Engine assembly

A technology of engines and components, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of complexity, vulnerable technology, high production cost, etc., and achieve the effect of simple structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

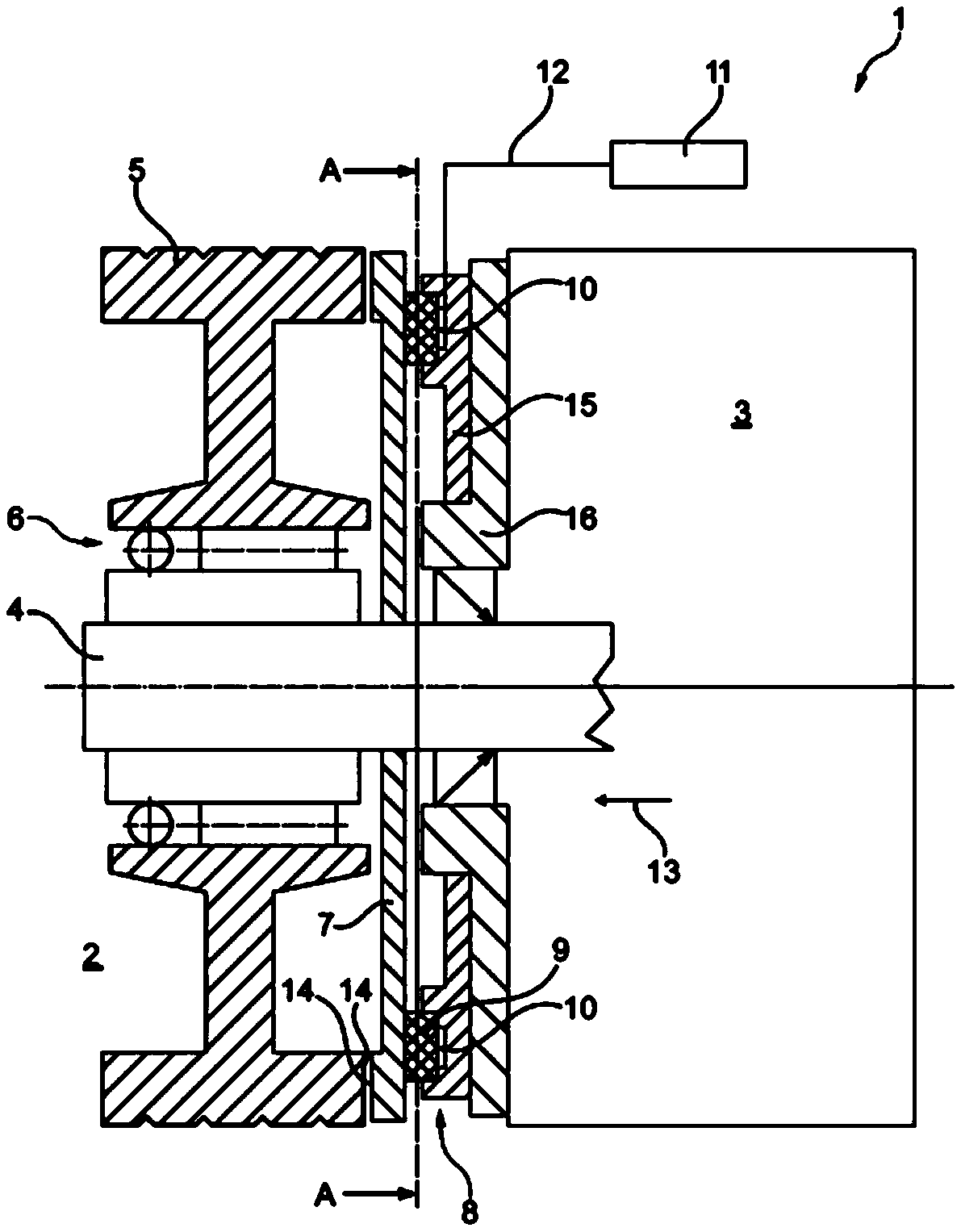

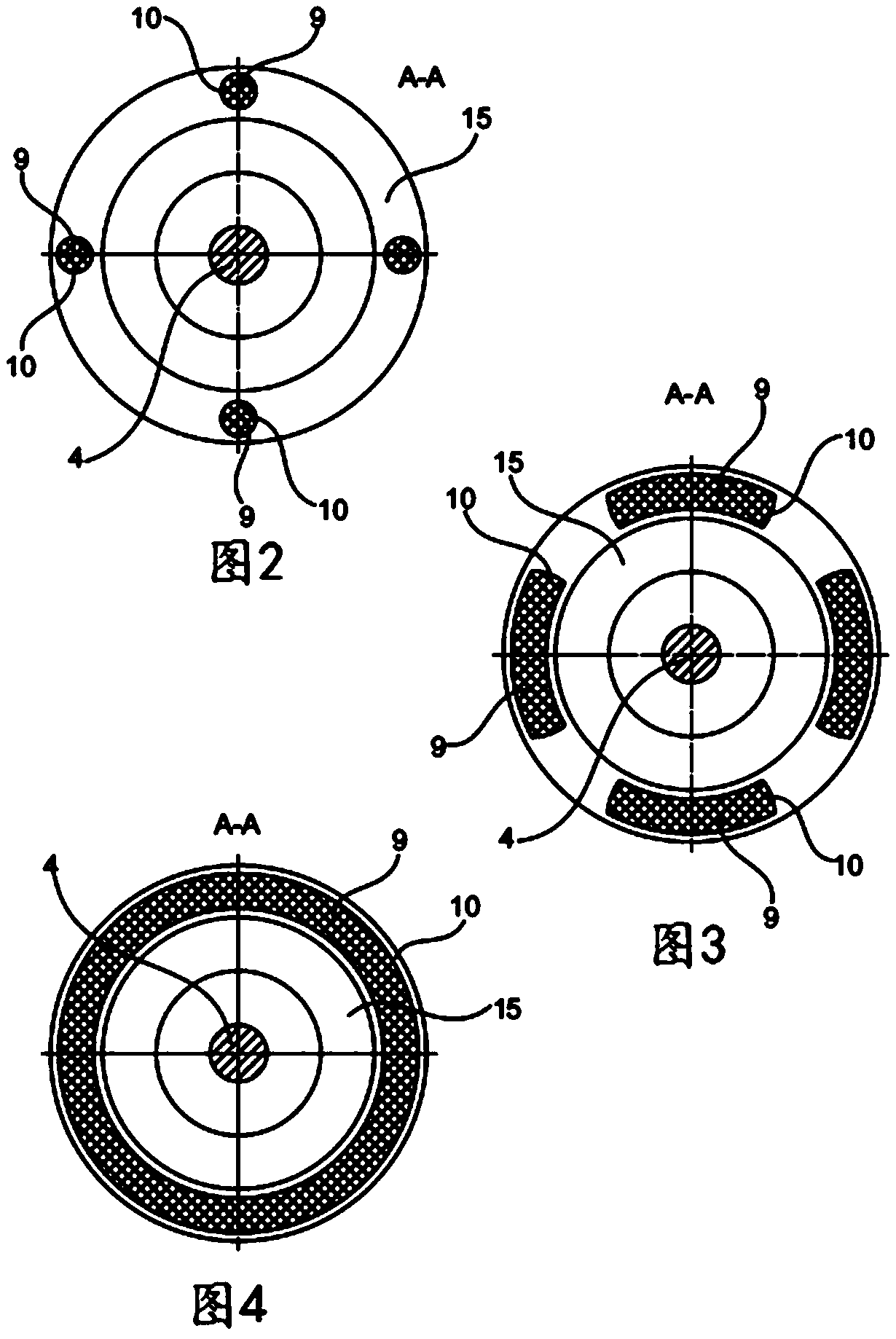

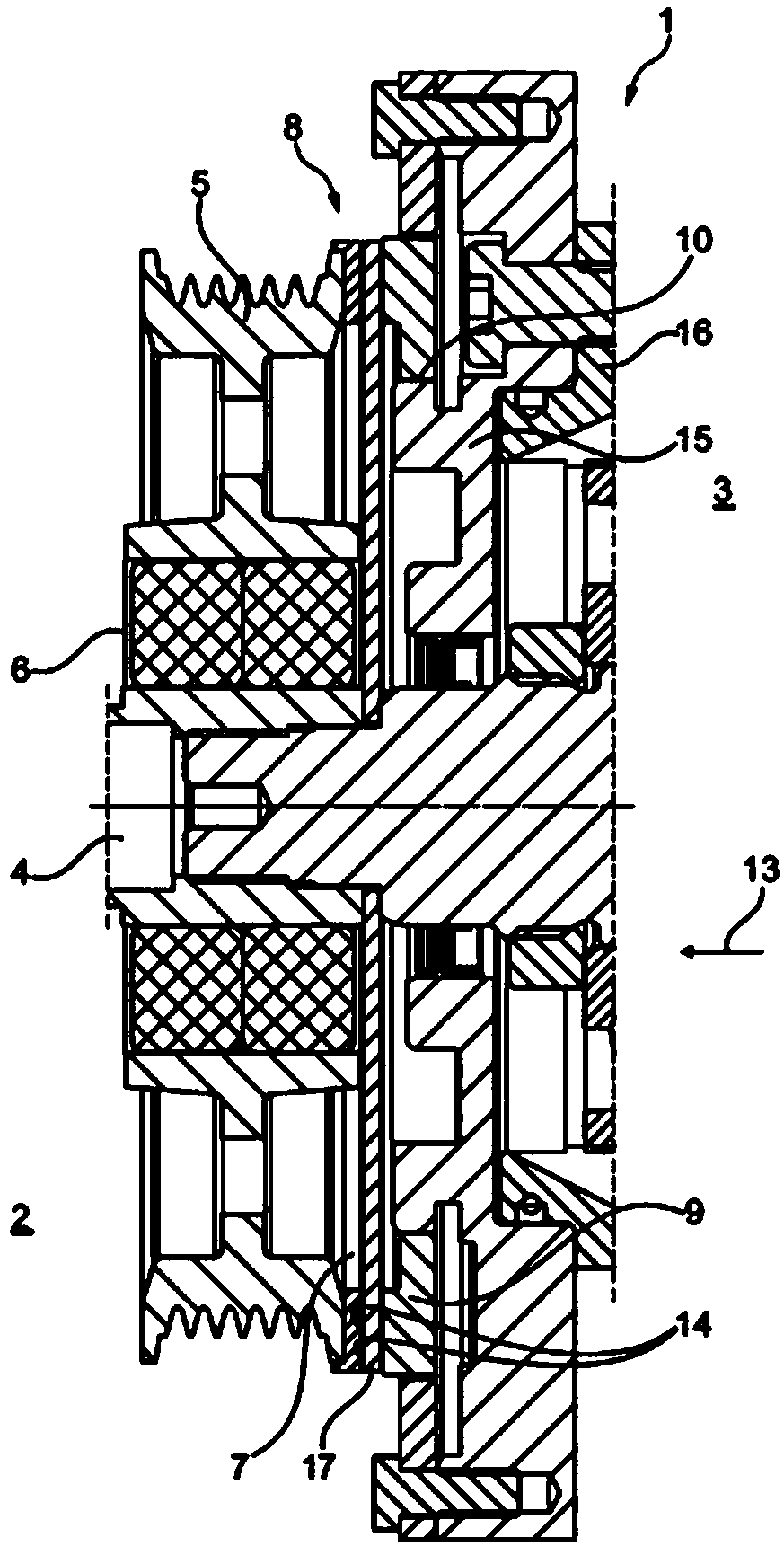

[0026] according to figure 1 and Figure 5 , the engine assembly 1 according to the invention comprises an internal combustion engine 2 and an expander 3 which can be coupled thereto in a direct or indirect force transmission. The expander 3 can thus be embodied, for example, as a so-called axial piston engine. The pulley 5 is thus arranged rotatably on the shaft 4 of the expansion machine 3 , wherein the pulley 5 is force-transmittingly connected to the internal combustion engine 2 via a belt drive not shown, ie directly or indirectly via The drive train of the power transmission is transmitted to the internal combustion engine 2 . The rotatable arrangement of the pulley 5 on the shaft 4 is achieved by means of corresponding rolling bearings 6 which provide for free movement. A drive disc 7 connected to the shaft 4 in a rotationally fixed manner is arranged axially adjacent to the pulley 5 on the shaft 4 . Also provided is a shaft coupling 8 comprising at least one elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com