Method of starting solid oxide fuel cell system

一种燃料电池系统、固体氧化物的技术,应用在固体电解质燃料电池、燃料电池、燃料电池助剂等方向,能够解决无法开始反应等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

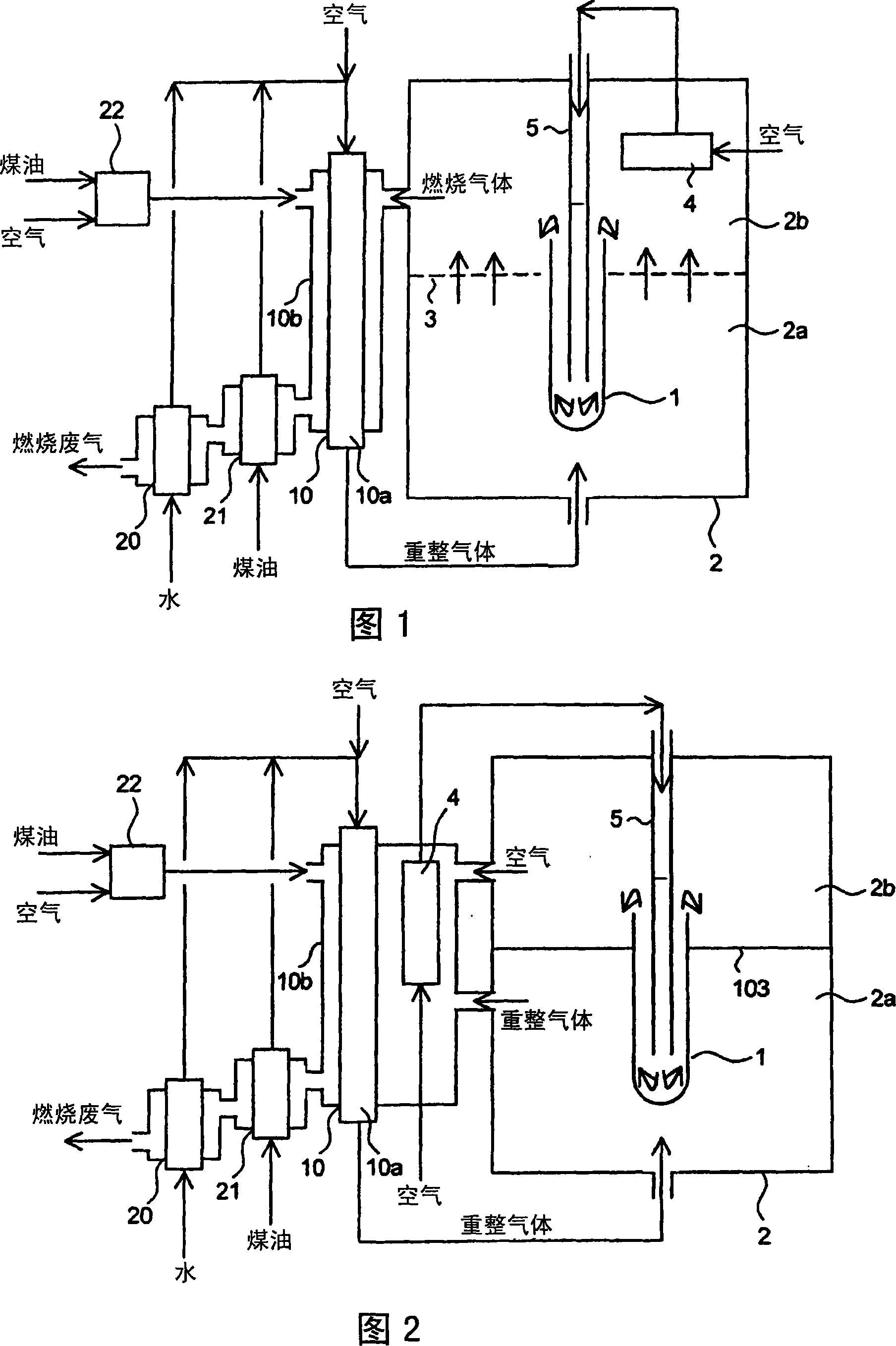

[0082] An example of an SOFC system to which the start-up method of the present invention can be applied is shown in FIG. 1 .

[0083] The cylindrical SOFC 1 is accommodated in a container (SOFC storage container). Although only one SOFC is shown in the figure, a plurality of SOFCs are arrayed. The SOFC storage container 2 is divided into an area (anode gas chamber) 2 a and an area (here, a combustion chamber) 2 b by a gas-permeable partition plate 3 inside. The reformed gas is supplied to the region 2a, and the reformed gas passes through the partition plate 3 and is supplied to the region 2b.

[0084] As the partition plate through which the gas can flow, for example, a perforated flat plate, a foamed flat plate, or a fabric-shaped flat plate made of heat-resistant metal or ceramics can be used. The partition plate through which gas can flow is a member for preventing combustion in the area (anode gas chamber) 2a.

[0085] The SOFC has a cylindrical shape with the cathode...

Embodiment 2

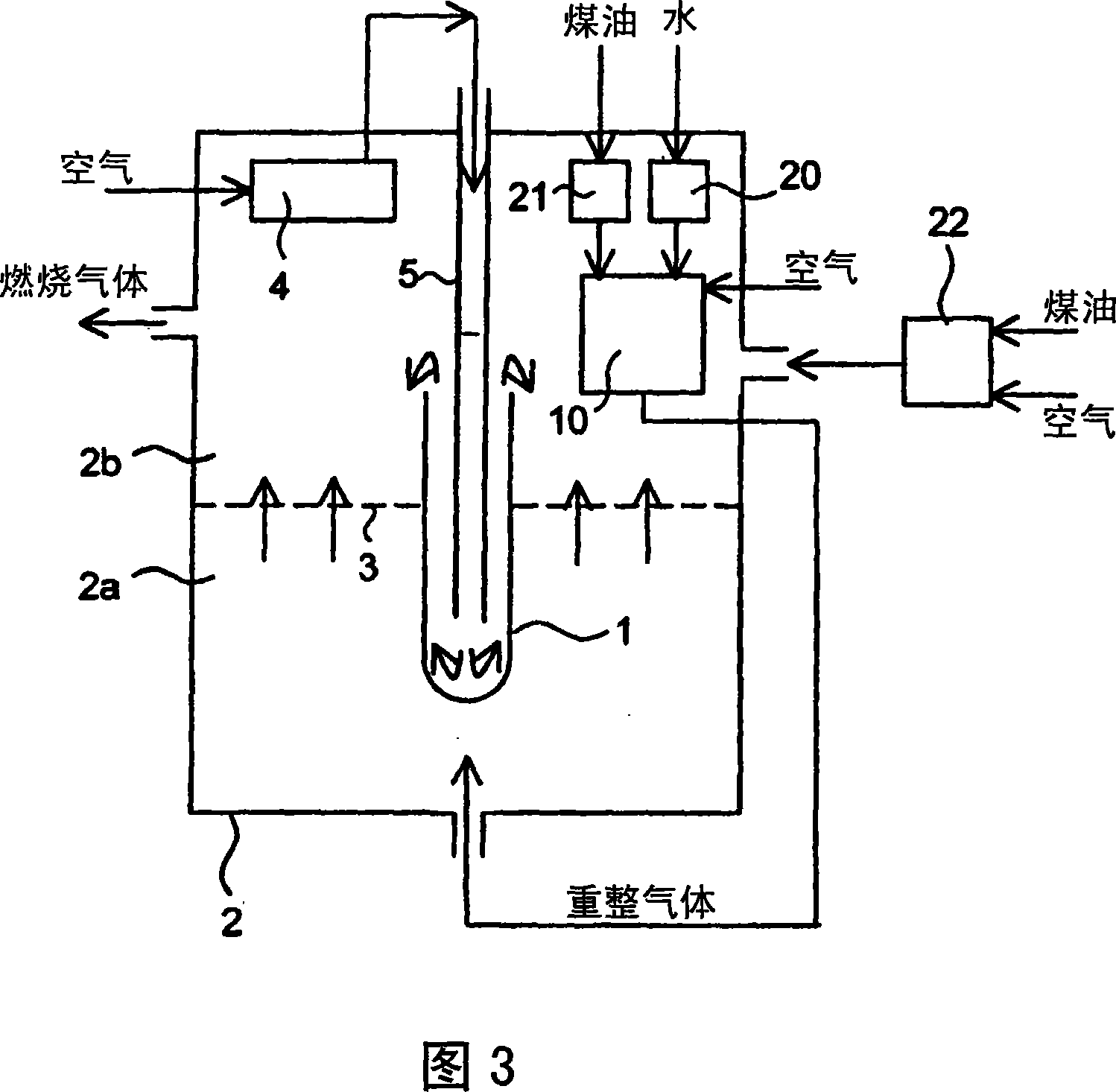

[0105] Another example of an SOFC system to which the start-up method of the present invention can be applied is shown in FIG. 2 . The SOFC region 2b of this SOFC system simply functions as a header for collecting the cathode exhaust gas, and supplies the anode exhaust gas and the cathode exhaust gas to the container 10b of the reformer (outside the reforming reaction tube) for combustion. Furthermore, an air preheater 4 is provided here. The region 2a and the region 2b are separated by a partition plate 103 that cannot pass through the gas. That is to say, in this example, the anode off-gas may be burned in the reformer instead of being burned in the container housing the SOFC. Except for this point, it is the same as the system shown in Example 1. The start-up operation can also be performed in the same manner as in Example 1, except that the reformed gas discharged from the anode chamber of the SOFC is combusted in the reformer.

[0106] As the combustion means for combu...

Embodiment 3

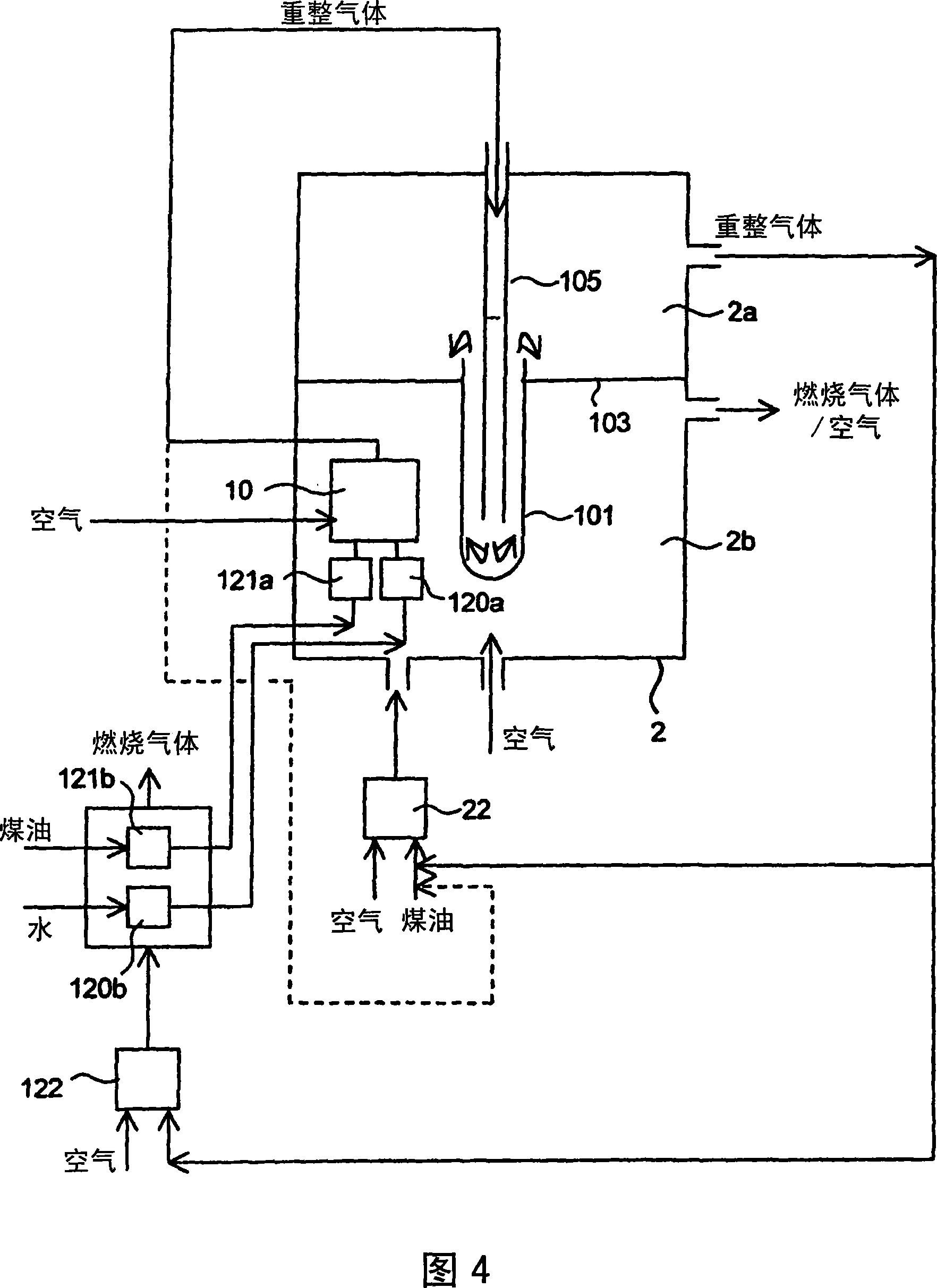

[0108] FIG. 3 shows another example of an SOFC system to which the start-up method of the present invention can be applied. In this SOFC system, the reformer 10, the kerosene gasifier 21, and the water gasifier 20 are installed in a region 2b of a container for storing SOFC. In this form, since the reformer vessel also serves as the SOFC storage vessel, the reformer can be constituted only by a reforming reaction section such as a catalyst reaction tube. Here, a reformer having the same configuration as the reforming reaction tube of Example 1 was used. In addition, the combustion gas generated in the start-up burner 22 is guided to the region 2b, and the temperature of the reformer, the kerosene vaporizer, and the water vaporizer can be raised by the combustion gas. Except for this point, it is the same as the system shown in Example 1. The start-up operation can also be performed in the same manner as in Example 1, except that the temperature of the reformer, kerosene vapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com