Automatic pressure relief type grouting anchor rod

A technology of grouting bolts and automatic venting, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc. It can solve the problems of time-consuming and laborious anchoring construction, affecting the effect of grouting, and clogging of grouting holes, etc., and achieves labor reduction. Strength, the effect of improving anchorage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

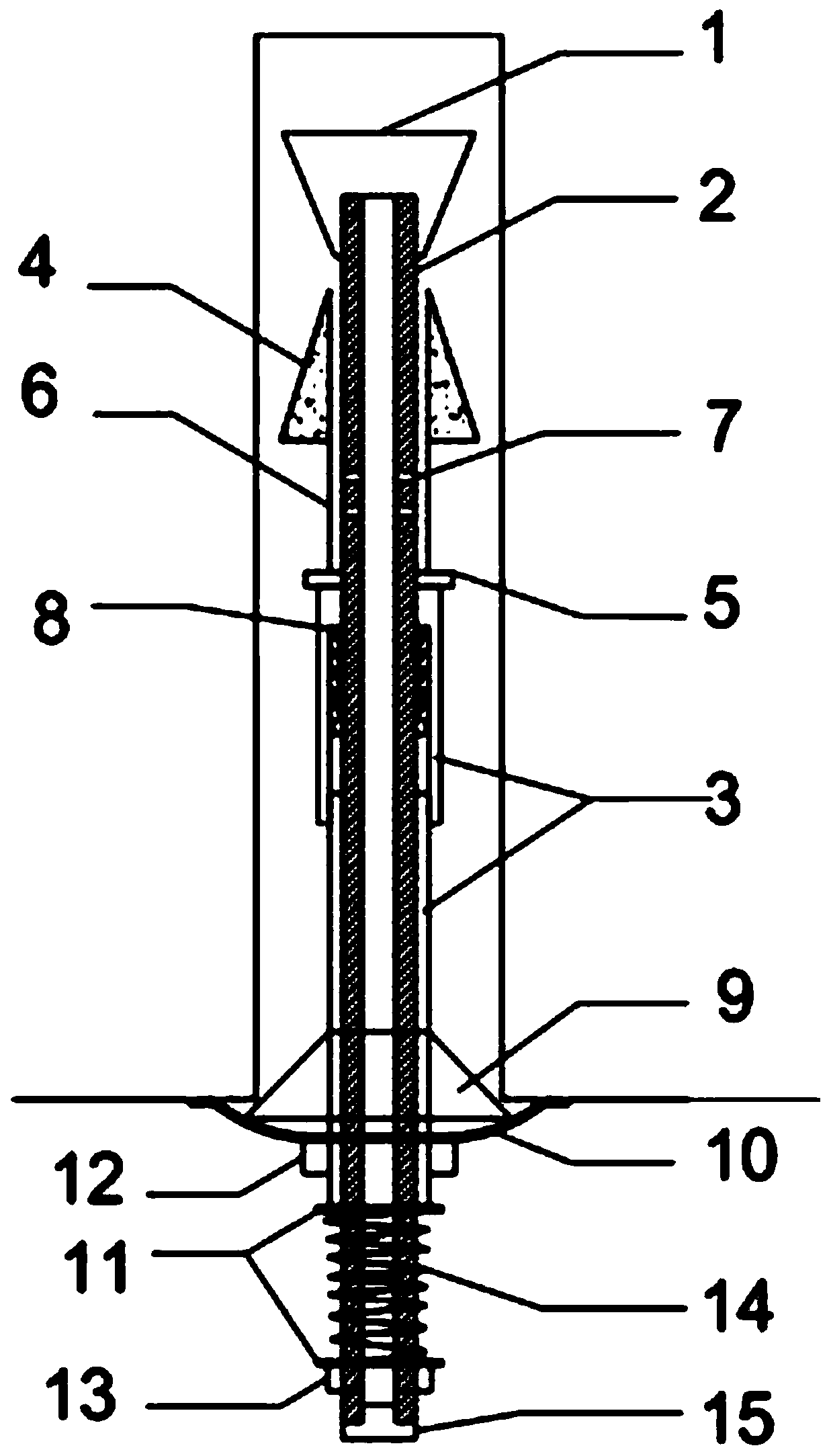

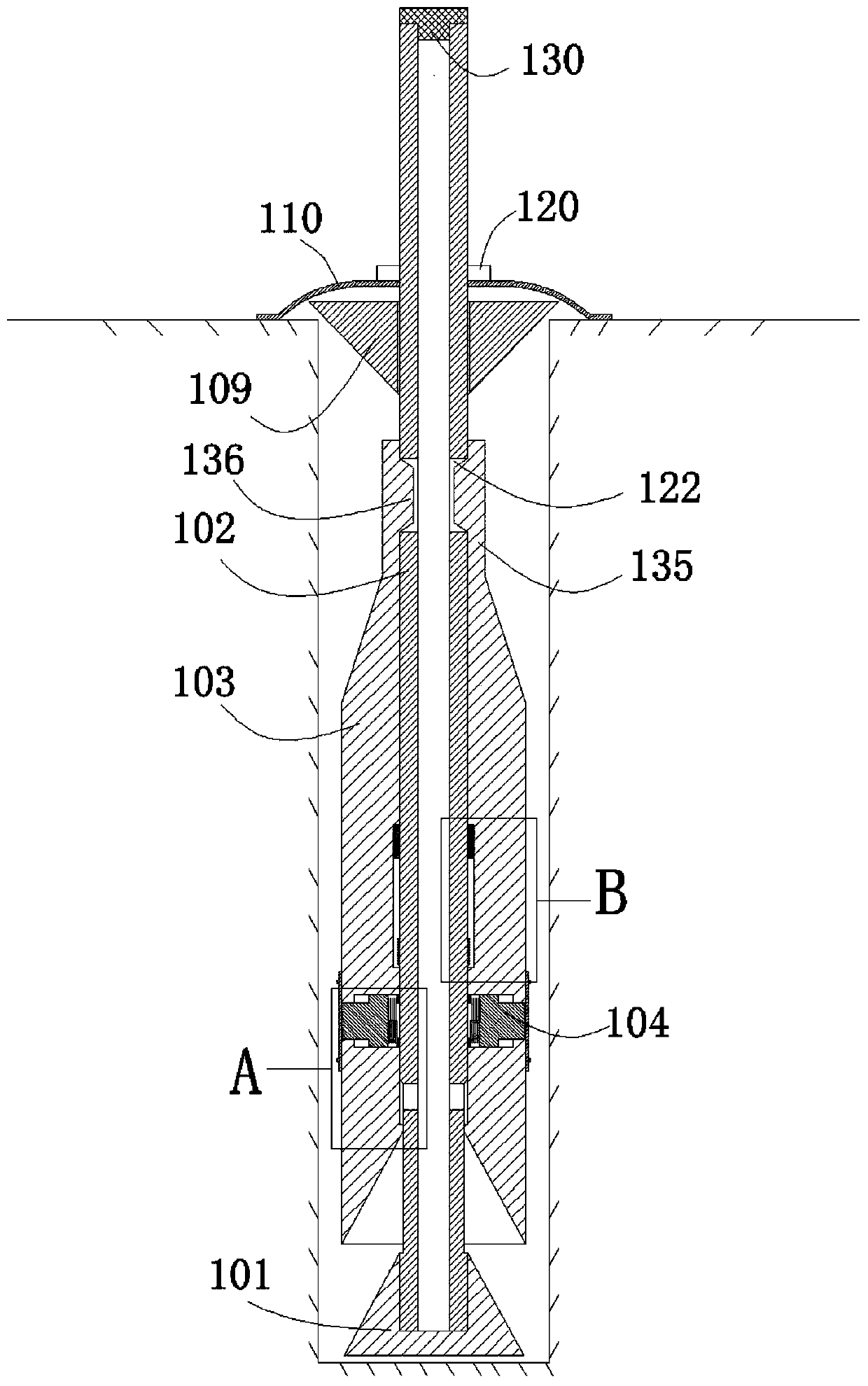

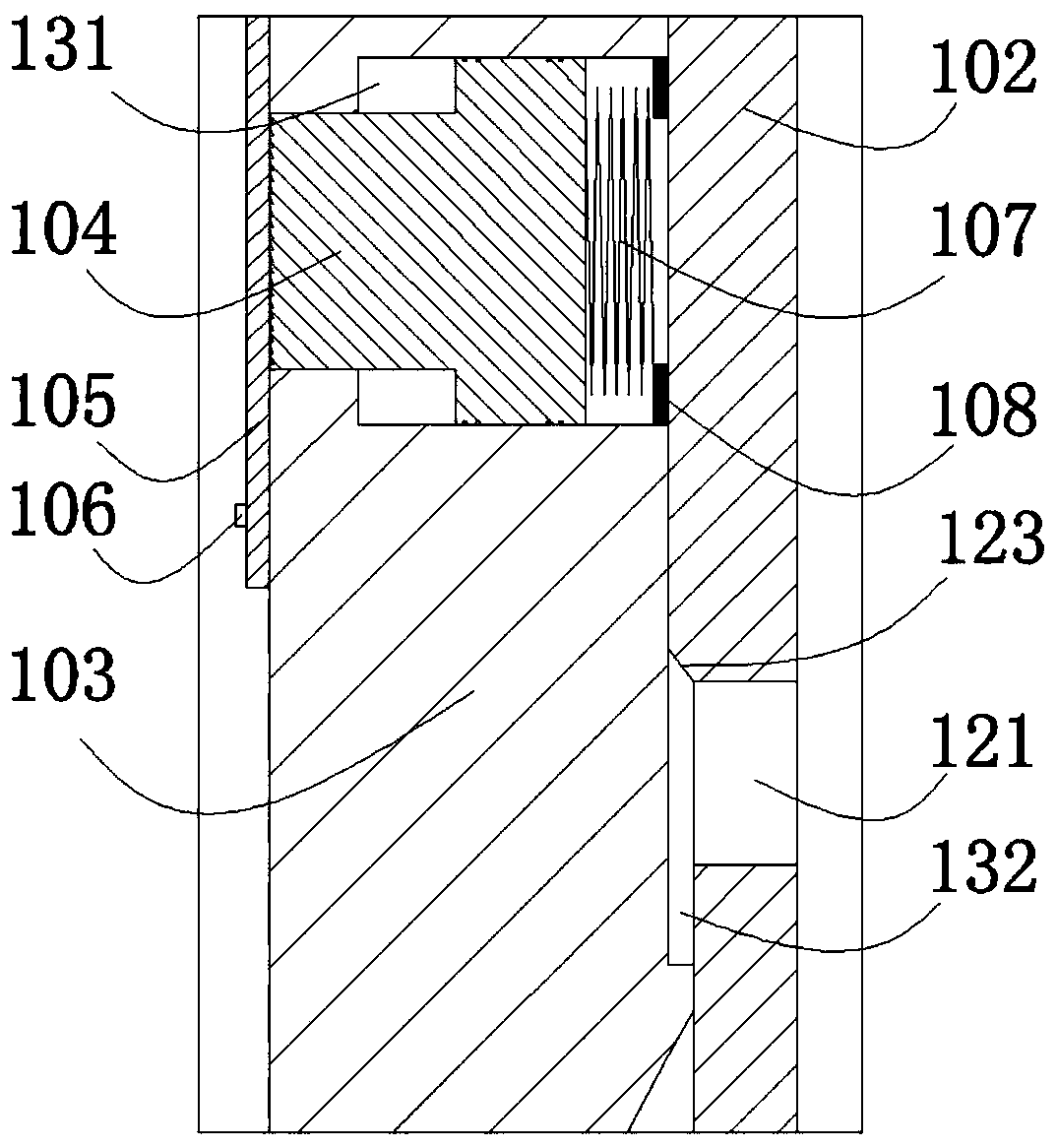

[0023] see figure 1 , shows the structure of the automatic pressure relief grouting anchor in this embodiment, which mainly consists of the anchor head 101, the anchor body 102, the anchor sliding sleeve 103, the anchor slider 104, the breakable block 105, Screw 106, spring 107, spring retaining ring 108, grout stopper 109, backing plate 110, lock nut 120 and grout plug 130 constitute. The anchor head 101 is fixed on the front end of the anchor body 102, the anchor sliding sleeve 103 is slidably and tightly sleeved on the anchor body 102, and the anchor sliding sleeve 103 is arranged behind the anchor head 101 at intervals, and the anchor sliding block 104, Broken baffles 105, screws 106, springs 107 and spring retain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com