Secondary tensile prestressed anchorage

A prestressing and anchoring technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problem of high material cost, achieve the effect of improving engineering safety, small prestressing loss, and improving anchoring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

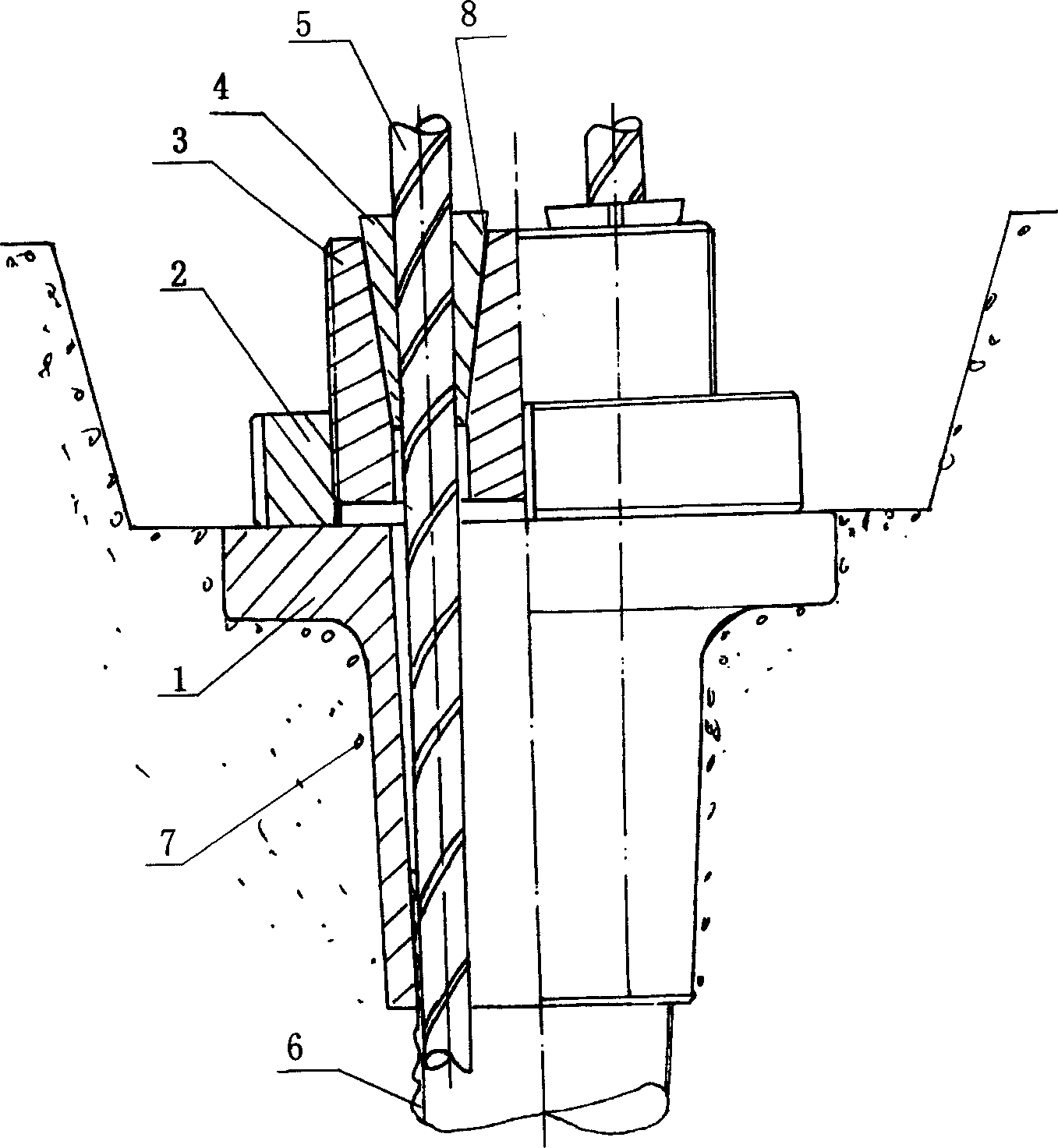

[0007] Depend on figure 1 As can be seen, the backing plate (1) is vertically installed in the concrete, and the outer garden of the support nut (2) is hexagonal, with a thickness of 30mm, and the internal thread of the support nut (2) is connected with the external thread of the anchor ring (3). The steel strand (5) passes through the tapered hole (8) of the clip (4) in the anchor ring (3). The working process is as follows: the first step is to stretch the prestressed steel strand to the design load value according to the conventional construction, and then release the tension. The load transfer route is anchor ring (3)→backing plate (1)→concrete member (7). The second step is to connect the anchor ring (3) with the tension rod with a connector, stretch the anchor ring (3) to the design load value as a whole, and tighten the support nut (2) to the side of the backing plate (1) to release the anchor Finally, the load transmission route is anchor ring (3)→support nut (2)→bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com