Patents

Literature

62 results about "Bilge pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bilge pump is a water pump used to remove bilge water. Since fuel can be present in the bilge, electric bilge pumps are designed to not cause sparks. Electric bilge pumps are often fitted with float switches which turn on the pump when the bilge fills to a set level. Since bilge pumps can fail, use of a backup pump is often advised. The primary pump is normally located at the lowest point of the bilge, while the secondary pump would be located somewhat higher. This ensures that the secondary pump activates only when the primary pump is overwhelmed or fails, and keeps the secondary pump free of the debris in the bilge that tends to clog the primary pump.

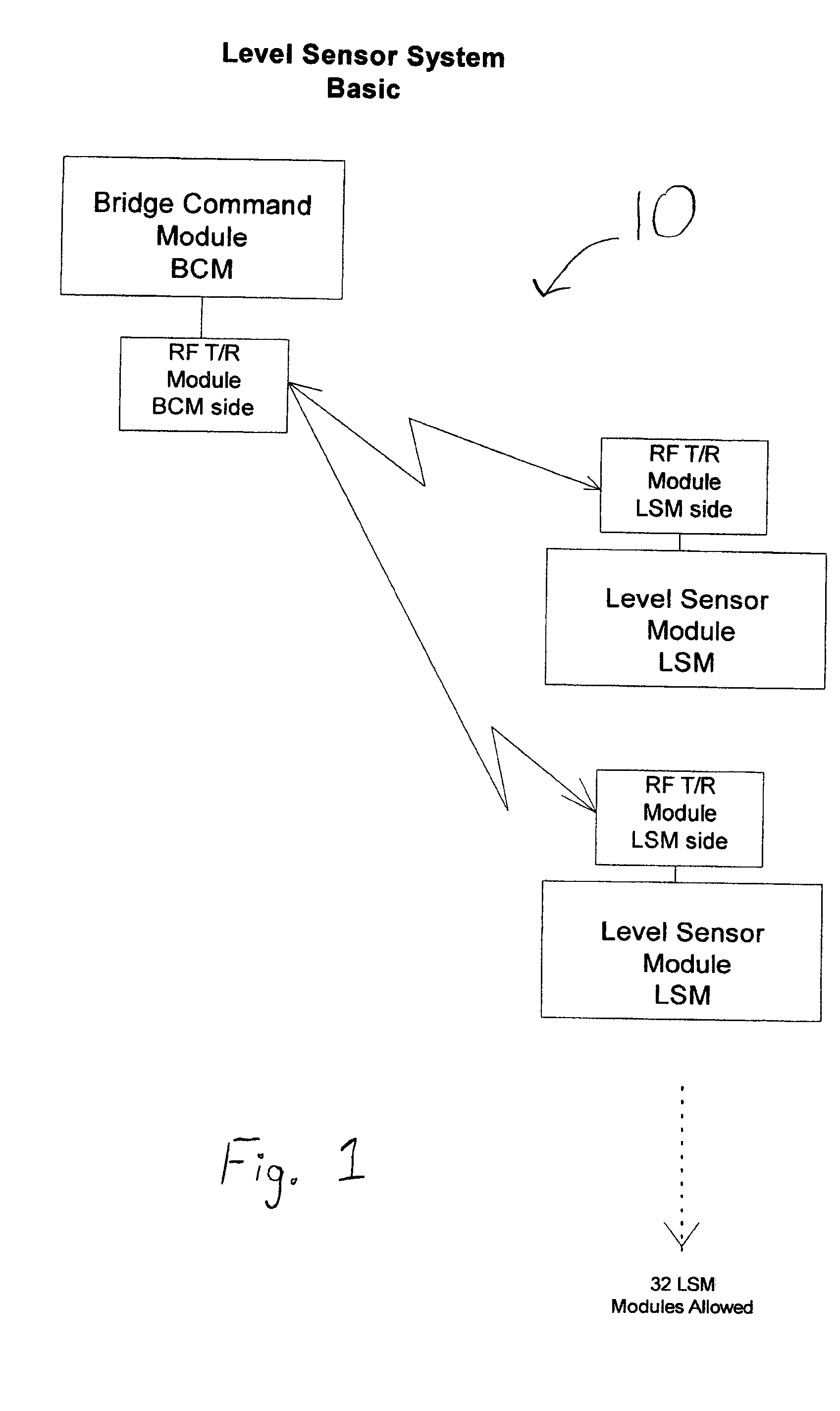

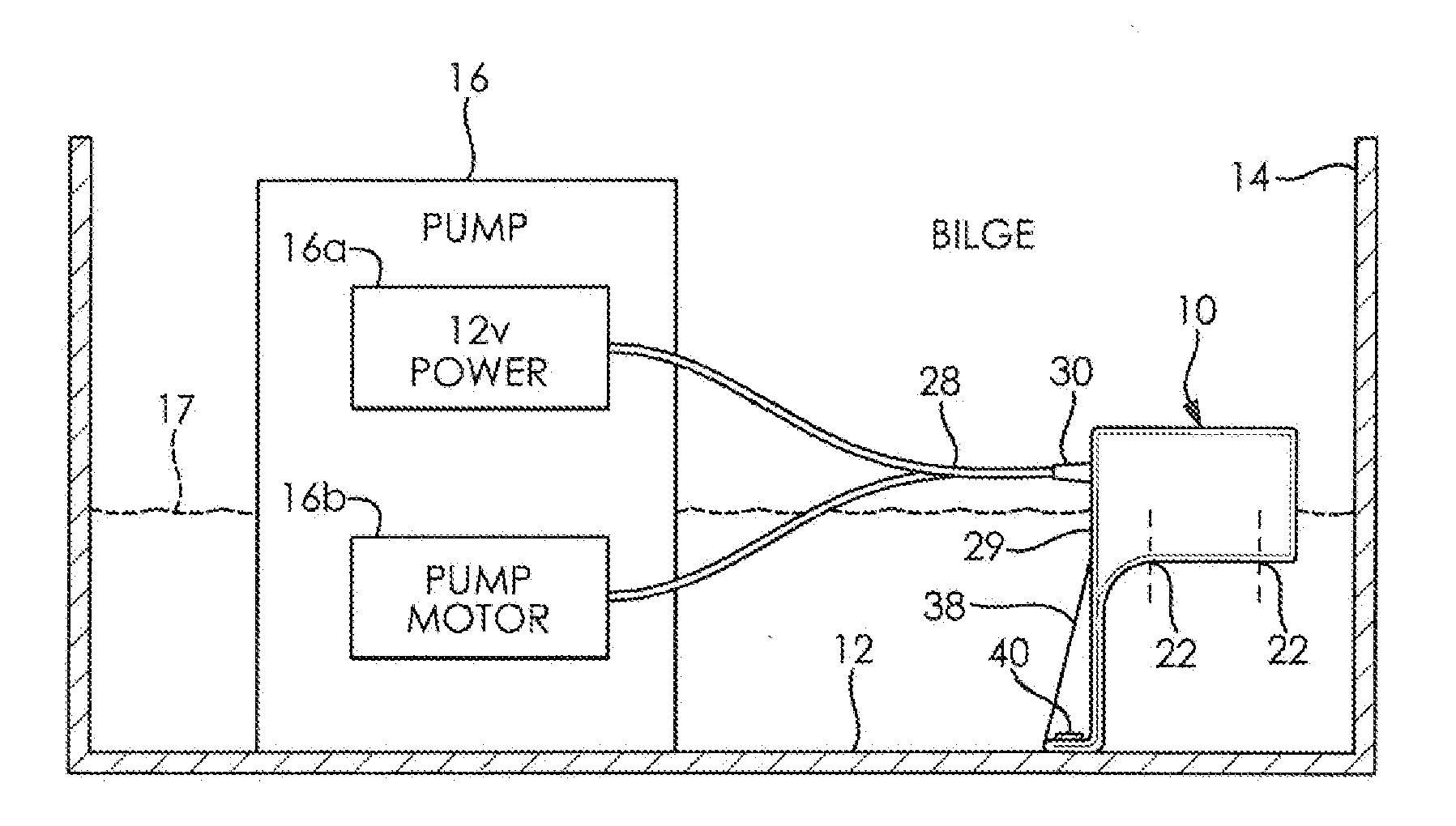

Level Sensor System

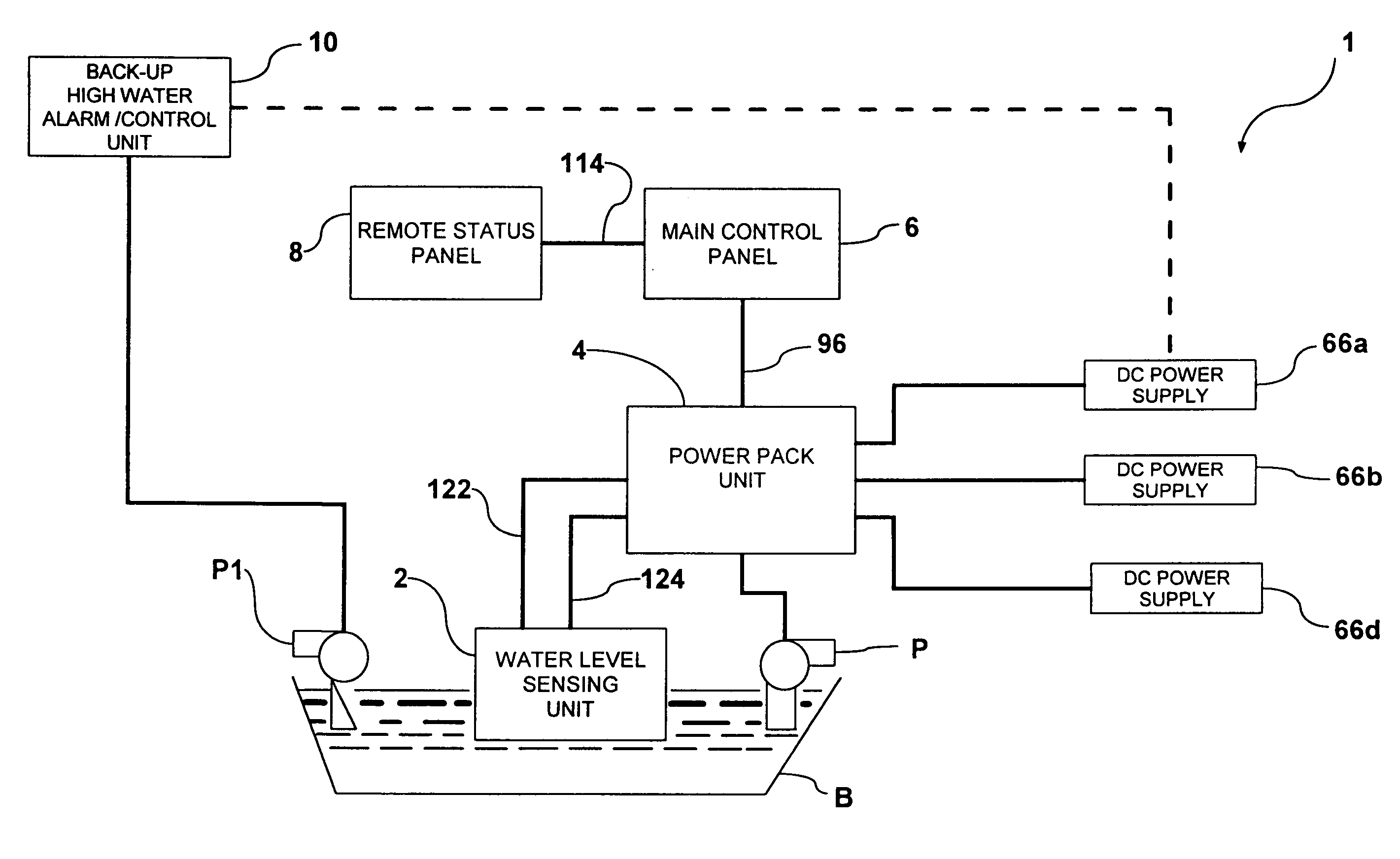

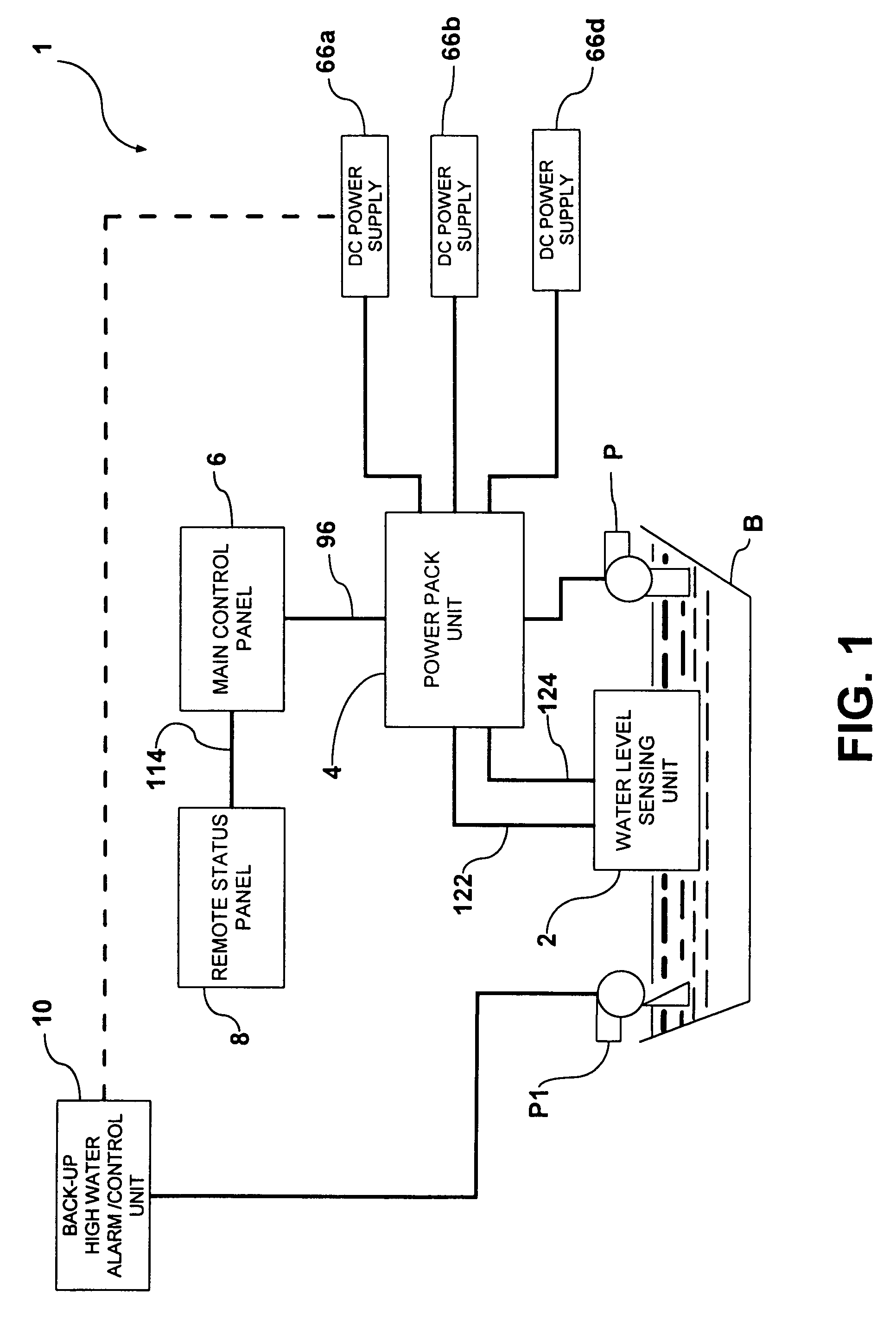

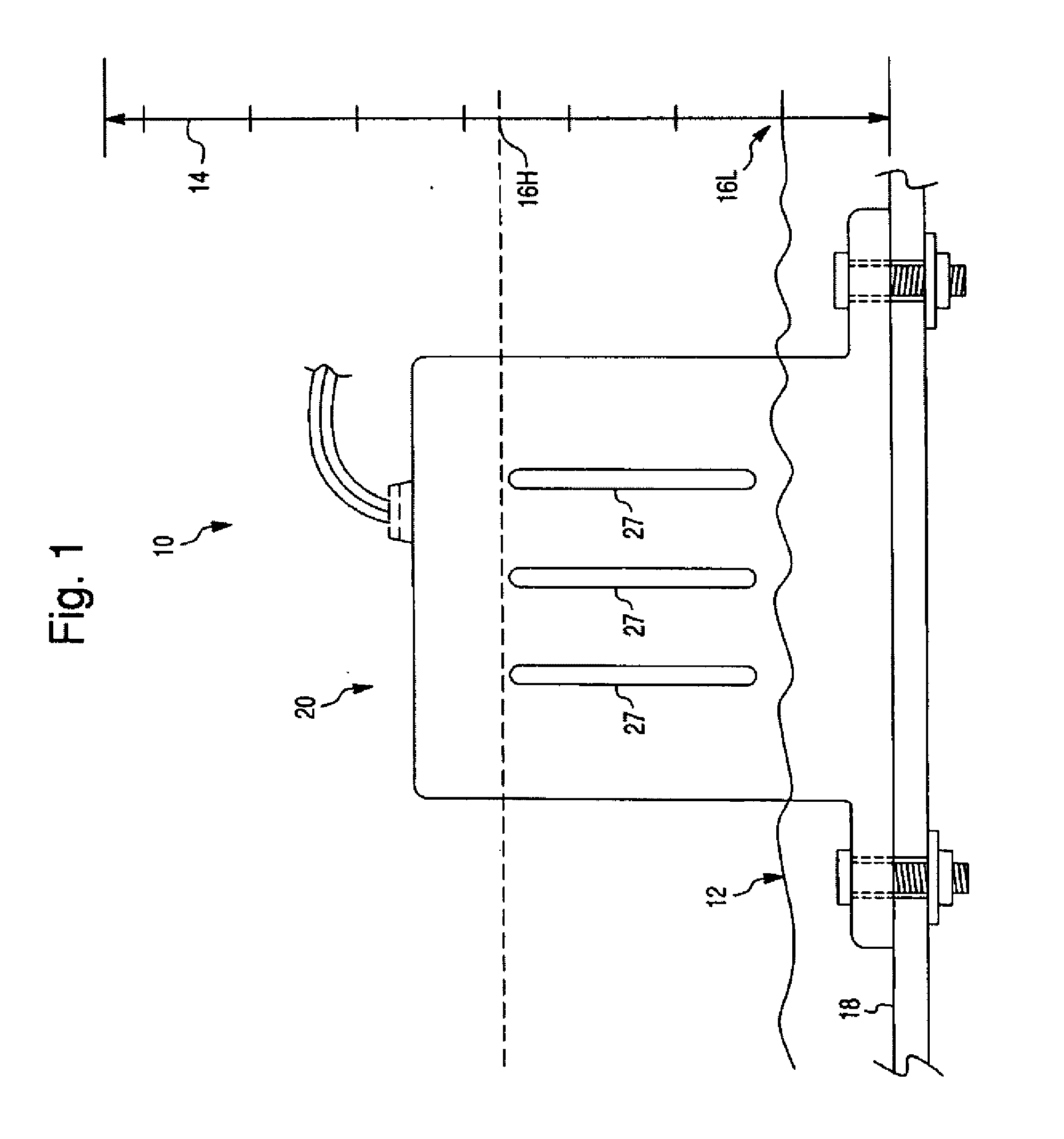

InactiveUS20100215511A1The result is accurateAuxillariesPump controlWireless transmissionAutomatic transmission

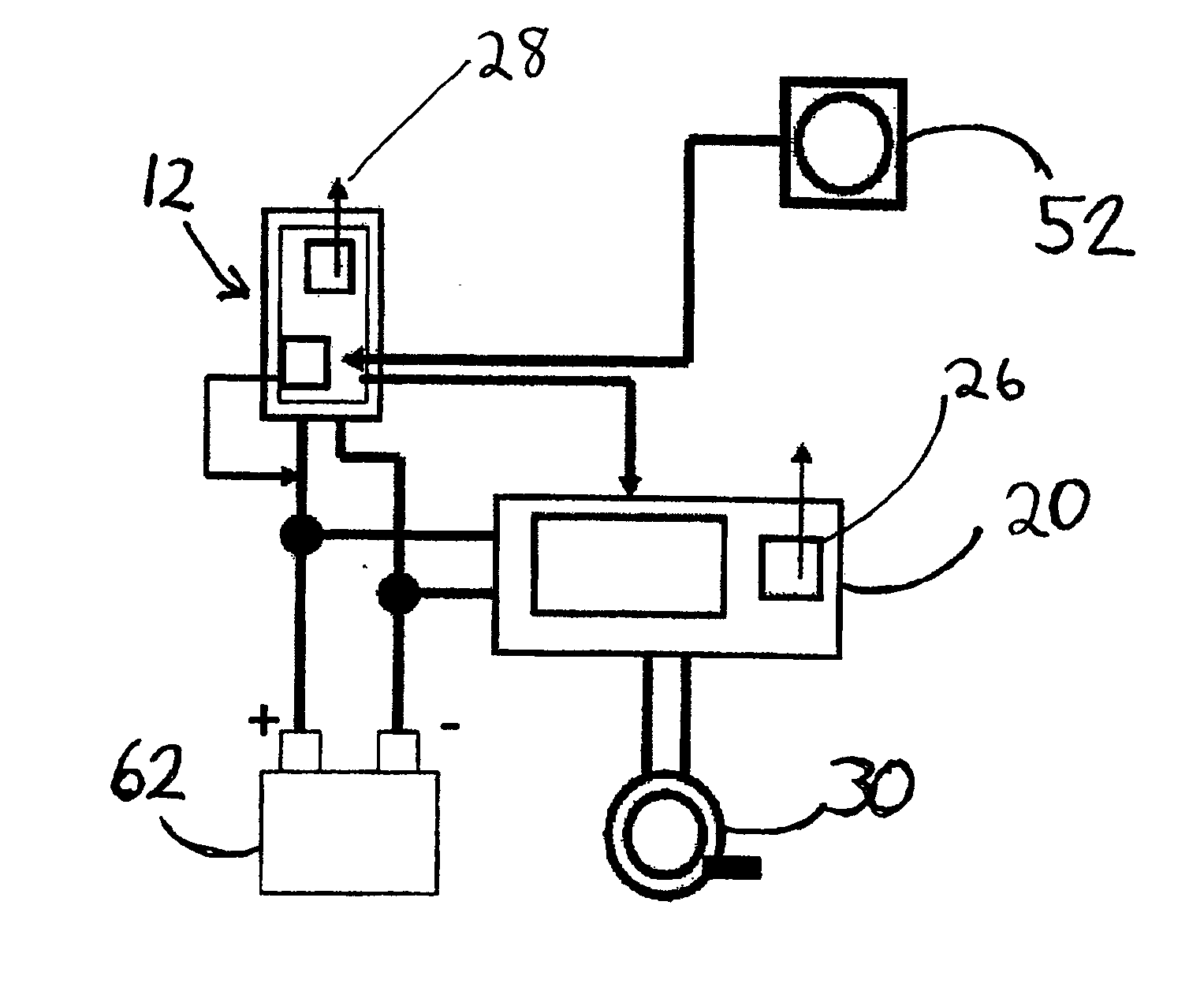

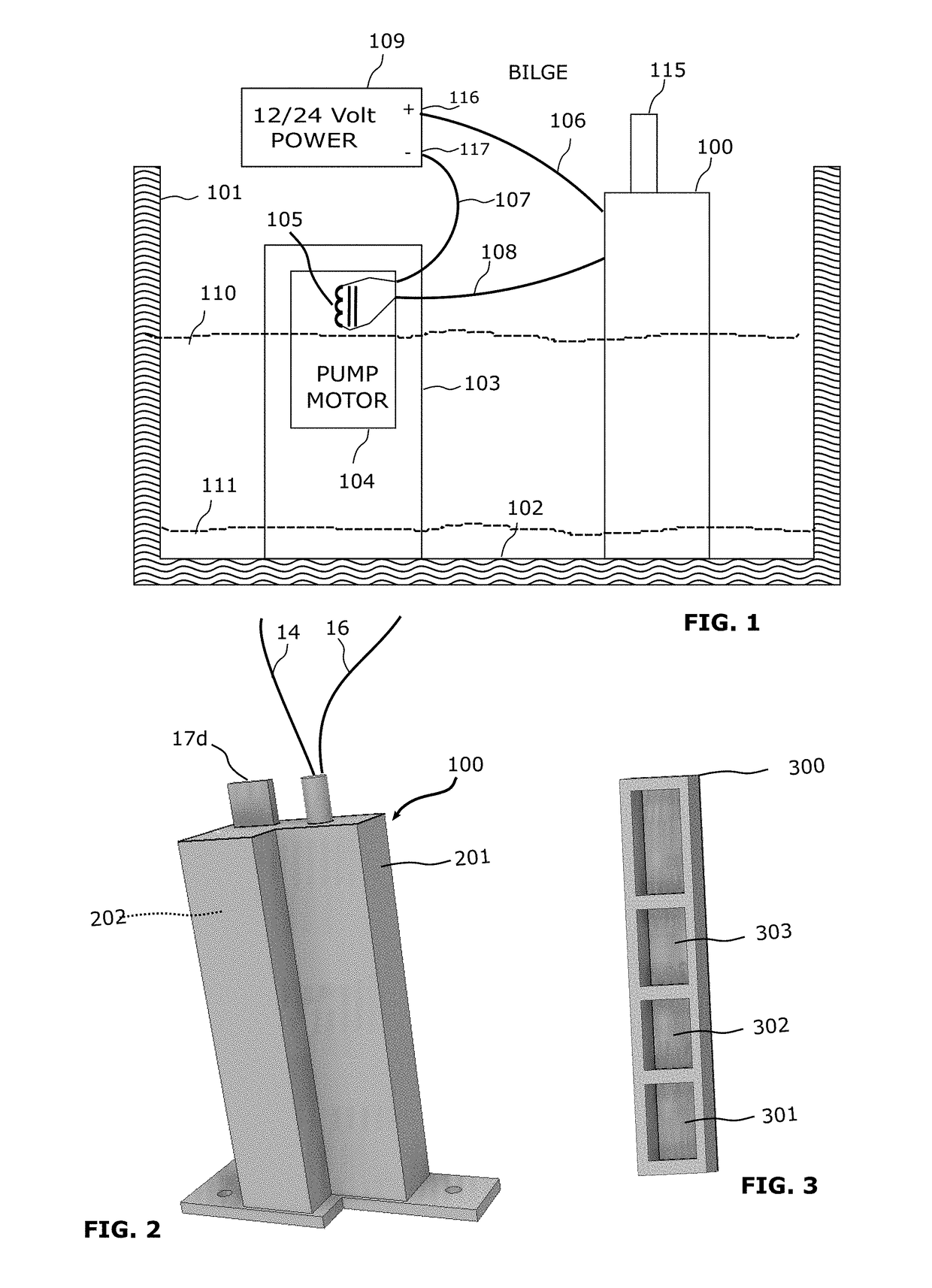

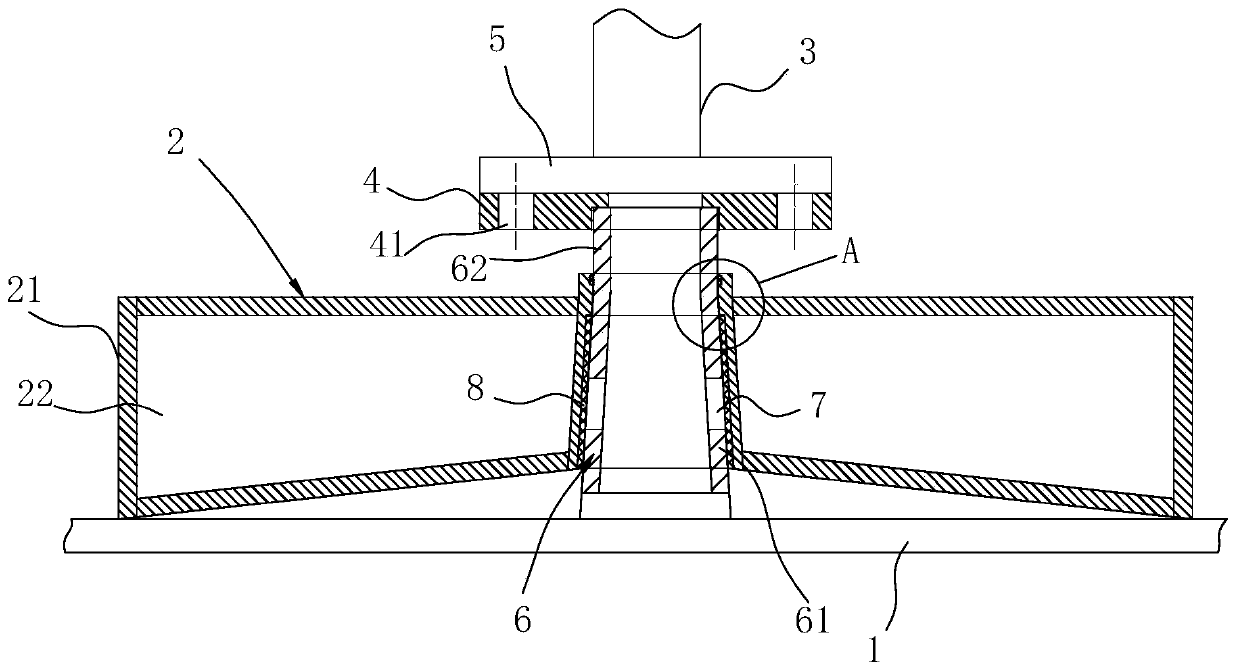

A system and method for turning on and off a bilge pump whereby bilge water level is detected using level sensors and bilge pumps are turned on and off based on the detected water level. The system further incorporates an automatic transmission outside the watercraft to alert of the water level in the bilge. The system is controllable from within the watercraft and remotely controllable through wireless transmission.

Owner:MOUNT EVEREST TECH

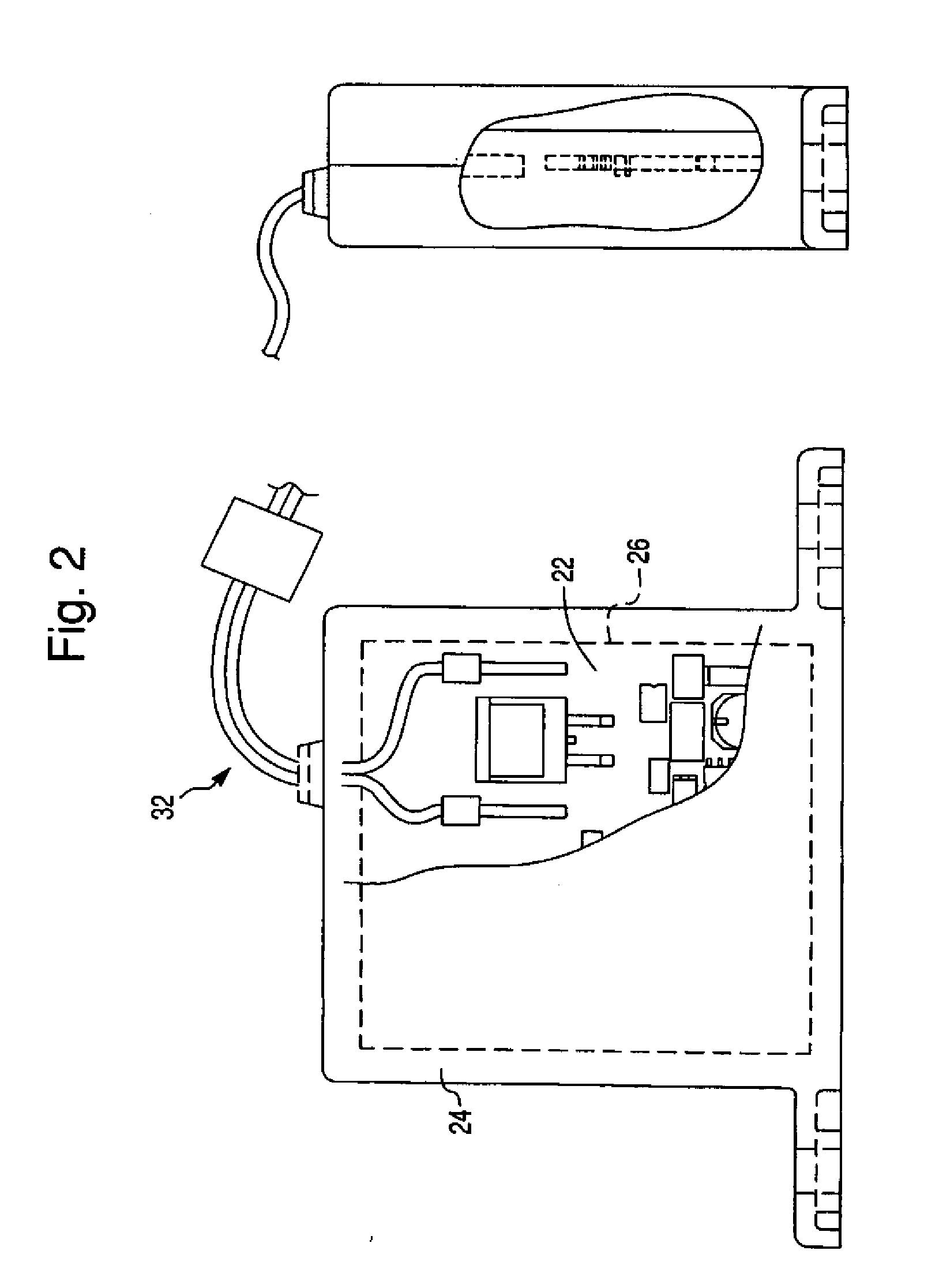

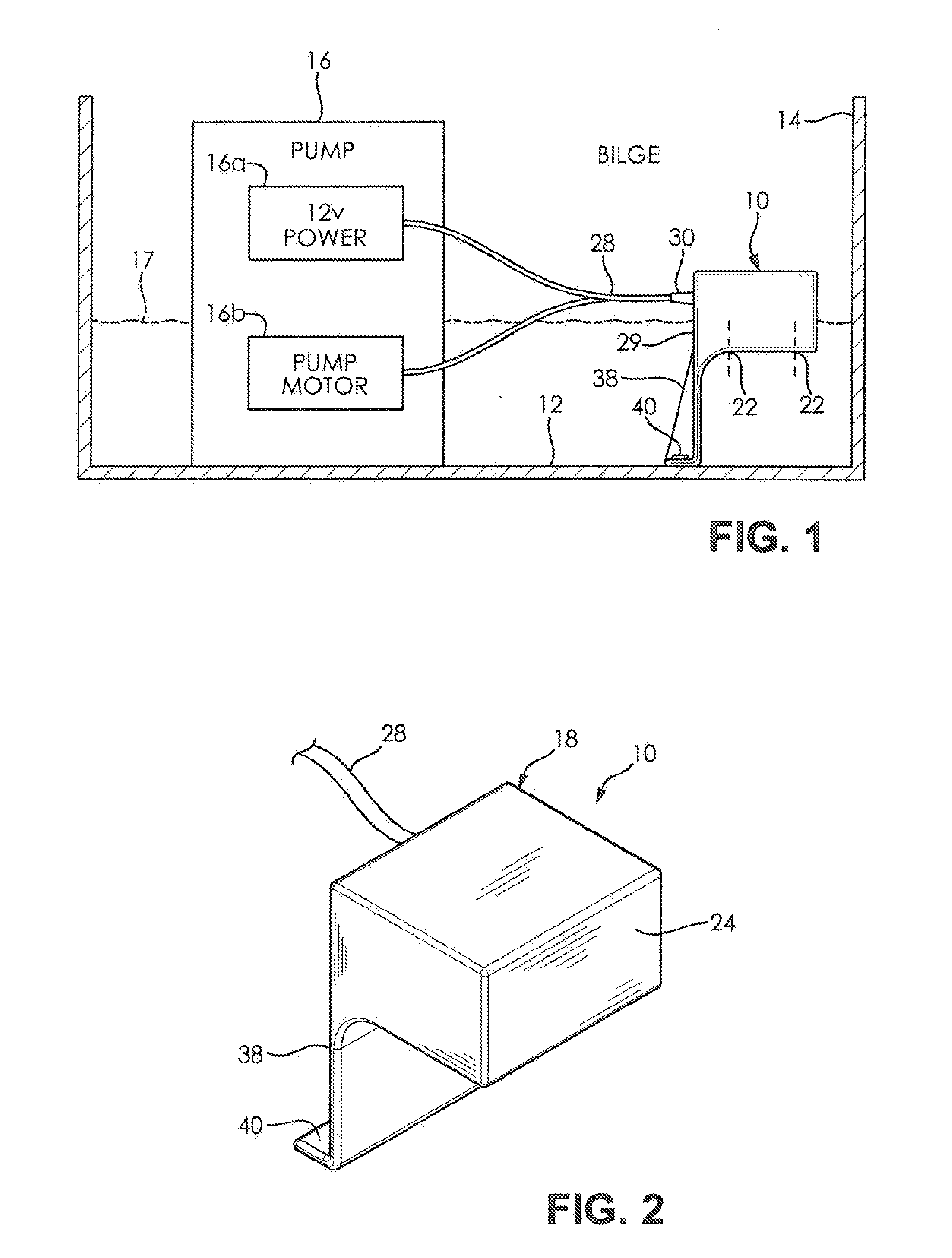

Solid state fluid level sensor

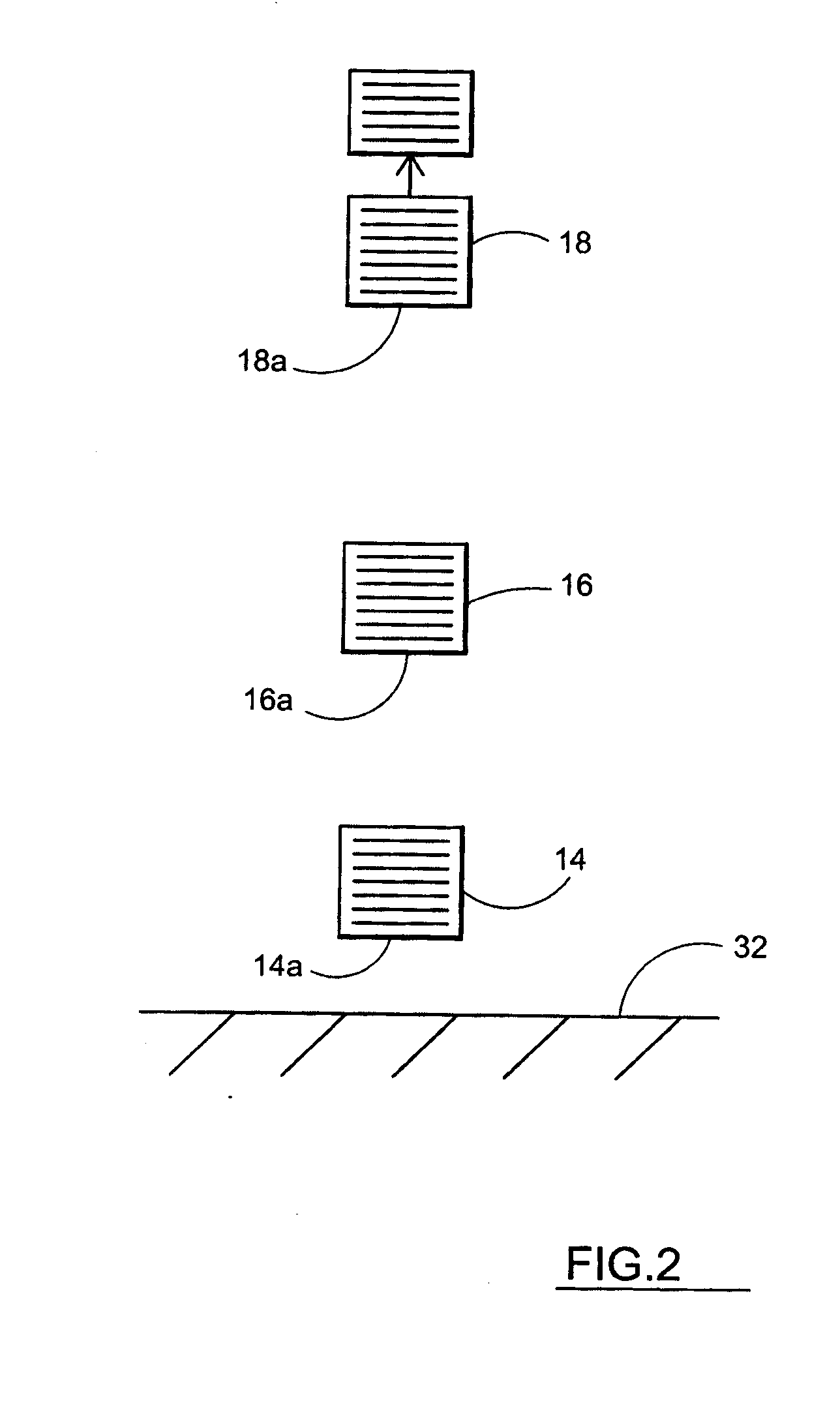

ActiveUS20060005622A1Prevent scalingResist attackPrinted electric component incorporationInspection/indentification of circuitsEngineeringVertical array

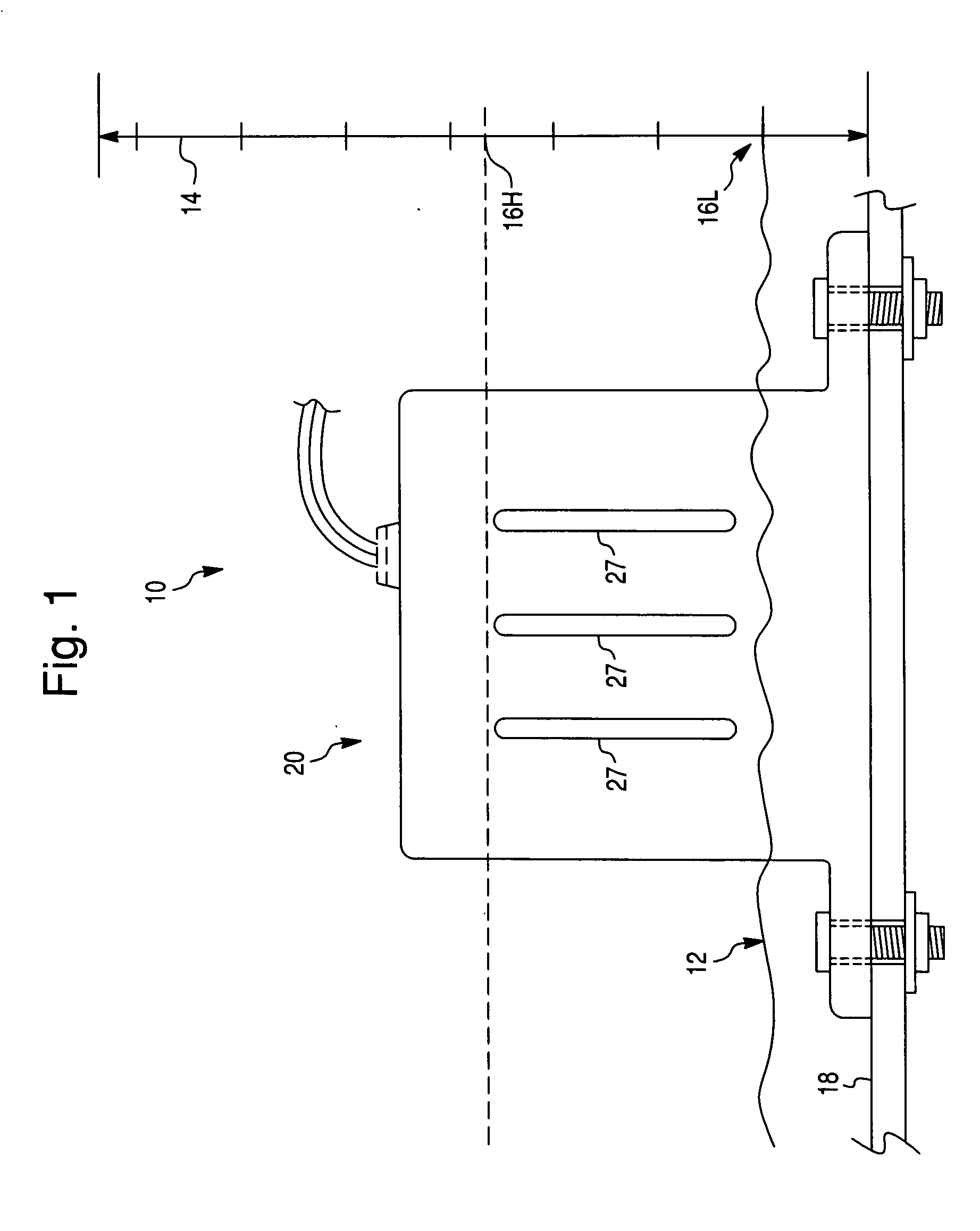

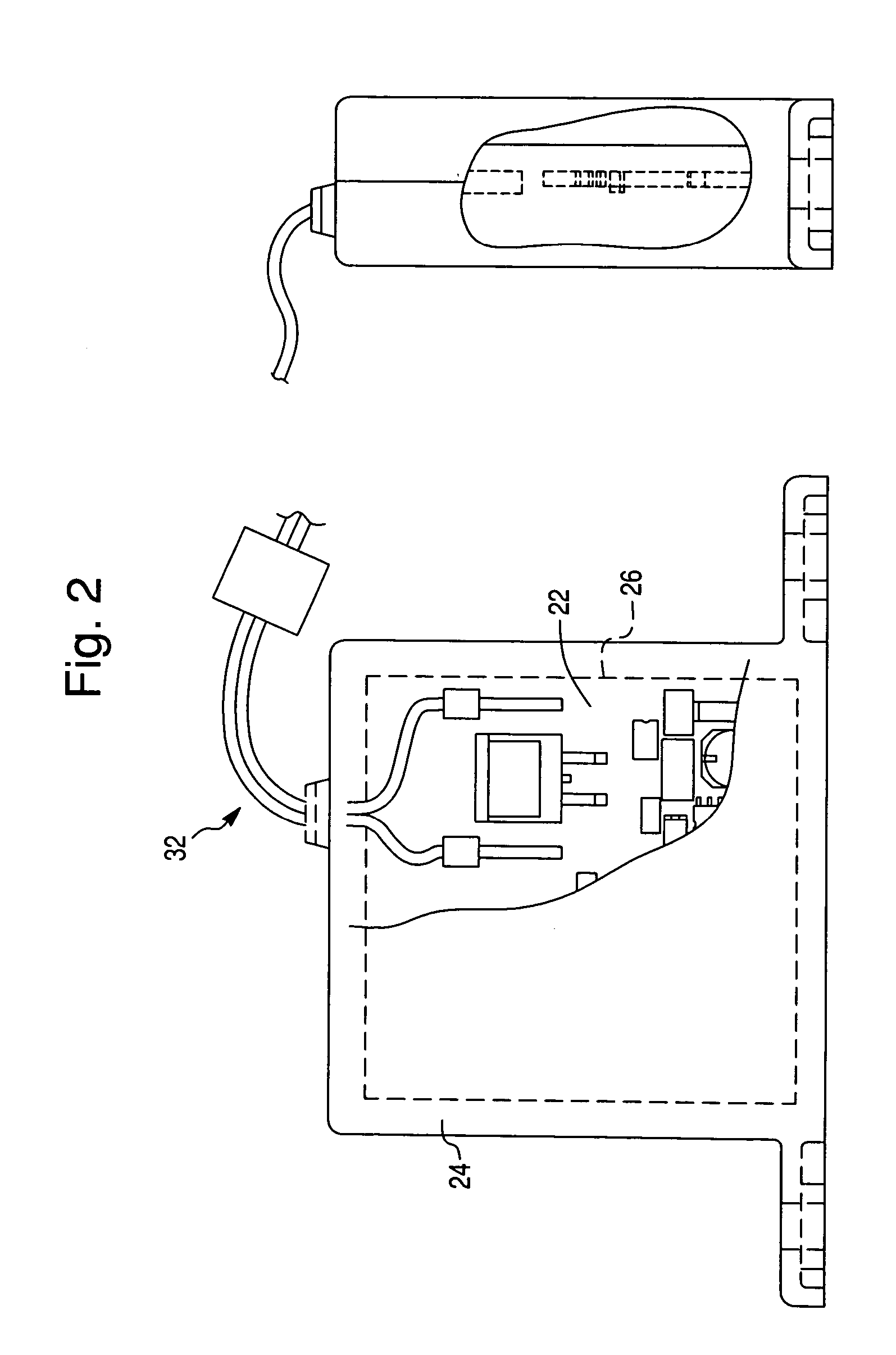

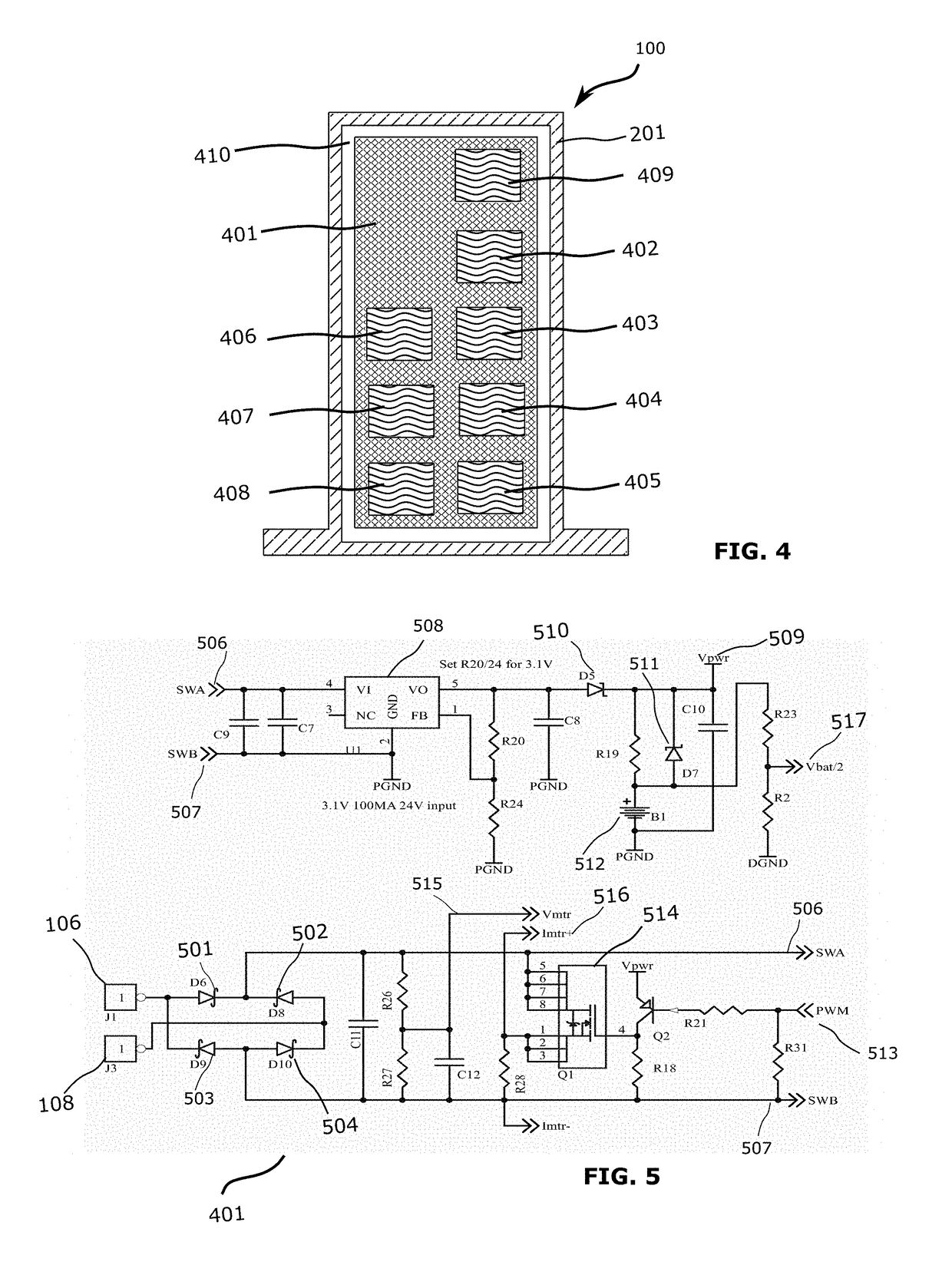

A sensor system for sensing liquid level in a bilge, for use in automatic bilge pump actuation. First and second field effect sensors are potted or sealed within a container or the bilge wall and are aligned in a vertical array and each comprise a substantially planar pattern of “electrodes” or conductive traces disposed on a printed circuit board (PCB) along with integrated circuits used to create a loop or arc-shaped electric field. As bilge liquid rises to the proximity or level of the field effect sensors, a change in the arc-shaped electric field is sensed and, in response, a bilge pump is automatically actuated to pump liquid out of the bilge. Optionally, the pump control can be programmed by use of a microprocessor to permit control of on-off timing and prevent undesirable effects of “sloshing.”

Owner:TOUCHSENSOR TECH

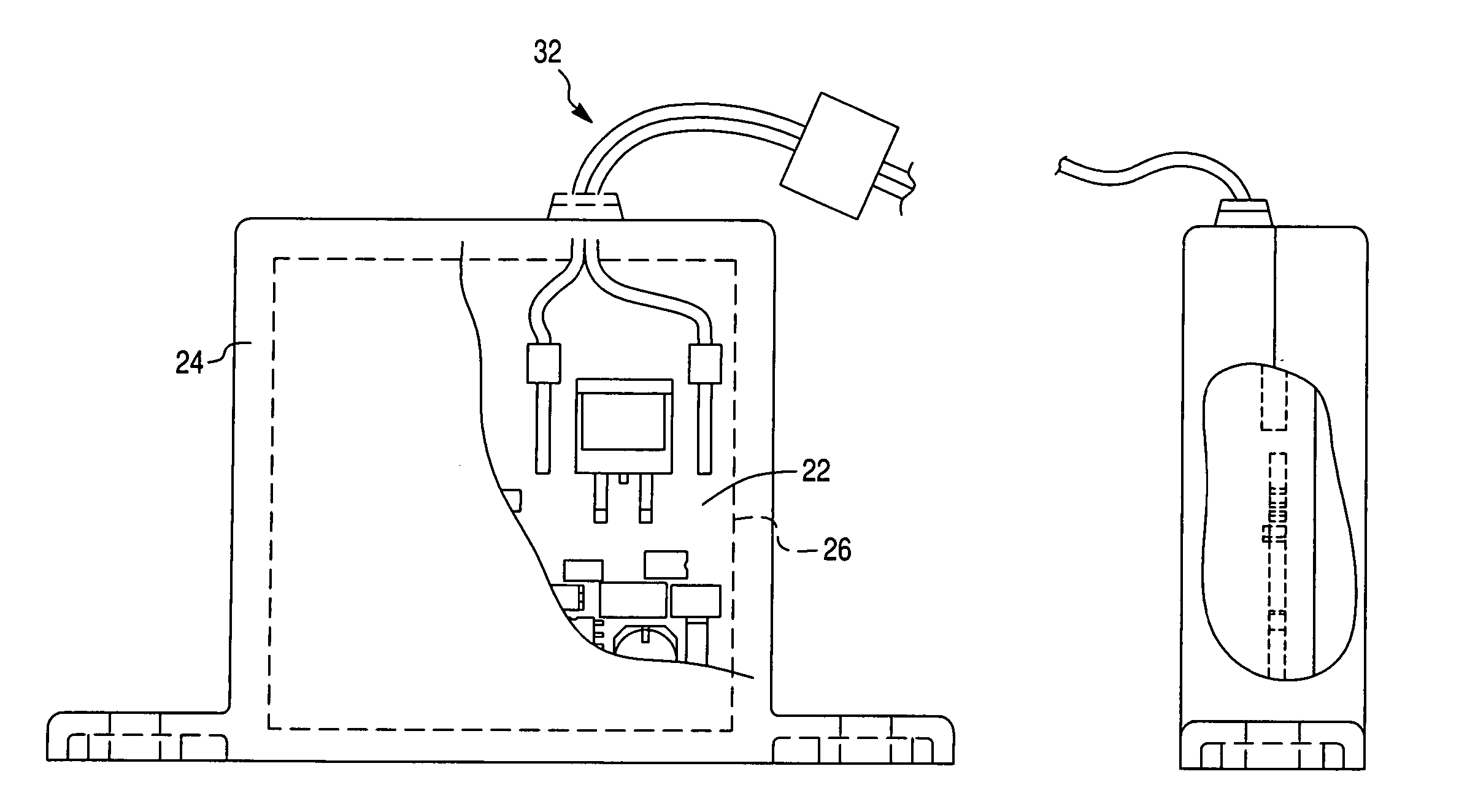

Method of and apparatus for detecting and controlling bilge water in a sea vessel

InactiveUS20090050042A1Reduce the possibilityAuxillariesSelf-bailing equipments/scuppersEngineeringSeawater

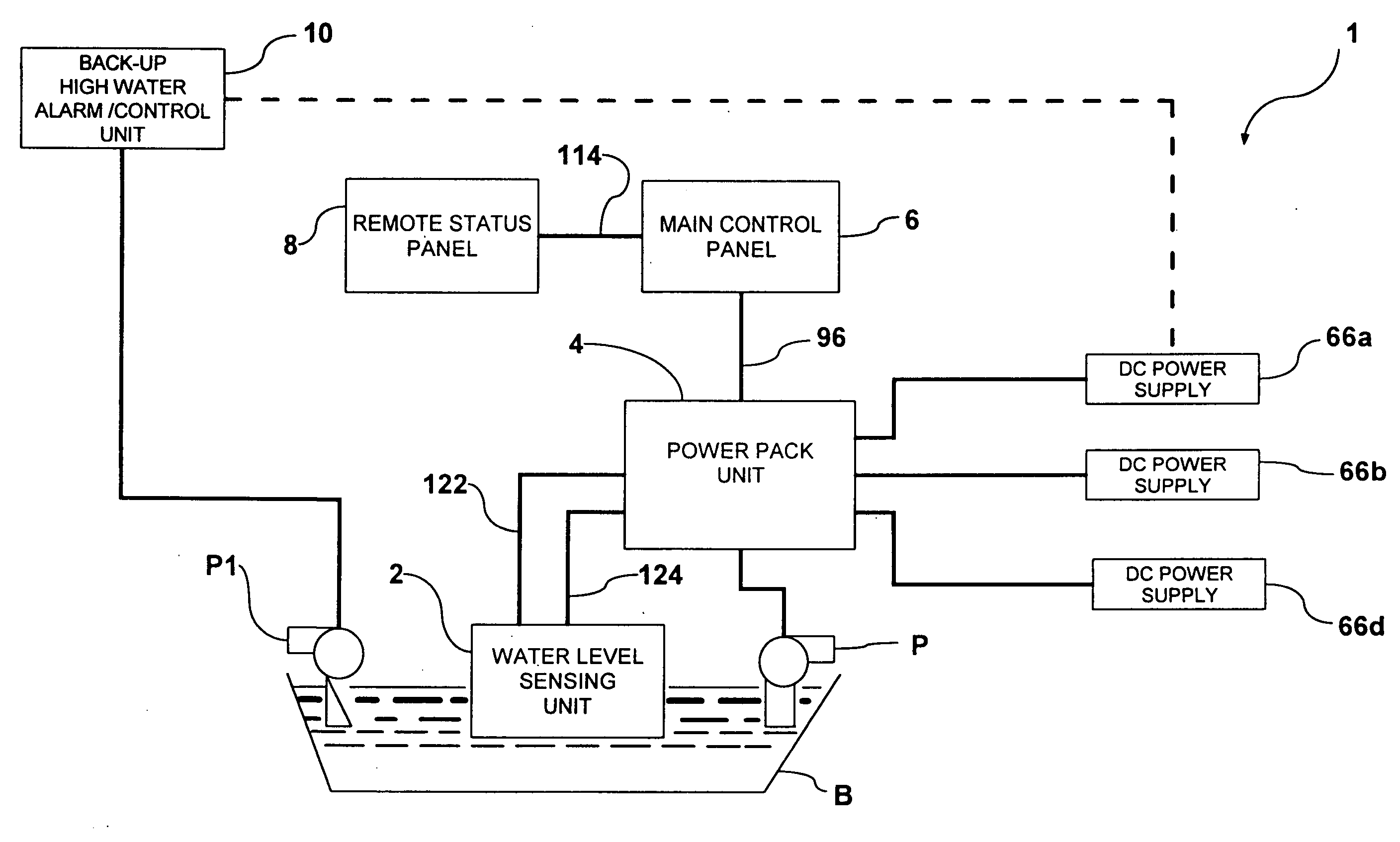

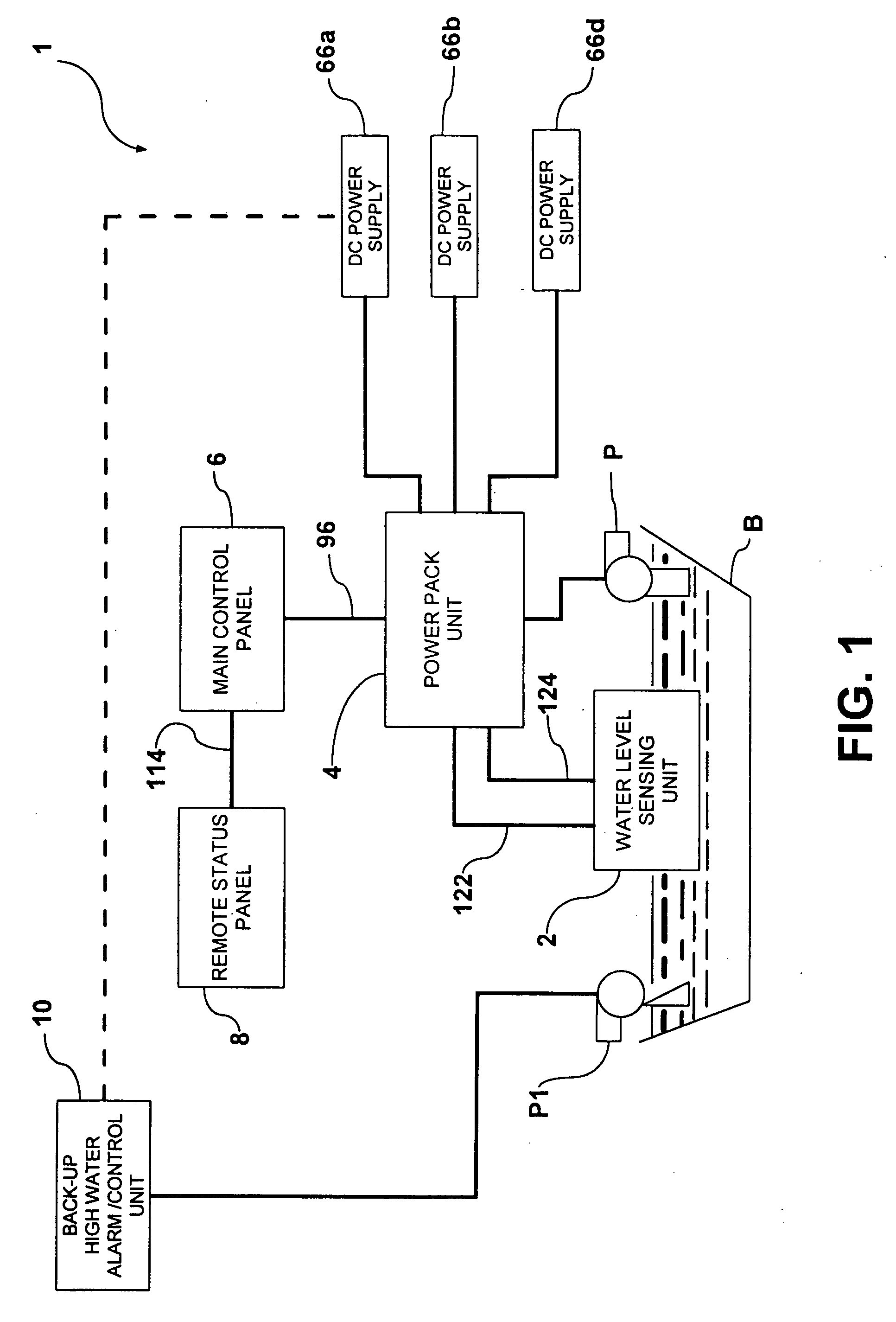

An improved bilge water level monitor, alert and control system for boats and other vessels. The system provides a method of detecting excessive leakage of water into the bilge and in response to the excessive water in the bilge, triggering an alarm to notify the operator and others and energizes bilge pumps to remove the excessive water. The system is designed with many redundancies in the sub elements and subsystems for safety. The system provides a means for reducing the likelihood of exhausting battery power in the event of a significant seawater leakage problem. The electrical power rating of the monitoring circuitry components is relatively low, thereby reducing the size and weight of those components relative to prior bilge pump monitoring and alert systems. There is no electrical wiring exposed to bilge water during system operation thereby reducing damage to the wiring components. The water level detection and control circuitry operates with sufficiently low amperage to substantially eliminate the hazard of spark-induced combustion.

Owner:WALDECKER DONALD E

Method of and apparatus for detecting and controlling bilge water in a sea vessel

InactiveUS7661380B2Reduce the possibilityReduced power ratingAuxillariesSelf-bailing equipments/scuppersEngineeringSeawater

Owner:WALDECKER DONALD E

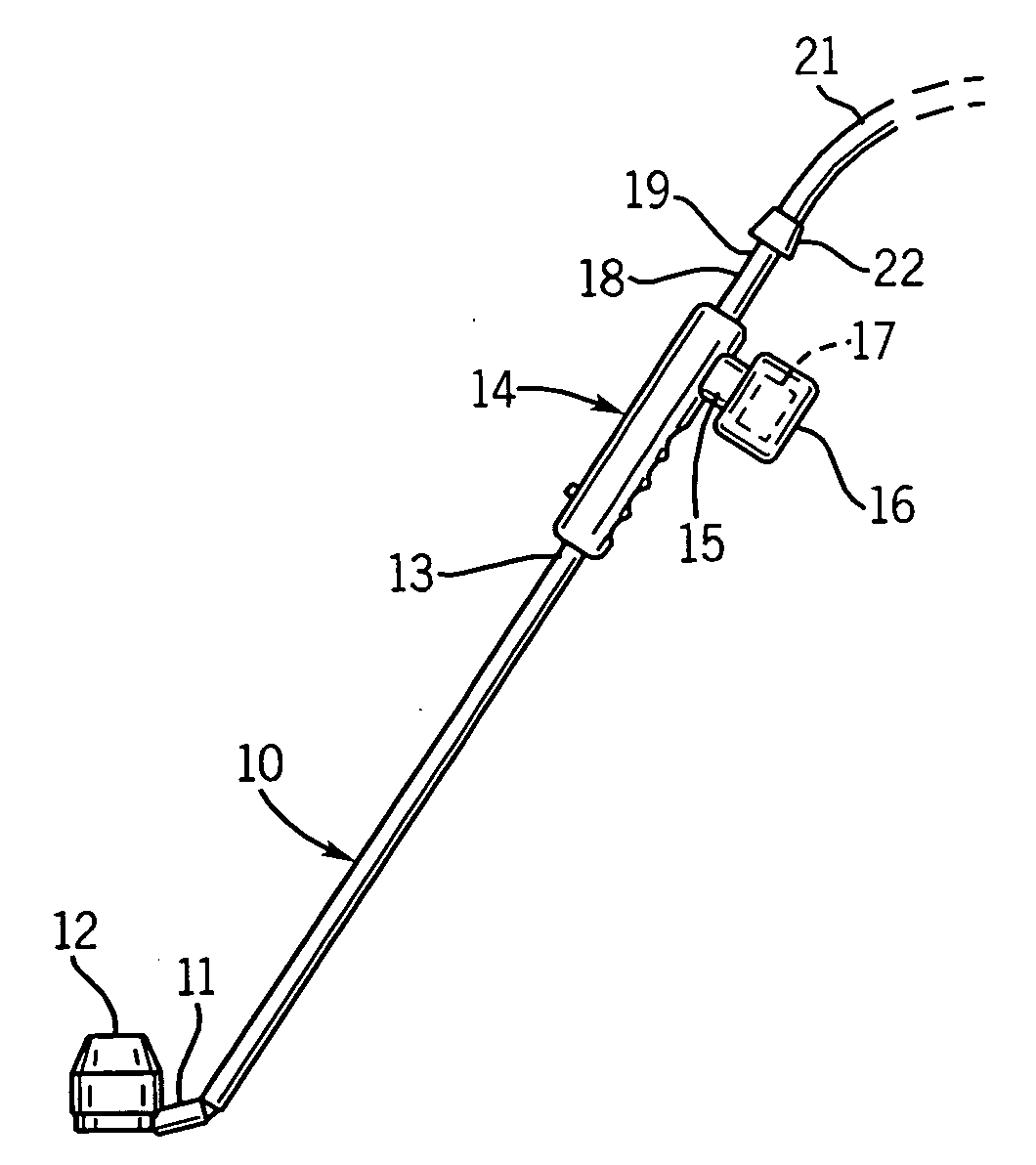

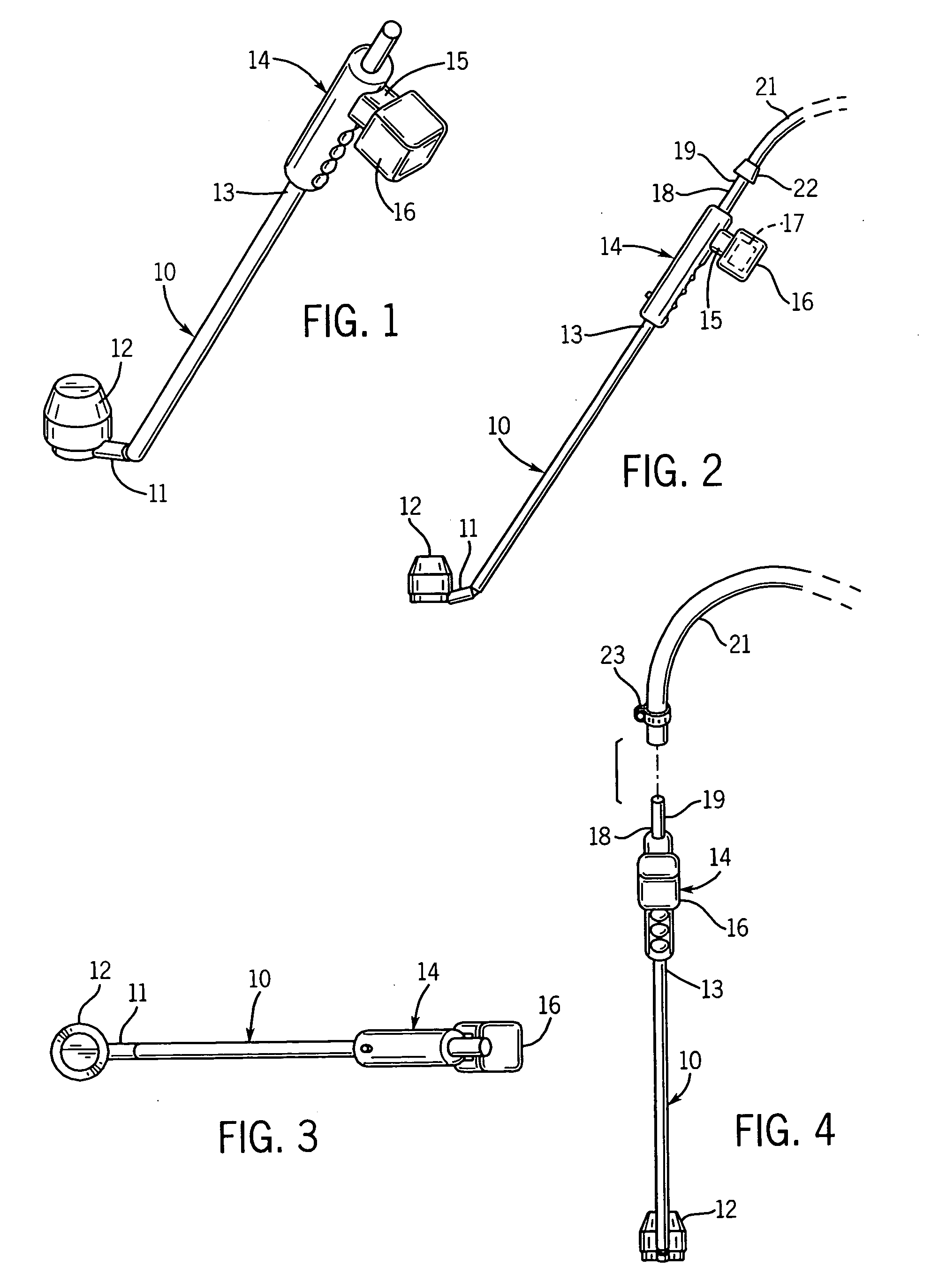

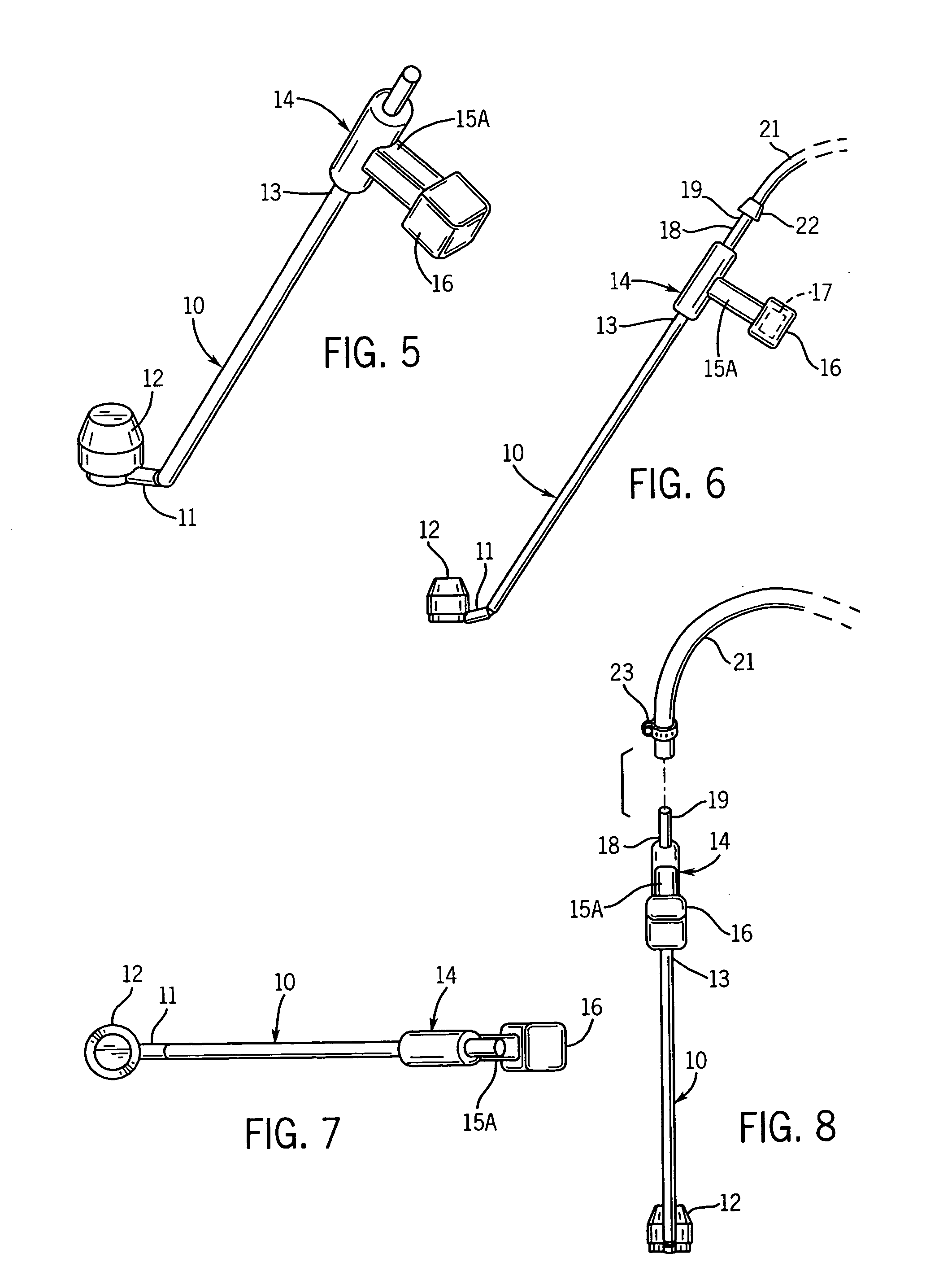

Manually portable electric bilge pump with a rechargeable battery

InactiveUS20050244287A1Minimizing exhausting repetitive arm movementMinimizing movement legPiston pumpsPositive-displacement liquid enginesElectrical batteryRechargeable cell

A manually portable bilge pump having a motor powered by a rechargeable battery, enclosed in a detachable battery housing, has an intake conduit extending downward to the deepest region of a vessel's bilge and a discharge conduit preferably extending overboard or to the galley sink for delivering pumped bilge water outside the vessel.

Owner:DOBRYNSKI GERALD M

Solid state fluid level sensor

ActiveUS20080095637A1Prevent scalingResist attackPrinted circuit assemblingPrinted electric component incorporationFluid levelVertical array

A sensor system for sensing liquid level in a bilge, for use in automatic bilge pump actuation. First and second field effect sensors are potted or sealed within a container or the bilge wall and are aligned in a vertical array and each comprise a substantially planar pattern of “electrodes” or conductive traces disposed on a printed circuit board (PCB) along with integrated circuits used to create a loop or arc-shaped electric field. As bilge liquid rises to the proximity or level of the field effect sensors, a change in the arc-shaped electric field is sensed and, in response, a bilge pump is automatically actuated to pump liquid out of the bilge. Optionally, the pump control can be programmed by use of a microprocessor to permit control of on-off timing and is prevent undesirable effects of “sloshing.”

Owner:TOUCHSENSOR TECH

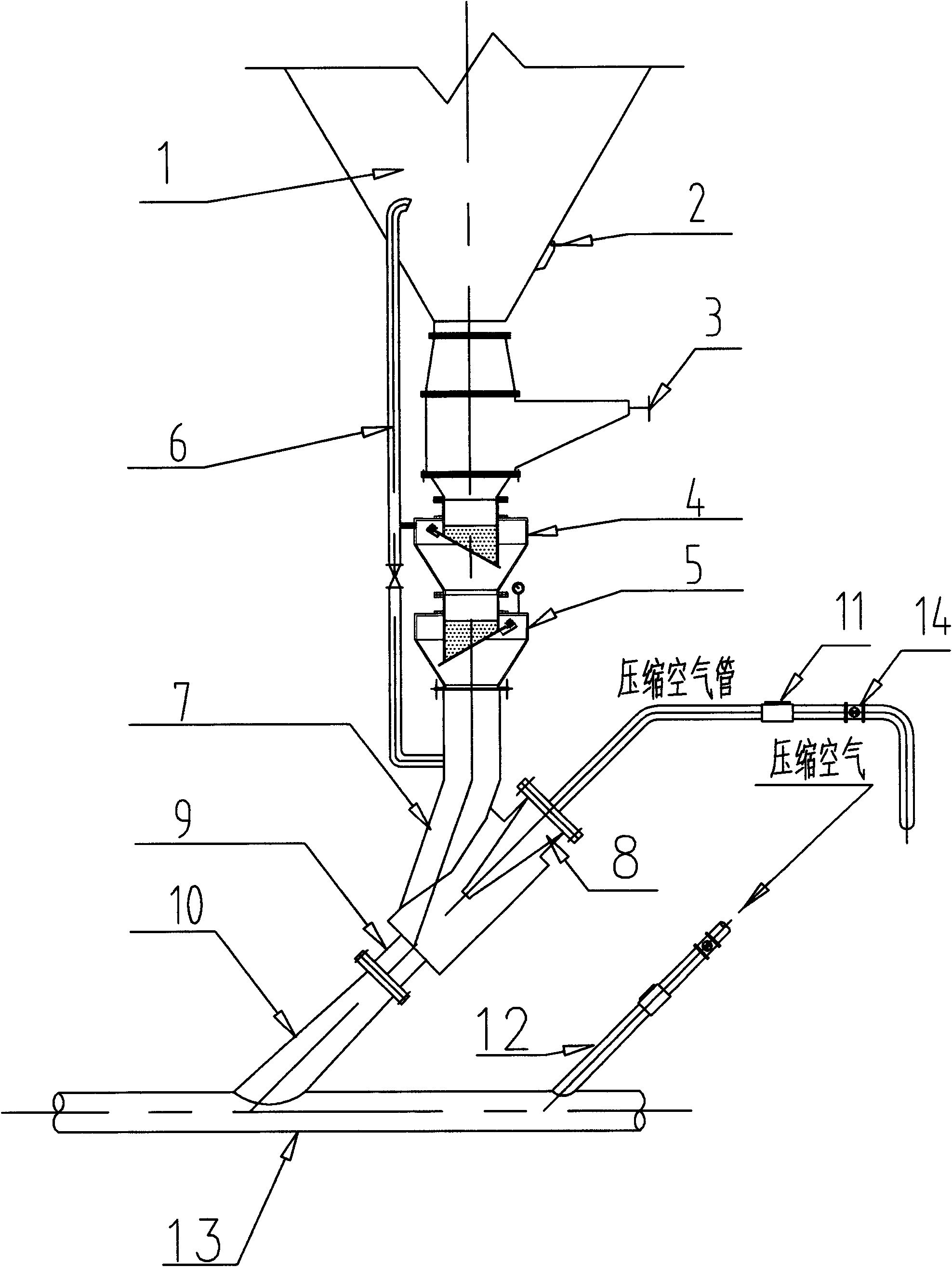

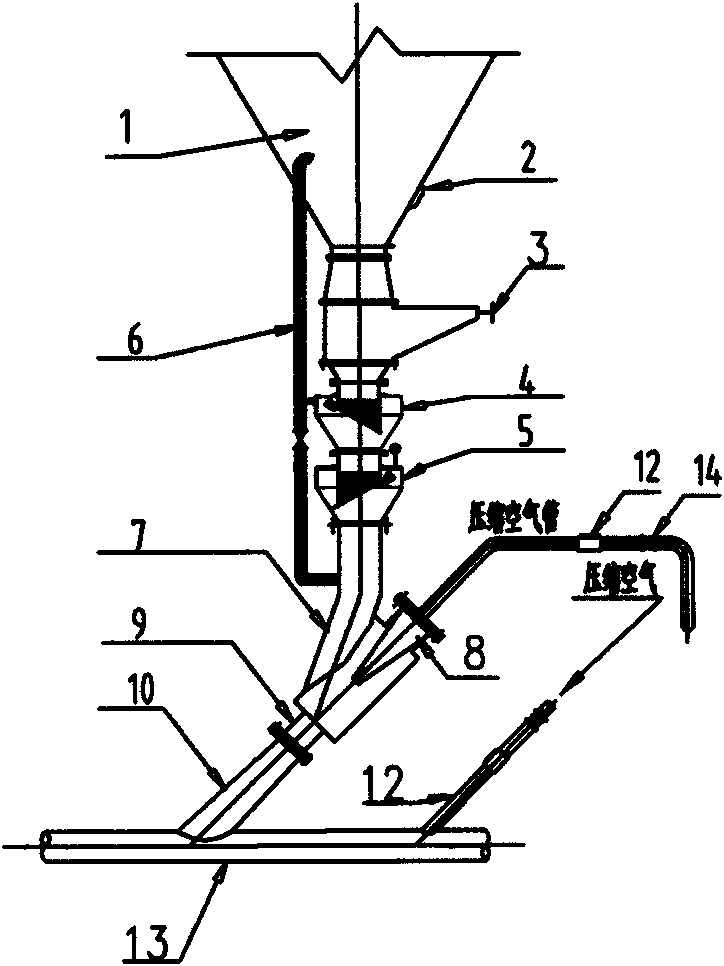

Blade stirring type pneumatic conveyor for easy caking materials

The invention relates to pneumatic conveyor, in particular to a blade stirring type pneumatic conveyor for easy caking materials. The blade stirring type pneumatic conveyor for the caking materials comprises a bilge pump, a feeding hole and a discharge hole, wherein the feeding hole and the discharge hole are both arranged on the bilge pump, and the bilge pump consists of an oval seal head at the top, a columniform cylinder at the middle and a conical seal head at the bottom. The blade stirring type pneumatic conveyor is characterized in that a scraper and a pneumatic blade are arranged inside the bilge pump and are fixed on a pneumatic structure at the top of a fixed shaft, the fixed shaft is a hollow circular tube, and the other end of the fixed shaft is connected with an air inlet extending out of the bilge pump. The invention has the characteristics of capability of effectively crushing the caking materials, reliable work, energy source saving, simple and convenient operation, strong practicability and the like.

Owner:杭州震乾科技有限公司

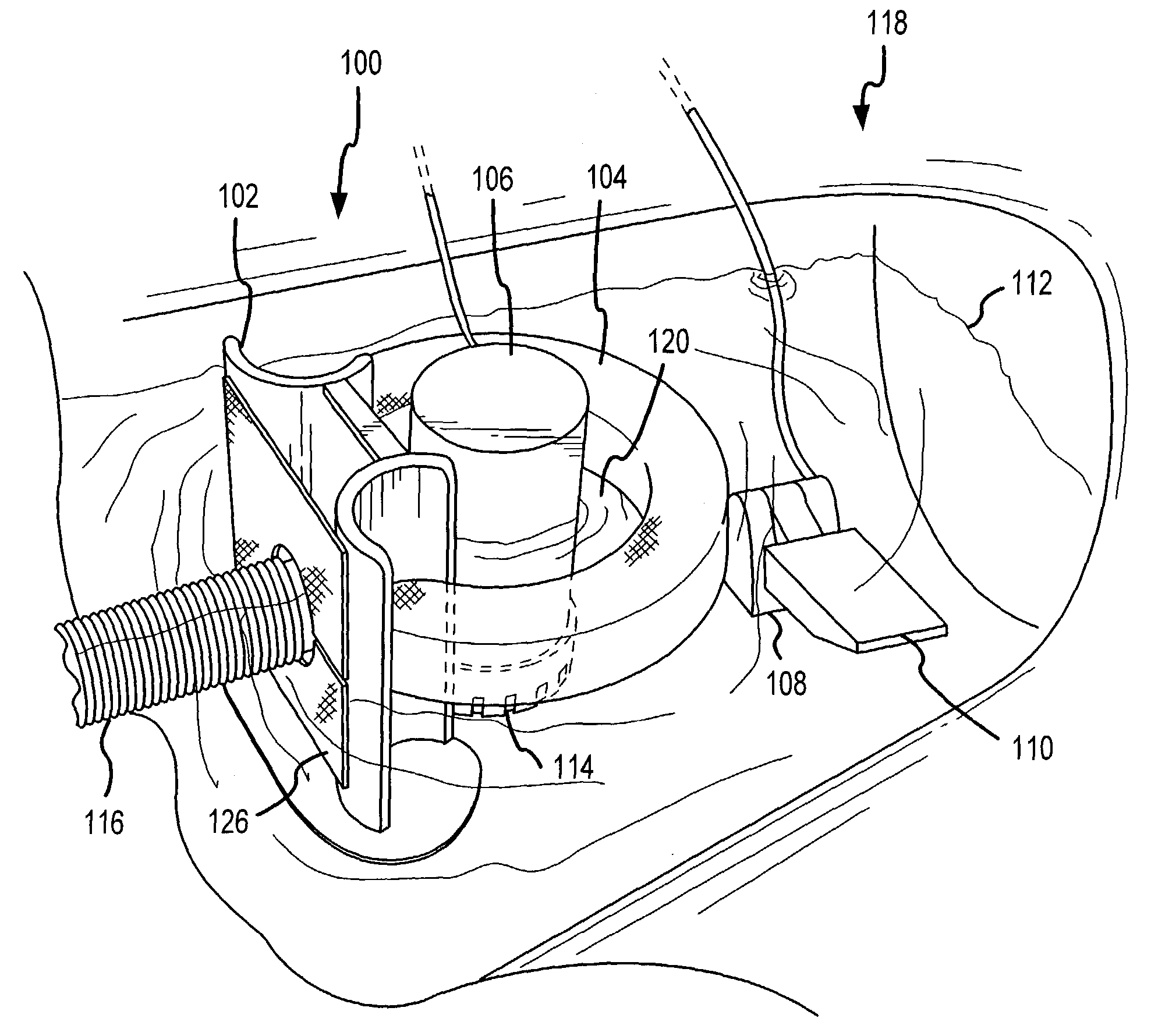

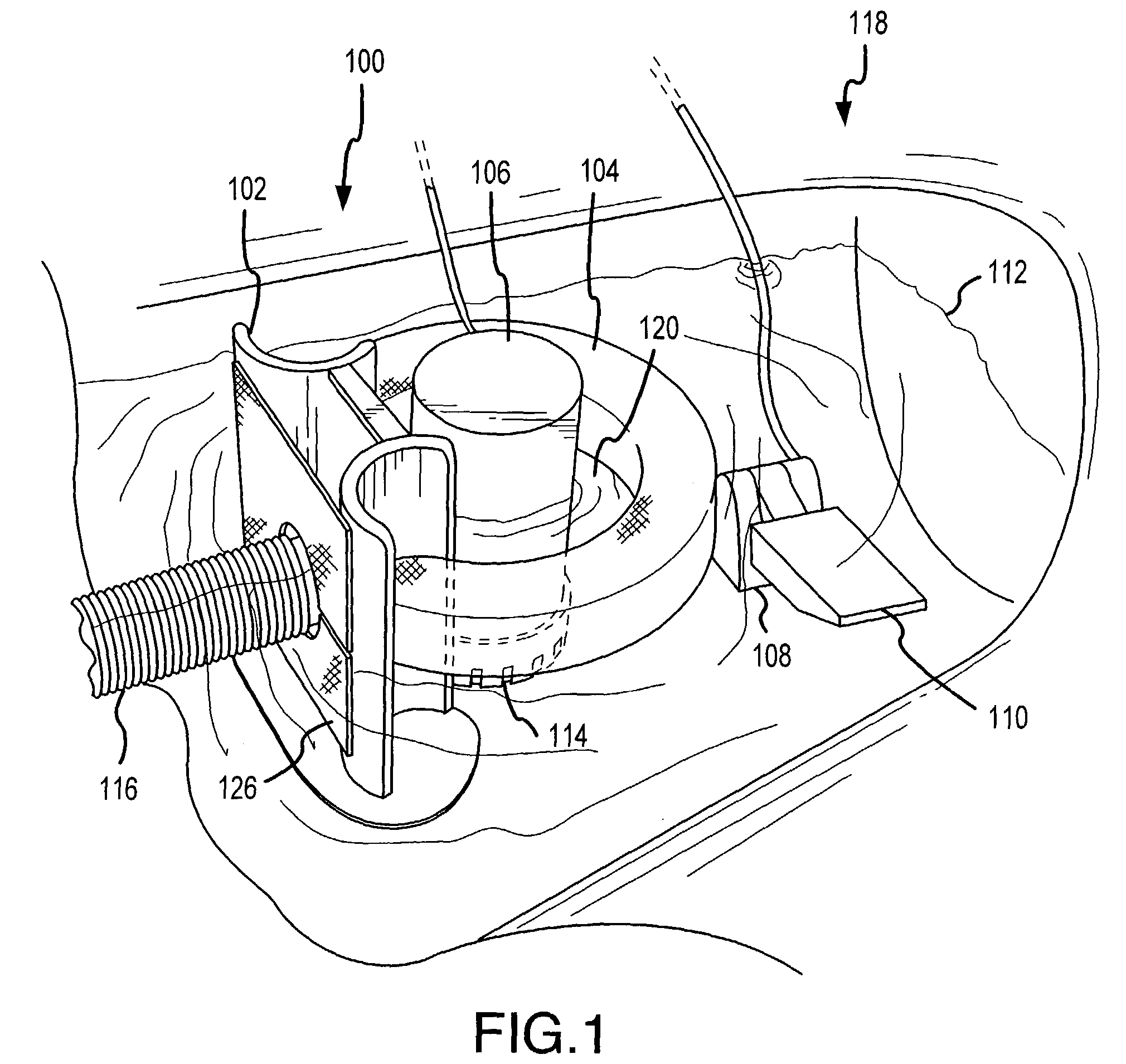

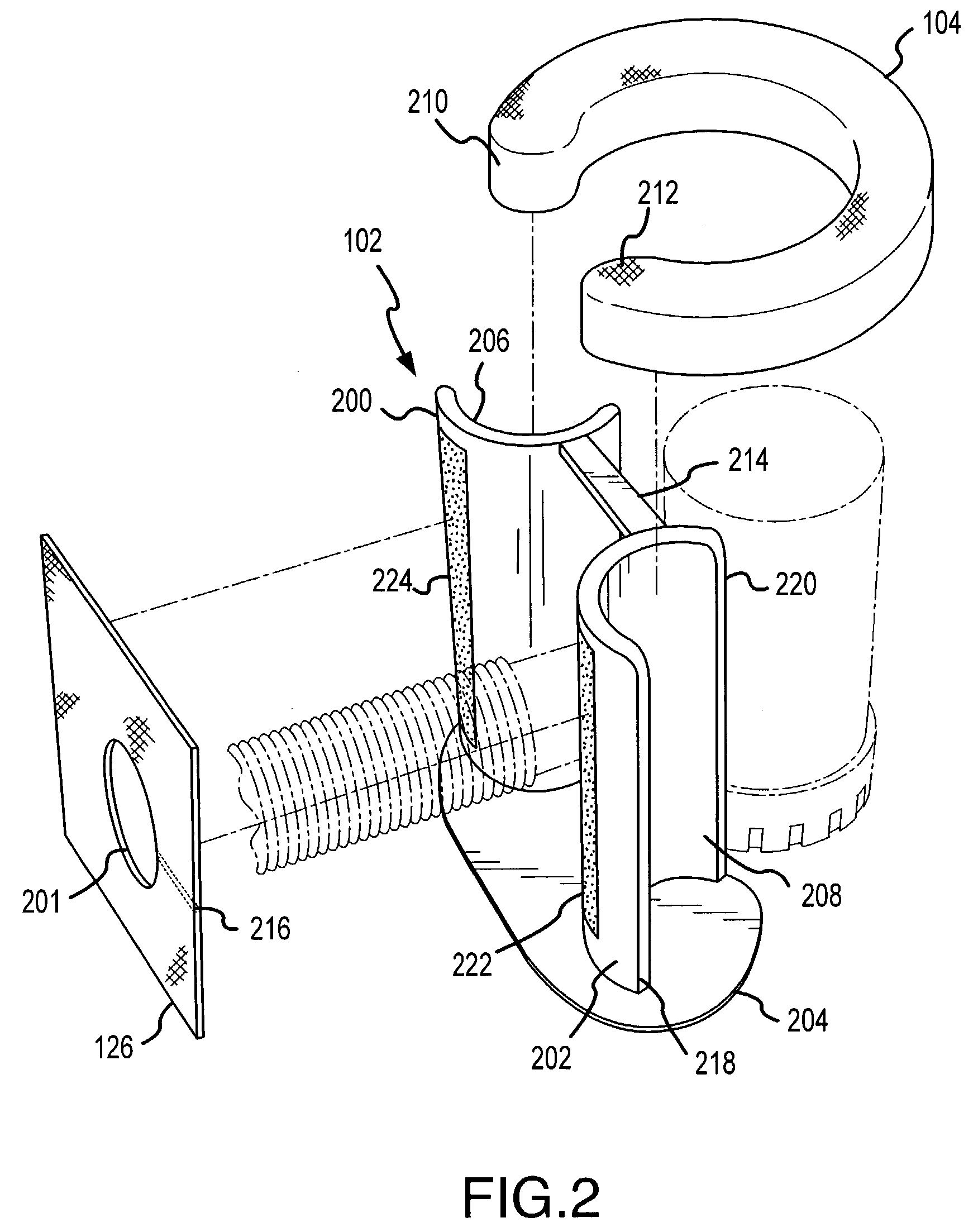

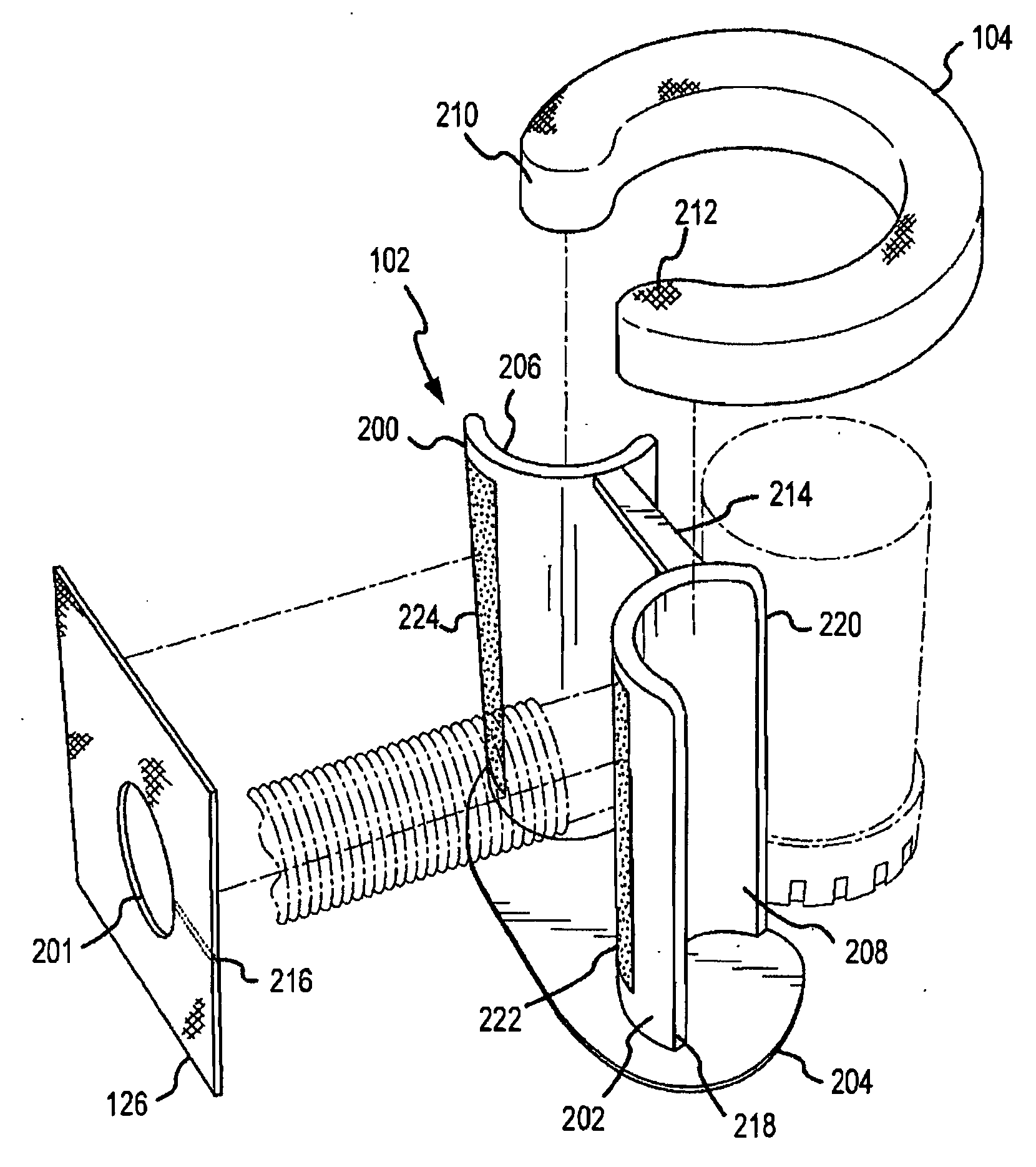

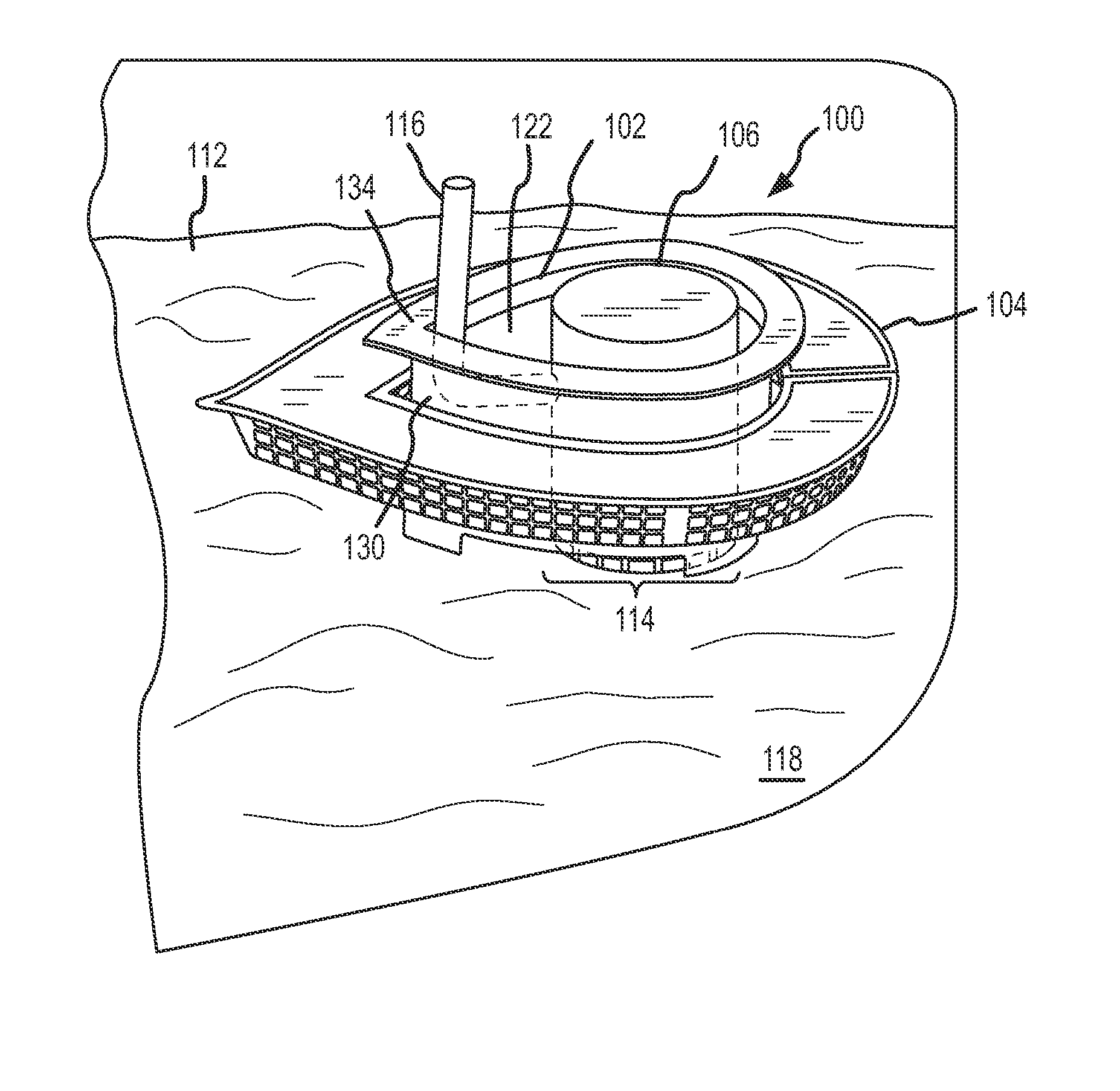

Water pollution prevention and remediation apparatus

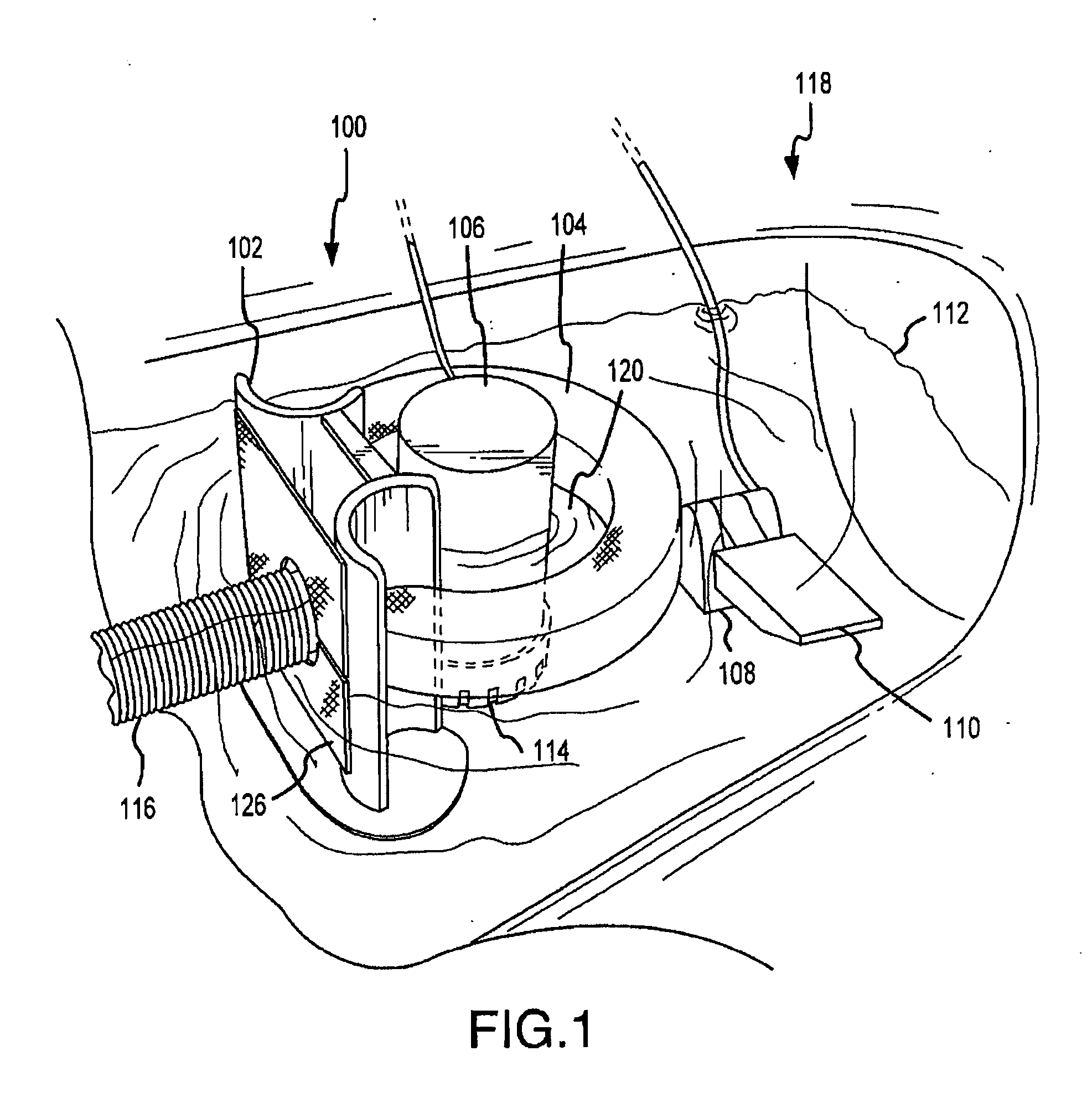

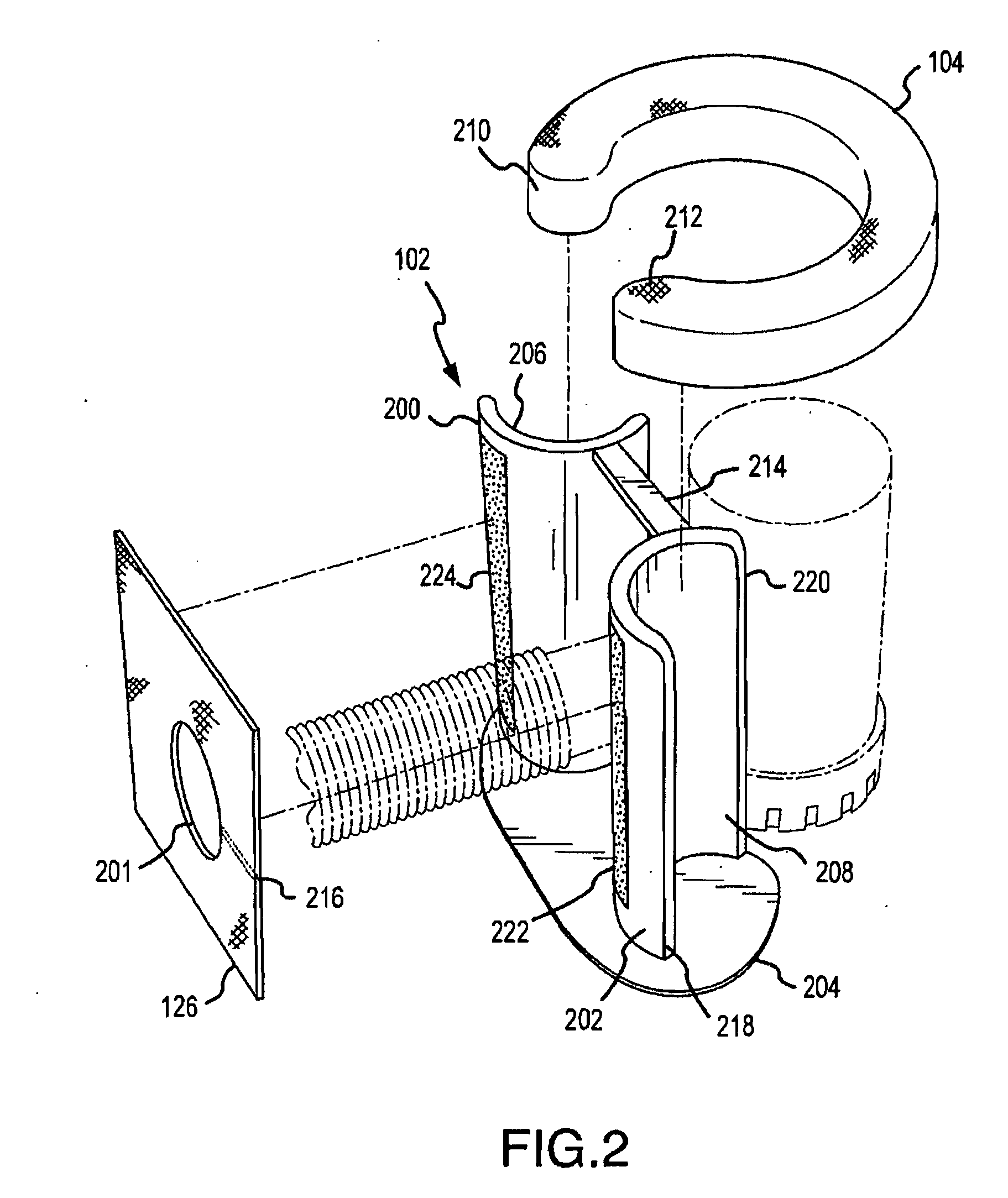

InactiveUS7138055B2Minimize and eliminate introductionPromote repairFatty/oily/floating substances removal devicesWater cleaningRestoration deviceFluid level

A fluid pollution prevention system for preventing the discharge of hazardous waste from a bilge of a marine vessel, and removal of the same from the bilge. The system includes an absorber for absorbing hazardous waste from a fluid in the bilge. The system further includes a locator for locating the absorber in a predetermined orientation relative to a bilge pump to prevent the discharge of hazardous waste from the bilge. In one embodiment of the invention, the locator is an upstanding member in relation to the fluid in the bilge and includes at least one locator channel defined along at least a portion of the locator for slidable receipt of the absorber. According to this characterization, the absorber is movable along the locator channel as a function of the bilge fluid level to absorb hazardous waste from the fluid and isolate an inlet of the bilge pump from receipt of the same.

Owner:CLUKIES PAUL

Water pollution prevention and remediation apparatus

InactiveUS20060096927A1Minimize and eliminate introductionPromote repairAuxillariesSolid sorbent liquid separationRestoration deviceFluid level

A fluid pollution prevention system for preventing the discharge of hazardous waste from a bilge of a marine vessel, and removal of the same from the bilge. The system includes an absorber for absorbing hazardous waste from a fluid in the bilge. The system further includes a pump that locates the absorber in a predetermined orientation relative to the pump to prevent the discharge of hazardous waste from the bilge. In one embodiment of the invention, the pump includes a housing having an outside surface that is adapted for disposition within an enclosed area defined by the absorber. According to this characterization, the absorber is movable along the outside surface of the pump housing as a function of the bilge fluid level to absorb hazardous waste from the fluid and isolate an inlet of the bilge pump from receipt of the same. In a further characterization, the fluid outlet vertically exits the pump housing such that the fluid outlet does not interference with the movement of the absorber.

Owner:CLUKIES PAUL ARTHUR

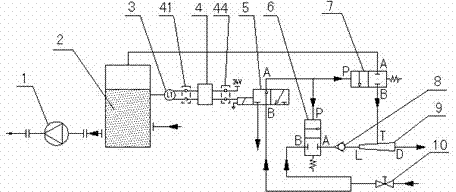

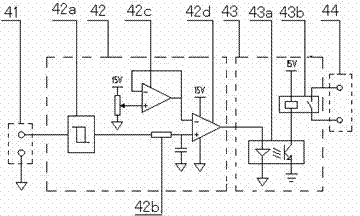

Automatic priming device for centrifugal pump

ActiveCN102644604AAvoid vacuumingHigh degree of automationPriming pumpPump controlCavitationEngineering

Owner:WUHAN MARINE MACHINERY PLANT

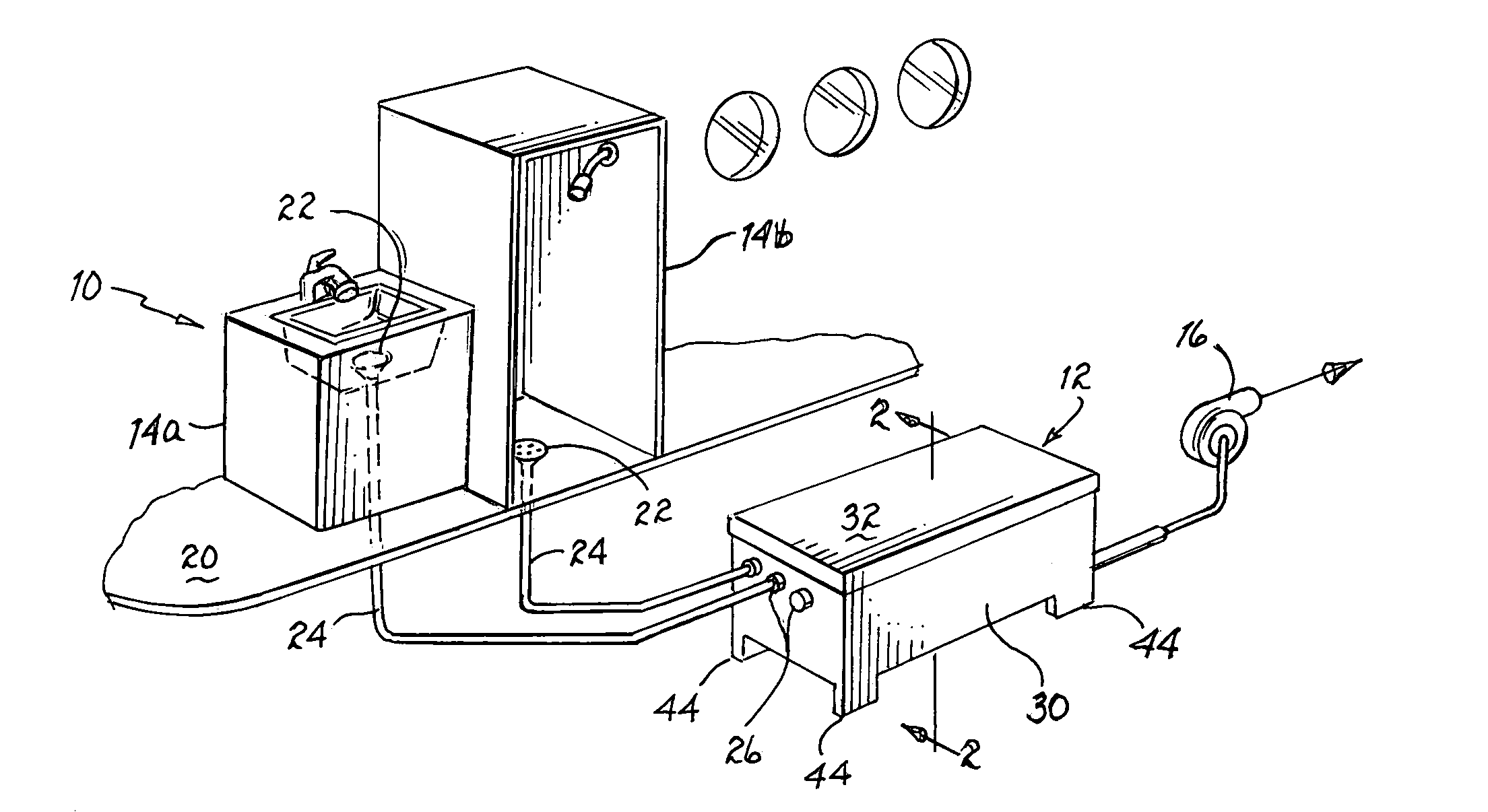

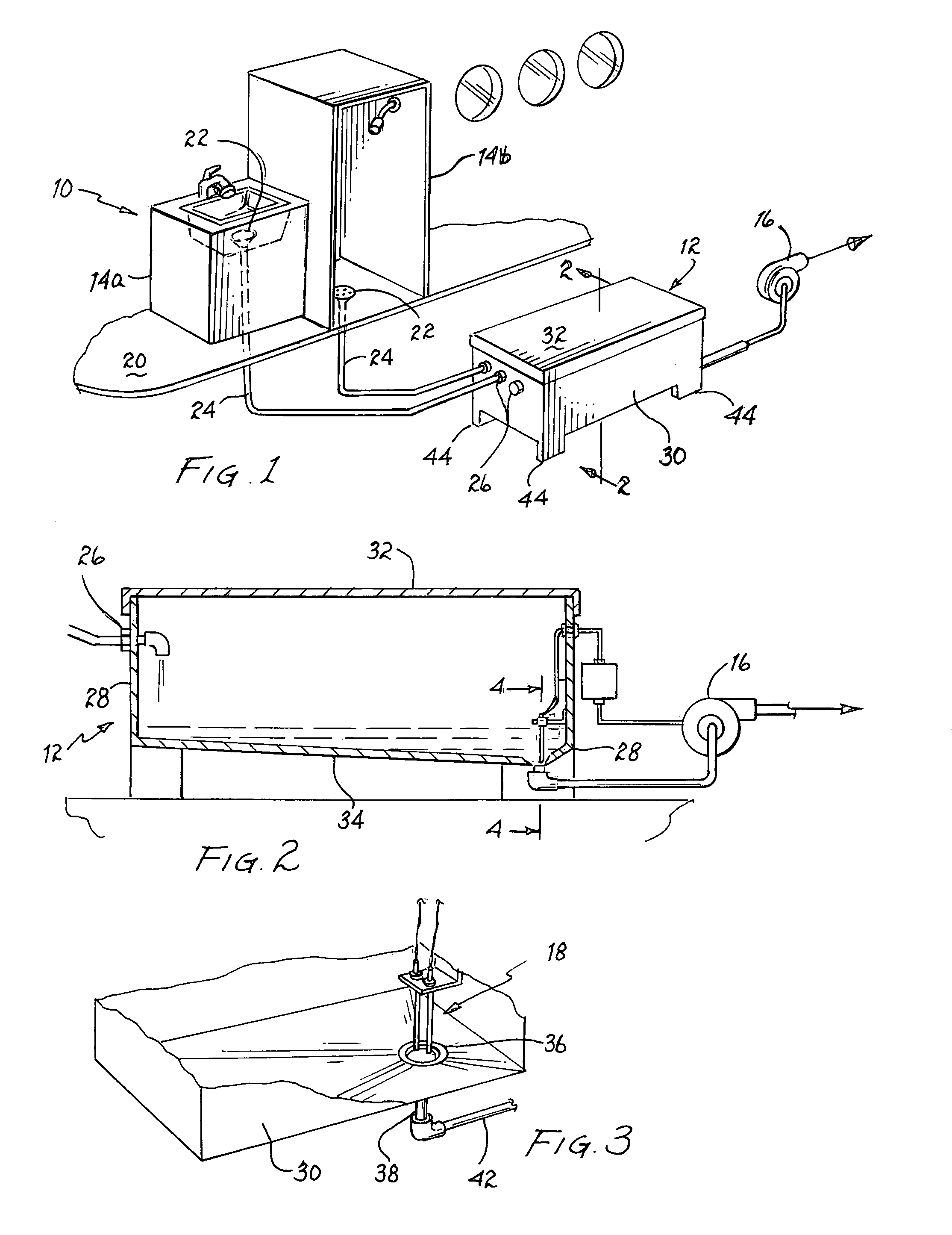

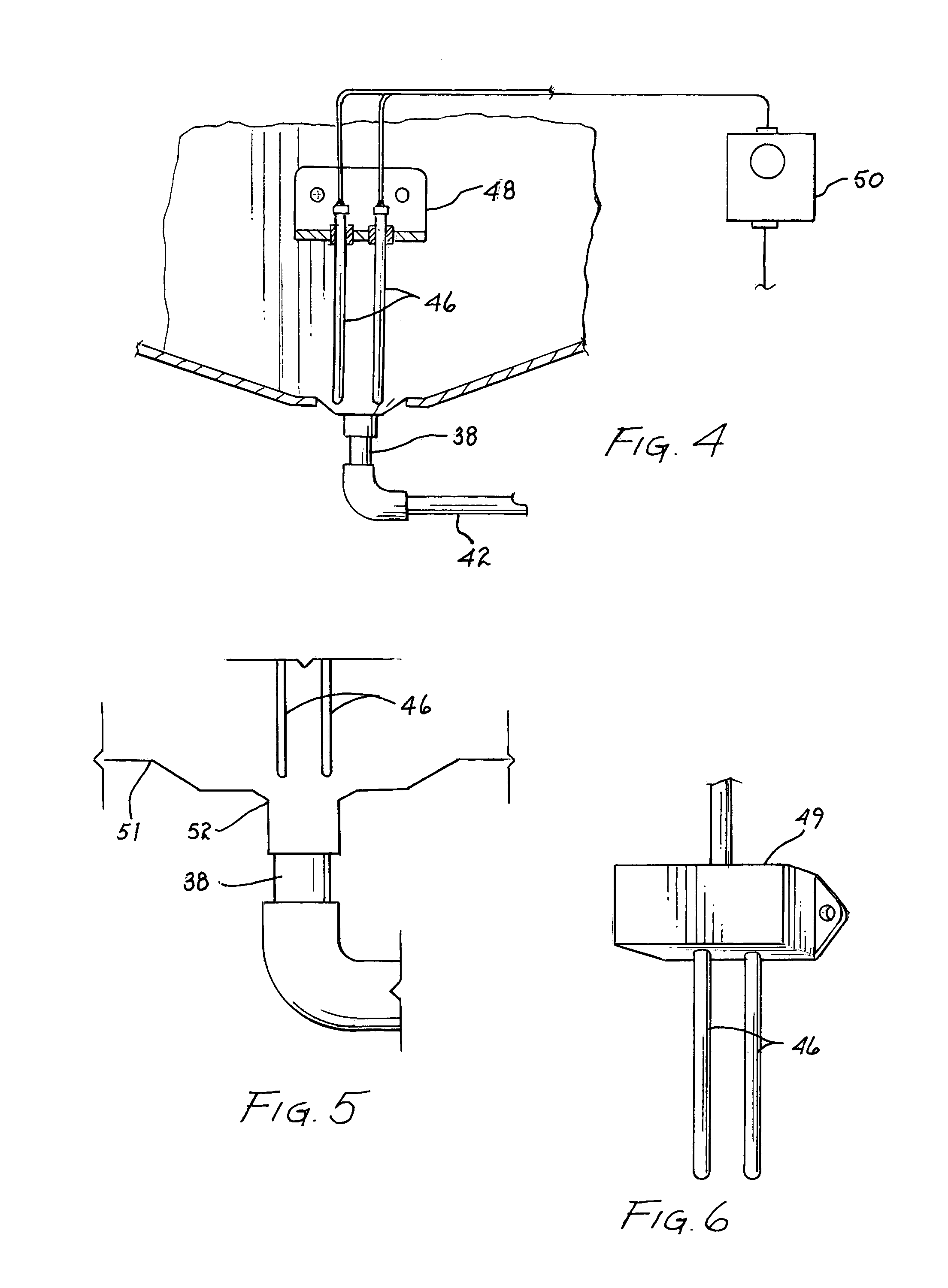

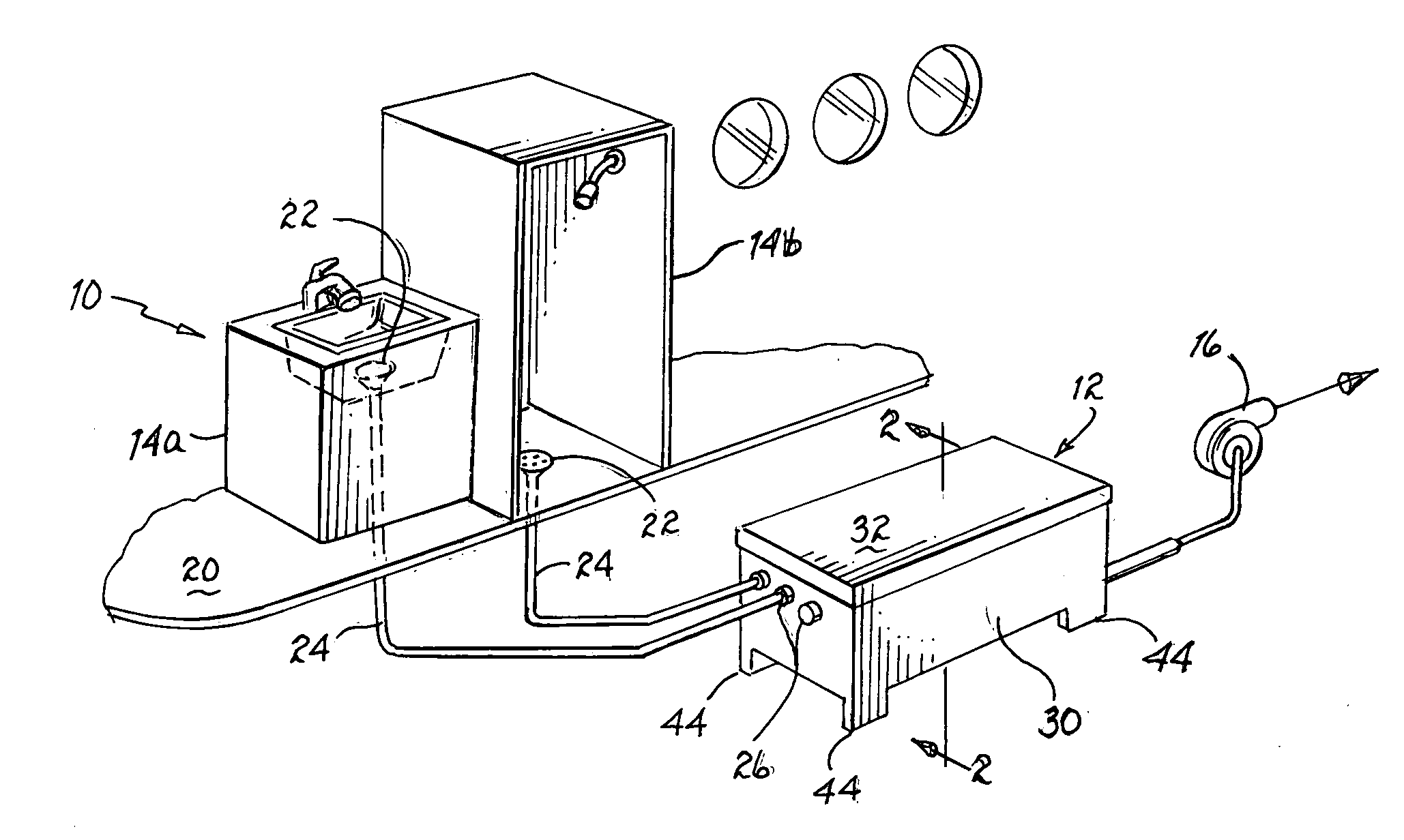

Marine greywater disposal system

An improved greywater disposal system is provided which substantially eliminates onboard standing greywater. The system includes one or more onboard plumbing fixtures fluidly connected to a greywater sump. The bottom of the greywater sump is sloped toward a drain therein at a low end. The prongs of a sensor may be suspended in the sump drain and / or in an inlet chamber defined at an inlet end of the greywater sump. The sensor is associated with a controller and sump or bilge pump. The pump is turned on when the prong tips of the sensor become immersed in greywater which occurs substantially simultaneously with the production of the greywater. The onboard plumbing fixtures include one or more sinks, showers, bathtubs, washing machines and air conditioning units. The system may be used on boats, ships, RVs, campers or the like.

Owner:DETWILER BRETT HOWARD

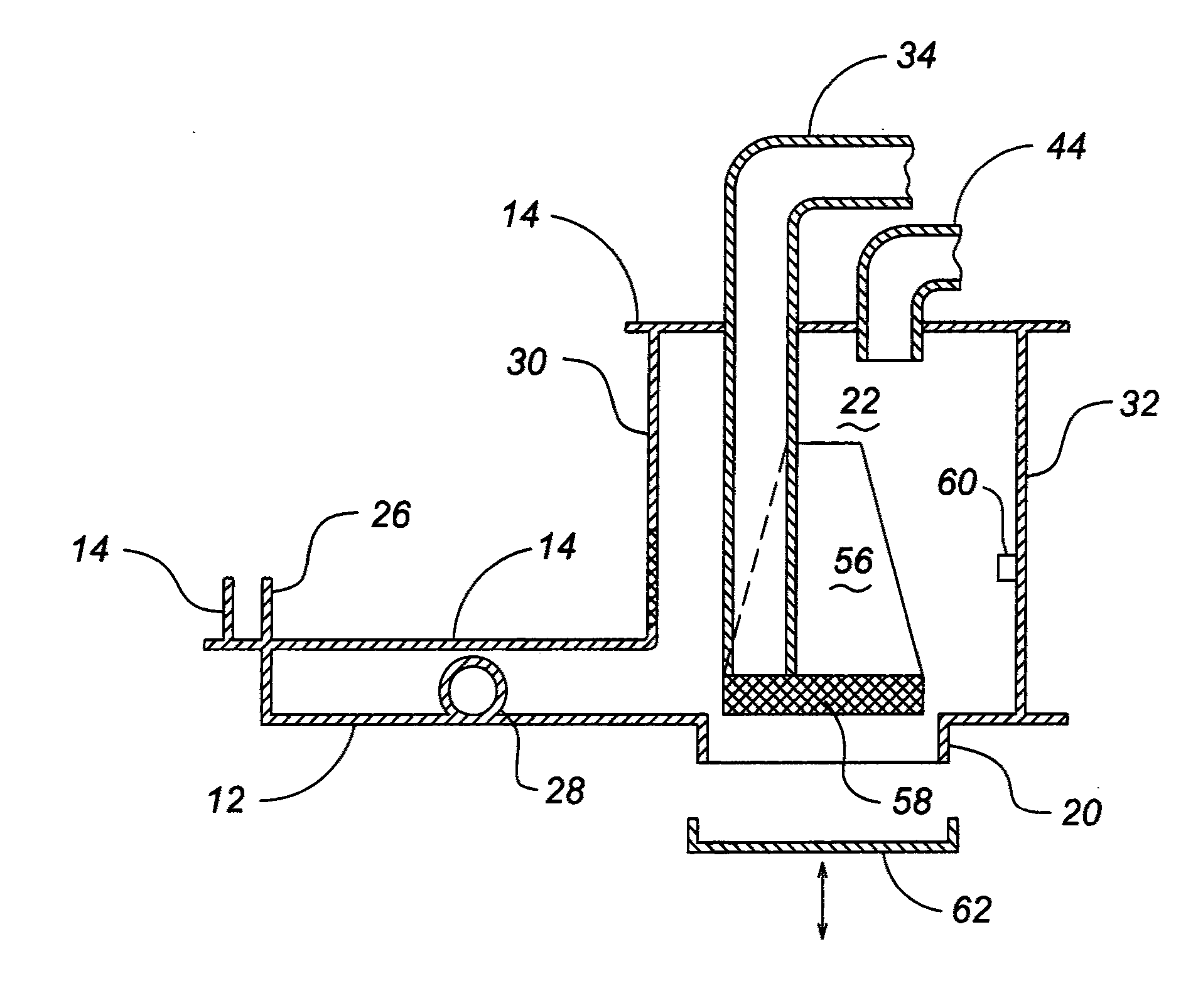

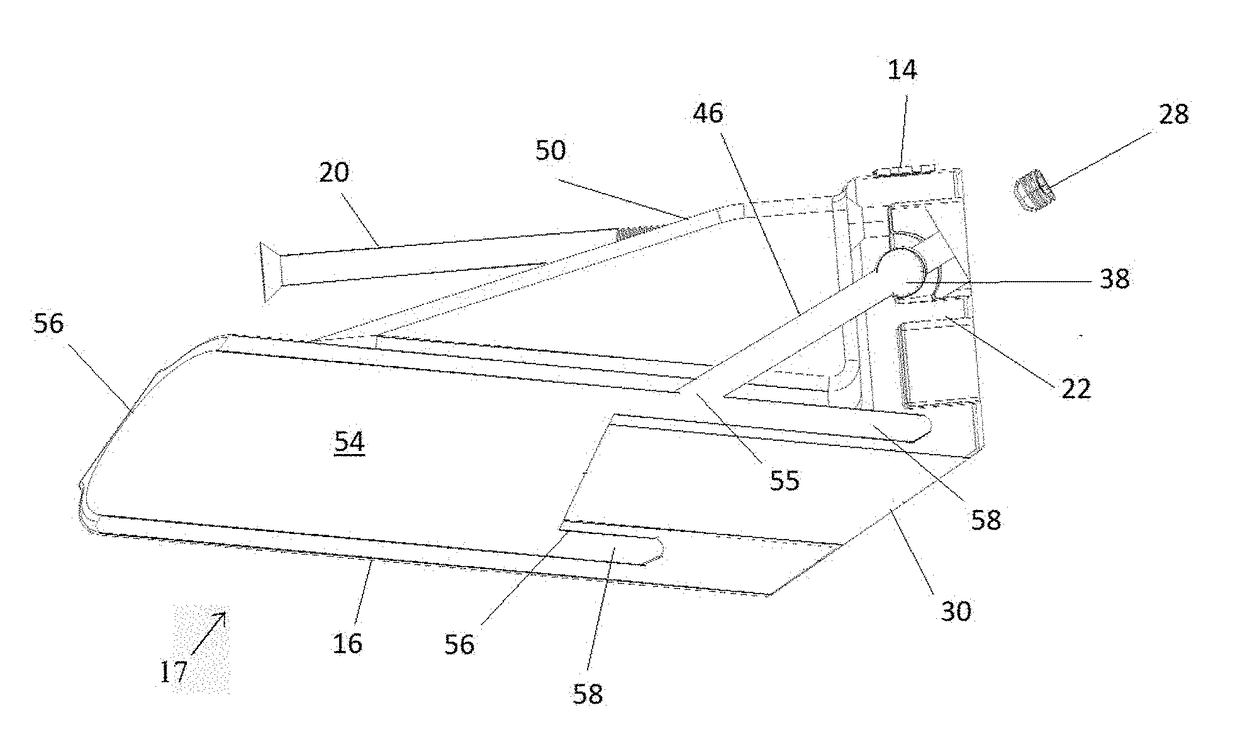

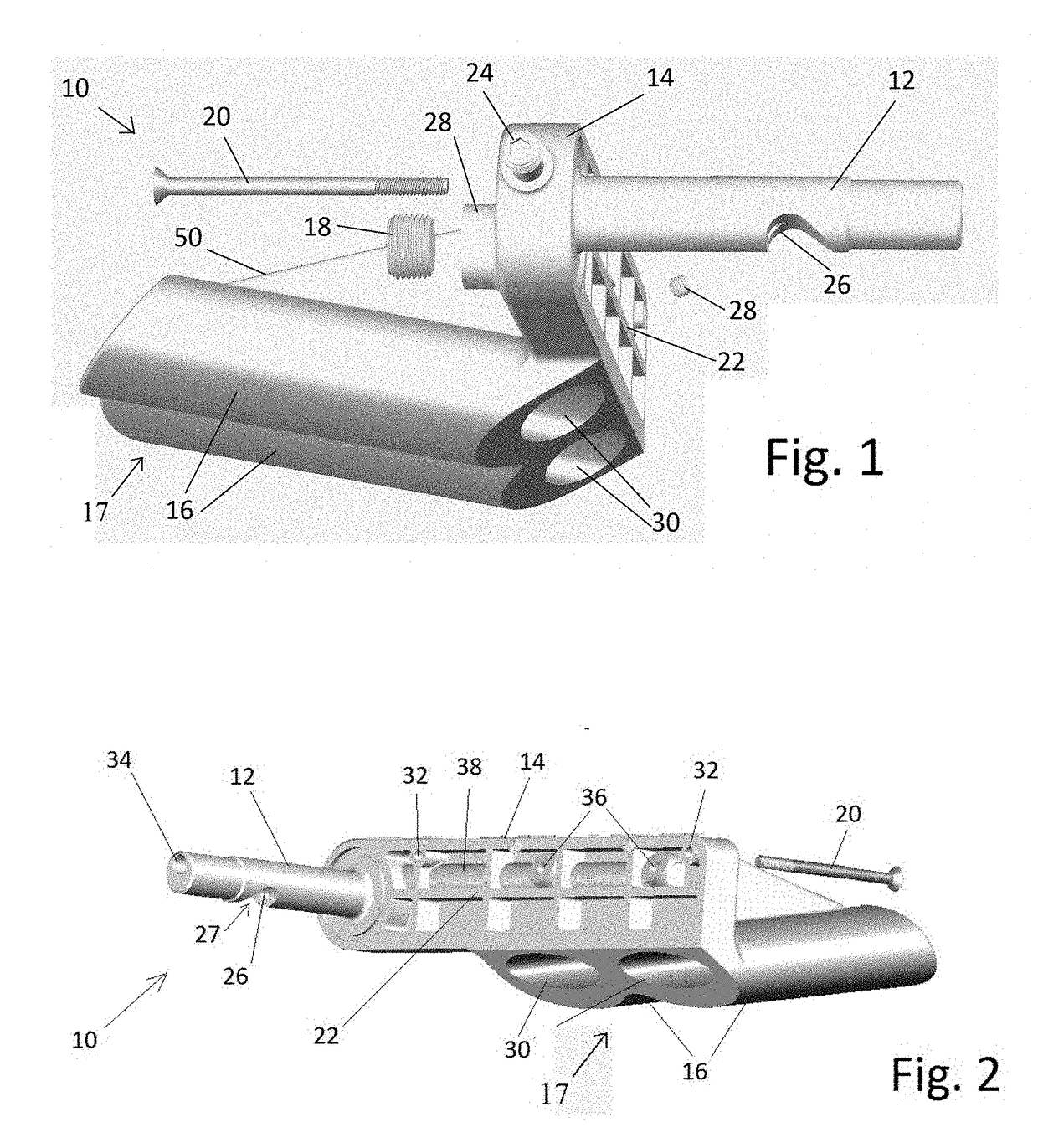

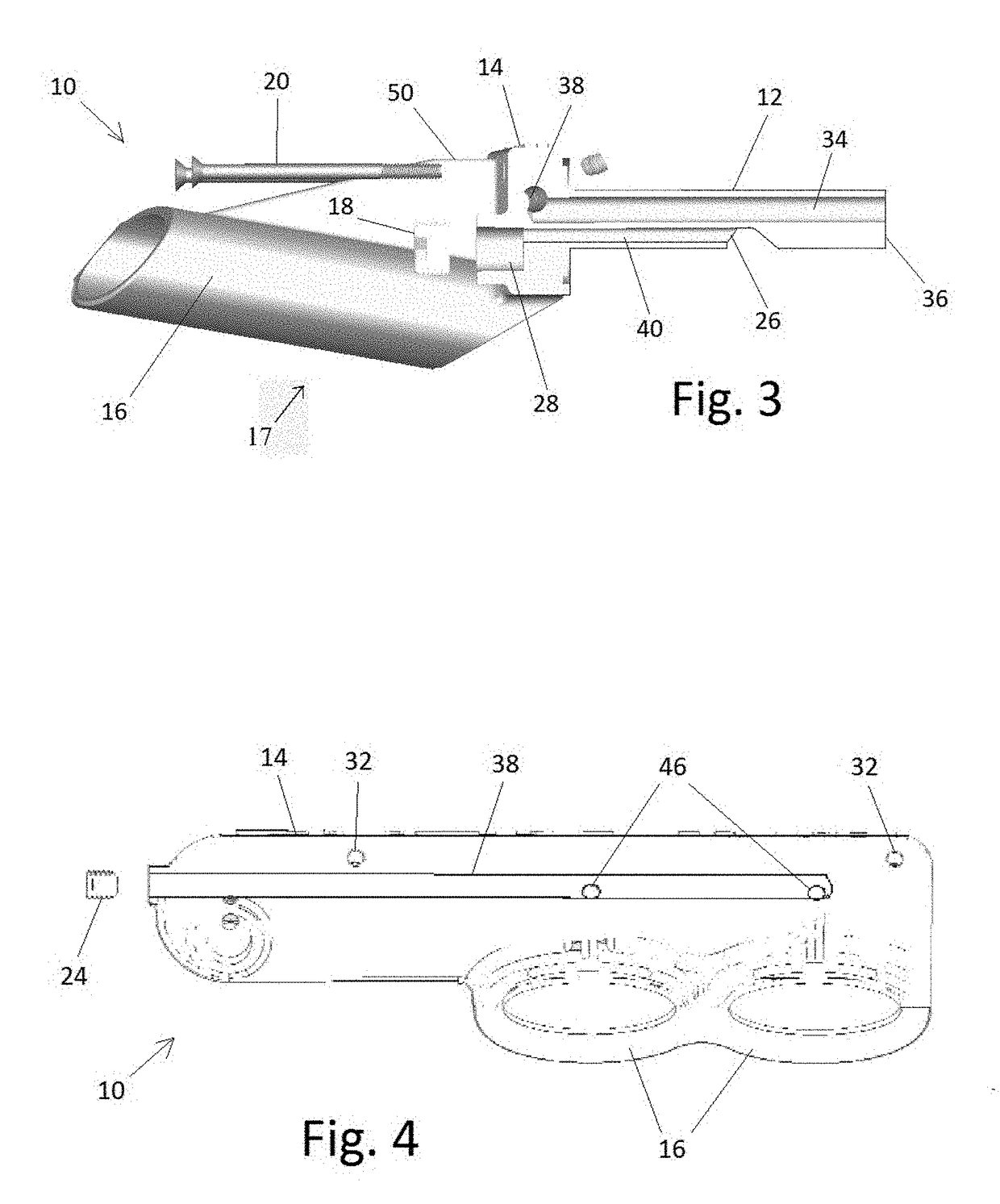

Bilge pump and method

ActiveUS20120171051A1Easy to removeEasy to replacePositive displacement pump componentsPressure pumpsVacuum assistedFire extinguisher

A vacuum assisted bilge pump small enough for the crowded spaces below decks in the engine and pump room of a boat which can also function as a transfer pump, a crash pump and a fire extinguisher. The pump comprises two chambers and is internally configured to aid in the separation of gas and liquid increasing pump throughput.

Owner:WALLACE WILLIAM L

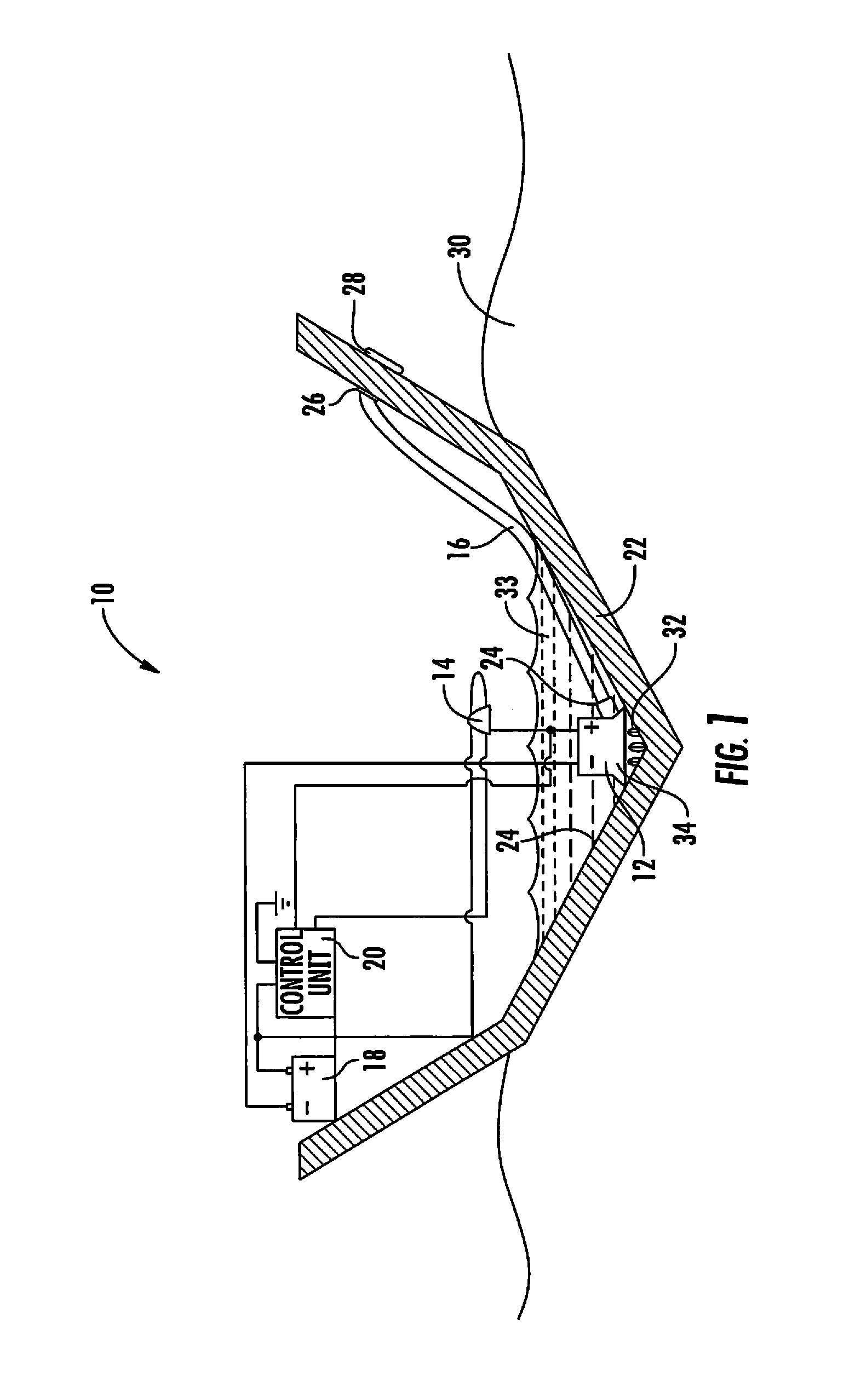

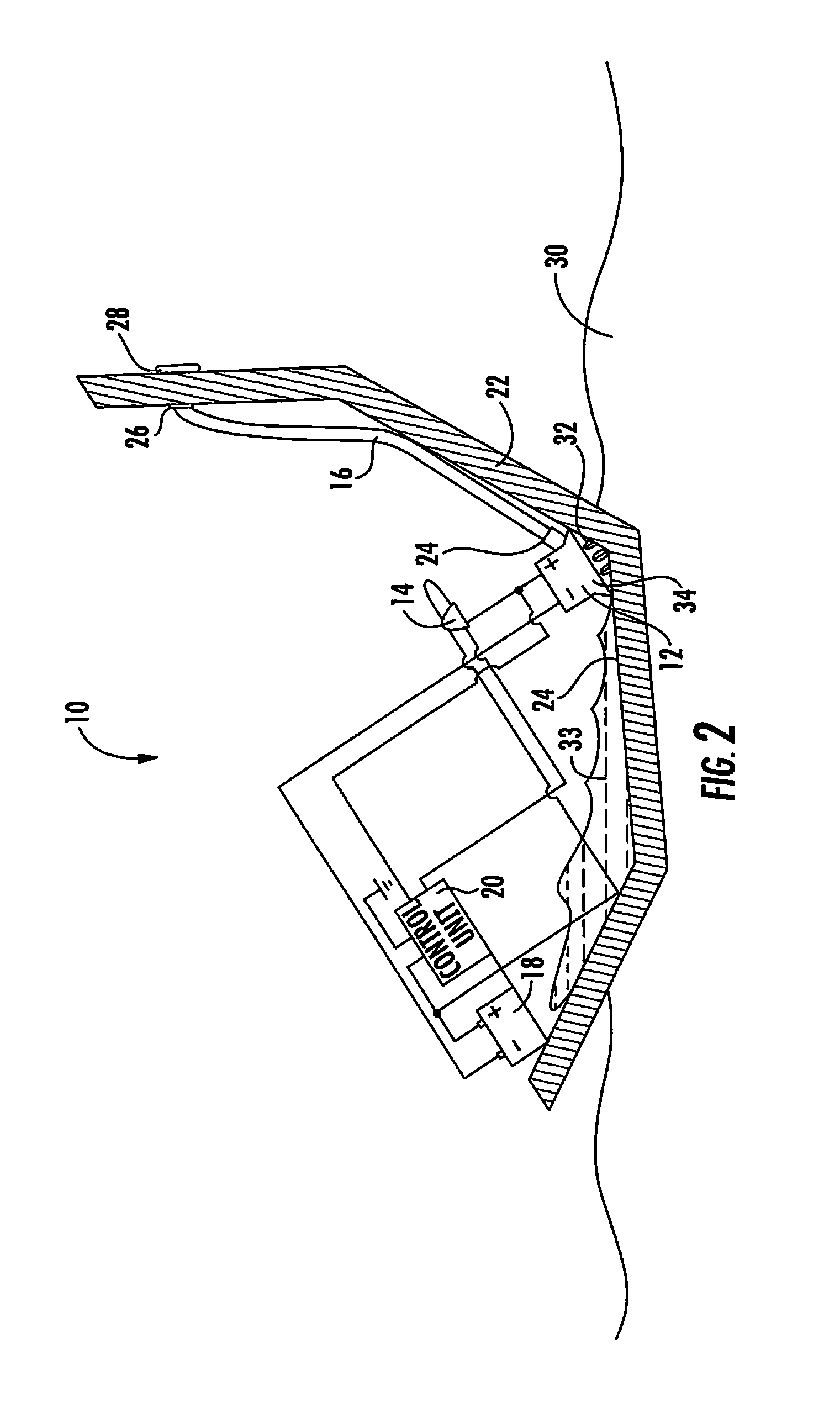

Method of and system for evacuating fluid in a sea vessel

InactiveUS20140048004A1Efficiently pumps outAvoid excessive wearLevel controlSelf-bailing equipments/scuppersMarine engineeringBilge pump

A system and method that controls the evacuation of fluid from a sea vessel and configured to prevent turning off the bilge pump during periods of water sloshing. The invention provides a control unit that is adaptable to any size vessel or bilge pump based on a learned experience gained by sensory information.

Owner:RUSSICK JAMES +1

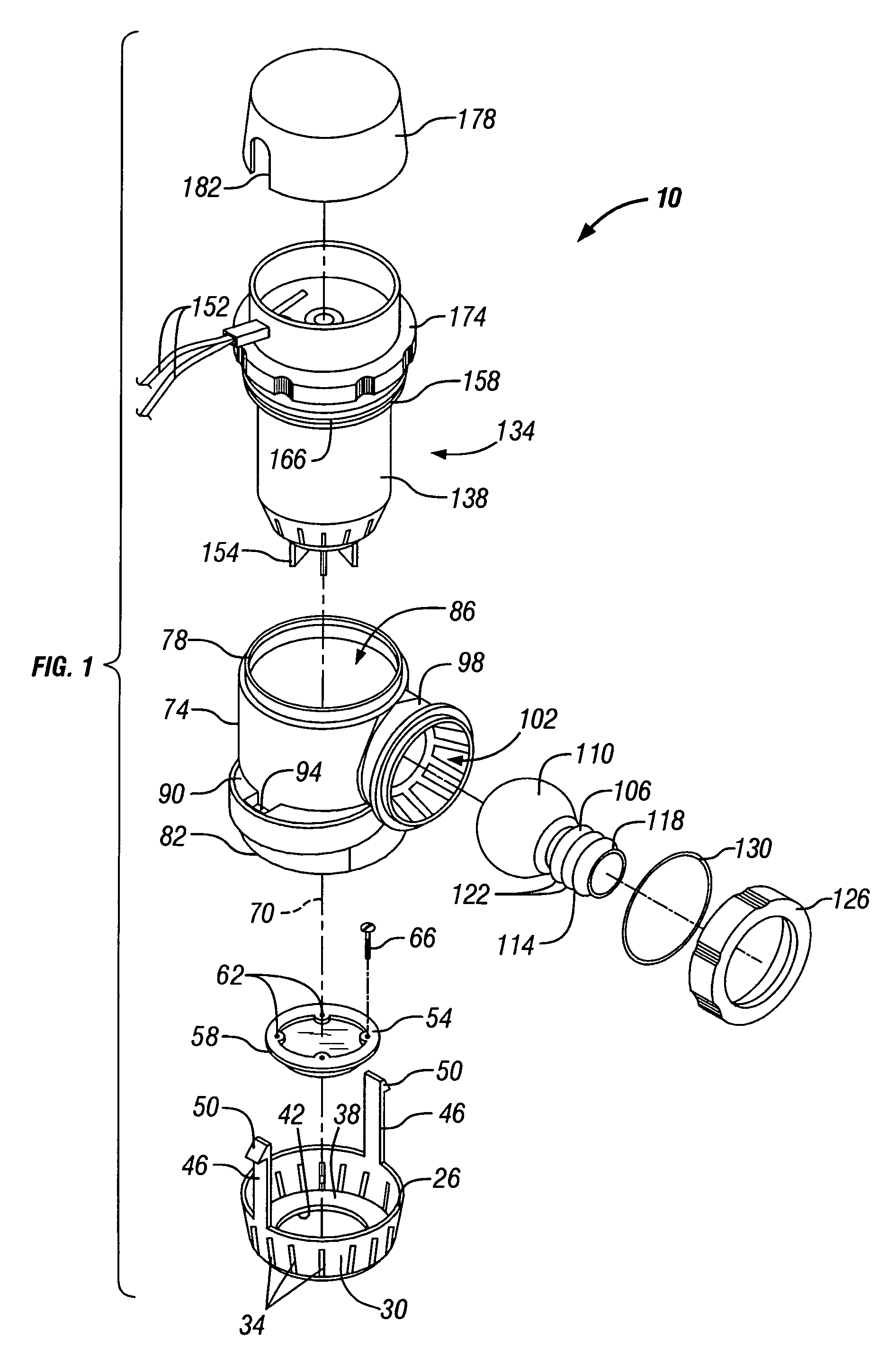

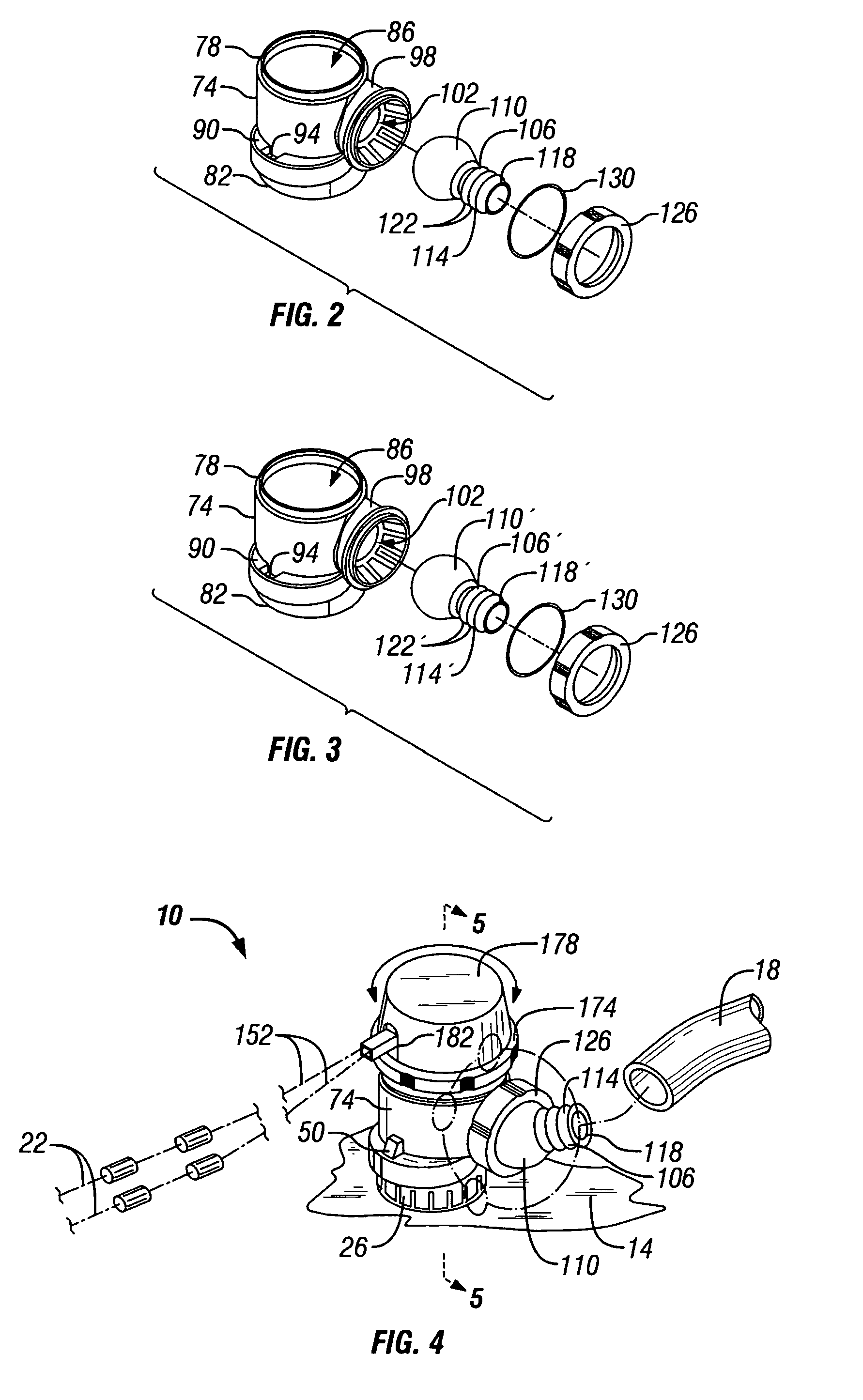

Bilge pump

InactiveUS7806664B2Easy to installIncrease contactEngine manufacturePositive displacement pump componentsBilge pumpNozzle

A bilge pump having a mounting member adapted to be mounted to a vessel and a base movably engageable with the mounting member and positionable in at least two positions relative to the mounting member. A housing is releasably coupled to the base and defines a cavity for receiving a motor. A locking ring is engageable with the motor and the housing to secure the motor in the cavity while allowing the motor to be movable with respect to the housing. The cavity in the housing communicates with an outlet portion defining a socket. An outlet nozzle having an outlet end is movably received in the socket so that the outlet end can be moved relative to the housing. These features can be employed individually or in combination to make the bilge pump highly adaptable, thereby facilitating installation.

Owner:SHURFLO

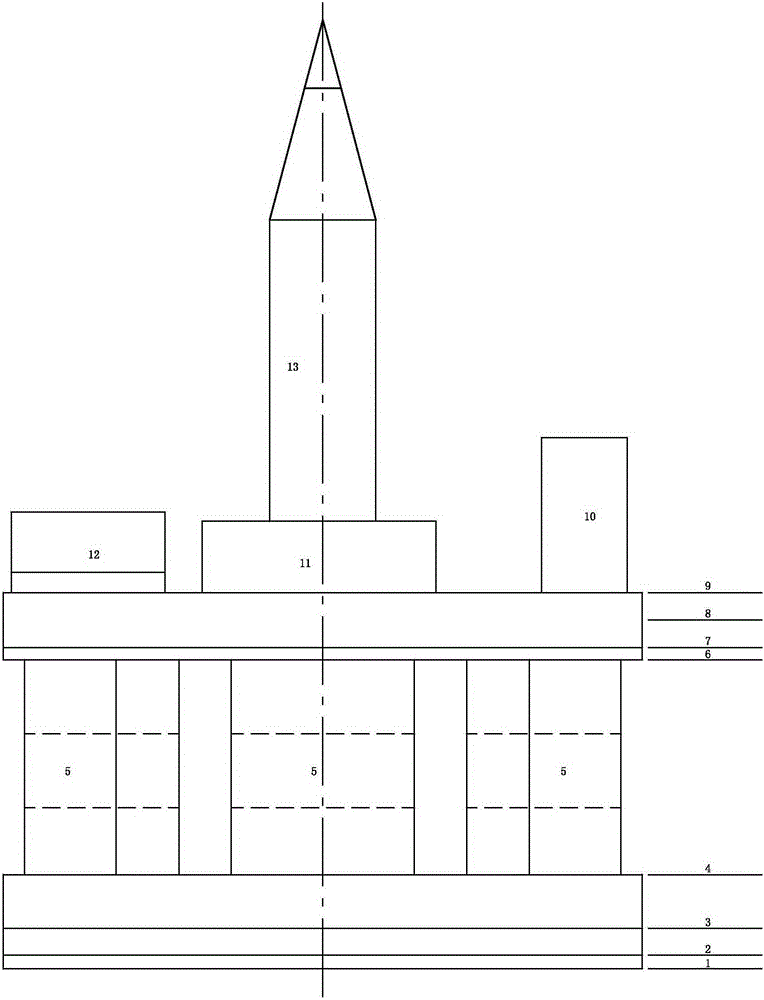

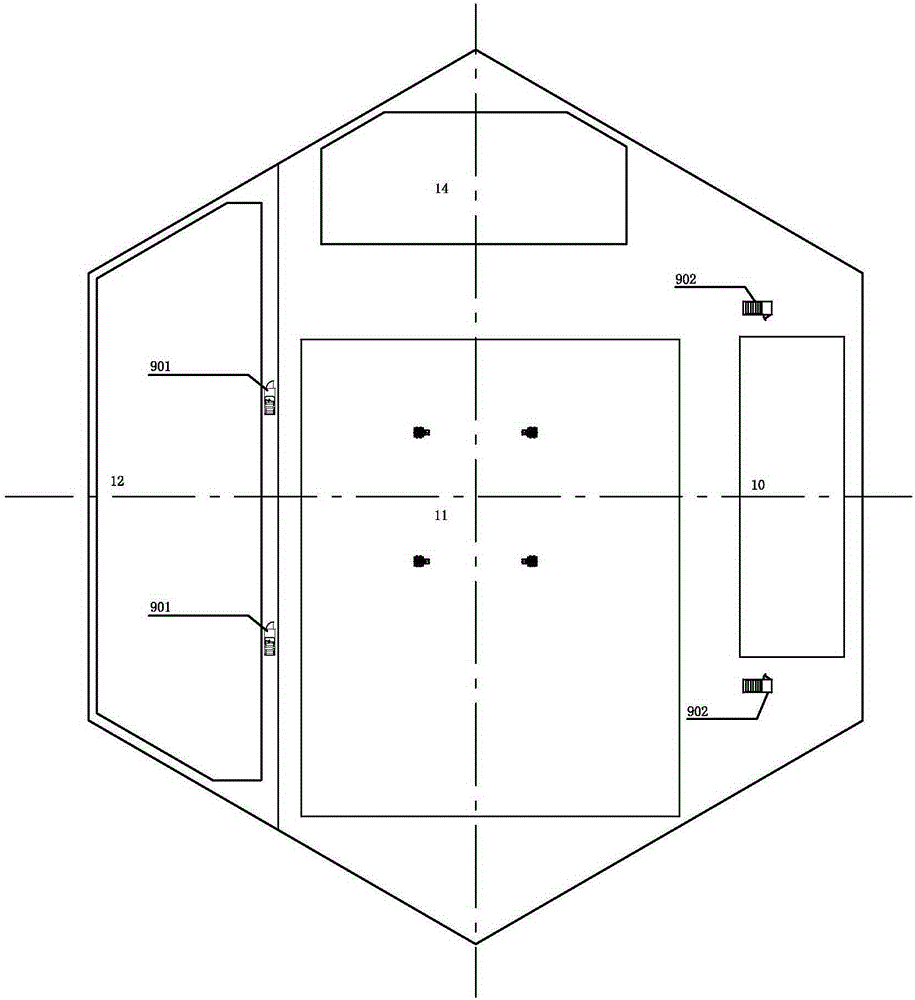

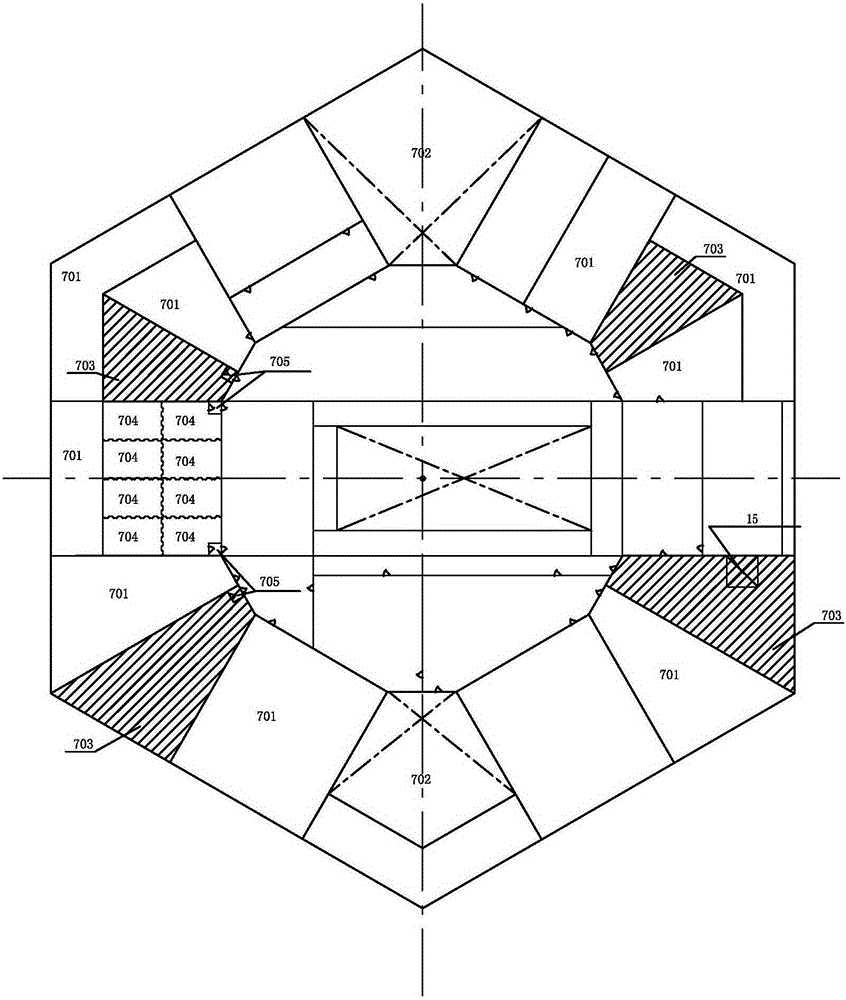

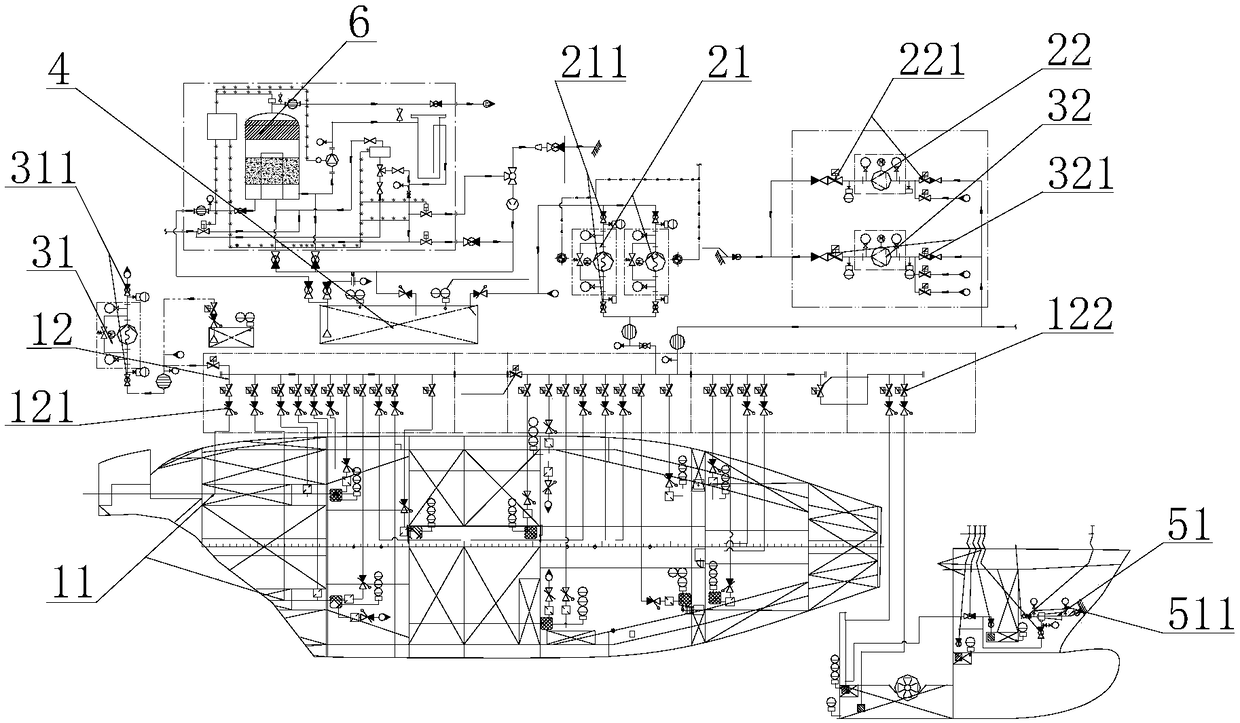

Floating type well drilling production oil storage device pump compartment design

ActiveCN105292391AReduce layoutReduce weightHull interior subdivisionFloating buildingsWell drillingBallast

The invention relates to a floating type well drilling production oil storage device pump compartment and the related structural design. The design requirement for FDPSO well drilling and oil gas treatment related functions can be met. According to the hexagonal floating type well drilling production oil storage device pump compartment design, two universal pump compartments, two cargo oil pump compartments and a pump compartment channel are included. The two universal pump compartments are used for arranging universal pumps used for a platform and well drilling. The universal pumps mainly comprise the ballast pump, the bilge pump, the fire pump and the sea water pump. The two cargo oil pump compartments are used for arranging cargo oil pumps and related equipment. The four pump compartments can be directly connected with an open deck of a main deck through the pump compartment channel. According to the floating type well drilling production oil storage device pump compartment design, the internal space of an FDPSO lower-portion hexagonal floating body structure is sufficiently utilized, and the equipment arrangement and the reasonable distribution of the equipment weight center of gravity are optimized. The floating type well drilling production oil storage device pump compartment design and the hexagonal FDPSO general arrangement are perfectly combined, and a living region of the main deck, a processing region of a production module, a well drilling region and the pump compartment and channel arrangement are organically combined.

Owner:DALIAN SHIPBUILDING IND

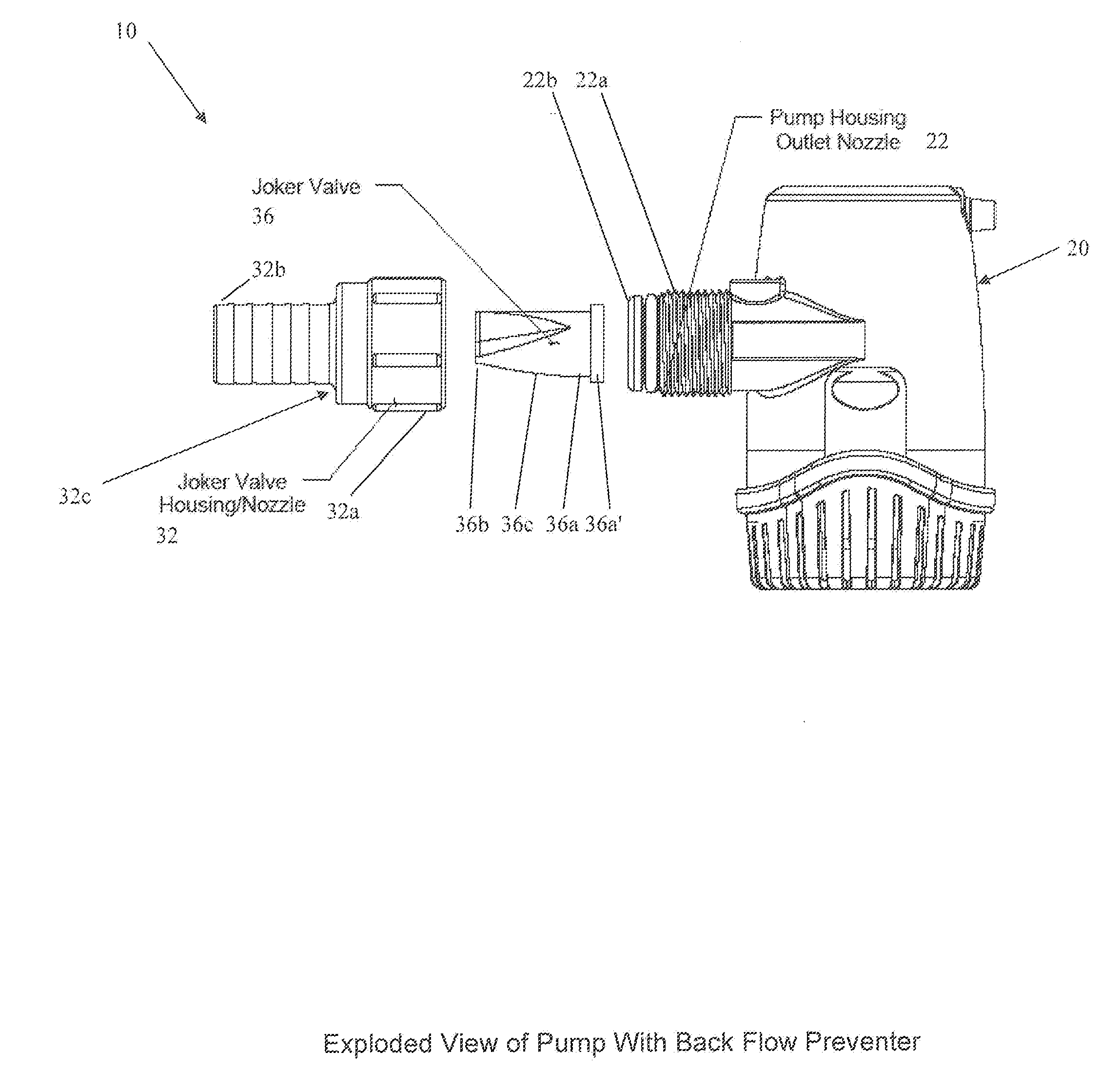

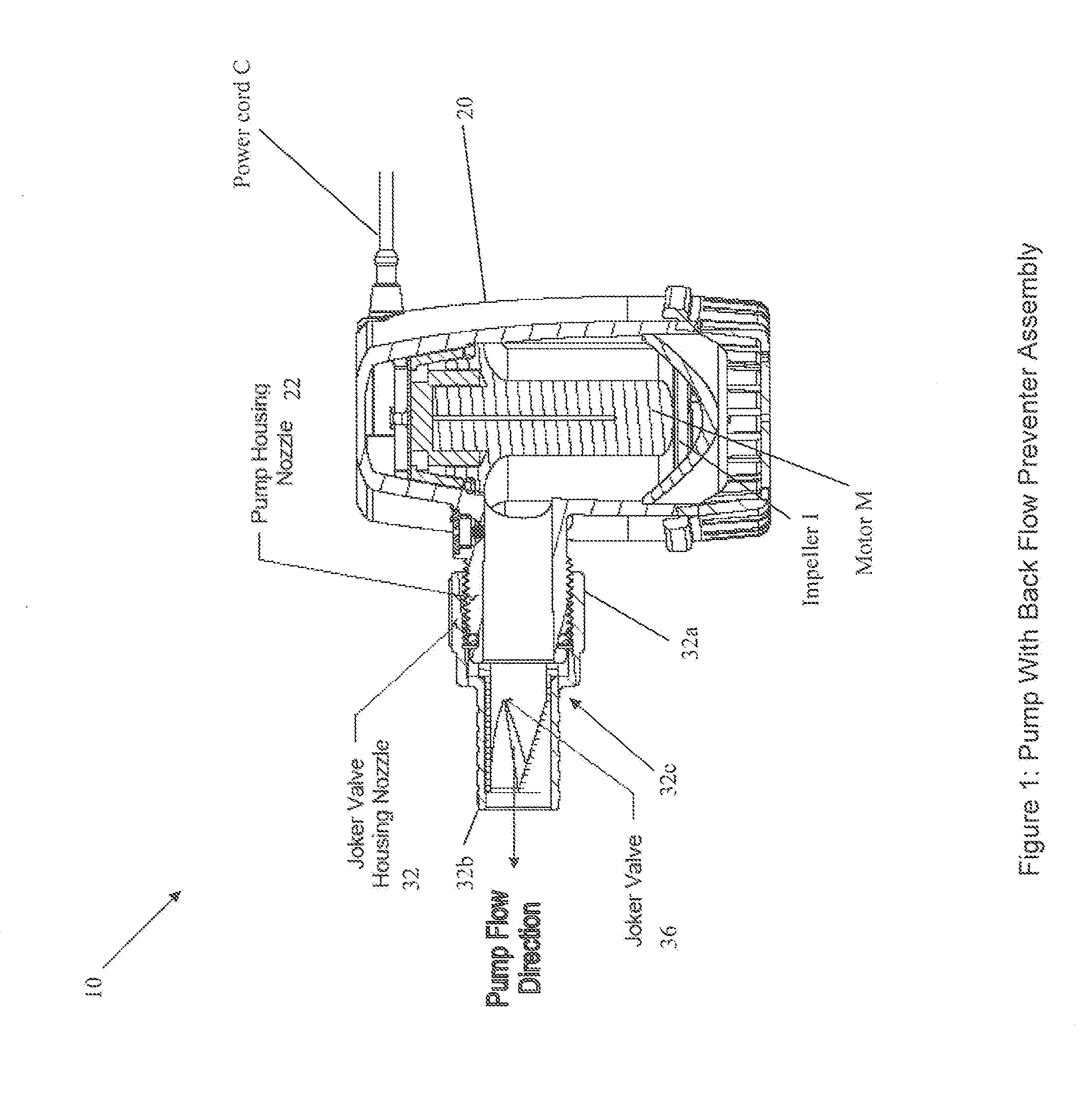

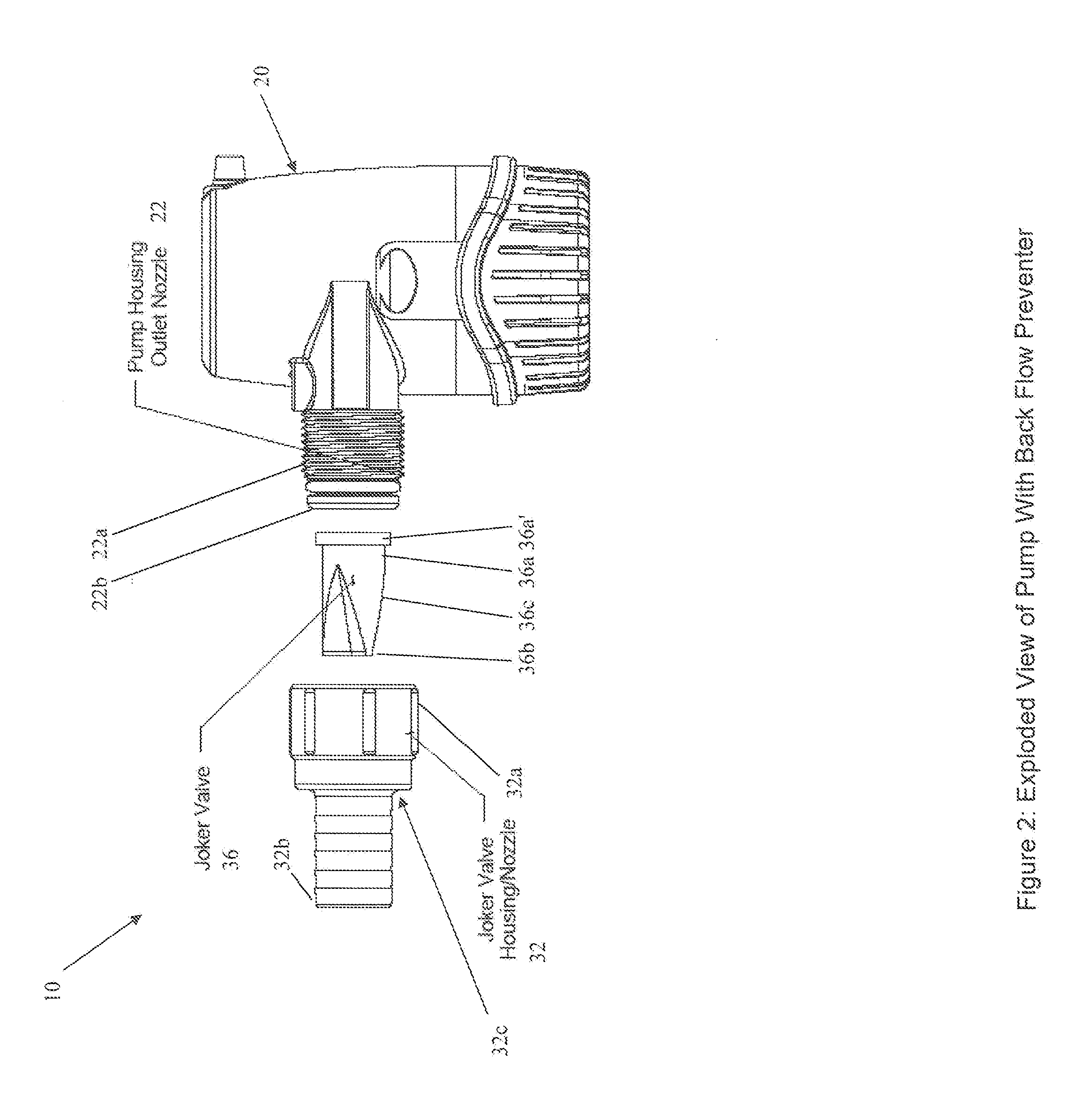

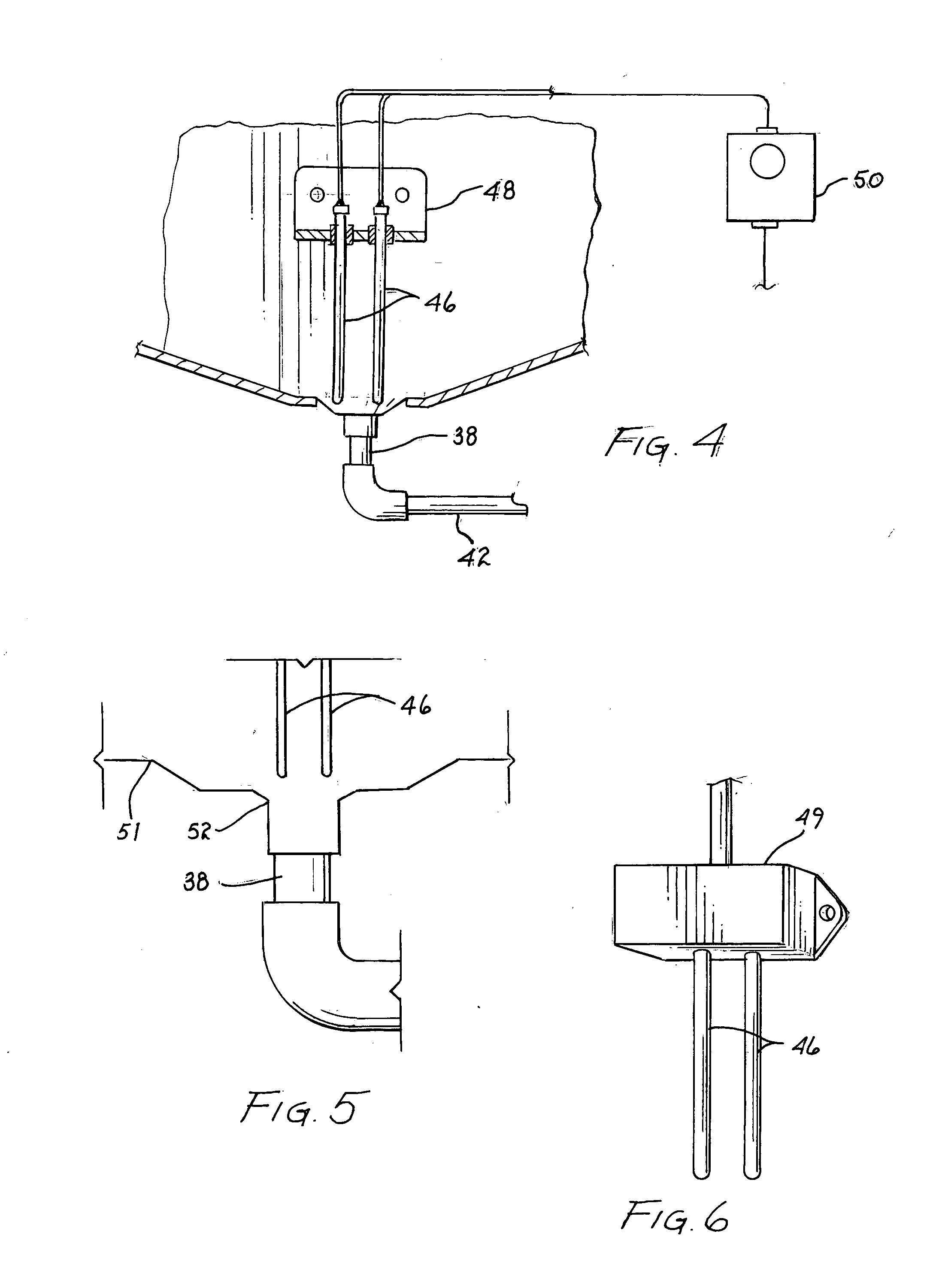

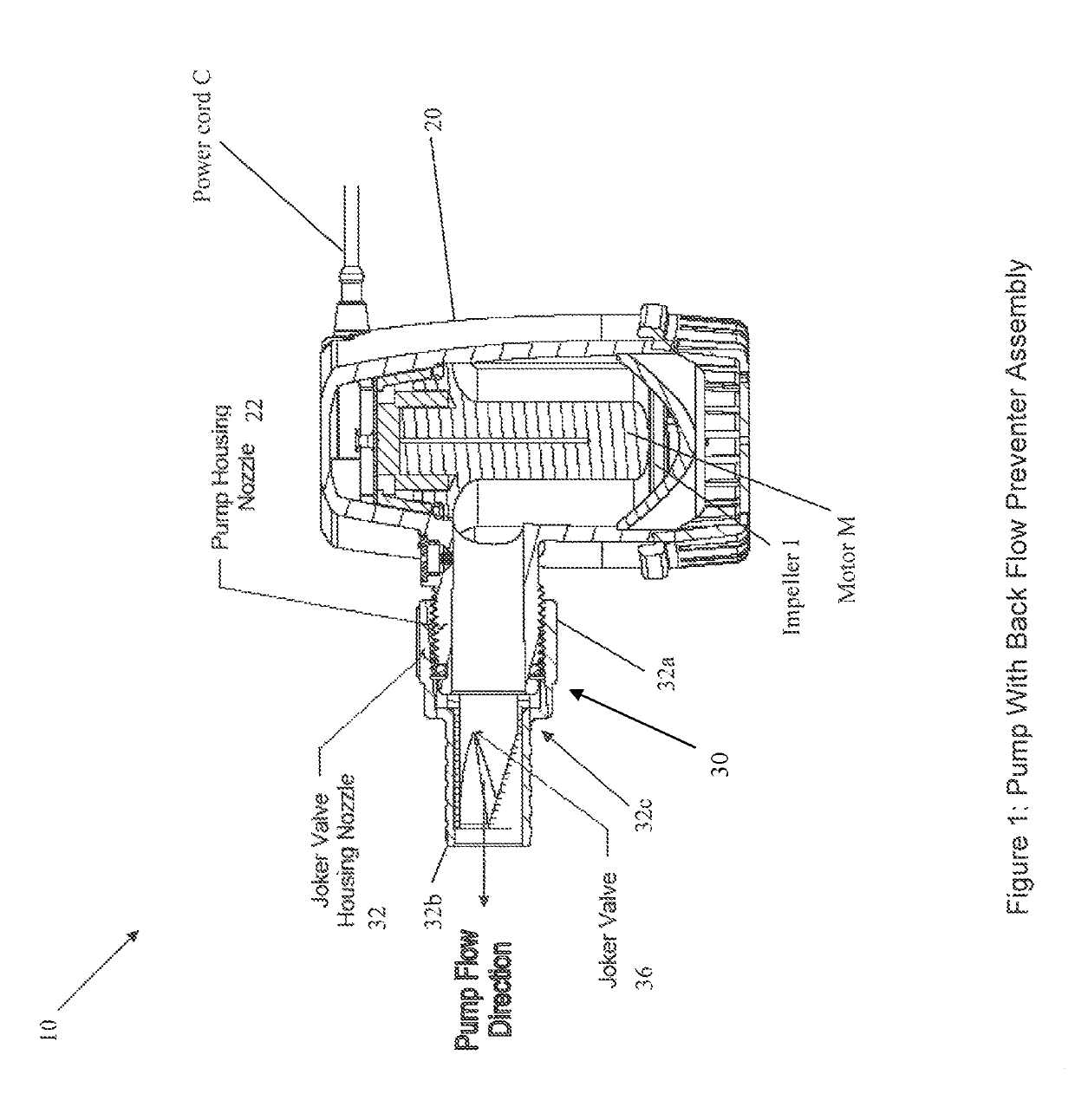

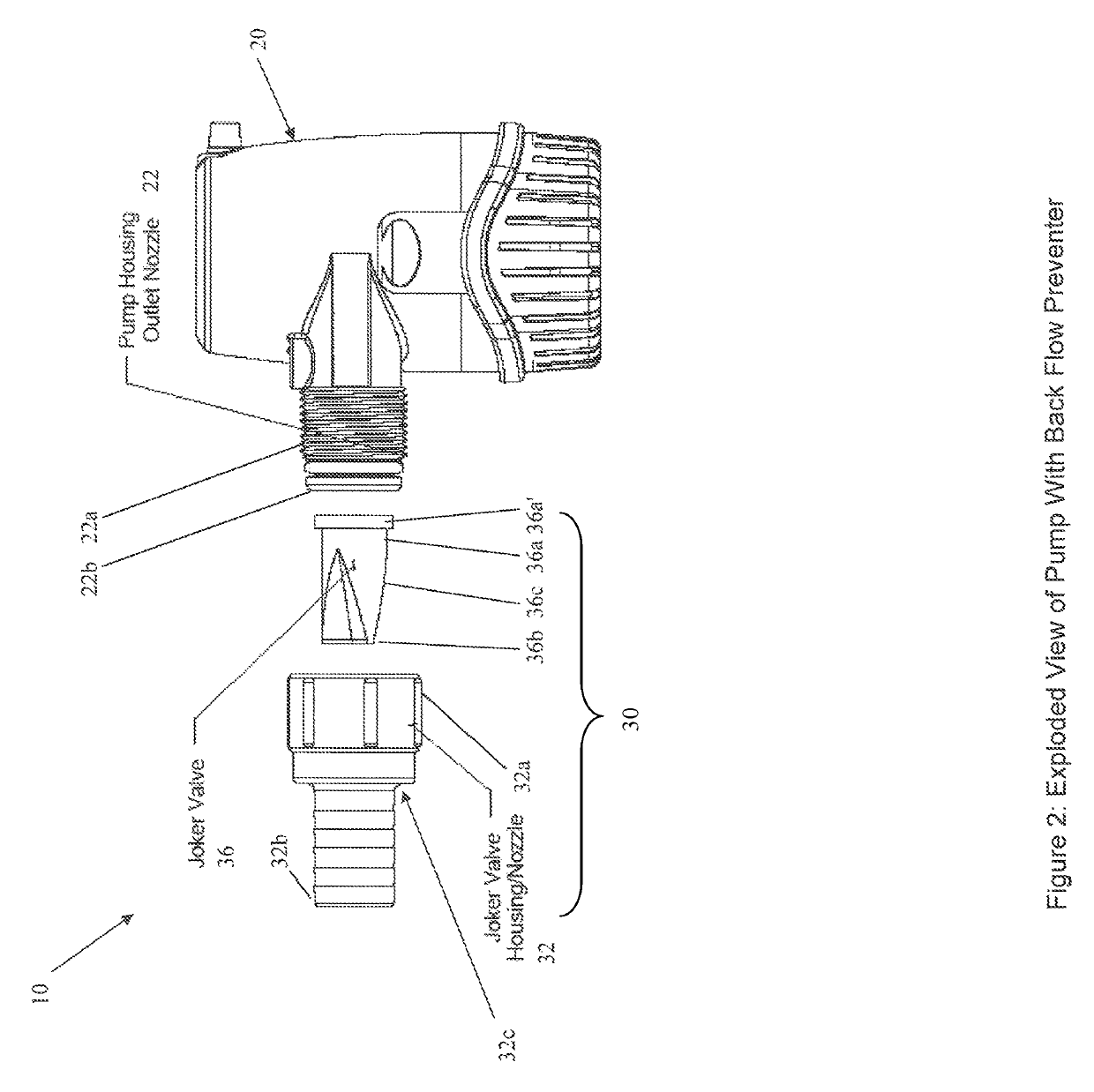

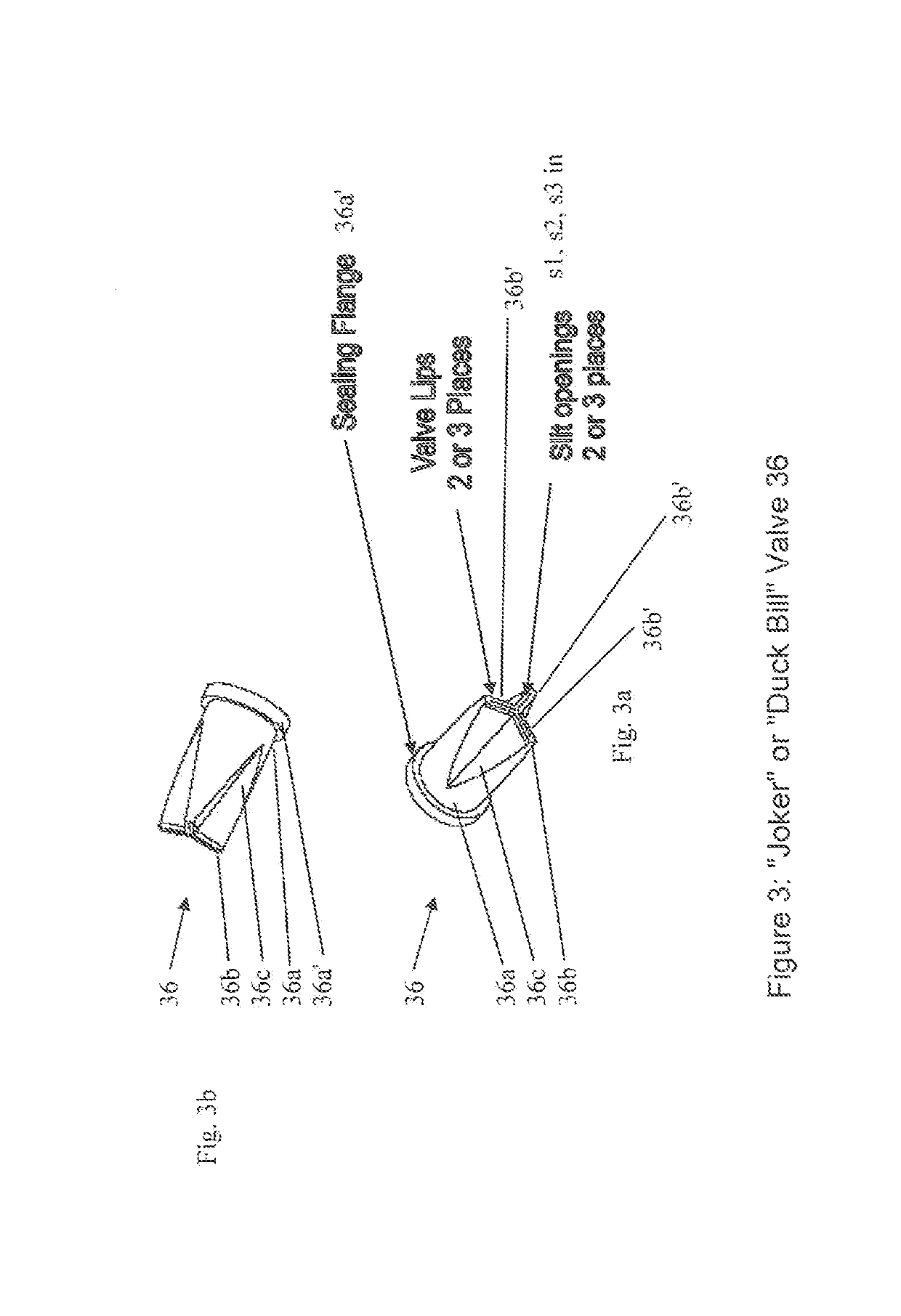

Bilge pump arrangement having back flow preventer

ActiveUS20150247504A1Prevent returnAvoid oscillationPump componentsCheck valvesBackflow prevention deviceCheck valve

Apparatus for providing liquid from a reservoir of liquid contained in a vehicle / vessel or other equipment, featuring a pump for pumping liquid having a pump housing outlet nozzle; and a back flow preventer assembly having an inlet end to couple to the outlet nozzle, having an outlet end to couple to an outlet hose for connecting to an outlet exiting a wall of a vehicle, vessel or other equipment, and having a duckbill-type check valve to provide liquid being pumped in one direction from the reservoir of the vehicle, vessel or other equipment to the outlet exiting the wall of the vehicle, vessel or other equipment via the outlet hose, and also configured to prevent residue liquid left in the outlet hose from flowing back into the pump and returning to the reservoir once the pump has completed pumping if the outlet exiting the wall of the vehicle, vessel or other equipment is above the outlet nozzle, so as to prevent on an on / off oscillation of the pump depending on the volume of residue liquid left in the outlet hose.

Owner:FLOW CONTROL LLC

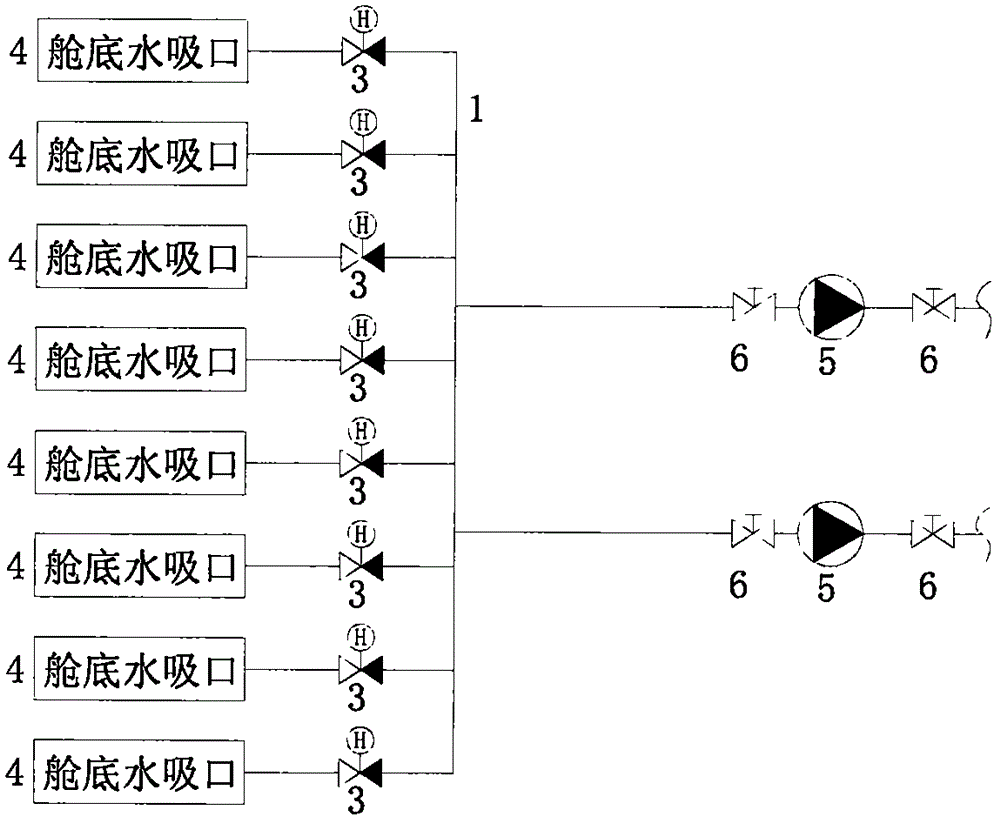

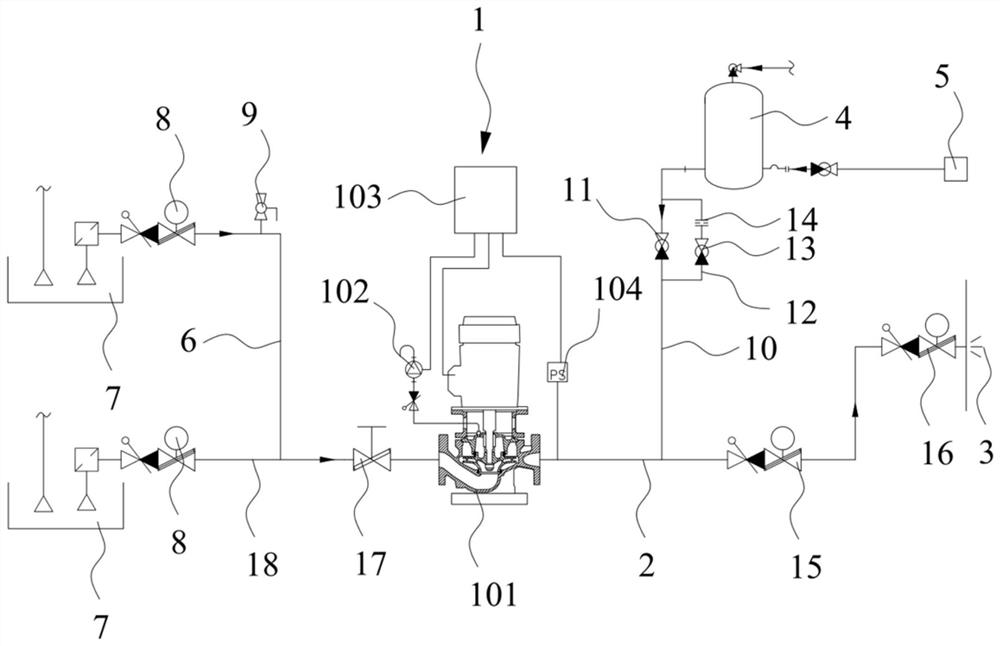

A marine dry bilge water collection system

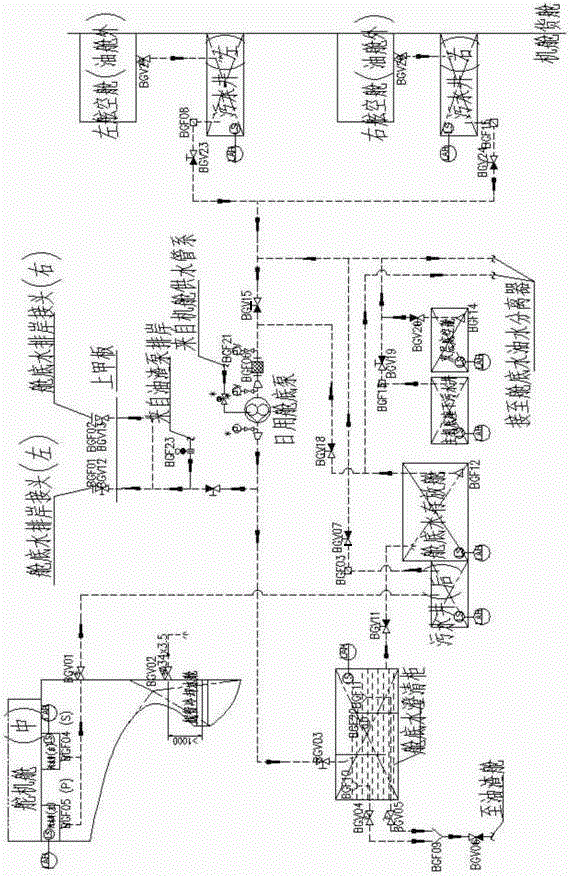

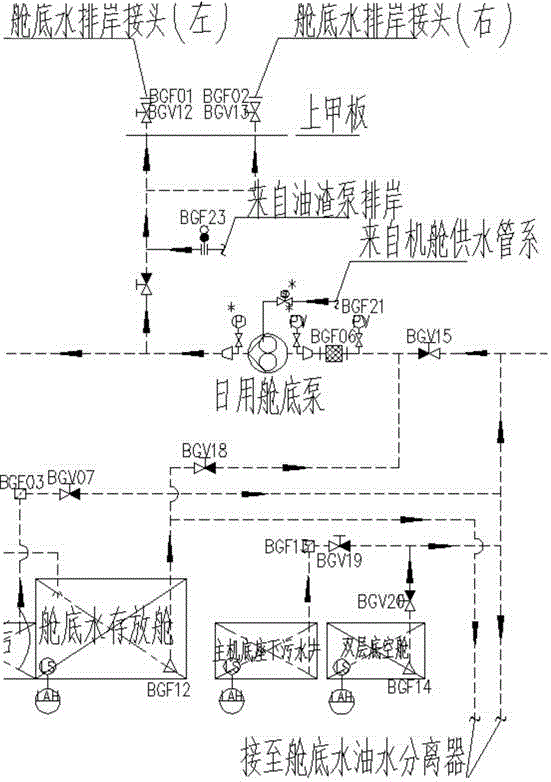

PendingCN108974252AEnsure safetyPrevents cavitationAuxillariesSelf-bailing equipments/scuppersEngineeringSewage

A marine dry bilge water collection system is disclosed. A marine dry bilge water collection system comprises a plurality of machinery spaces, a plurality of cargo compartments, a main engine compartment, a propulsion engine compartment and a bilge tank, wherein a plurality of sewage wells are arranged in the machine compartment and the cargo compartment, a plurality of sewage wells are communicated with each other through a connecting pipeline, a check valve is arranged at the connection of each sewage well and the connecting pipeline, and daily bilge pumps and bilge pumps of the main enginecompartment are arranged in the main engine compartment; One end of the main engine room daily bilge pump is communicated with each sewage well through a pipeline, and the other end is communicated with the bilge tank through a pipeline; One end of the main engine bilge pump is communicated with each sewage well through a pipeline, and the other end is communicated with the bilge tank through a pipeline; A daily bilge pump for that propulsion engine room and a bilge pump for the propulsion engine room are arrange in the propulsion engine room.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

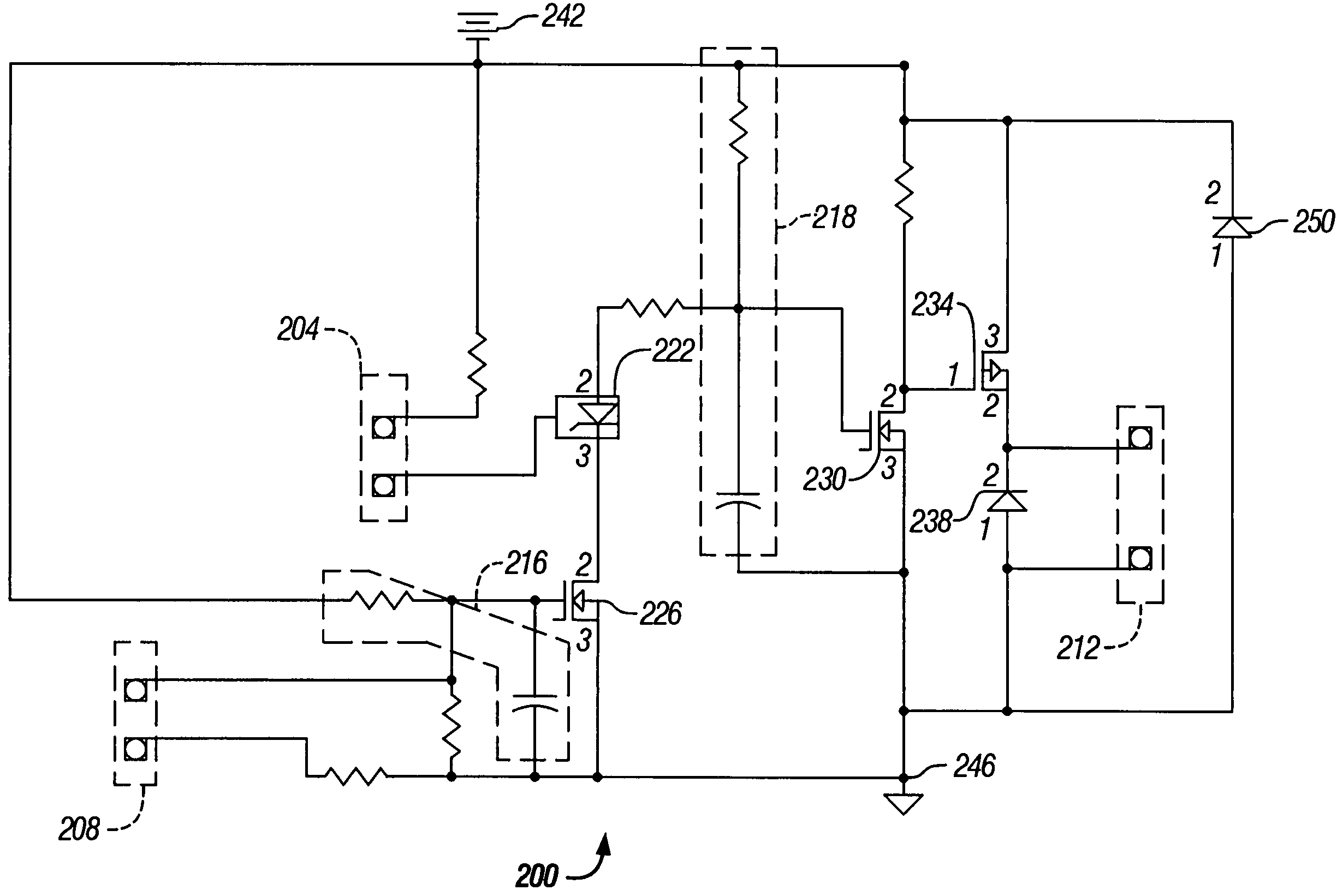

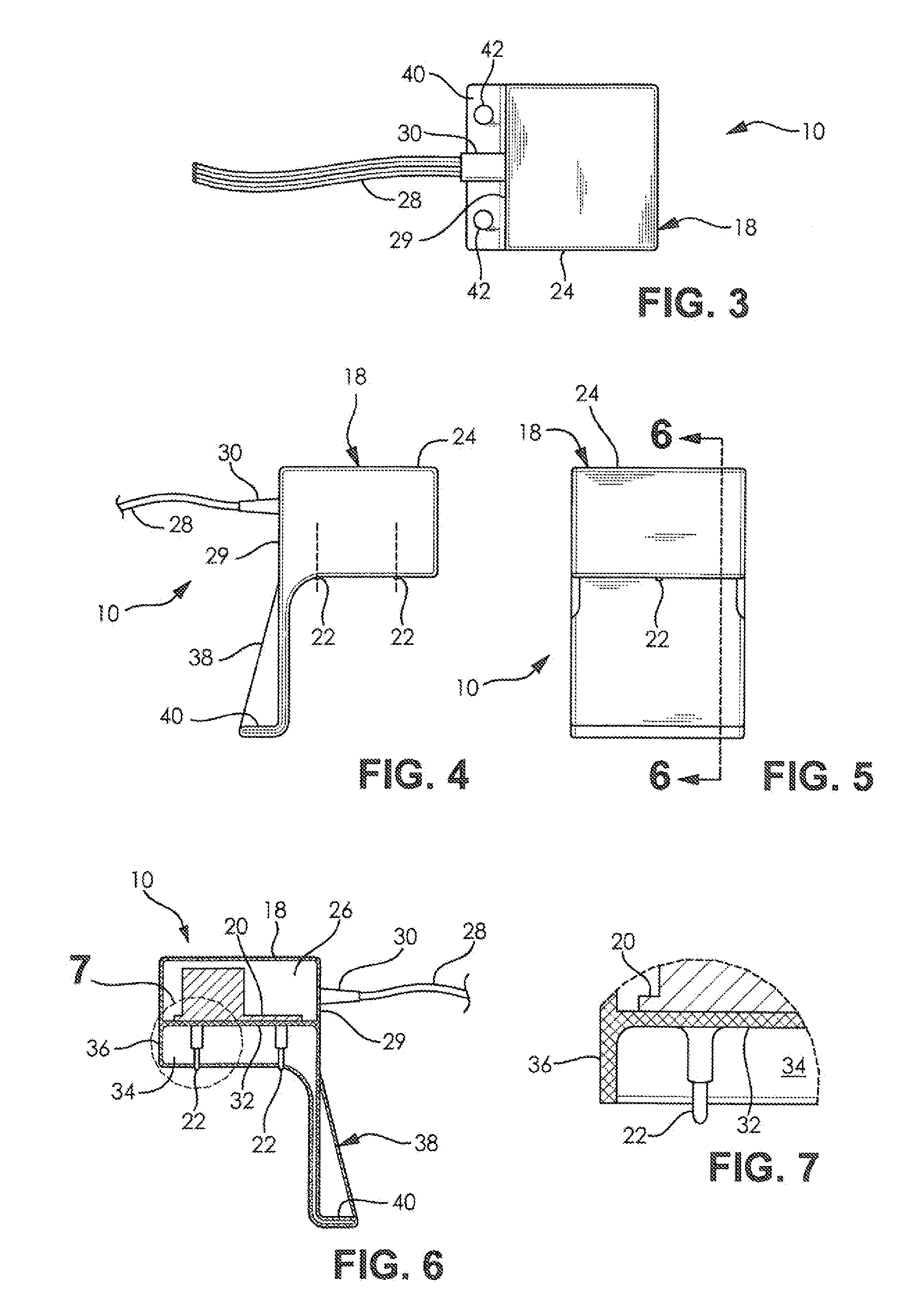

Solid state bilge pump switch

ActiveUS20130140912A1Low costBoards/switchyards circuit arrangementsElectric switchesCurrent sensorEngineering

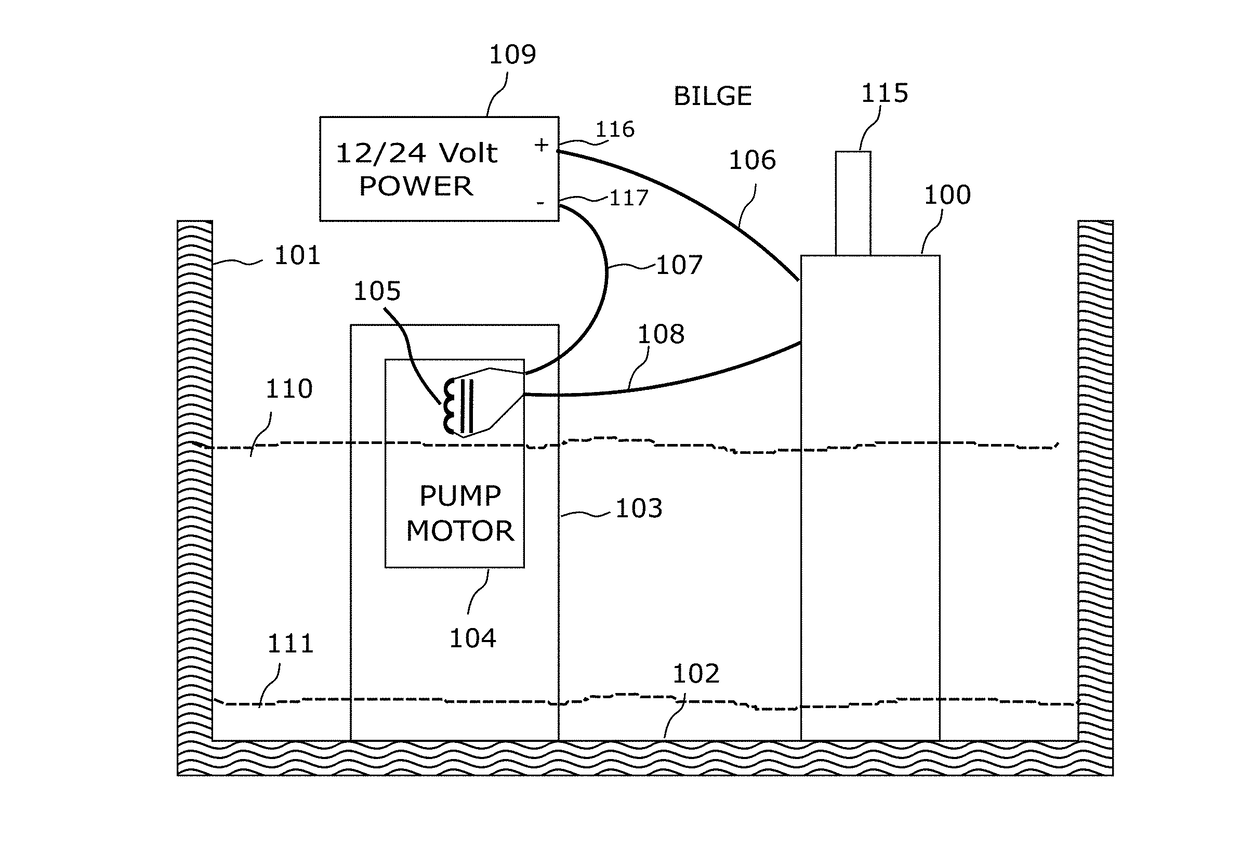

A switch for a bilge pump of a boat includes a pair of probes for providing a probe signal indicating the presence of fluid at the probes, a current sensor for providing a sensor signal indicating electric current of the pump; and a controller programmed to energize the pump when a threshold level of the probe signal indicates the presence of fluid and to de-energize the pump when a threshold level of the sensor signal indicates that the pump is not pumping fluid. The controller can also be programmed to dynamically change the threshold level of the probe signal based on a prior probe signal that indicates changing probe conditions.

Owner:LAKE RED ROCK

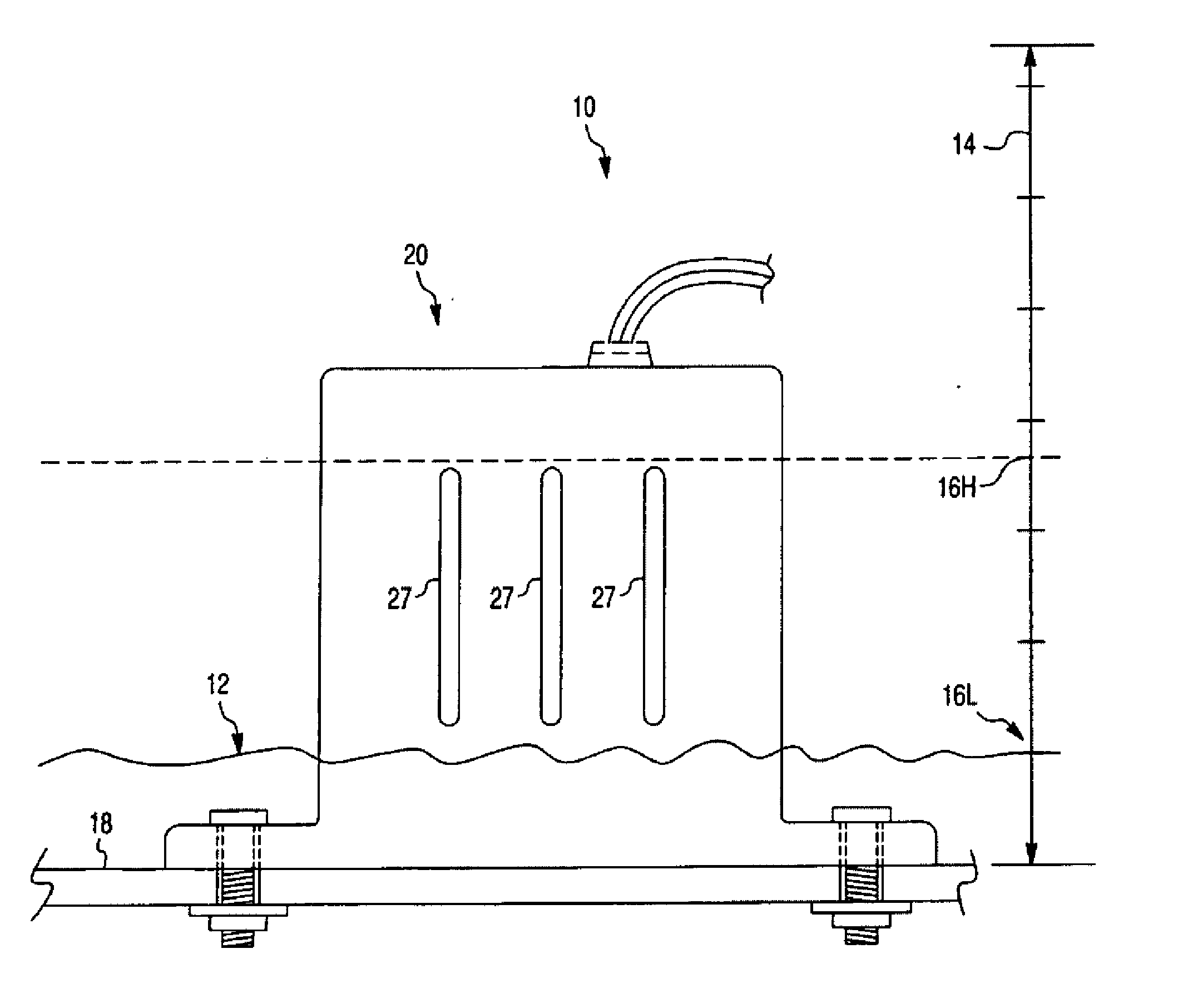

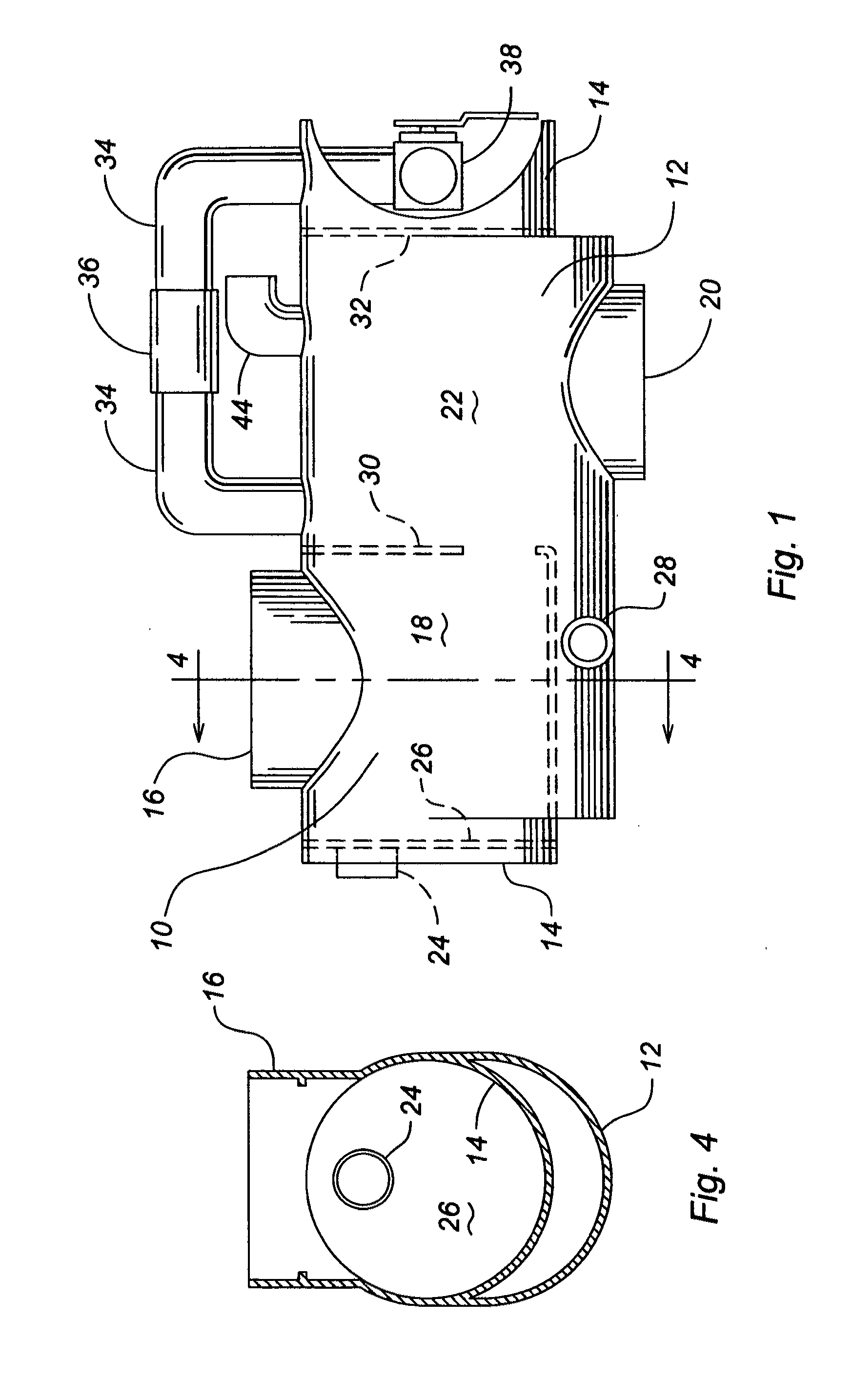

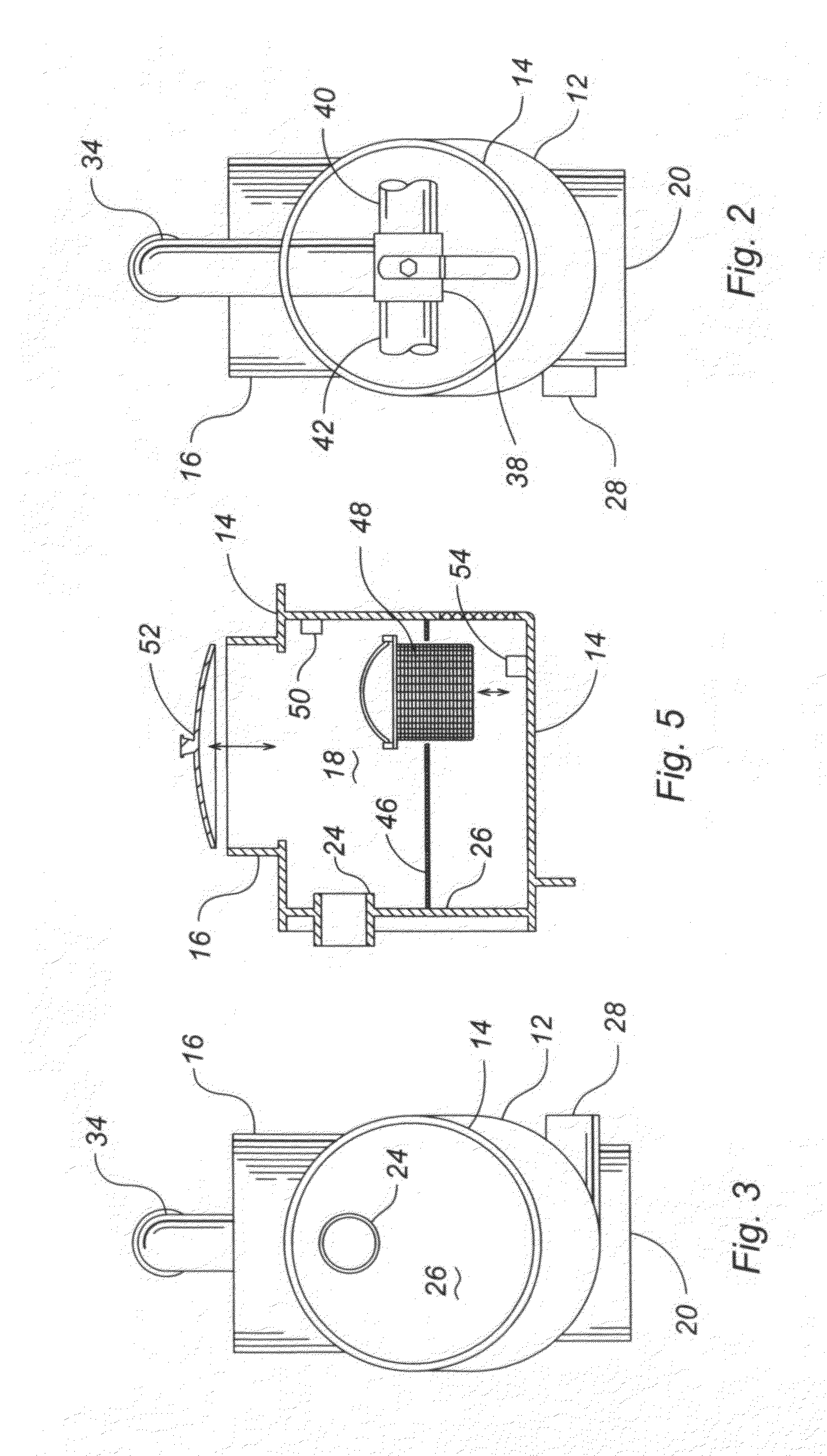

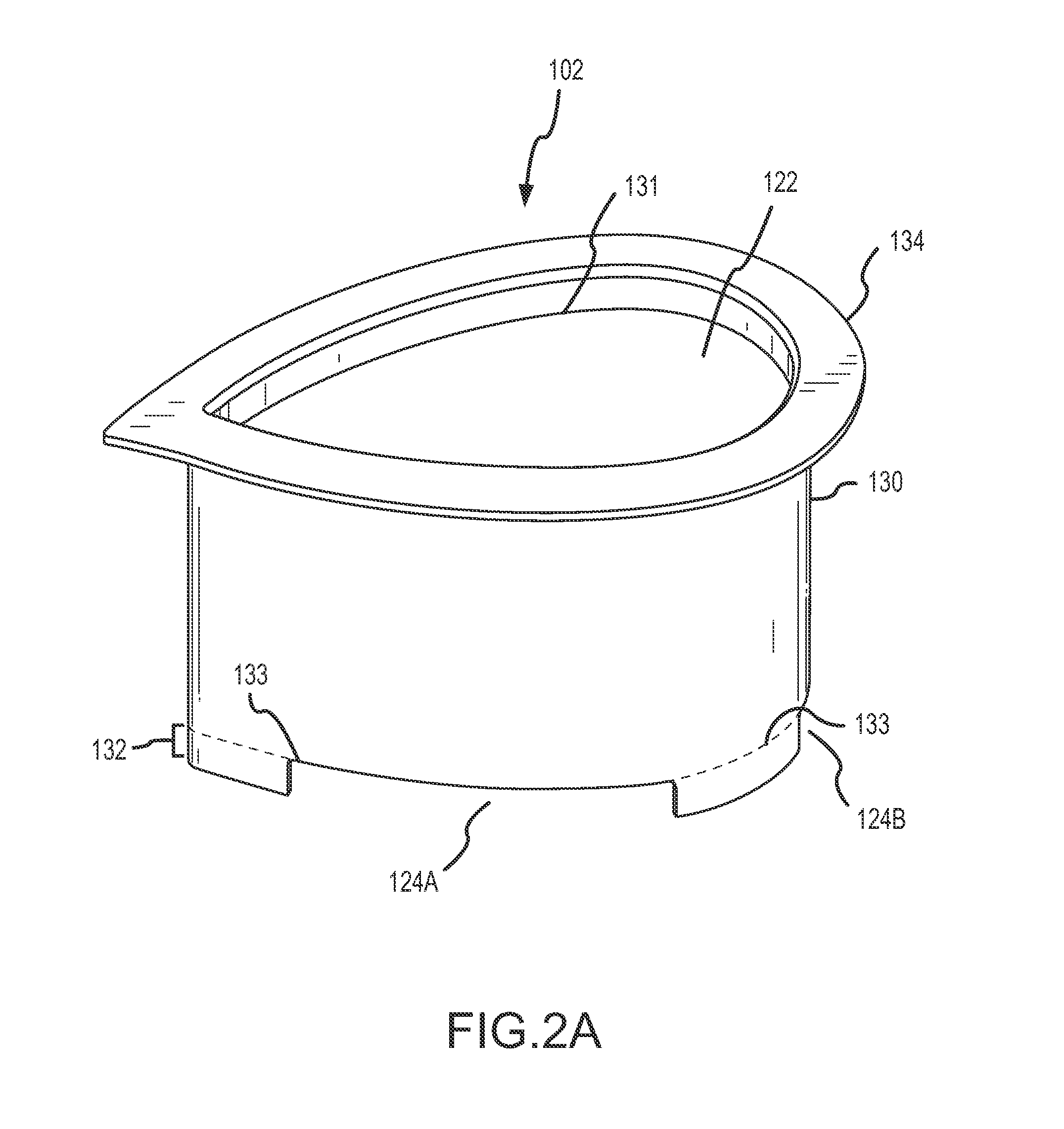

Automatic bilge pump system

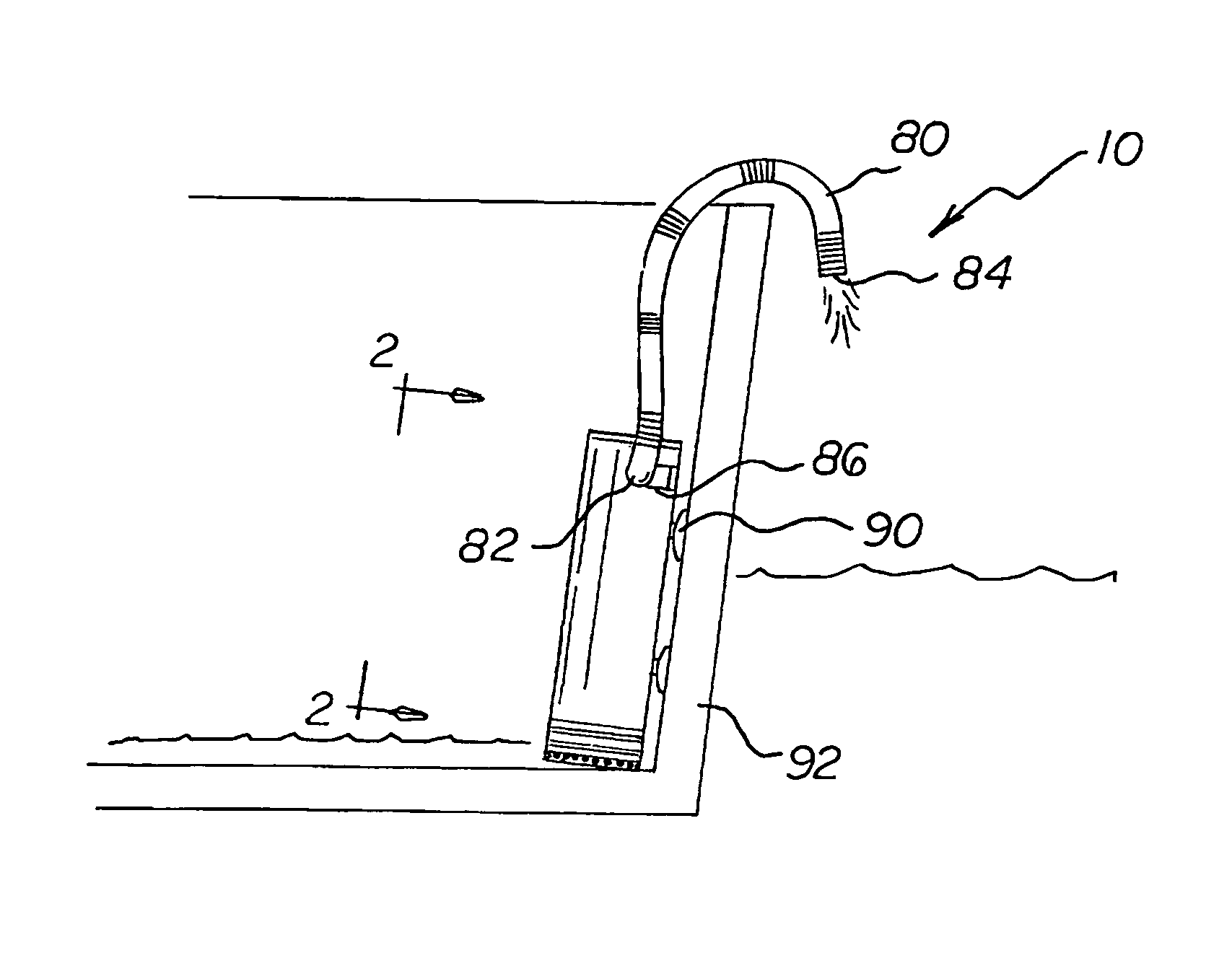

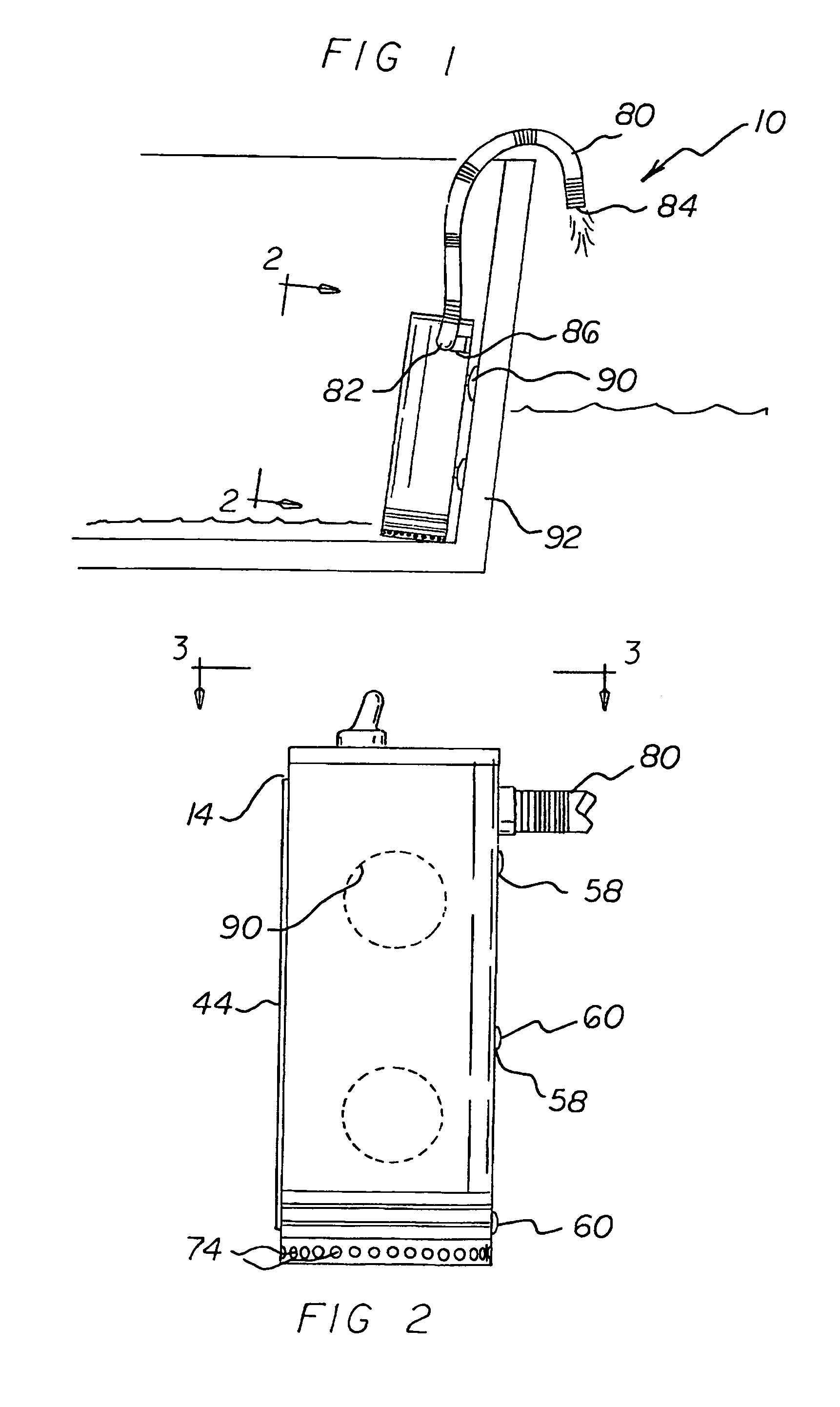

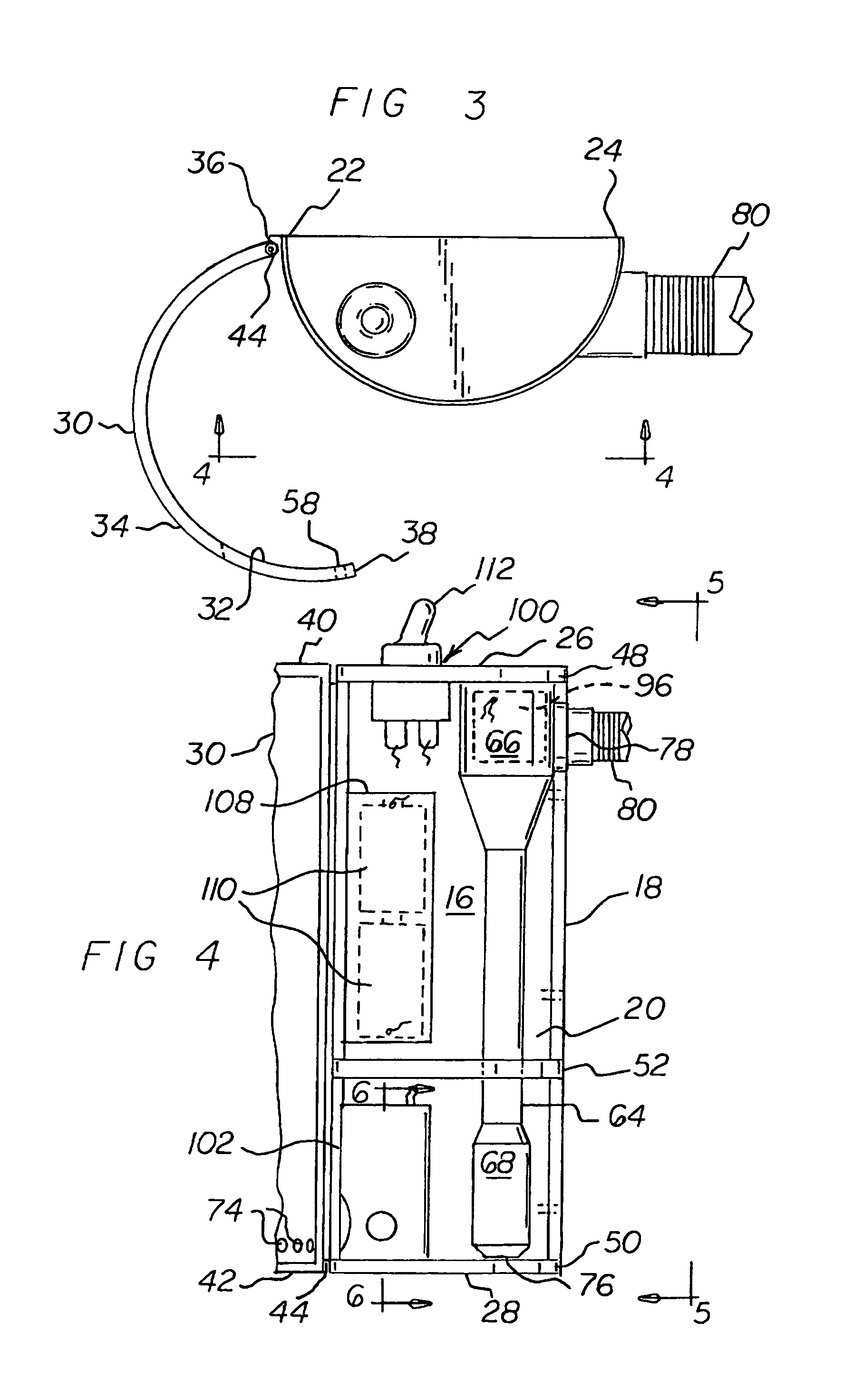

InactiveUS7841286B1Easy and efficient to manufactureDurable and reliable constructionAuxillariesSelf-bailing equipments/scuppersBilge pumpWaste management

A container has a base and a cover. A housing is provided within the container. The housing has an upper extend and a water passageway for the upward flow of water. A hose extends laterally from the upper extent of the housing. A pump in the housing moves water through the housing and the hose. A control assembly controls the operation of the pump.

Owner:BOCHENSKI SEBASTIAN

Electronic Bilge Pump Switch with Monitoring and RF Communication, Apparatus and System

An electronic controller for a bilge pump providing the functions of monitoring liquid level in a boat bilge, and controlling the operation of the bilge pump, and monitoring the bilge pump operation, including bilge temperature, the bilge pump current and voltage, and maintaining a log of the collected data and providing the data to a remote device. In addition, the pump controller dynamically adjusts the bilge pumps operation based on commands received from a remote device and the logged data. In addition, the system monitors for hazardous materials within the bilge fluid preventing discharge within protected water ways.

Owner:VON MUELLER CLAY WERNER

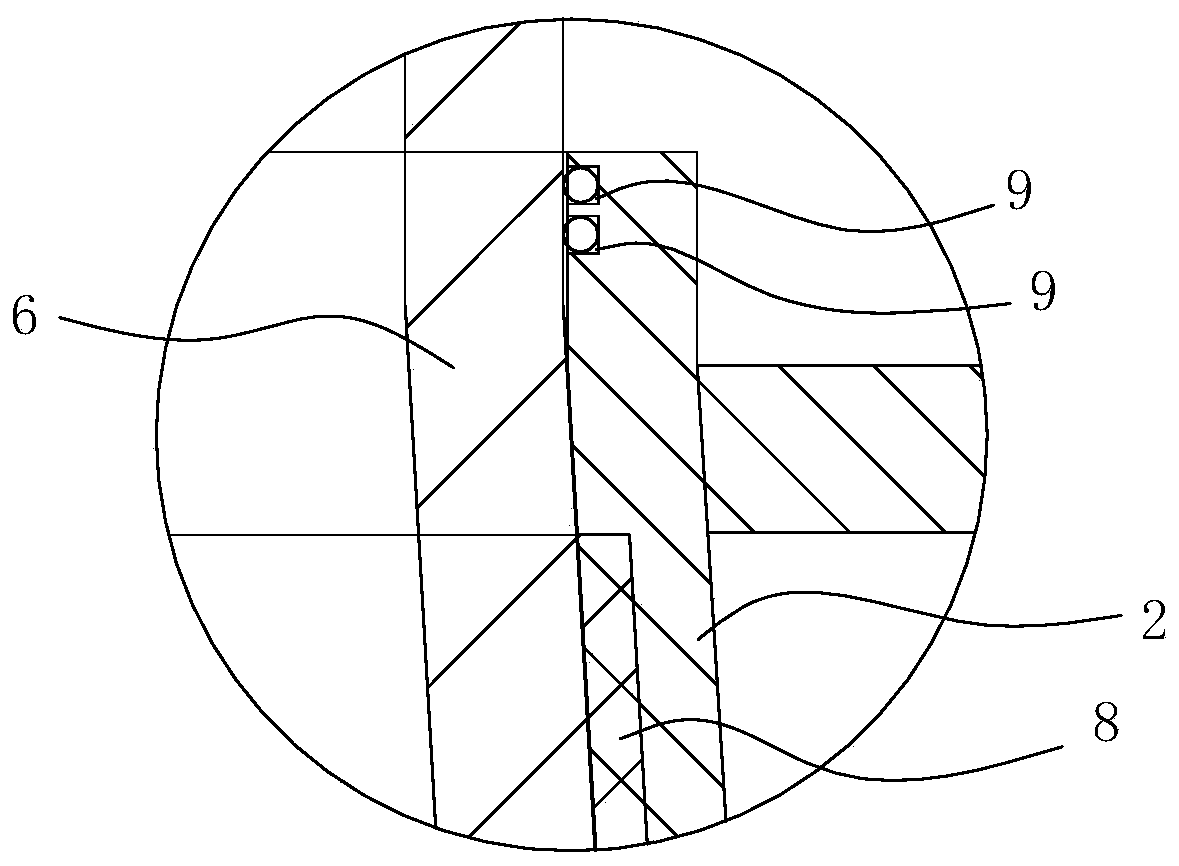

Ship water absorption device and ship

ActiveCN109795618AAvoid enteringStable suctionSelf-bailing equipments/scuppersVessel partsBilge pump

The invention discloses a ship water absorption device which comprises a water absorption pipe and a floating component which are positioned inside a cabin. One end of the water absorption pipe is connected with a bilge, the other end of the water absorption pipe is connected with a supporting pipe, a water inlet for entering of accumulated water in the cabin is formed in the side wall of the water absorption pipe, and the floating component sleeves the periphery of the water absorption pipe and can vertically float relative to the water absorption pipe to selectively plug the water inlet. Bythe design, the floating component can automatically close the water inlet along with change of the accumulated water in the cabin, air can be timely prevented from entering the water absorption pipefrom the water inlet, a bilge pump can smoothly pump accumulated water in other cabins, so that normal operation of a bilge water system is ensured, and safety of a ship is improved. The invention further provides the ship which is low in manufacturing cost and good in safety.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

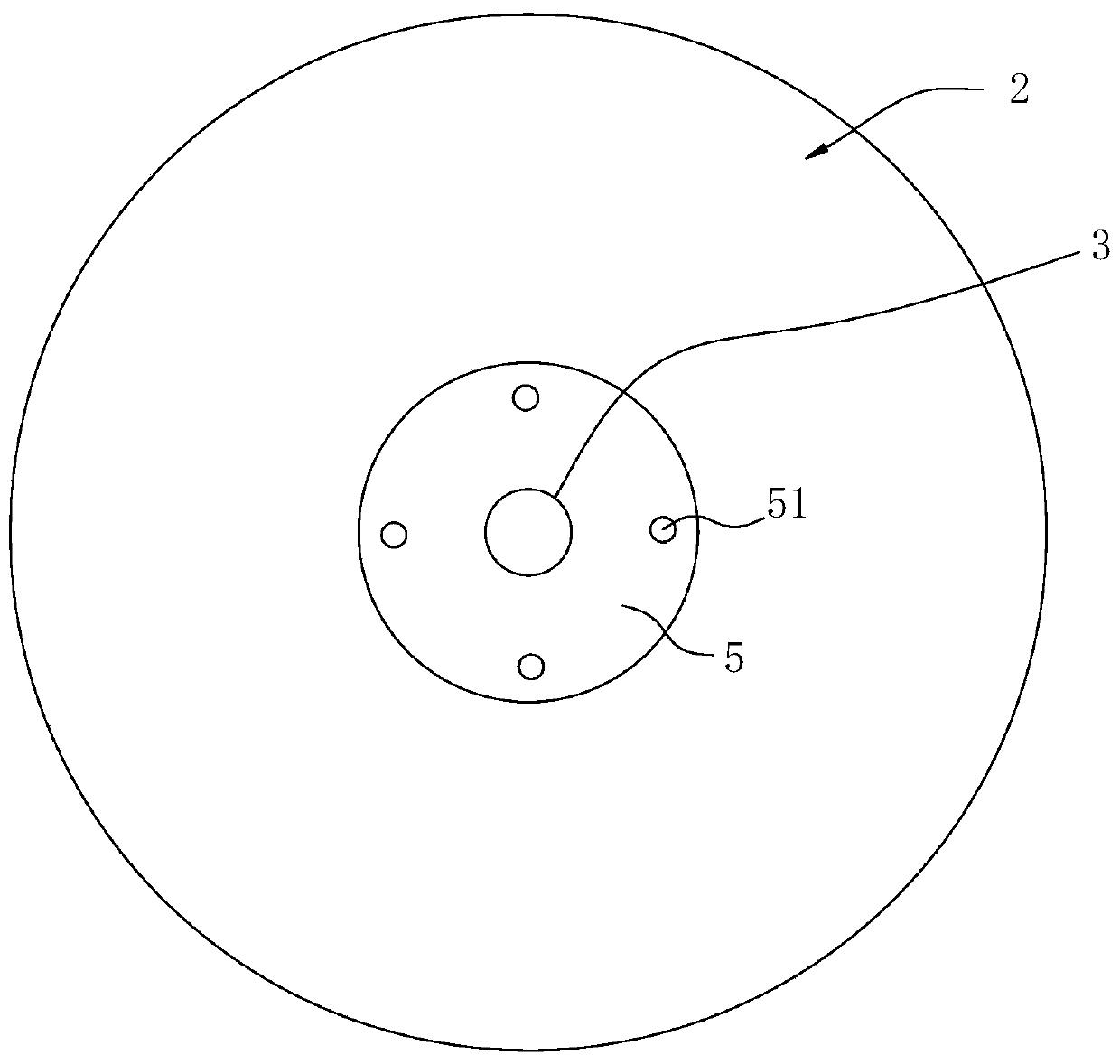

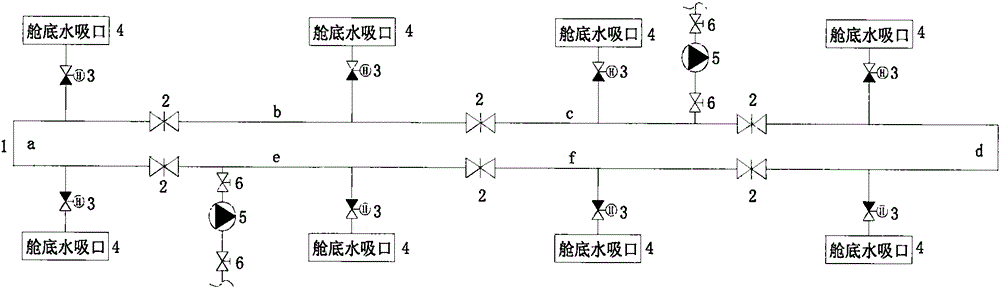

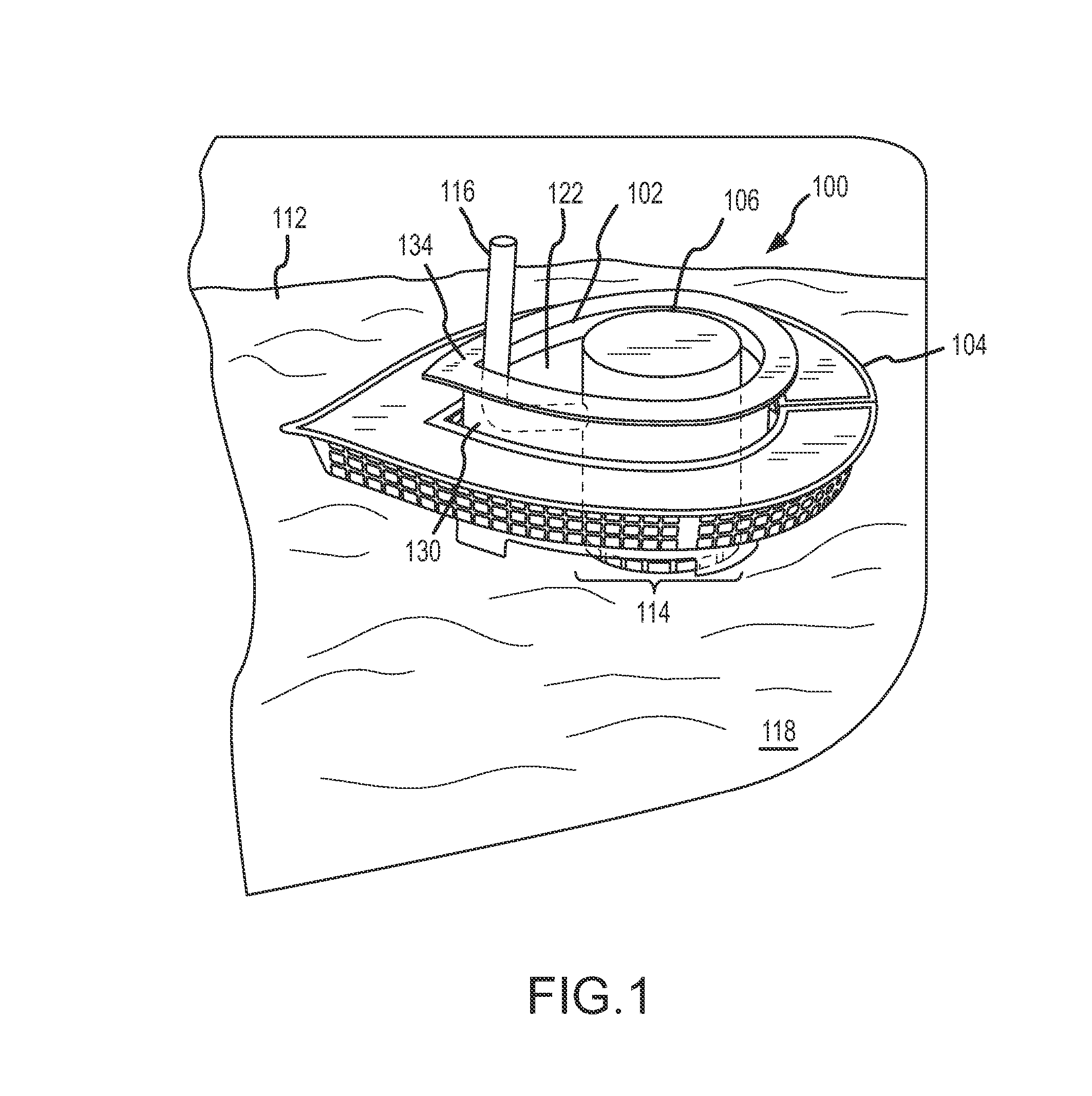

Annular header pipe type bilge system for ocean nuclear power platform

InactiveCN106314682AIncrease redundancyImprove reliabilitySelf-bailing equipments/scuppersVessel partsFluid controlIsolation valve

The invention discloses an annular header pipe type bilge system for an ocean nuclear power platform, relates to the technical field of bilge systems, and aims to solve the problem of influence on running of the entire system since the header pipe type bilge system tends to leak when a certain segment of pipeline fails in the prior art. In the bilge system, each bilge water suction port is connected with an annular header pipe through a fluid-controlled cut-off check valve; the annular header pipe is partitioned into a plurality of segments through isolating valves; bilge pumps are connected to the header pipe through cut-off valves. The isolating valves are in open states normally; when water is accumulated in a certain cabin and needs draining, the fluid-controlled cut-off check valve and the cut-off valves corresponding to the cabin are opened remotely, and the bilge pump is started, so that bilge water can be drained. The annular header pipe and the isolating valves are provided, so that the redundancy degree of the system functions is increased: when a certain segment of pipeline fails, the failed segment of pipeline can be isolated through the isolating valves, and the header pipe consisting of the rest of the segments of the pipelines can still run normally, the system functions are not influenced, normal running of the system is ensured, and the system reliability is improved.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND +1

Bilge water barrier and pollution prevention system

InactiveUS20070138080A1Avoid enteringAvoid volumeWater cleaningSelf-bailing equipments/scuppersPetrochemicalPollution prevention

A fluid pollution prevention system for preventing the discharge of hazardous waste from a bilge of a marine vessel. The system includes an continuous sidewall that defines a vertically enclosed volume. When positioned within a bilge, the sidewall forms a barrier to petrochemicals floating on a fluid surface within the bilge. An opening near a base of the sidewall permits fluid from beneath the fluid surface to enter the vertically enclosed volume. Such fluid is substantially free of petrochemicals and may be removed form the vertically enclosed volume. Accordingly, by pumping fluid out of the enclosed volume, fluid may be removed form the bilge substantially free of petrochemicals. In one arrangement, the vertically enclosed volume may be sized to receive a bilge pump.

Owner:PAUL ARTHUR CLUKIES

Marine greywater disposal system

An improved greywater disposal system is provided which substantially eliminates onboard standing greywater. The system includes one or more onboard plumbing fixtures fluidly connected to a greywater sump. The bottom of the greywater sump is sloped toward a drain therein at a low end. The prongs of a sensor may be suspended in the sump drain and / or in an inlet chamber defined at an inlet end of the greywater sump. The sensor is associated with a controller and sump or bilge pump. The pump is turned on when the prong tips of the sensor become immersed in greywater which occurs substantially simultaneously with the production of the greywater. The onboard plumbing fixtures include one or more sinks, showers, bathtubs, washing machines and air conditioning units. The system may be used on boats, ships, RVs, campers or the like.

Owner:DETWILER BRETT HOWARD

Bilge pump arrangement having back flow preventer

ActiveUS10302090B2Prevent returnAvoid oscillationPump componentsCheck valvesBackflow prevention deviceEngineering

Apparatus for providing liquid from a reservoir of liquid contained in a vehicle / vessel or other equipment, featuring a pump for pumping liquid having a pump housing outlet nozzle; and a back flow preventer assembly having an inlet end to couple to the outlet nozzle, having an outlet end to couple to an outlet hose for connecting to an outlet exiting a wall of a vehicle, vessel or other equipment, and having a duckbill-type check valve to provide liquid being pumped in one direction from the reservoir of the vehicle, vessel or other equipment to the outlet exiting the wall of the vehicle, vessel or other equipment via the outlet hose, and also configured to prevent residue liquid left in the outlet hose from flowing back into the pump and returning to the reservoir once the pump has completed pumping if the outlet exiting the wall of the vehicle, vessel or other equipment is above the outlet nozzle, so as to prevent on an on / off oscillation of the pump depending on the volume of residue liquid left in the outlet hose.

Owner:FLOW CONTROL LLC

Cabin bilge water preprocess system for ship

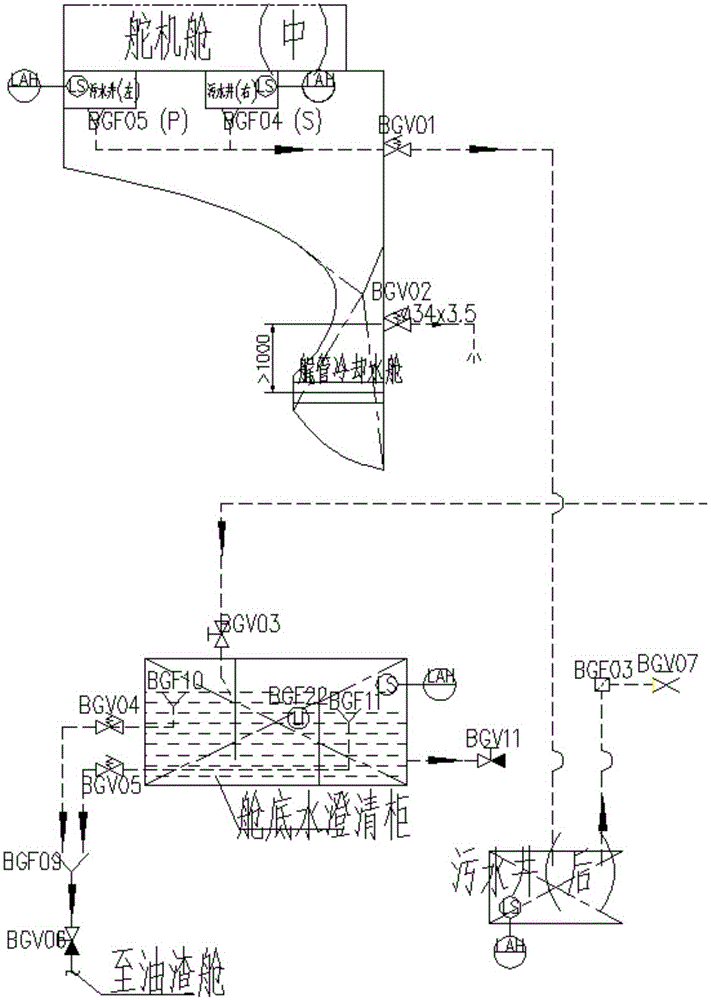

InactiveCN105383676AImprove cleanlinessReduce labor intensityFatty/oily/floating substances removal devicesAuxillariesWater storageNacelle

The invention relates to a cabin bilge water preprocess system for a ship. The cabin bilge water preprocess system is characterized by comprising sewage wells, a daily service cabin bilge pump, a bilge water clarifying tank and a bilge water storage cabin which are sequentially connected, wherein the height of the bilge water clarifying tank is higher than that of the bilge water storage cabin; sewage in the sewage wells is pumped to the bilge water clarifying tank through the daily service cabin bilge pump, and is precipitated and filtrated; after the sewage in the bilge water clarifying tank is precipitated and filtrated, the sewage flows downwards to the bilge water storage cabin under the action of gravity; the sewage in the bilge water storage cabin is transported to a bilge water oil-water separator under the action of an oil-water separation pump, so that oil-water separation is performed. According to the cabin bilge water preprocess system disclosed by the invention, the oil content of the bilge water actually drained into the bilge water storage cabin is substantially decreased, the work load of the bilge water oil-water separator can be effectively reduced, and the cabin bilge water preprocess system is environment-friendly and energy-saving; the dreg content of the bilge water actually drained to the bilge water storage cabin is substantially decreased, so that the work difficulty and the work intensity of seamen for desilting can be effectively reduced.

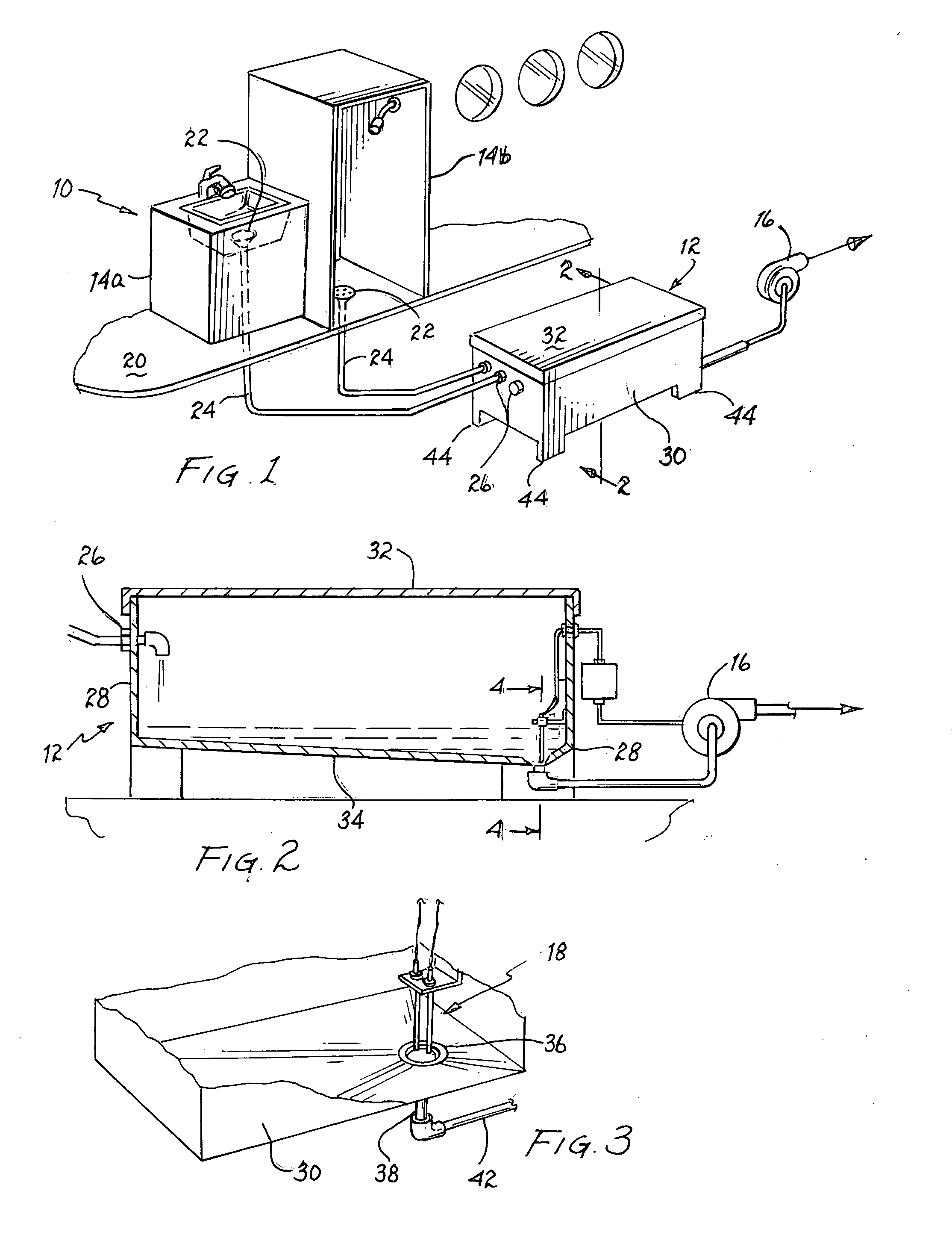

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

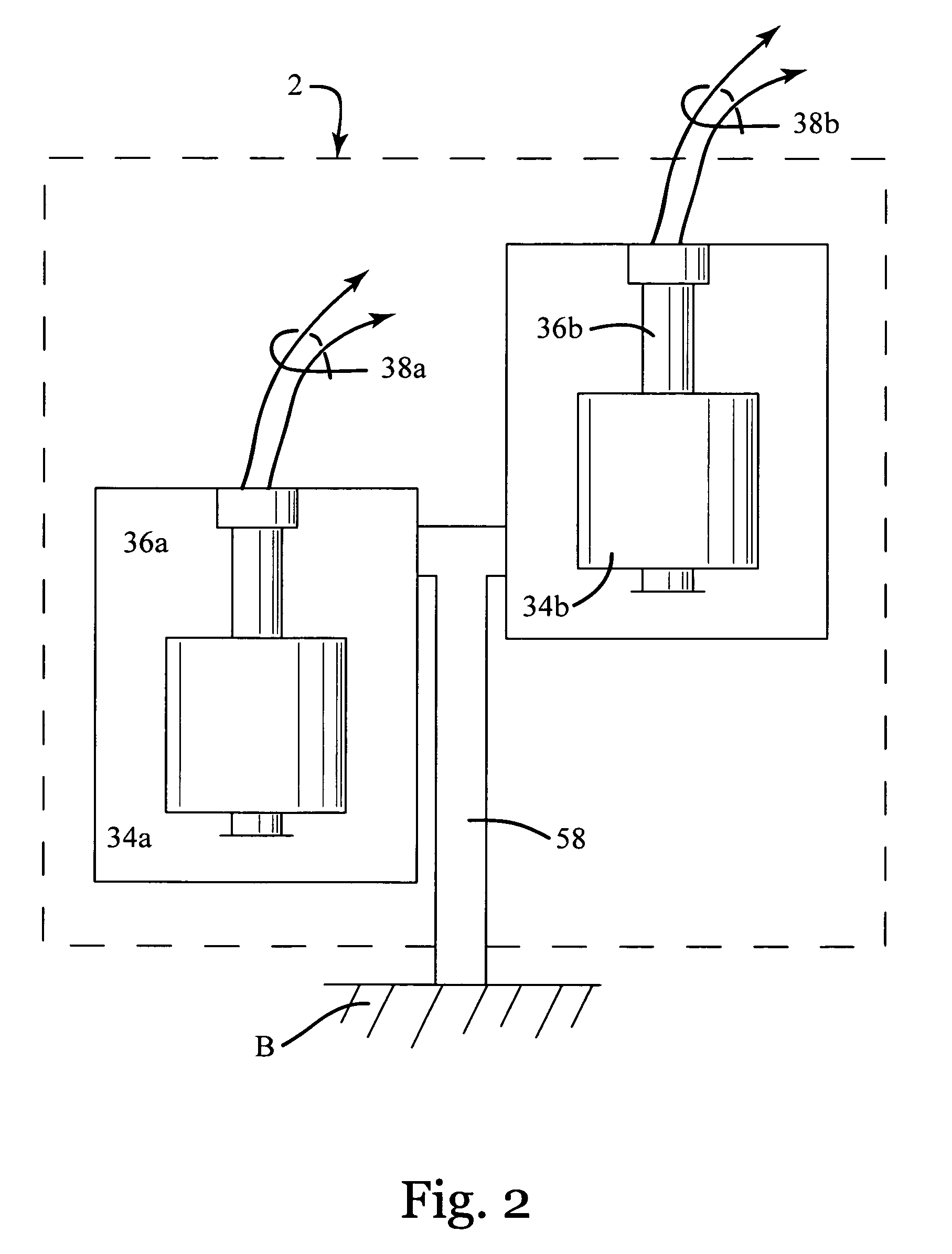

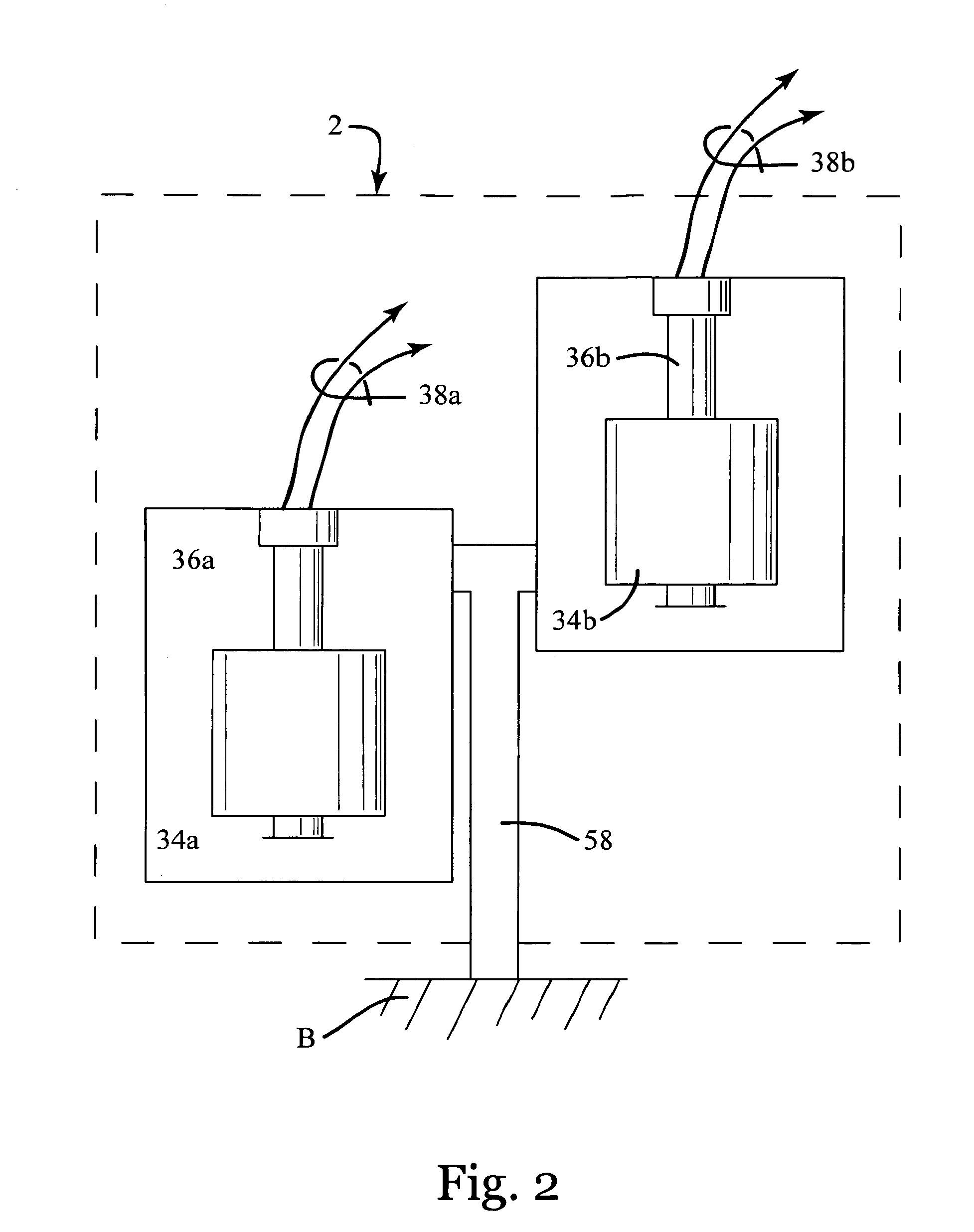

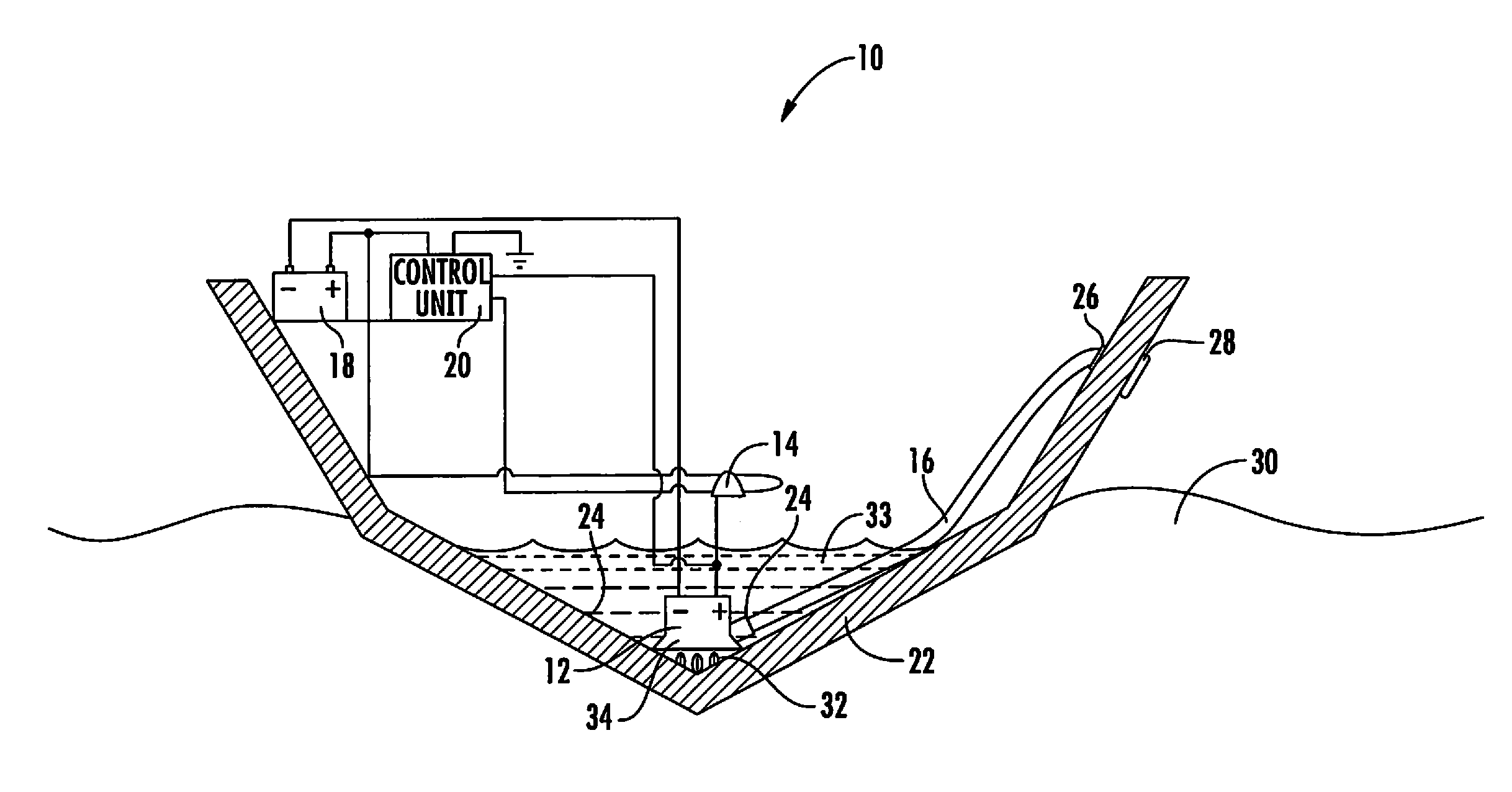

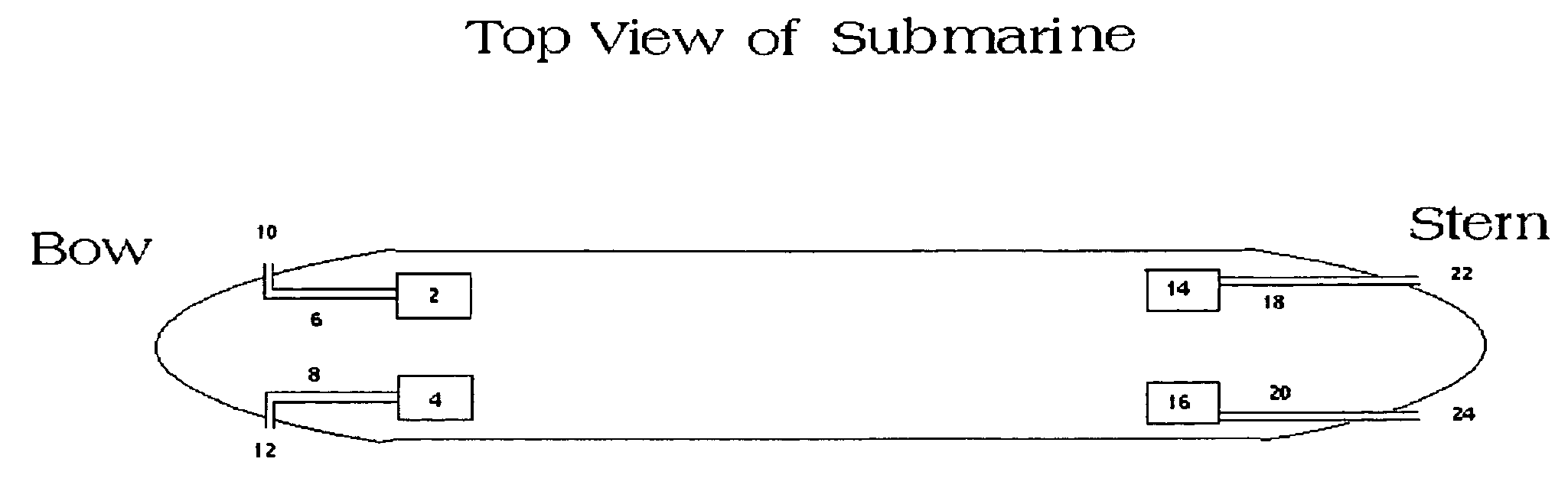

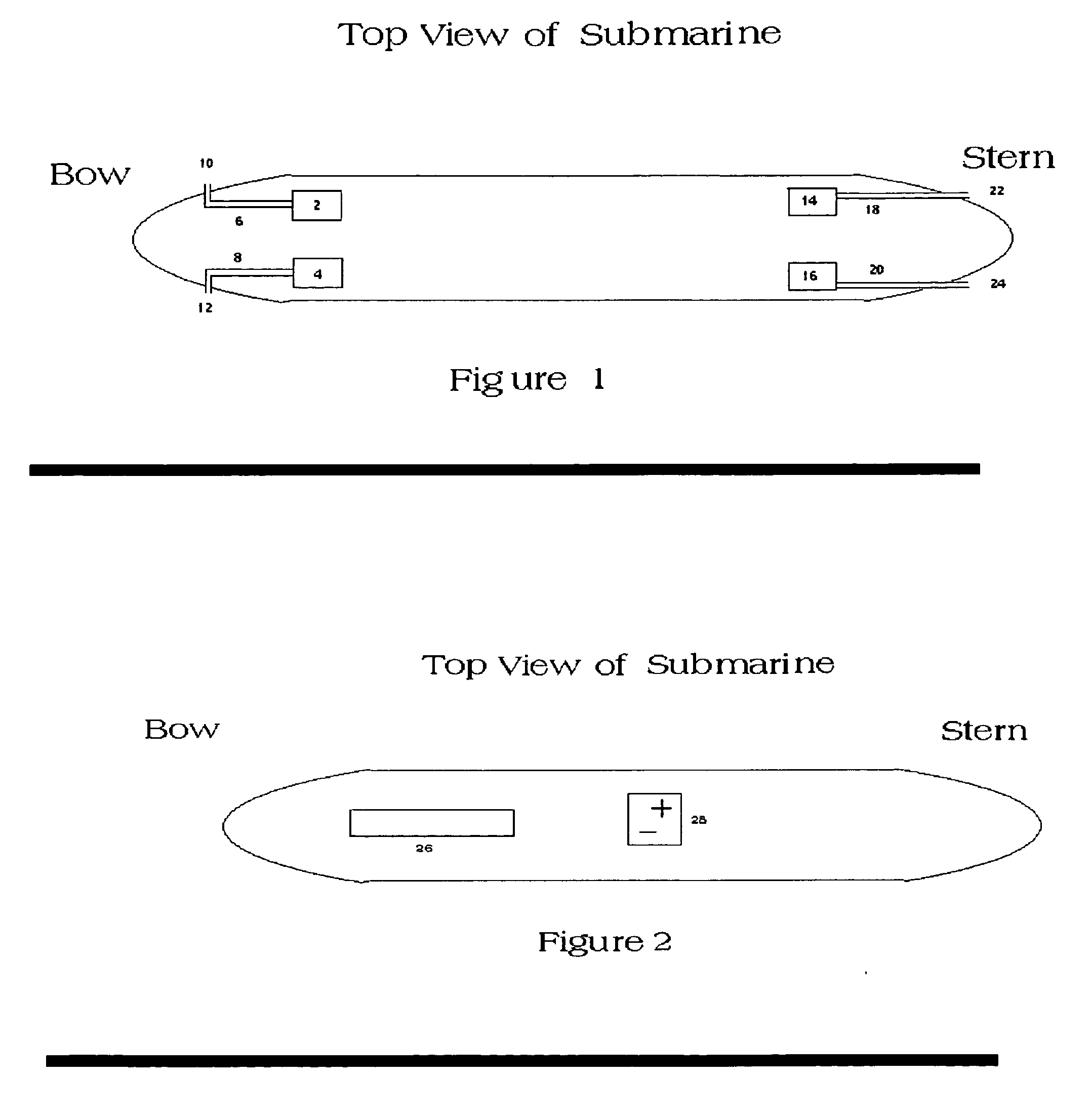

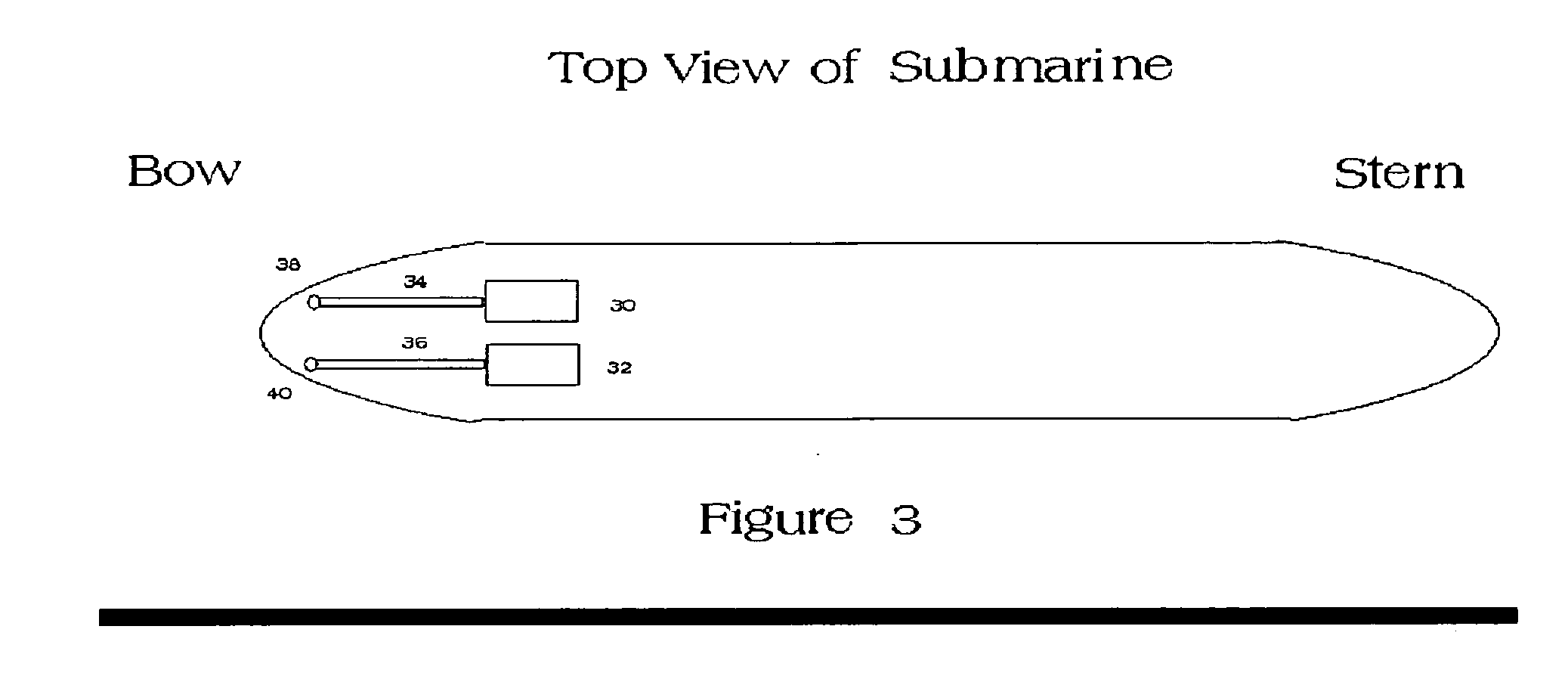

Model Submarine Control/Propulsion System

A control / propulsion system for a model submarine 4 to 7 ft. in length, (can vary within reasonable limits) using bilge pumps, RC components, and exacting ballast to make the submarine completely functional without any external moving parts such as propeller, rudder, and dive planes. Unlike most model submarines which use external moving parts for directional control such as propeller, dive planes and rudder, the proposed control / propulsion system accomplishes complete directional control without the use of any external moving parts. This is accomplished with bilge pumps providing jet water thrust through fixed nozzles for all directions, forward, reverse, left, right and down. Since the submarine is positively buoyant the cessation of forward thrust allows the submarine to surface. This is an added safety feature in case of loss of radio signal. Additionally the functional components of the proposed control / propulsion system are extremely simple compared to other typical model submarines. The major components are simply a battery, to supply power, a watertight chamber, housing the radio and electrical components, bilge pumps, to provide jet water thrust, and fixed directional nozzles and plumbing to provide desired directional control. The simplicity of this system greatly enhances the reliability of the model submarine and provides trouble-free operation for many hours without the concern of losing the submarine.

Owner:YOURK TOM WALTER

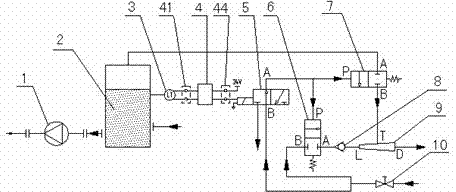

Rational positive-pressure pneumatic pressure ash handling system

InactiveCN102152971ASimplified Pneumatic Ash Handling SystemBulk conveyorsPositive pressureEngineering

The invention relates to a rational positive-pressure pneumatic pressure ash handling system in a coal fired power plant. A positive-pressure concentrated-phase pneumatic pressure ash handling systems commonly adopted by the coal fired power plant currently implement discontinuous powder transmitting and conveying by taking a bilge pump as a secondary storage container; while a concentrated rational positive-pressure pneumatic pressure ash handling system uses an electronic baffle door, a solid powder flow monitor, and a mixed pipe to replace the bilge pump, a charge valve, and a discharge valve, and change discontinuous ash conveying into rational positive-pressure pneumatic pressure ash handling system so as to overcome the defect that a discontinuous ash handling system can possibly threaten the safety running of an electric dust catcher due to insufficient conveying power. The rational positive-pressure pneumatic pressure ash handling system not only can improve the ash conveying capacity of the system, but also can monitor the flow state and ash / air ratio of the conveyed ash; moreover, relevant accessories and devices such as the bilge pump, the charge valve, and the discharge valve, and the like can be saved, and the quantity of ash conveying pipelines is reduced.

Owner:孙家鼎

Static bilge pump

InactiveUS20170191504A1Easy to integrateSelf-bailing equipments/scuppersPressure pumpsEngineeringHigh pressure

A static bilge pump has a body surrounded by a shell, forming a motive plenum therebetween. Inlets in the front of the shell allow a motive fluid to enter the motive plenum. The motive plenum tapers, decreasing in cross-sectional area along with width as it moves toward its aft, and ends at a motive nozzle. The body houses a suction chamber in fluid communication with a suction inlet that is in fluid communication with the bilge of a boat. Ejectors are positioned proximal to and between the motive nozzle and the discharge outlet. When the static bilge pump is exposed to fluid flow from its front to its stern, such as when a boat is in motion, water enters the motive inlets, filling the motive Plenum and acting as a motive fluid. The motive fluid is ejected at high pressure from the motive nozzle, creating suction at the ejectors and discharging the motive fluid as well as liquid with in the suction chamber out the discharge outlet.

Owner:PALMISANO DOUG

Bilge water system and ship

PendingCN112278150ASolve the problem of storing gasEasy to check for leaksSelf-bailing equipments/scuppersVessel partsWater sourceOutfall

The invention discloses a bilge water system and a ship and relates to the technical field of ship bilge water systems. The bilge water system comprises a bilge water pump, a water outlet pipe, a pressure water tank, a first water suction pipe, a suction port valve and a vent valve, wherein the bilge water pump comprises a water suction port and a water outlet, and one end of the water outlet pipeis communicated with the water outlet while the other end is communicated to the outboard of a ship; an outlet of the pressure water tank is communicated with the water outlet pipe; the other end ofthe first water suction pipe is communicated with a sewage well of the ship; the suction port valve is arranged on the first water suction pipe and is close to the sewage well; the vent valve is arranged at the highest point of the first water suction pipe and located between the suction port valve and the water suction port. The bilge water system solves a problem of air storage in the pipeline,shortens the exhaust time, can enable water to be always stored in the system pipeline, enables certain water pressure to be maintained in the pipeline, only enables water to seep out and does not enable air to seep in when a flange on the pipeline is not tightly sealed or loosened, and is convenient to check leakage of the pipeline.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com