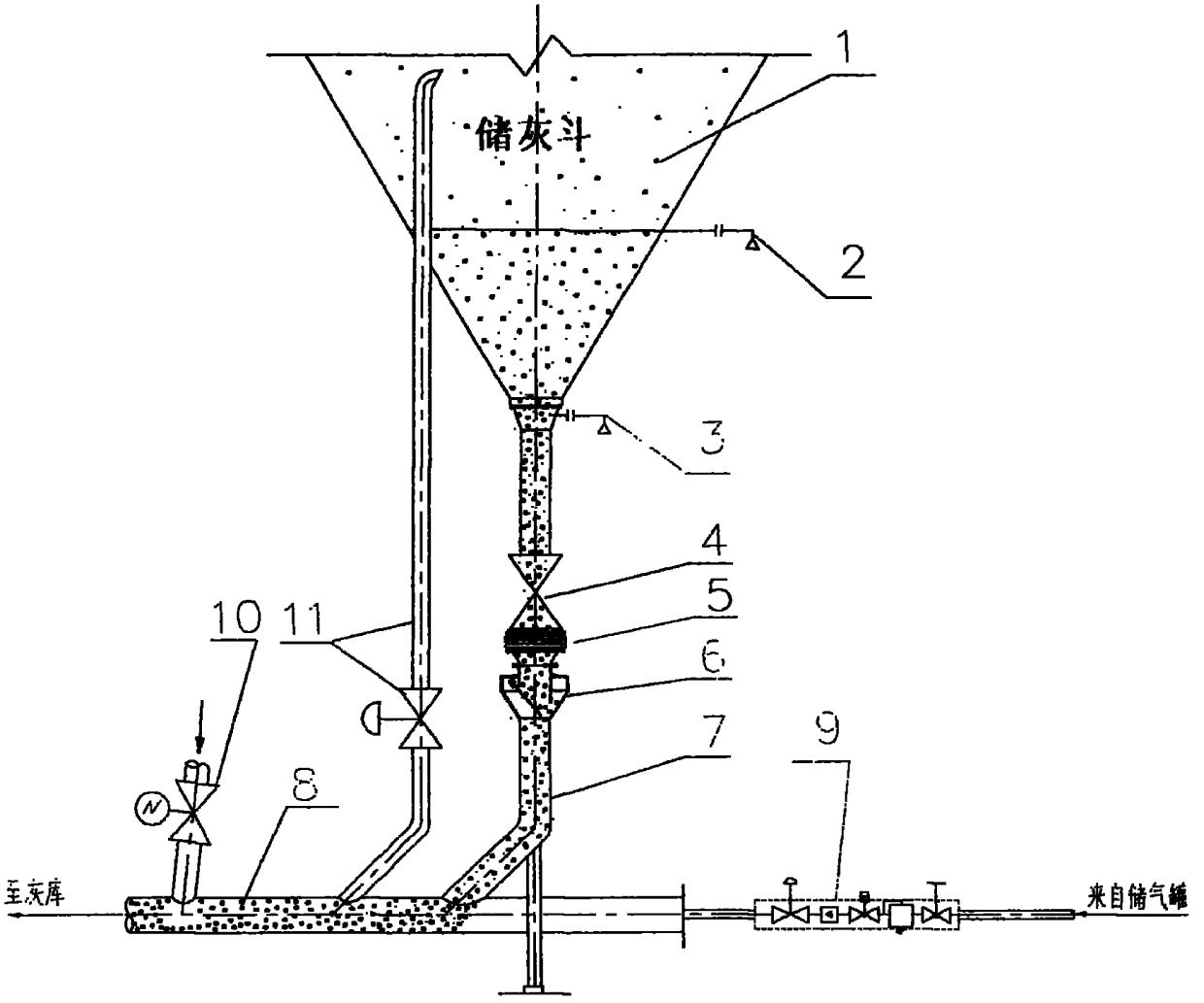

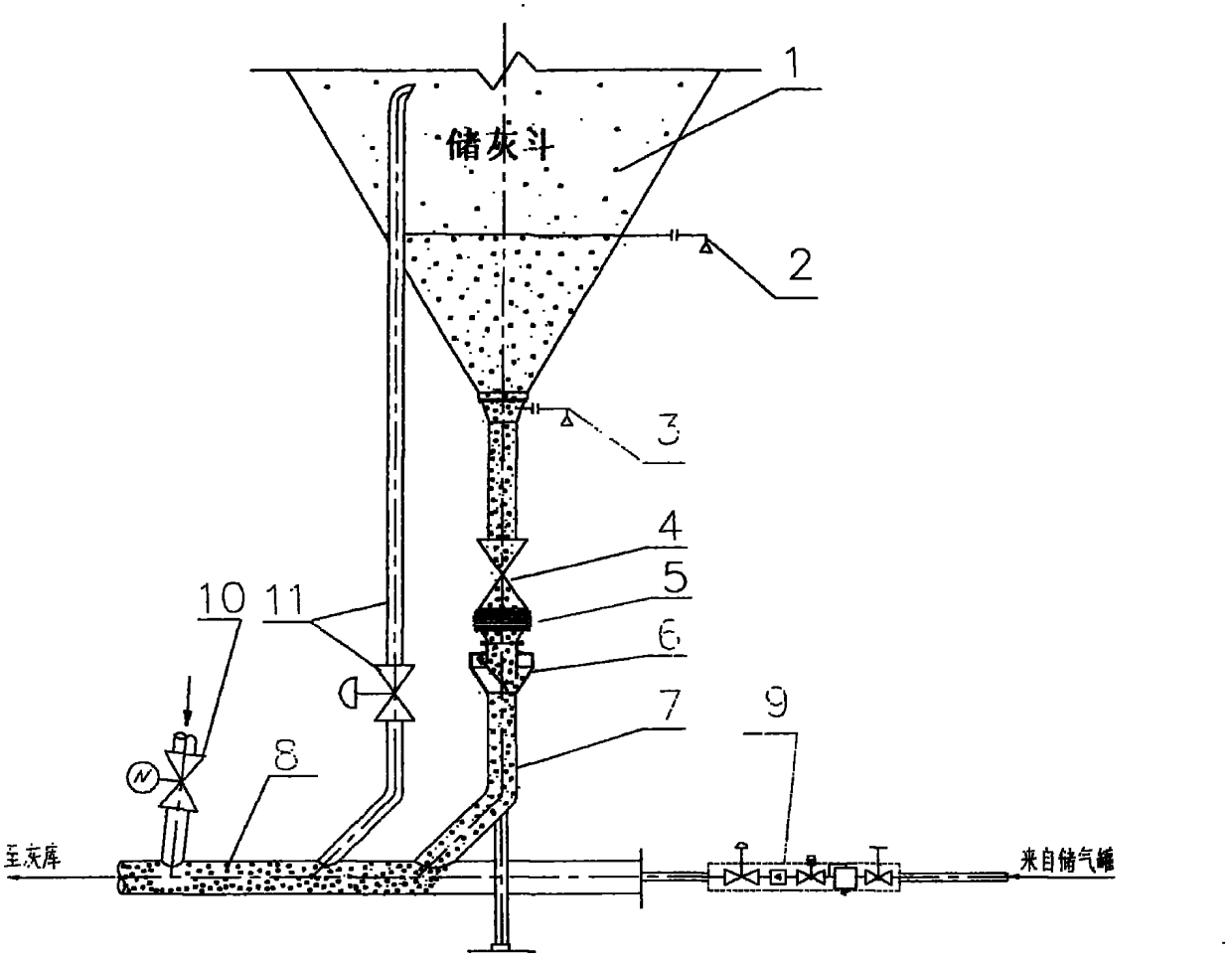

Safe and energy-saving dynamic pneumatic ash removal system

An energy-saving and pneumatic technology, which is applied in the field of safe and energy-saving dynamic pneumatic ash removal system, can solve problems such as high material level alarm accidents in the ash storage hopper of electrostatic precipitators, threats to the safety and economic operation of coal-fired power plants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Firstly, among the ash storage hoppers under the electric field of the electrostatic precipitator I, select the one with the largest ash discharge capacity, and calculate its maximum ash discharge capacity Q (kg / s), and set the conveying capacity of fly ash as (Q+ΔQ ) (kg / s), during the operation of the ash removal system, the ash discharge capacity of the ash storage hopper changes in direct proportion to the boiler load and the ash content of the coal fired. The maximum real-time ash discharge capacity of the ash storage hopper Qs(kg / s)=Q×boiler load rate (%), and the ash delivery volume is set according to (Qs×1.1). This setting makes the real-time ash discharge volume of the ash storage hopper always smaller than the delivery volume of the ash removal system, and the ash storage bucket will not generate a high material level alarm. Determine the ash storage volume (Q+0.1Q) of the ash storage hopper according to such settings. The ash storage volume setting determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com