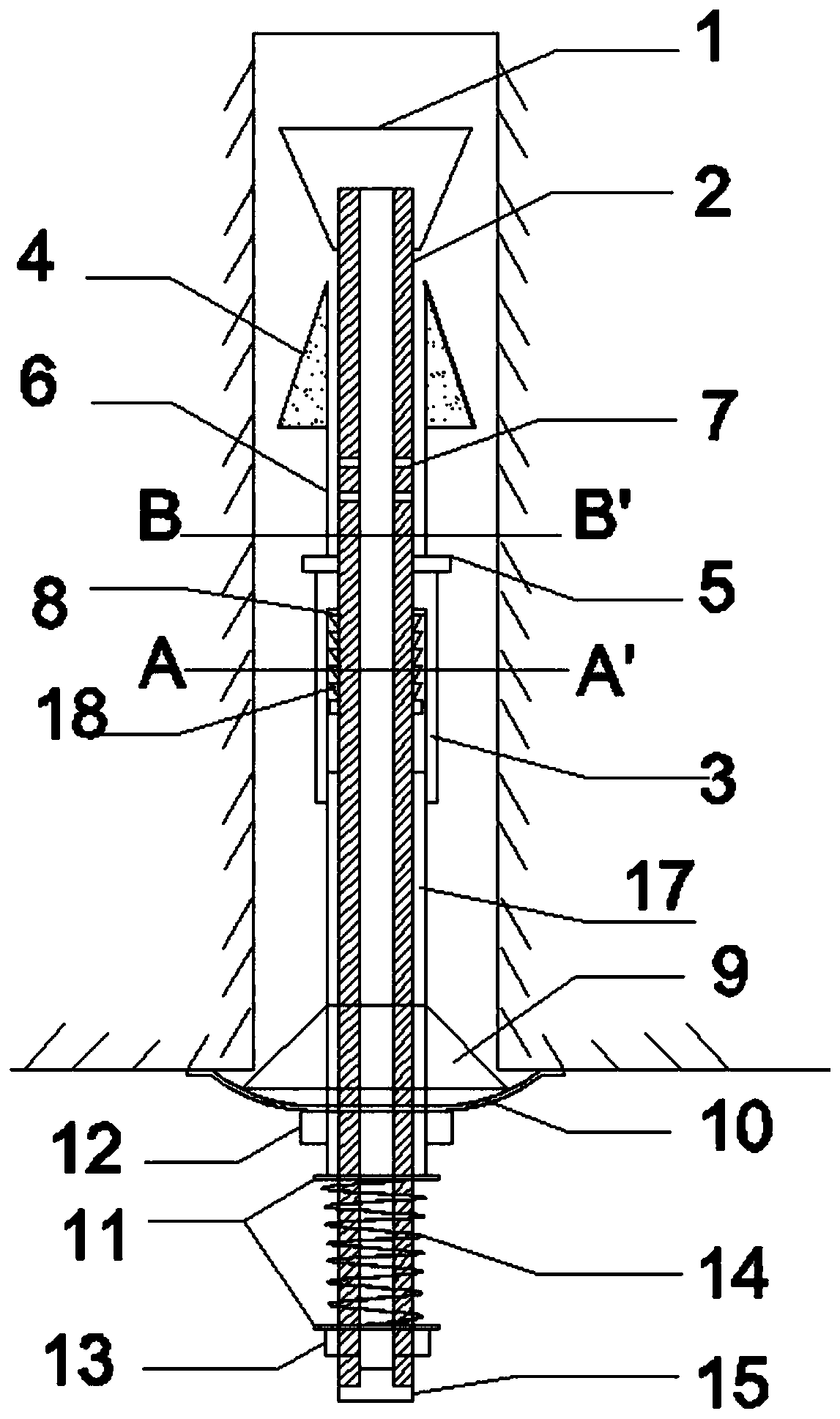

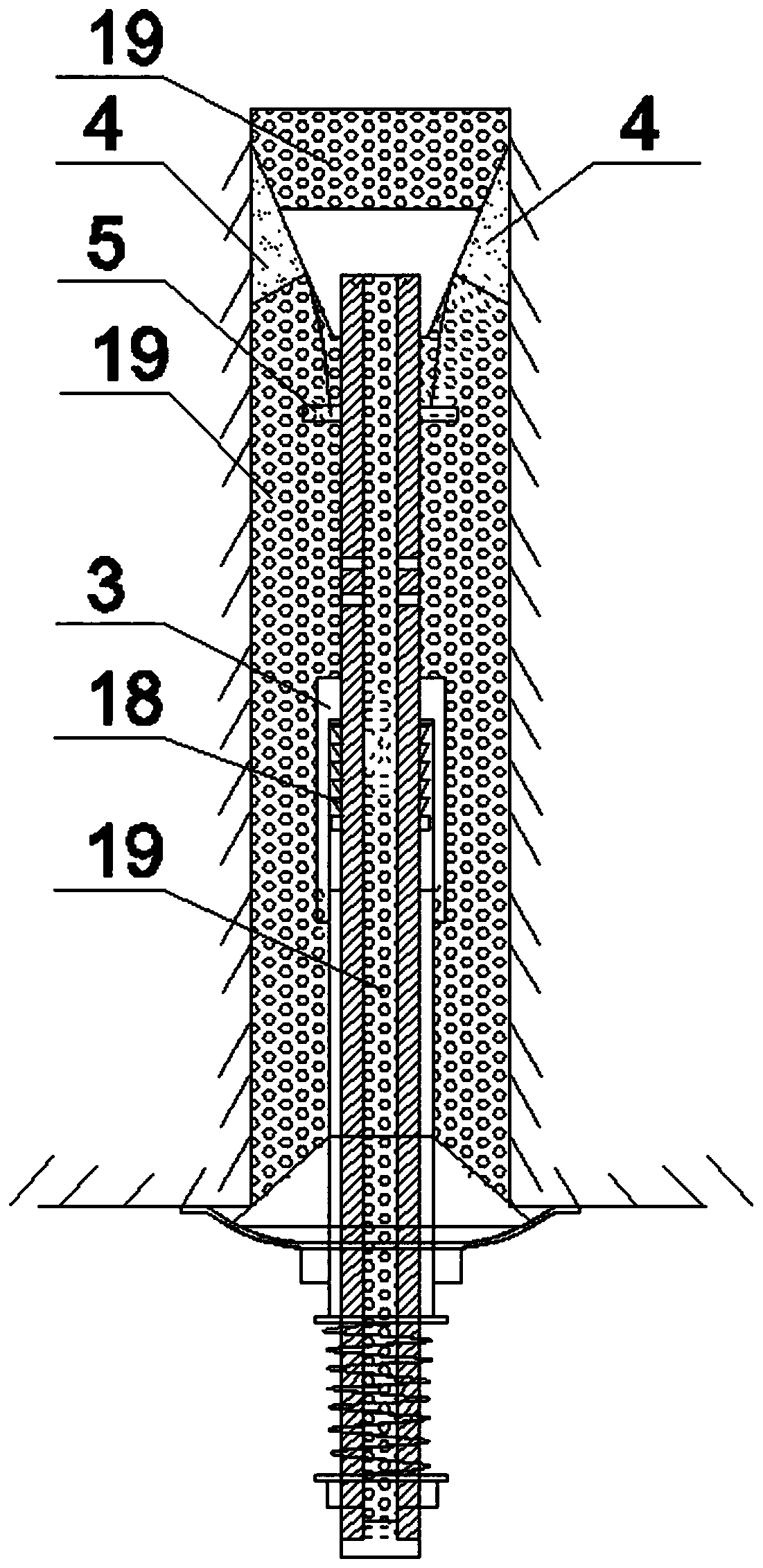

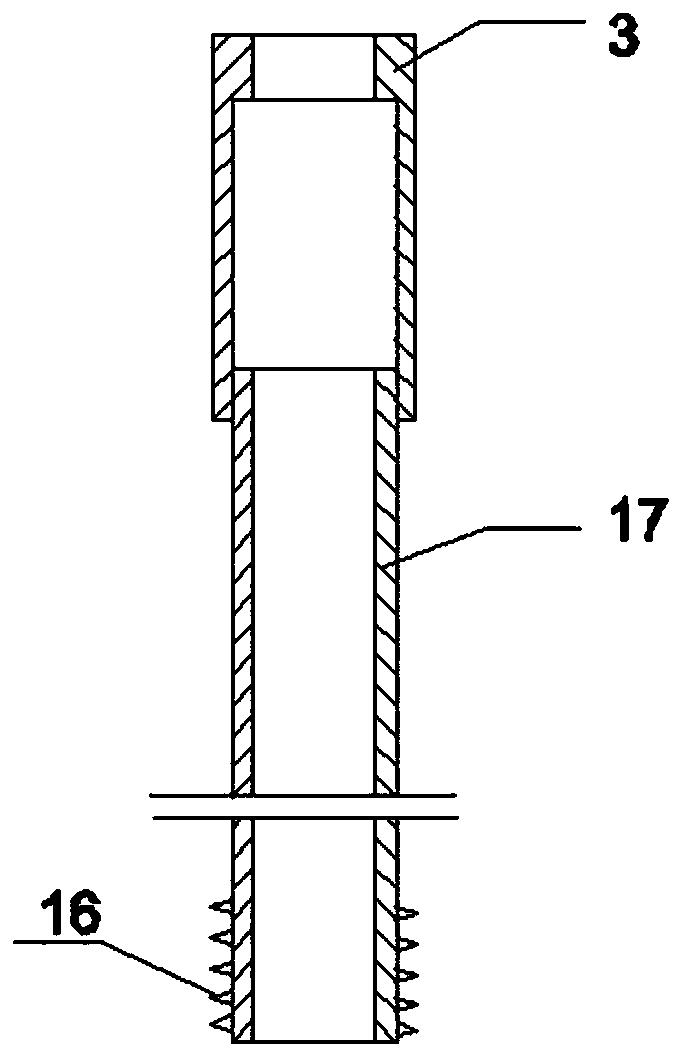

[0019] In the description of the drawings, the number 1 is the bolt head, 2 is the bolt body, 3 is the upper sleeve, 4 is the wedge-shaped rigid block body, 5 is the steel sheet fixing ring, 6 is the positioning adjustment steel sheet, and 7 is the grouting hole. 8 is an isolation rubber ring, 9 is a grout stopper, 10 is a grout stopper backing plate, 11 is a screw washer, 12 is a grout stopper nut, 13 is a fastening nut, 14 is a spring, 15 is a grout stopper, and 16 is a Thread, 17 is the positioning lower sleeve, 18 is the pre-unloading projection, and 19 is the cement slurry.

[0020] The self-adaptive pressure relief grouting bolt of the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods: as shown in the figure, this embodiment includes a bolt body 2, an adaptive locking device, a grouting hole 7, a stop The grout plug 9, the grout stopper backing plate 10, the fastening nut 13 and the grout plug 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com