Cabin bilge water preprocess system for ship

A bilge water and pretreatment technology, applied in water treatment devices, flocculation/sedimentation water/sewage treatment, ship construction, etc., can solve problems such as unfavorable crew safety and health, inconvenient personnel entry, low work efficiency, etc., and achieve design Ingenious, reduce the concentration of oil pollution, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

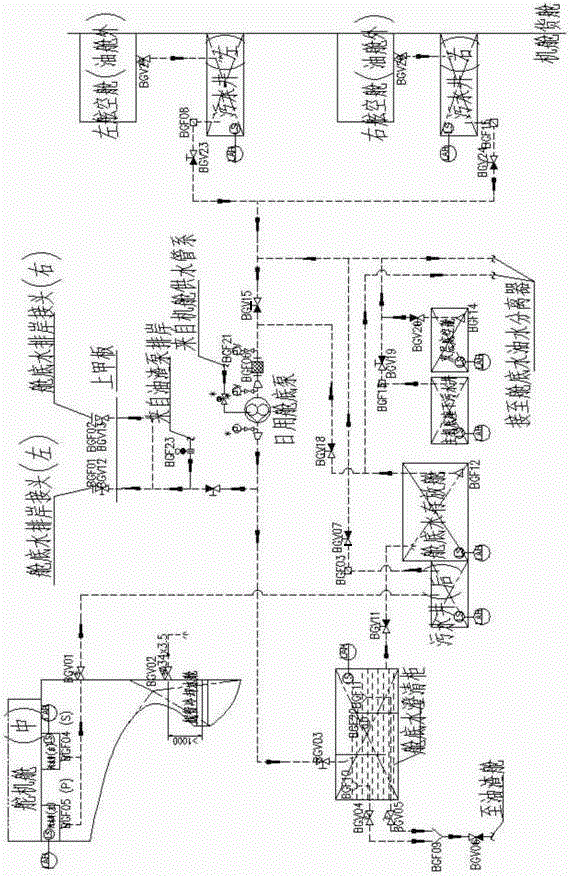

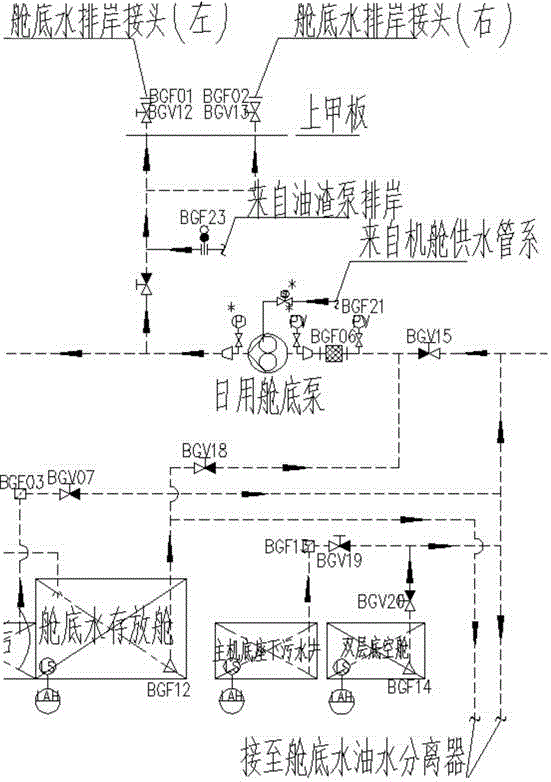

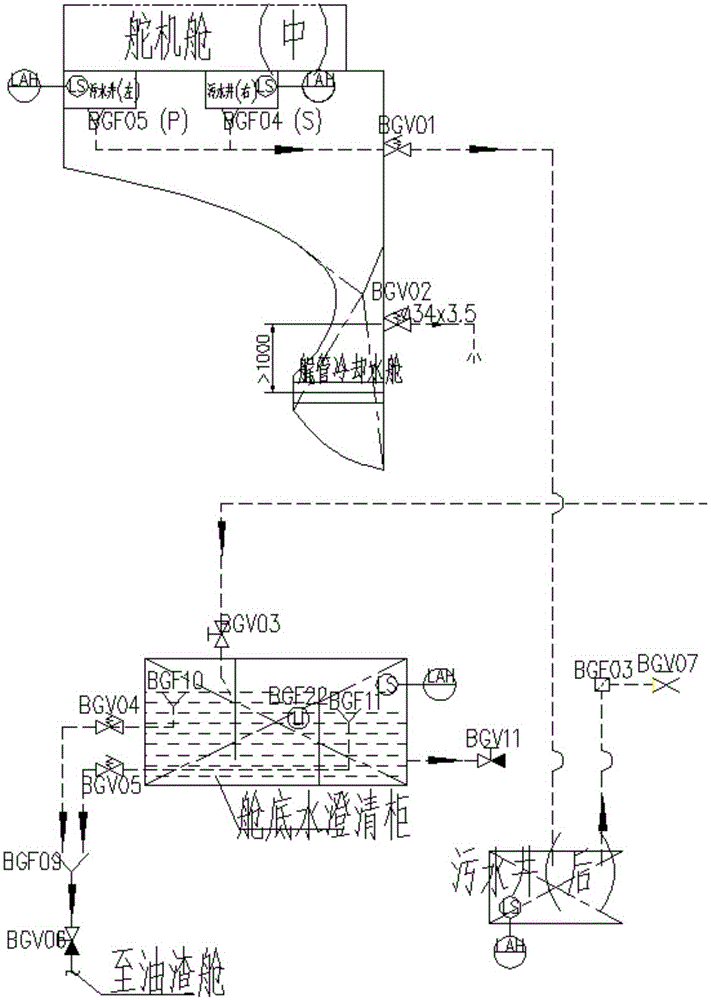

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] The invention is produced in combination with the design of the engine room bilge water system of the bulk carrier. Ship engine room bilge water refers to the equipment in the ship engine room, such as main propulsion diesel engine, diesel generator, boiler, oil purifier, oil supply unit, etc. water etc.

[0027] Such as figure 1 As shown in , there are sewage wells for collecting bilge water in the engine room, two at the head of the engine room and one at the rear;

[0028] Use the daily bilge pump to pump the bilge water in the engine room to the bilge water clarification tank;

[0029] Two partitions are designed inside the clarification cabinet to divide the cabinet into three areas: left, middle and right. The left side and the middle part are connected at the bottom of the cabinet, and the middle part and the right side are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com