Fully sealed coal roadway tunneling and anchoring synchronous machine

A fully-sealed, synchronous machine technology, applied in cutting machinery, slitting machinery, installation of anchor rods, etc., can solve the problems of longer anchoring time, longer empty top distance, large dust volume, etc., to improve the safety operation factor, improve The effect of driving efficiency and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

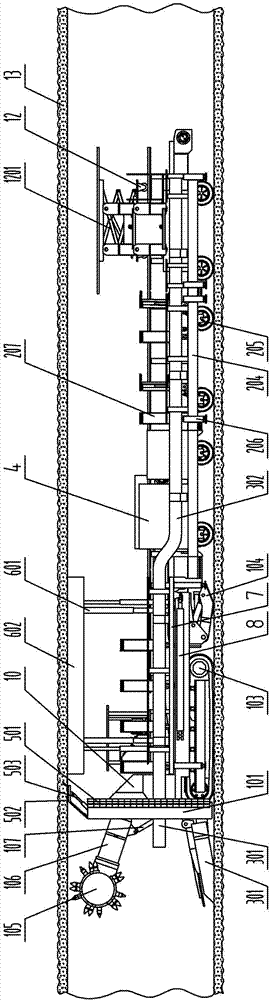

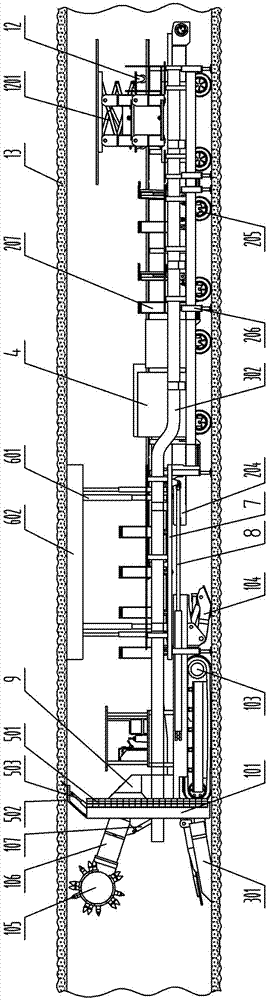

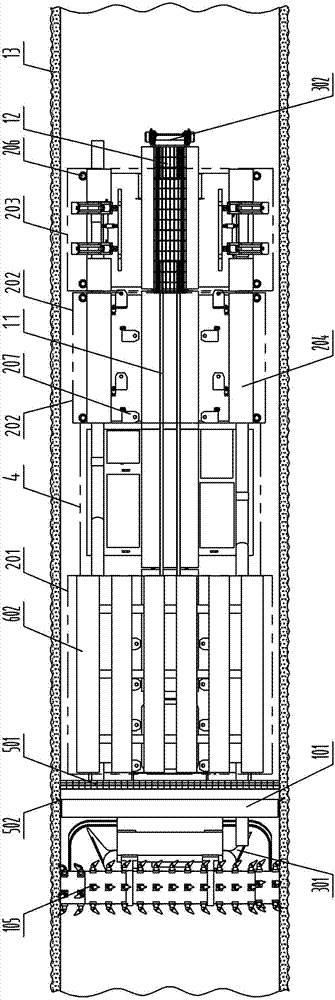

[0033] see figure 1 , figure 2 and image 3, in the figure, the fully sealed coal roadway bolt synchronous machine of the present invention includes a tunneling device 1, a sealing and dust removal device, an anchoring device 2, a coal loading and conveying device 3, a power system 4 and a hydraulic system, and the tunneling device 1 includes a main body 101, the retractable cutting part 102 installed at the front end of the body part 101, the walking part 103 installed at the bottom of the body part 101, the rear support part 104 installed at the rear end of the body part 101, the anchoring device 2 includes a first , second and third rock bolters 201, 202, 203, the first rocker drill 201 is installed between the cutting part 101 of the tunneling device 1 and the power system 4, the second and third rock bolters 202 , 203 are installed in turn after the power system 4, and the first, second, and third rock bolters 201, 202, and 203 all include a vehicle frame 204, a group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com