Blade stirring type pneumatic conveyor for easy caking materials

A pneumatic conveying and agitating technology, which is applied in the field of blade agitating pneumatic conveying devices, can solve the problems of low pressure resistance of equipment, limited conveying distance, easy loss of moving parts, etc., and achieve the effects of reliable operation, energy saving and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

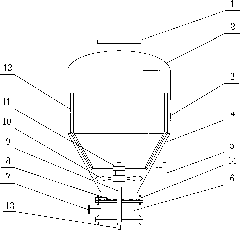

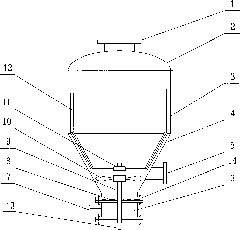

[0013] As attached to the manual figure 1 As shown, a blade-stirring pneumatic conveying device for materials that are easy to agglomerate. The hollow pump body is formed by the upper oval head 2, the middle cylindrical body 3 and the lower conical head 4. There is a feed port 1 on the oval head 2. There is a discharge port on the conical head 4 and a fluidization chamber 6 on the bottom of the conical head 4 . The conical head 4 is connected to the fluidization chamber 6 with flanges 14, and there is a fluidization device 8 between the flanges 14. The fluidization chamber has an air inlet 7. A scraper 12 and a blade 10 are arranged inside the pump body, and the scraper 12 and the blade 10 are fixed on the aerodynamic structure 11 of the fixed shaft 9, and the air inlet 13 connected to the other end of the fixed shaft extends out of the pump. The fixed shaft 9 is a hollow circular tube. Compressed gas enters from the inside of the fixed shaft 4 and blows out through the pn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com