A composite anchor for frp tendons

A composite anchorage technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as prone to bending and eccentric tension, complex anchoring process operation, short anchorage bonding length, etc., and achieve high anchorage efficiency , Avoid pinching the tendons and reduce the length of the anchoring device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] For a further understanding of the present invention, further description will now be given below in conjunction with the accompanying drawings.

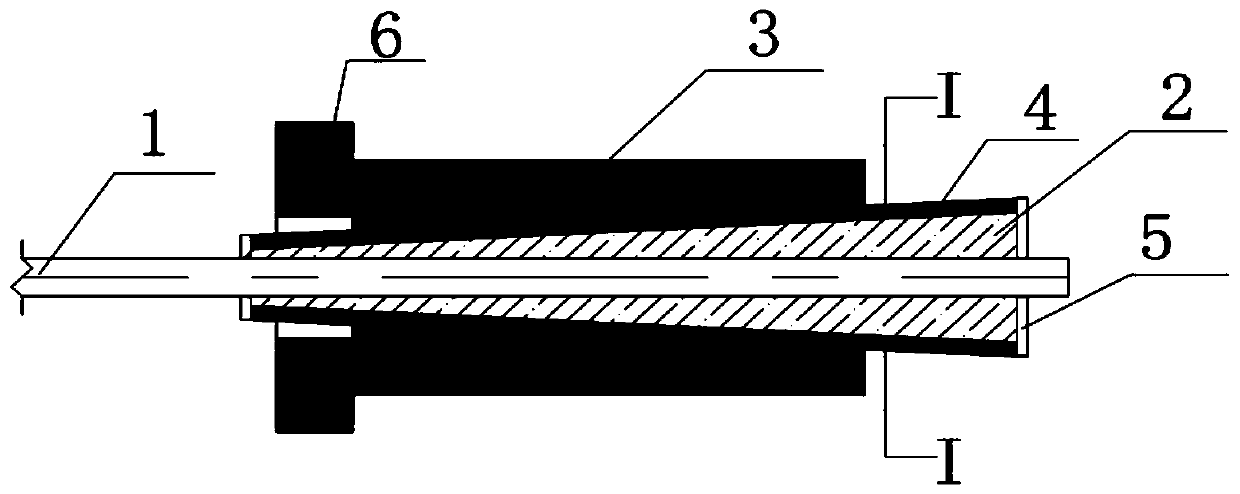

[0024] figure 1 It is a longitudinal sectional view of a composite anchor, which includes a conical metal cylinder 4, a circular anchor ring 3, a bonding medium 2, and an end plug 5; the inside of the circular anchor ring is cone-shaped, and the inner wall is smooth For processing, the metal cylinder is a cone-shaped cone cylinder, the inner wall is roughened, and there is an angle difference of 0.1° to 0.3° between the circular anchor ring 3 and the metal cylinder 4 .

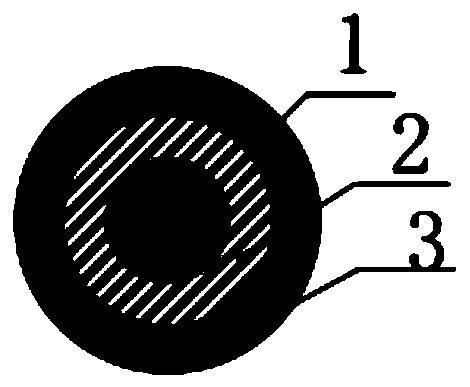

[0025] figure 2 I-I sectional view, the cross section of the conical metal cylinder 4 is circular, the FRP rib 1 is located at the center, the central gap is filled with the bonding medium 2, and the bonding medium 2 needs to be cured until it is completely cured.

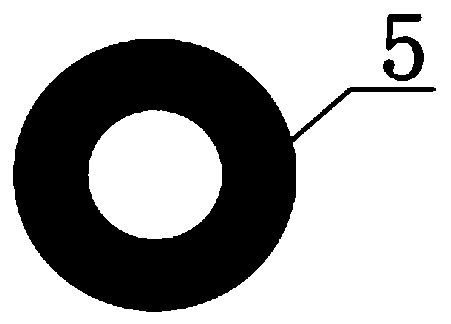

[0026] image 3 It is the structure diagram of the end plug. The end plug 5 is in the shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com