Full-automatic hot-pressing membrane laminating assembly line for plywood and hot-pressing membrane laminating method thereof

A plywood, fully automatic technology, used in other household appliances, the joining of wooden veneers, flat products, etc., can solve the problems of high labor intensity, complex movements, and inapplicability of employees, so as to improve product quality and ensure worker safety. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

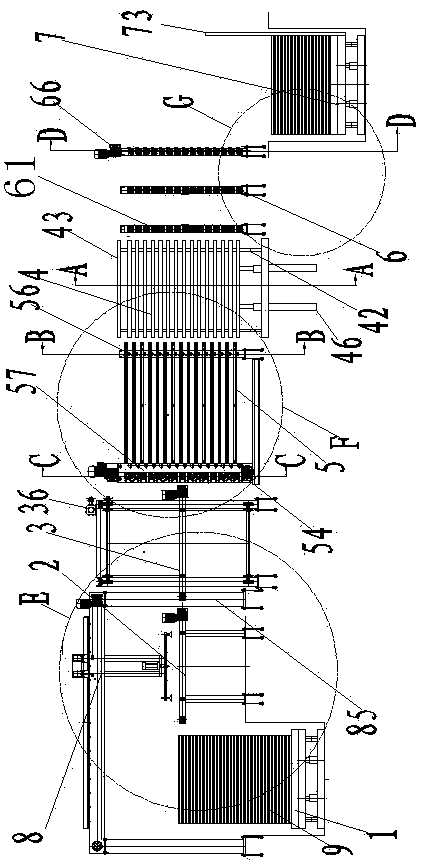

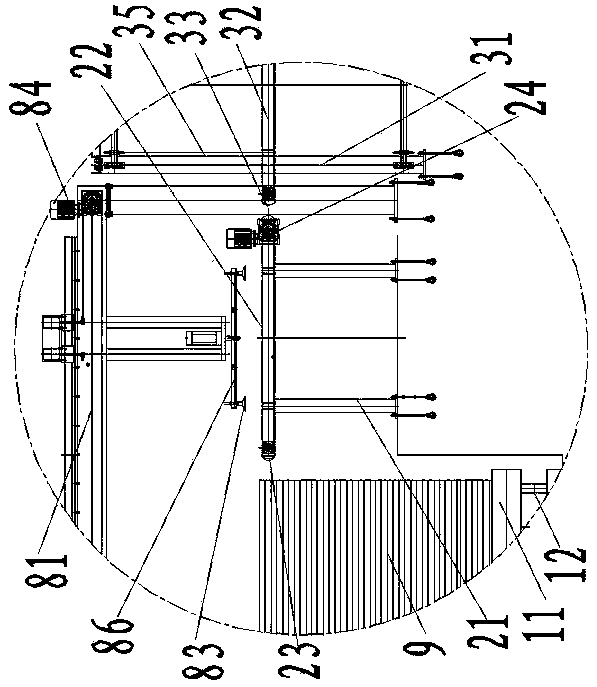

[0092] Example 1. Such as Figure 1-20 As shown in the figure, the plywood automatic hot-pressing and laminating line is characterized in that it includes an adsorption device 8, a film conveying device 2, a lifting conveyor 3, a loading machine 5, a hot press 4, and a cooling stand arranged in sequence from left to right. 6. The board receiving device 7, and the adsorption device 8 capable of feeding the film conveying device 2.

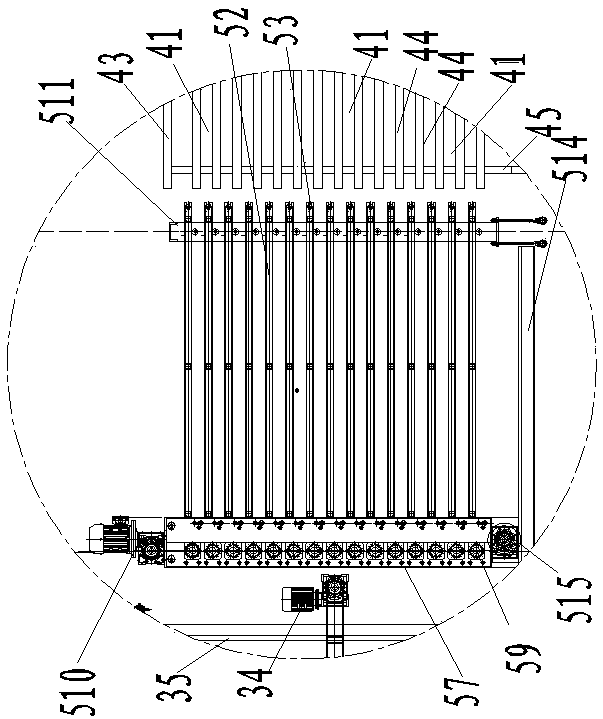

[0093] The board loading machine 5 is vertically arranged with the third plywood horizontal conveyor belt frame 52 with the same number as the hot-press chamber 41 of the hot-press machine 4 and the positions are respectively corresponding to the height of the hot-press chamber 41 of the hot-press machine 4 , on the cooling frame platform 6 Vertically arranged with the fourth plywood horizontal conveying device 61 which has the same number as the hot press chamber 41 of the hot press 4 and whose top surface position corresponds to the height of the...

Embodiment 2

[0120] Example 2. Such as Figure 24-28 As shown, the difference between this embodiment and the embodiment is that: the sliding block of the sliding guide rail 81 is provided with a liftable device 82 . Loading machine support frame 56 comprises two columns 511; Between the two columns 511 is provided with the same quantity as the third plywood horizontal conveyor belt frame 52 for rolling support each third plywood horizontal conveyor belt frame 52 and keeps its top surface level The scroll axis 512 of the state.

[0121] The fourth plywood horizontal conveying device 61 includes a number of turning rollers 62 installed on the cooling stand 6 with top surfaces on the same plane, each turning roller 62 of the same height is connected by a transmission chain 65, and the turning rollers 62 on the cooling stand 6 have three rows The front end of a row of rotating rollers 62 on the cooling frame platform 6 is fixed with a second electromagnetic clutch 63, and is movably connect...

Embodiment 3

[0122] Example 3. Such as Figure 29-30 As shown, the difference between this embodiment and the first embodiment is that the second plywood horizontal conveying frame elevating device includes a lifting support device 37 arranged below the second plywood horizontal conveying frame 32 and connected with the second plywood horizontal conveying frame 32 . Each third plywood horizontal conveyor belt frame 52 is respectively provided with a third conveyor belt 53 driving motor. The synchronous lifting device includes two sets of synchronous lifting arm assemblies, and the planes where the two synchronous lifting arm assemblies are located pass through the two ends of the front side of each hot pressing plate 44 respectively. The fourth plywood horizontal conveying device 61 comprises the turning rollers 62 installed on the same plane with some top surfaces on the cooling shelf platform 6, and each turning roller 62 of the same height is connected by an endless conveyor belt 67, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com