Styrene Butadiene Rubber Finished Block Packaging Mechanism

A technology of styrene-butadiene rubber and finished products, which is applied in the direction of packaging, can solve the problems of not being able to adapt to packaging well, and achieve the effects of convenient packaging, improved work efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

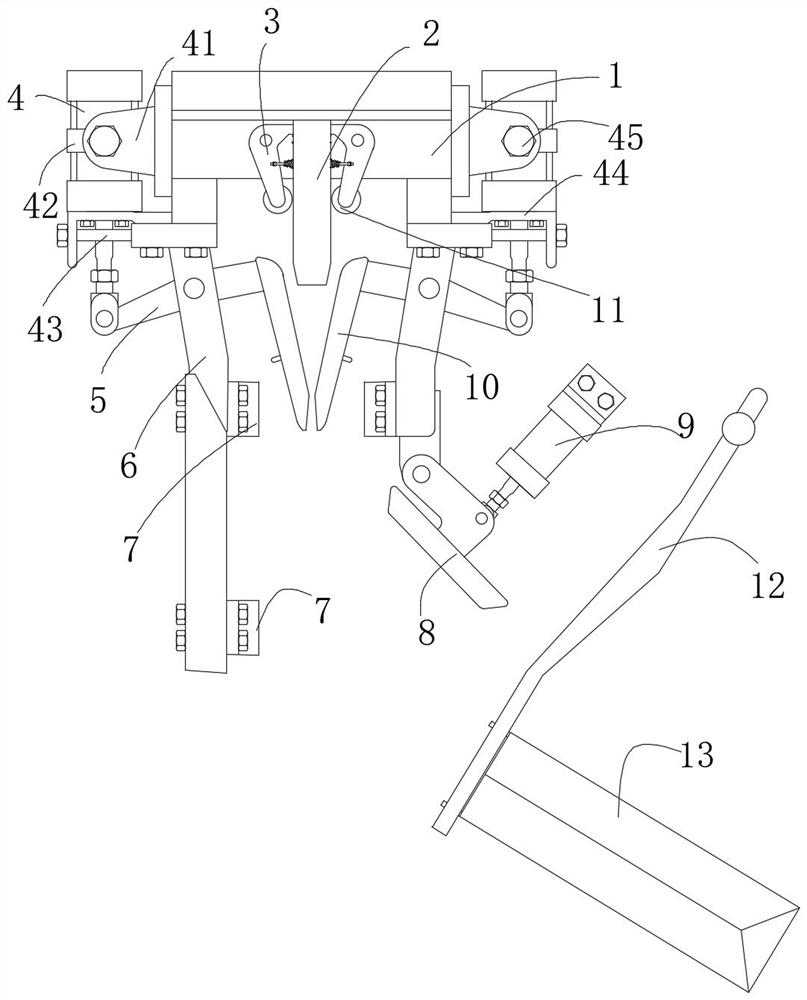

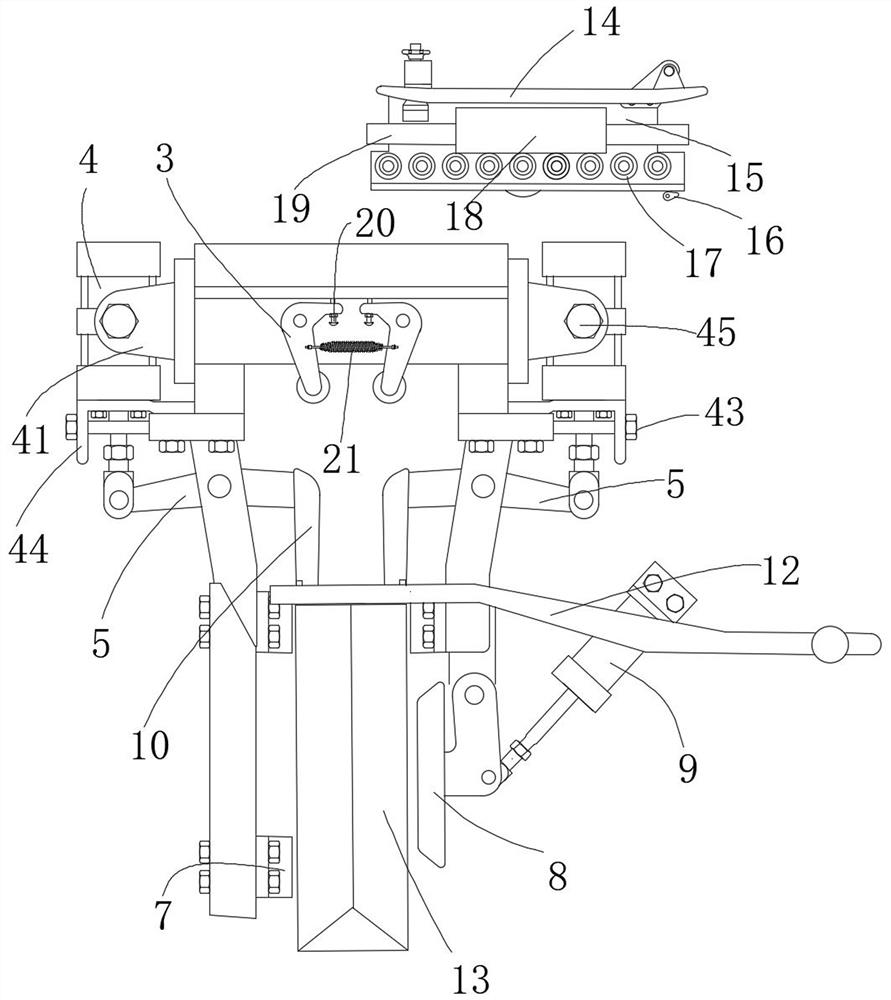

[0029] In conjunction with the accompanying drawings, this styrene-butadiene rubber finished product block packaging mechanism is arranged on the outlet end side of the production line, and is used to receive the finished product block 18 made on the production line, and utilizes the packaging bag 13 to pack the finished product block 18, and the finished product block After 18 suits are finished, packaging bag 13 is transported to the outside and accepts the sewing sealing of machine sewing equipment.

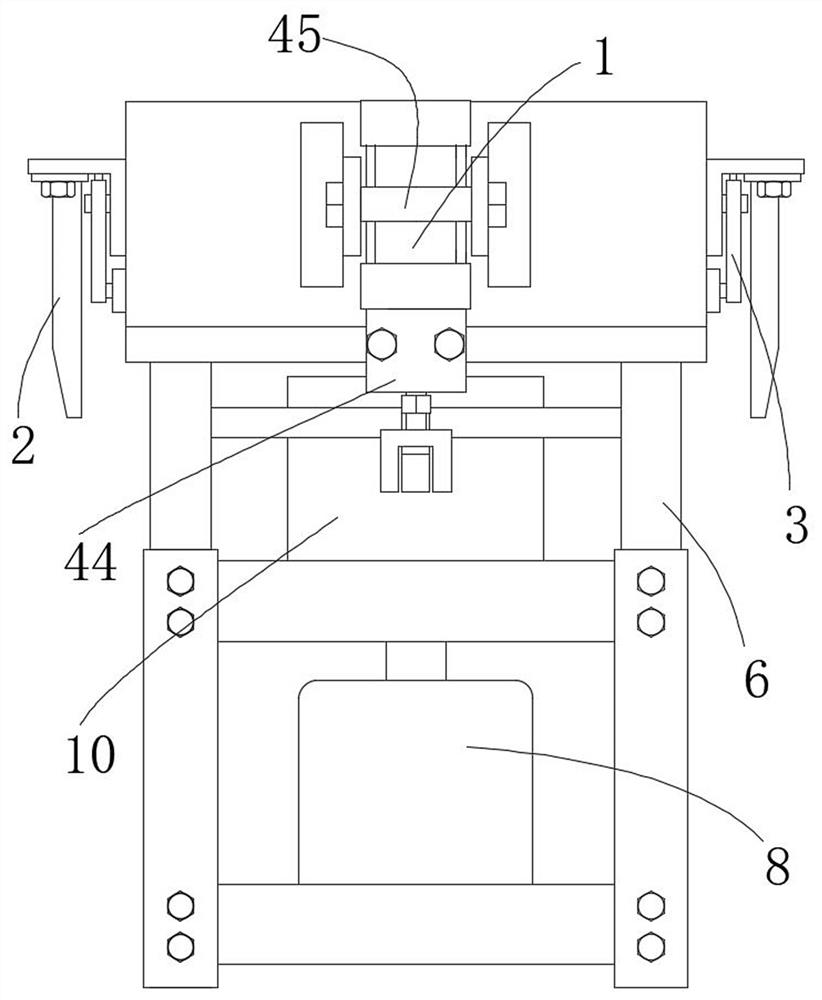

[0030] The structure of this packaging mechanism includes a connecting seat 1, which is set up high. The connecting seat 1 has a side wall, and the inner side of the side wall is surrounded by a cavity. A conveying channel for the finished product block 18 is formed in the cavity. The conveying channel Set in the vertical direction. Two hanging frames 6 are fixed on the lower end surface of the connecting seat 1, and the hanging frames 6 protrude downward in the vertical direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com