Coke oven flue gas waste heat recovery technology

A coke oven flue and waste heat recovery technology, applied in waste heat treatment, process efficiency improvement, furnace, etc., can solve the problems of unreasonable main and auxiliary flue valve forms, energy waste, inaccurate control system, etc., to avoid dew point Corrosion problem, wide adaptability, investment saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

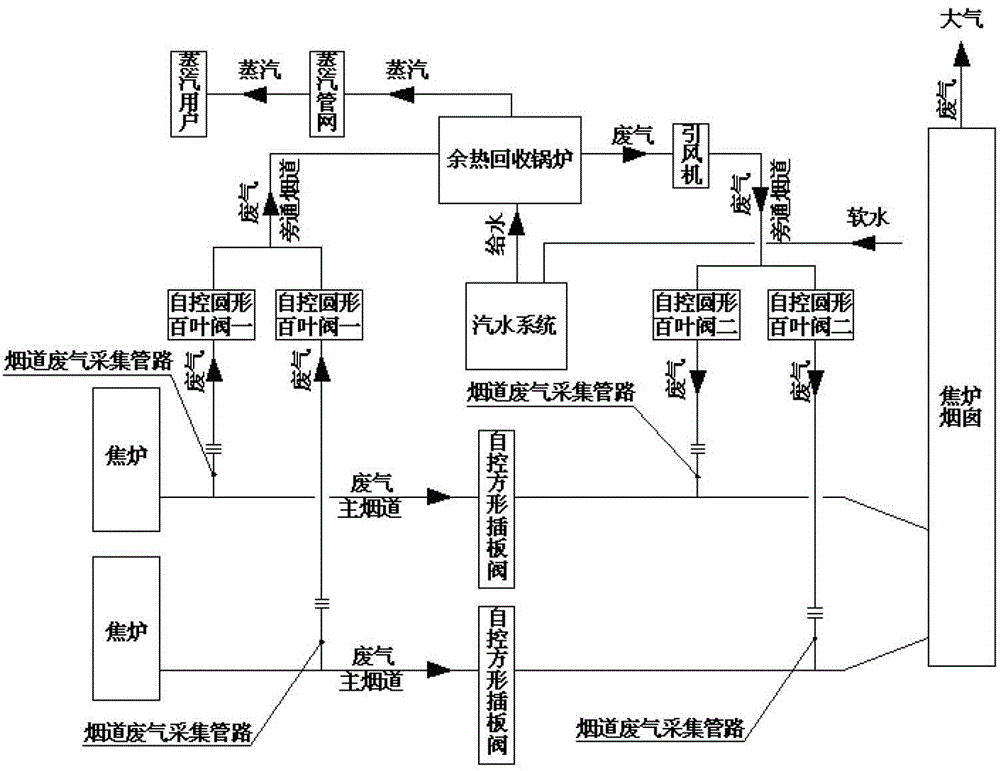

[0028] See figure 1 , is a schematic block diagram of a coke oven flue waste heat recovery process embodiment of the present invention, including a main flue, an auxiliary flue, a steam water system, an induced draft fan and a coke oven chimney, and a self-controlled square inserting plate is set on the main flue Valve; set the automatic control circular shutter valve on the auxiliary flue, including the automatic control circular shutter valve 1 on the auxiliary flue at the inlet side of the waste heat recovery boiler and the automatic control circular shutter valve 2 on the auxiliary flue at the outlet side of the induced draft fan; the layout of the induced draft fan On the outlet side of the waste heat recovery boiler, the system of the present invention is matched with two coke ovens.

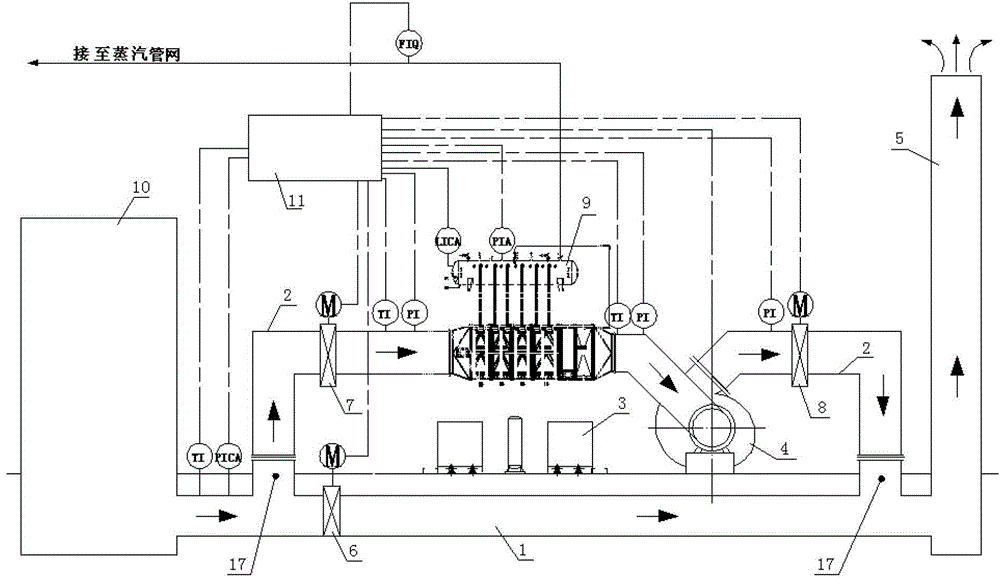

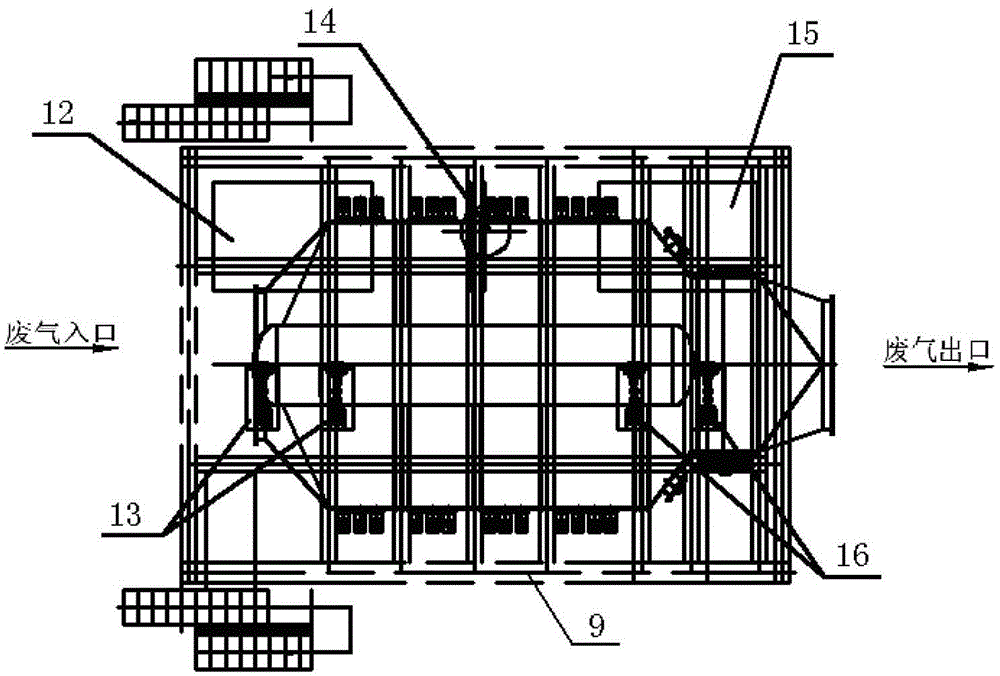

[0029] See figure 2 , image 3 , is a confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com