Viscous material extruder and application thereof

An extruder and material technology, which is applied in the field of processing and preparation of viscous materials, can solve the problems of high processing and assembly requirements, high cost of extruder, complex structure, etc., and achieve convenient discharge, easy molding, and guaranteed driving efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

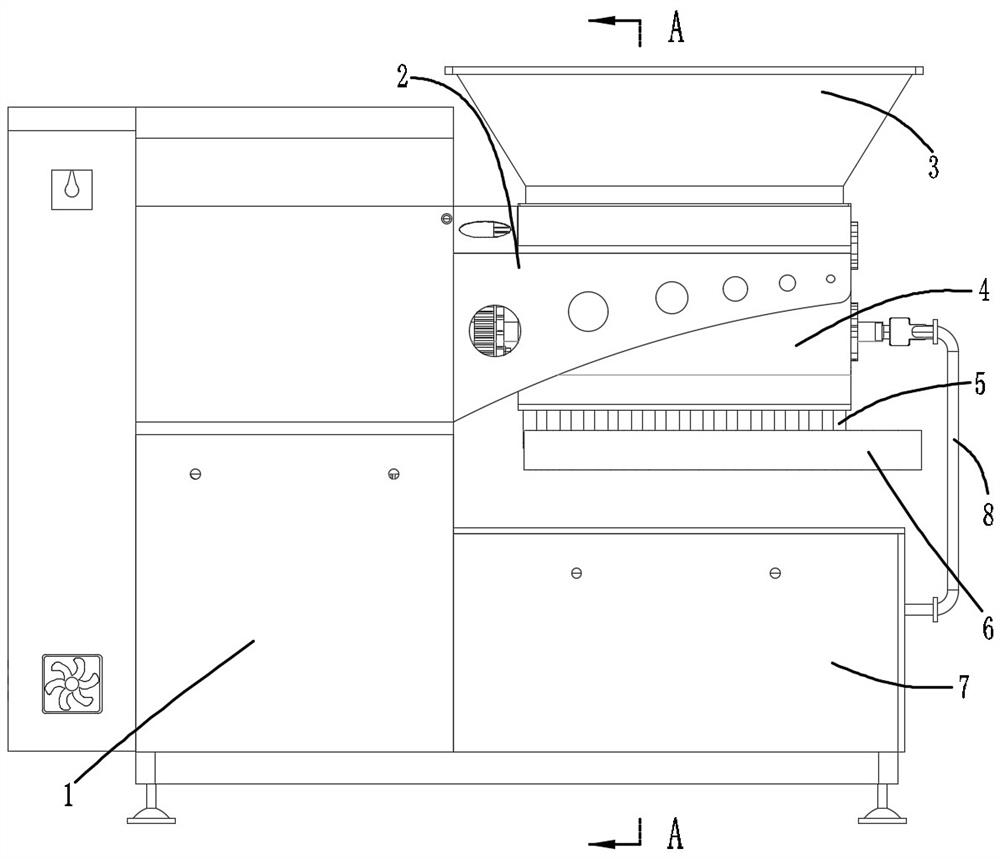

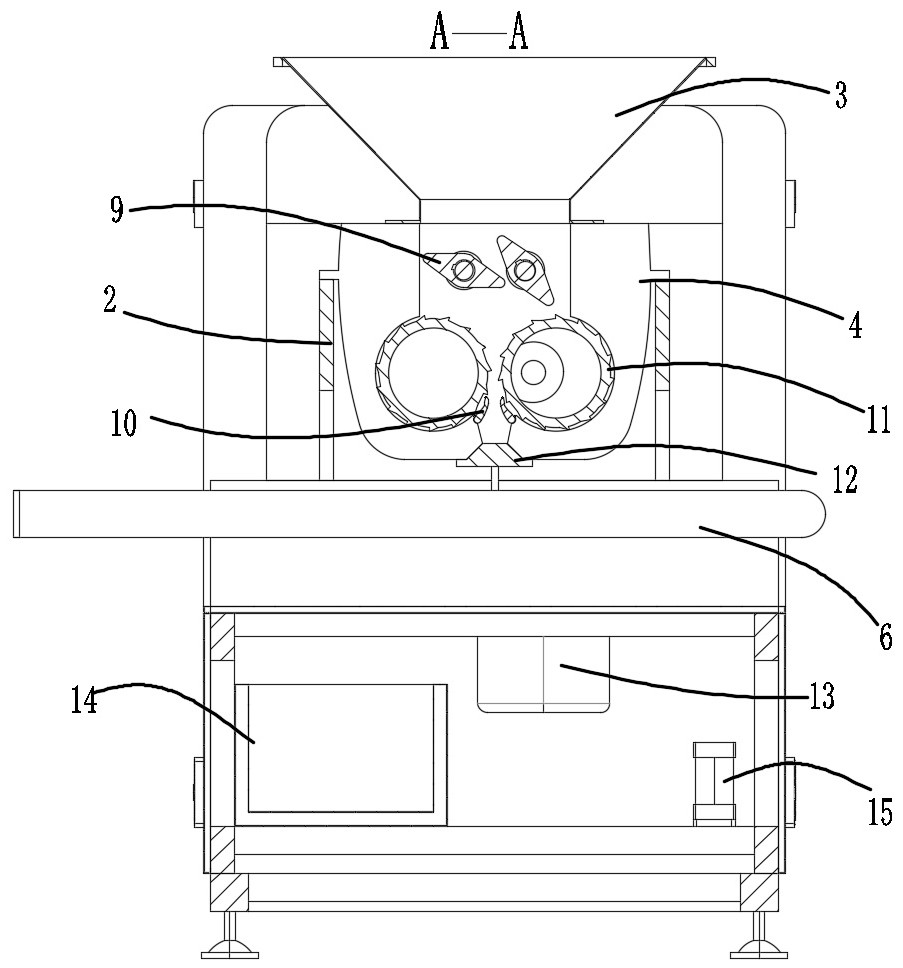

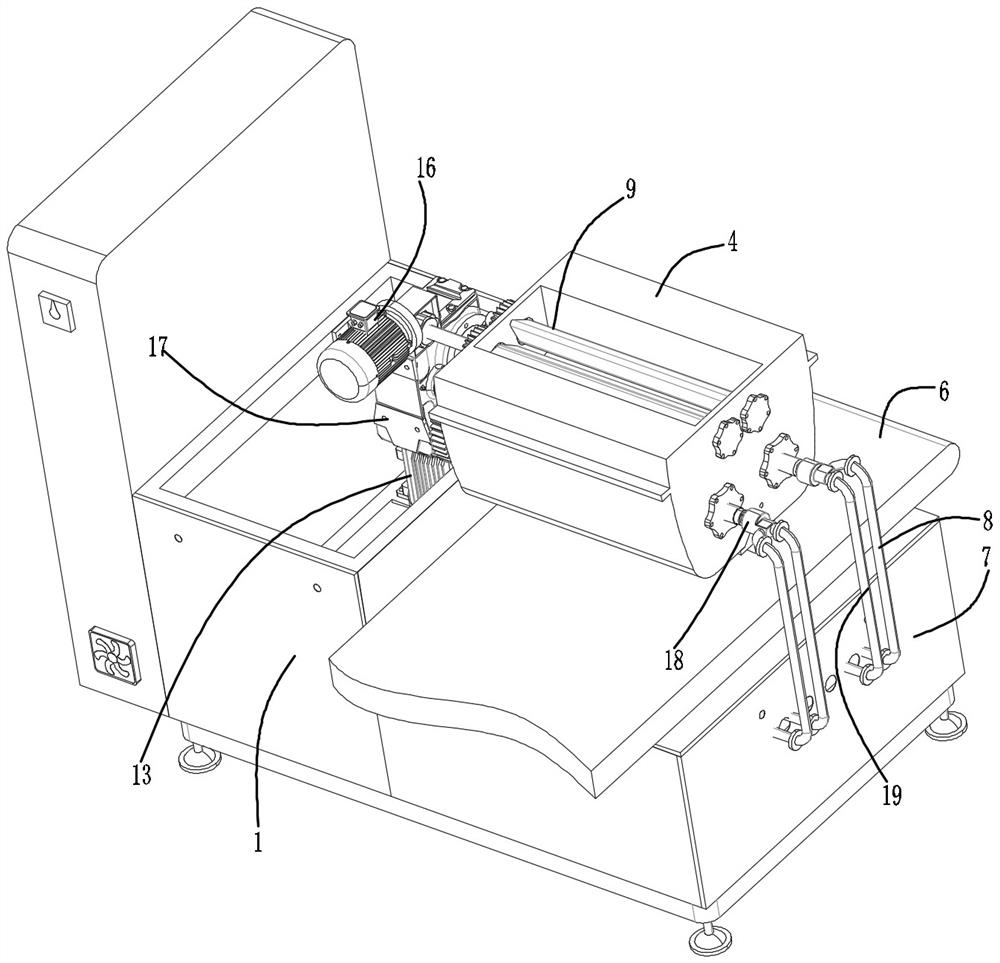

[0029] With reference to the drawings, the viscosity material extruder is used for extruding and discharging sugar material with a certain viscosity, so as to form the sugar material. The structure of the extruder includes a frame 1, one side of the frame 1 is a counterweight, and the other side is provided with two cantilever arms 2 extending in the horizontal direction, and the two cantilever arms 2 clamp the hollow silo 4. The upper and lower ends of the silo 4 are respectively provided with a feeding port and a discharging port, a hopper 3 is fixed at the feeding port, and a discharging mold 12 is provided at the discharging port. The sugar material is put into the hopper 3, and enters the silo 4 from the feeding port, and is formed and discharged in the discharging mold 12 at the discharging port. figure 1 , 2 It is shown in the discharge mold 12 that the material is discharged in the form of forming a plurality of candy bars 5, or it can be discharged in the form of a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com