Spiral ring belt type barnyard manure crushing and scattering mechanism

A spiral ring and spiral technology, which is applied in the field of spiral ring belt manure crushing and spreading mechanism, can solve the problems of drop, harm, lack of application ratio, etc., and achieve the effect of good work continuity, low cost and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

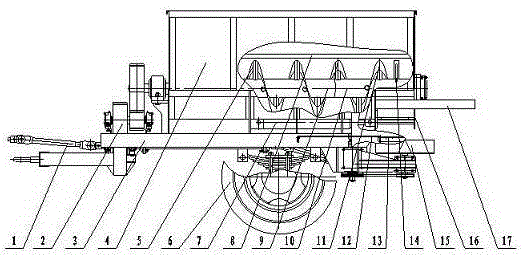

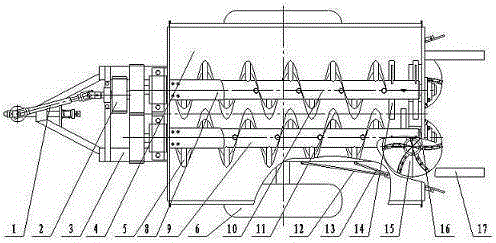

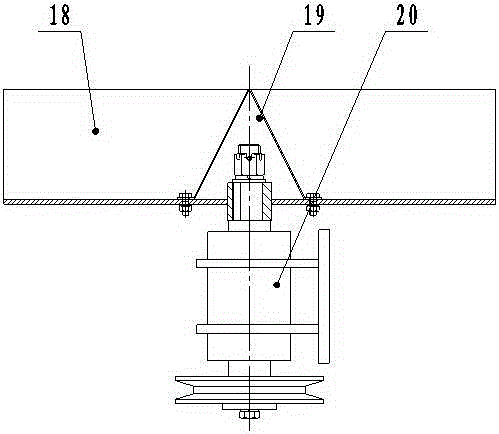

[0014] As can be seen from the accompanying drawings, the fertilizer box 4 is installed horizontally on the frame 3, and the main transmission shaft 9 and the driven transmission shaft 10 are installed below the fertilizer box 4 in parallel, corresponding to the bottom surface of the ω-shaped box body. The spiral ring belt 11 is symmetrically and interlacedly installed on the driving transmission shaft 10 through the spiral support 5. The spiral ring belt 11 rotates in the opposite direction on the two transmission shafts, and the longitudinal circumferential surfaces intersect. The ends of the main transmission shaft 9 and the driven transmission shaft 10 are symmetrically staggered and broken Teeth 14, the inside of the fertilizer box 4, and the upper part of the spiral ring belt 11 are equipped with buffer beams 8, and the bottom of the fertilizer box 4 is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com