Automatic lead inserting device for mould pressing forming combined fireworks

A combination of fireworks and compression molding technology, which is applied in pyrotechnics, weapon types, offensive equipment, etc., can solve the problems of not being able to adapt to the insertion and introduction of compression molding combined fireworks, and achieve high production efficiency, good work continuity, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

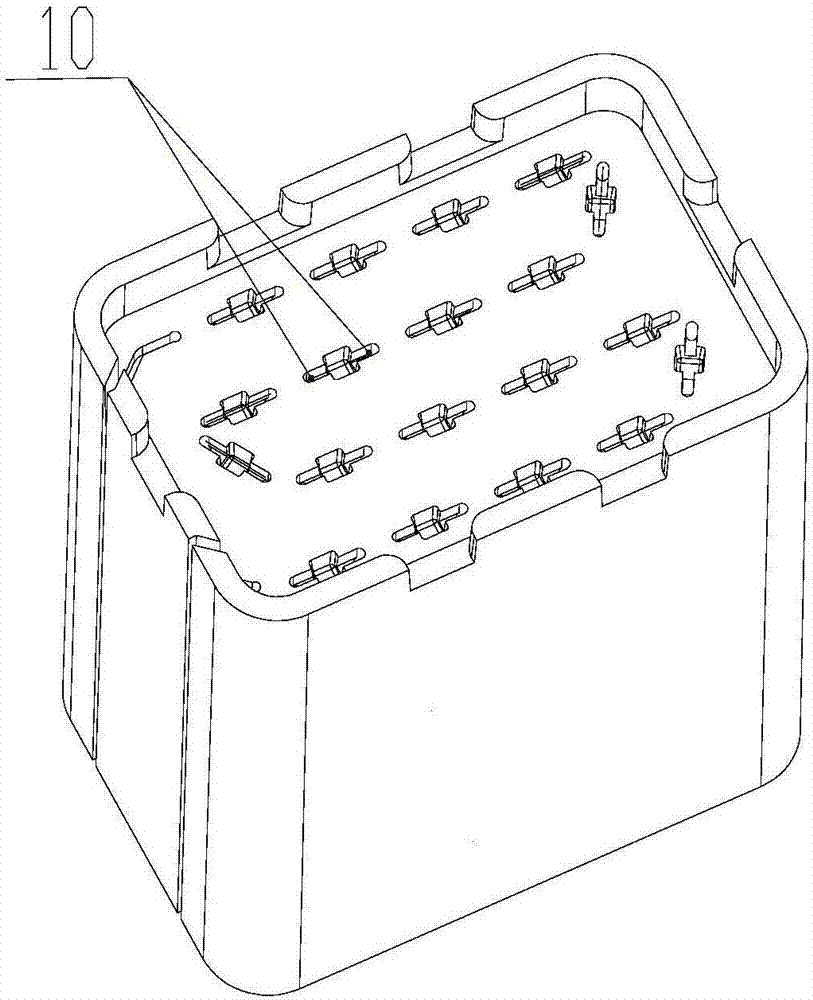

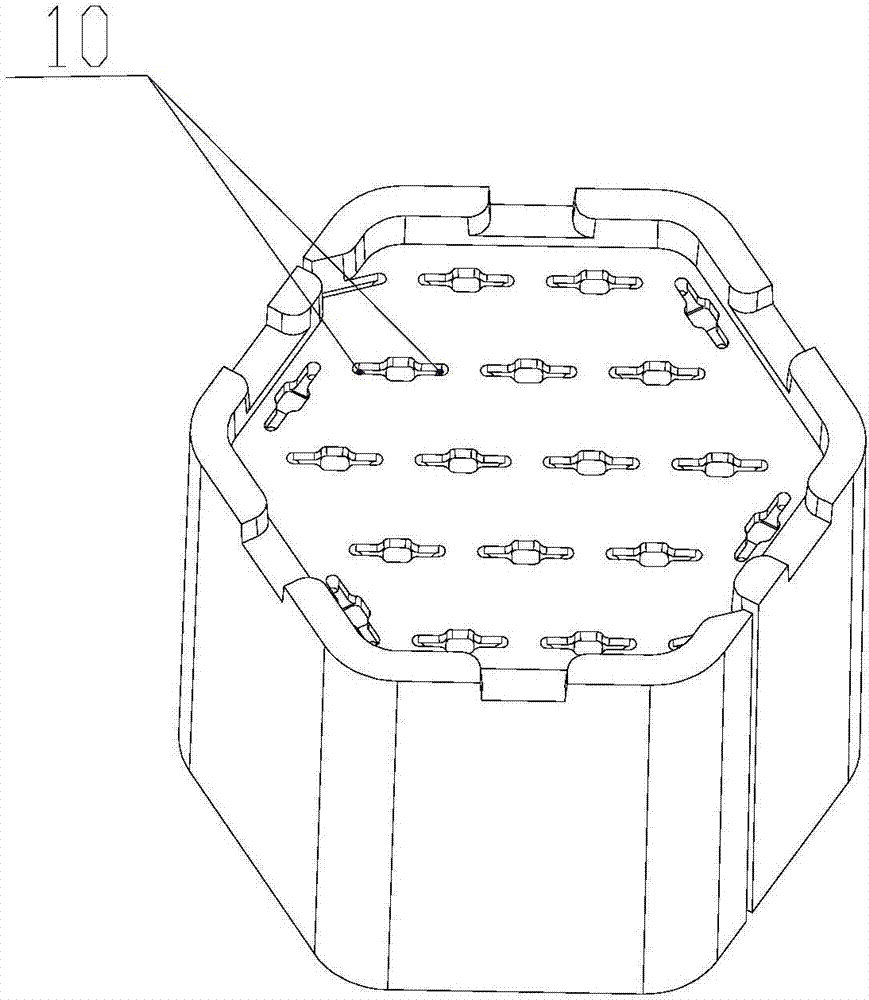

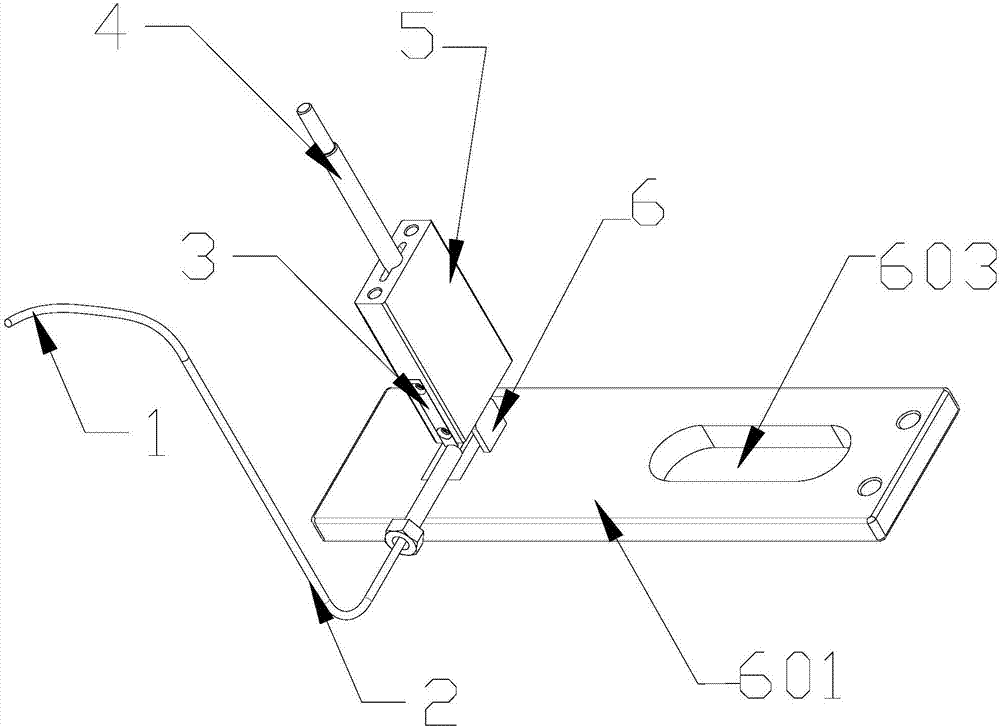

[0041] Embodiment 1: see attached Figure 3-6 , reflecting a specific structure of the present invention, the automatic insertion device for molding combined fireworks is composed of a wire conveying mechanism, a wire cutter 3, a folding sleeve 5, a folding punch 4, and a folding plate 6 : the folding sleeve 5 is connected to the first driving mechanism to reciprocate up and down, and the folding sleeve 5 is provided with a folding groove cavity 501 that runs through the up and down direction of the body.

[0042] The folding punch 4 is connected to the second driving mechanism to reciprocate up and down, the folding punch 4 is set in the folding groove 501 , and the lower end of the folding punch 4 is provided with a pressing head 401 .

[0043]The folding plate 6 is installed on the base plate 601, and the base plate 601 is connected to the third driving mechanism through the driving notch 603 to reciprocate laterally, driving the folding plate 6 to switch positions between ...

Embodiment 2

[0048] Embodiment 2: see attached Figure 7 , the difference from Embodiment 1 is that the device also includes a lead wire connection mechanism: a connection sleeve 703 is correspondingly arranged on the opposite side of the lead wire input end, and the connection sleeve 703 is connected to the fourth driving mechanism in the direction toward the lead wire input end reciprocating motion.

[0049] When the lead wire delivery mechanism transports the lead wire 701 between the guiding sleeve and the folding plate through the guiding tube 702, the connecting sleeve 703 moves from the original starting point toward the end of the guiding tube 702, and the port of the guiding sleeve 703 Docking with the port of the infusion tube 702, the lead wire 701 enters the connecting sleeve 703; after the lead wire conveying mechanism is finished feeding, the connecting sleeve 703 moves in the reverse direction but does not return to the original starting point, so that the end of the lead wi...

Embodiment 3

[0050] Embodiment 3: see attached Figure 8-11 , an insertion and introduction unit is composed of a lead wire conveying mechanism, a lead wire receiving mechanism, a lead wire cutter 828, a folding lead sleeve, a folding lead punch, and a folding lead plate, and eight insertion and lead units are arranged side by side, wherein:

[0051] The folding sleeves 804 of each insertion unit are jointly connected to the first driving mechanism (that is, two folding cylinders 826) and reciprocate up and down at the same time: the specific connection structure is that the folding cylinders 826 drive the eight folding sleeves 804 through the insertion positioning plate 810 .

[0052] The indexing punches 803 of each insertion unit are jointly connected to the second driving mechanism (that is, two insertion cylinders 806) and reciprocate up and down at the same time: the specific connection structure is that the insertion cylinder 806 drives eight indexing punches through the insertion p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com