Tension self-locking device for grouting anchor cable

A self-locking device and pulling force technology, applied in the installation of bolts, mining equipment, earthwork drilling, etc., can solve the problems of lower utilization rate of anchoring agent, lower anchoring efficiency, and failure to reach the expected pullout resistance of anchor cables. Simple installation, increase anchoring efficiency, and avoid the effect of looseness in the hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

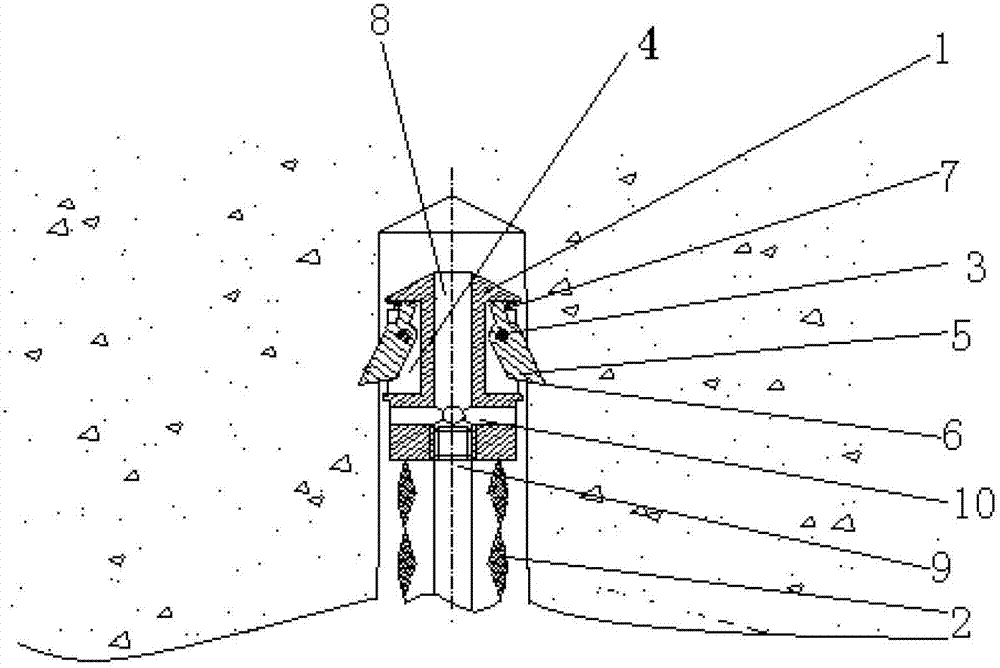

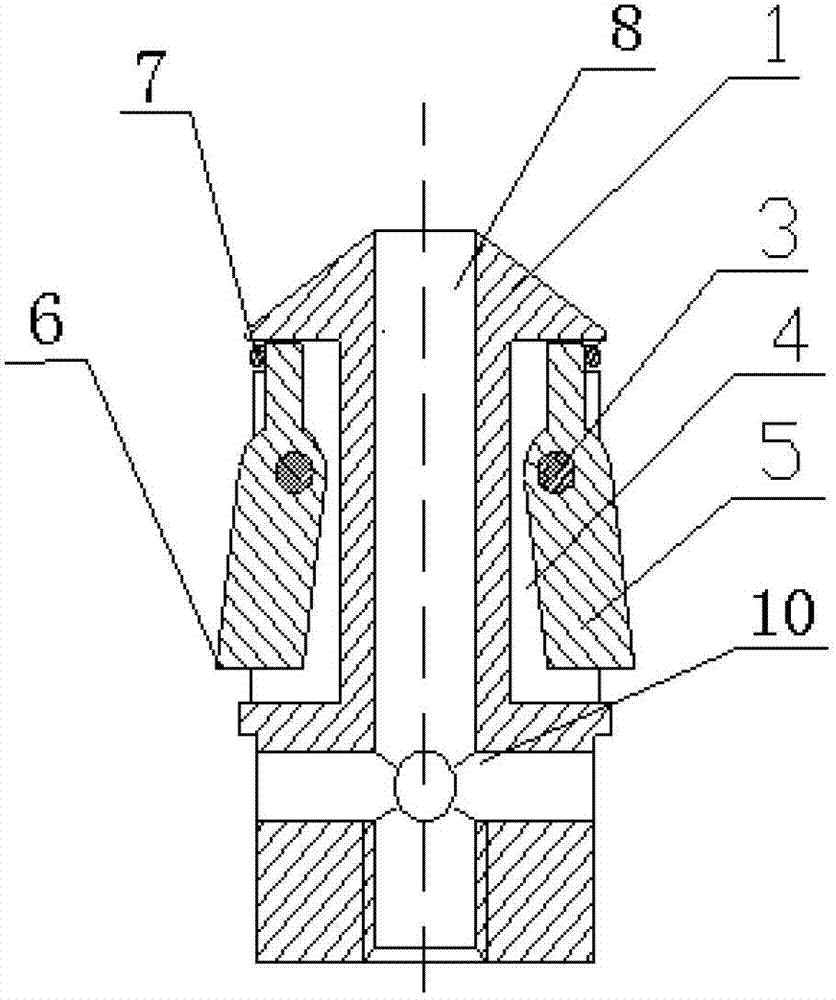

[0015] Referring to the accompanying drawings, a tension self-locking device for grouting anchor cables includes a lock claw seat 1 fixedly connected to the front end of the cable body 2, and the cable body 2 extends into the lock claw seat 1 through a central grouting pipe. The front end of the lock claw seat 1 is sharpened, and the side wall of the lock claw seat 1 is provided with a ring groove 4, and in the ring groove 4, 6 pieces of single-piece lock claws 5 distributed in the circumferential direction are hinged through the revolving pin 3, and the single-piece lock claw 5 The bottom end is tilted outward, and the bottom end of the single-piece lock claw 5 has lock teeth 6 that can be embedded in the inner wall of the tunnel. Grouting channel 8, the central grouting channel 8 communicates with the front end of the central grouting pipe 9, the front end of the central grouting pipe 9 is threadedly connected to the bottom end of the locking claw seat 1, and the outer side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com