Automatic priming device for centrifugal pump

A technology of automatic water diversion and centrifugal pump, applied in the direction of pump, pump control, driving pump, etc., can solve the problems of increasing the manufacturing and operating costs of the device, failing to play an early warning and protection role, and difficulty in processing vacuum tanks, so as to enhance the driving ability, The effect of avoiding critical instability and low production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

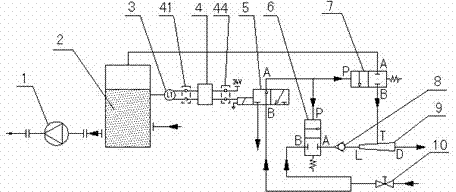

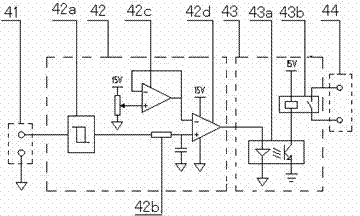

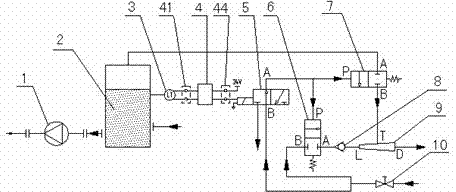

[0019] see figure 1 : An automatic water diversion device for a centrifugal pump, comprising a centrifugal pump 1, a gas-liquid separation tank 2, a liquid level sensor 3, a controller 4, an electromagnetic reversing valve 5, pneumatic valves 6 and 7, a one-way check valve 8, and an injector 9 and the stop valve 10, the gas-liquid separation tank 2 is respectively connected with the centrifugal pump 1, the liquid level sensor 3 and the second pneumatic valve 7, the input of the controller 4 is connected with the liquid level sensor 3, and the output is connected with the electromagnetic reversing valve 5, The electromagnetic reversing valve 5 is connected with the first pneumatic valve 6 , the second pneumatic valve 7 and the stop valve 10 , the injector 9 is connected with the second pneumatic valve 7 , and is connected with the first pneu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com