Rational positive-pressure pneumatic pressure ash handling system

A pneumatic and ash storage technology, applied in conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problems of large conveying output, threatening the safe operation of power plants, and increasing ash content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

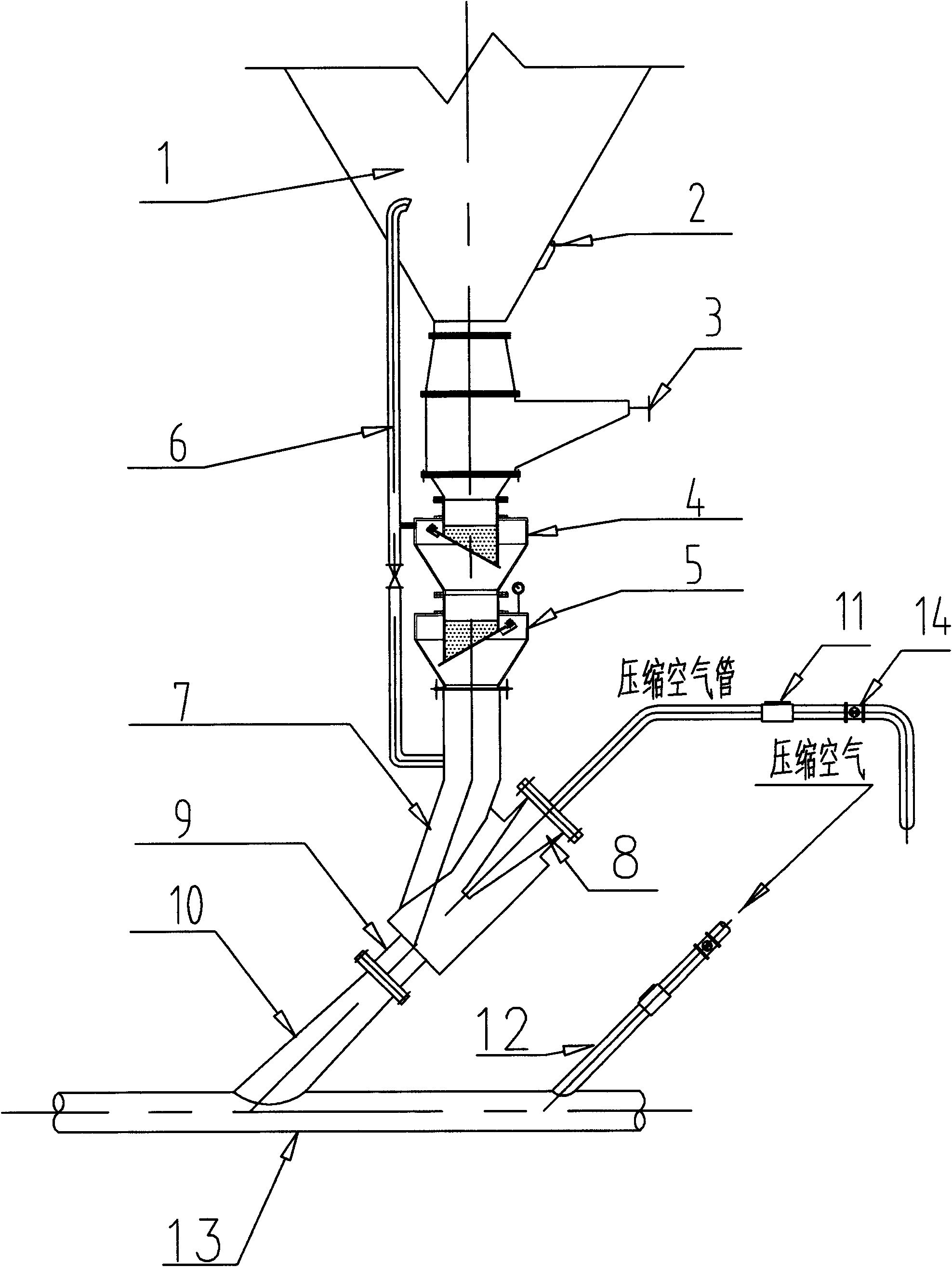

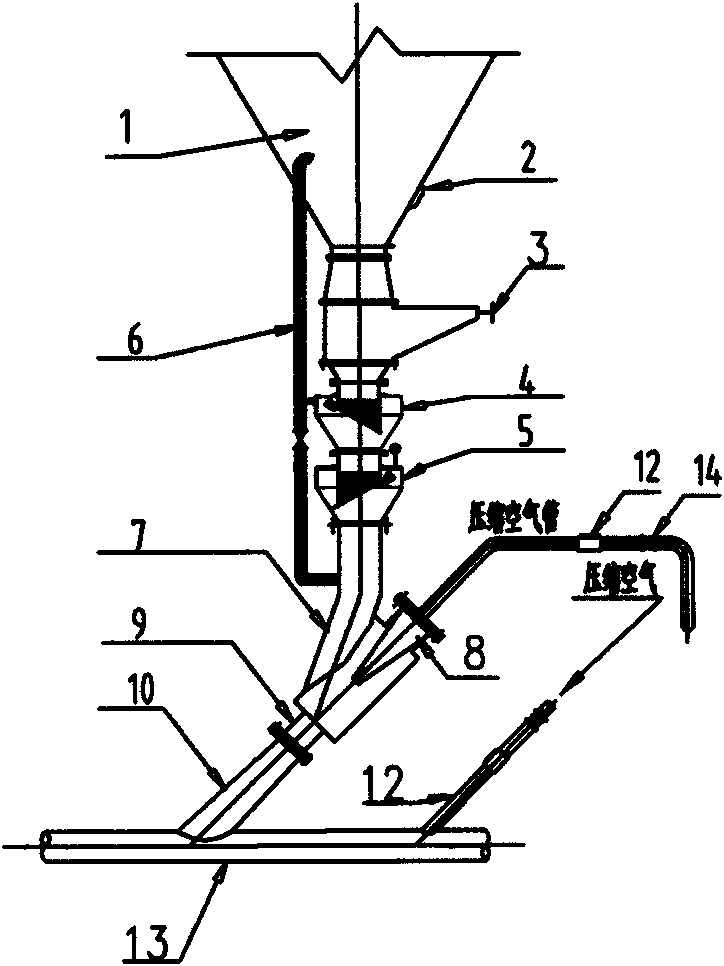

[0008] In the accompanying drawings, a material level gauge (2) is provided at the middle and lower part of the side wall of the ash storage hopper (1), the lower opening of the ash storage hopper is equipped with a plug-in door (3) for maintenance, and the lower string is equipped with an electric baffle door ( 4) and the solid powder flow monitoring device (5), the ash falling pipe (7) is connected with the mixing pipe (9), and the lower end of the mixing pipe is equipped with an oblique insertion pipe (10), and the fly ash collected by the electric dust collector is in the When the material level meter (2) can detect the ash level, the electric baffle door (4) will automatically open and adjust to an appropriate angle, so that the passing fly ash will pass through the solid powder flow monitoring device (5), and the instantaneous The flow value is the maximum quantitative dense-phase conveying capacity. When the powder storage capacity of the ash storage hopper under the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com