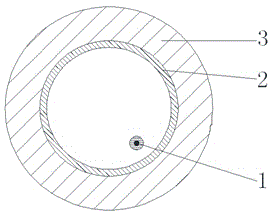

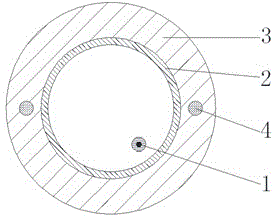

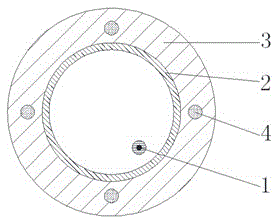

Vibration sensing optical cable and use method thereof

A sensing optical cable, sensing optical fiber technology, applied in the direction of light guide, optics, optical components, etc., can solve the long-term reliability of the sensing optical cable is not high, can not be fully satisfied, the false alarm rate is high, achieve easy long-distance multi-point Distributed measurement, simple and reasonable structure setting, fast and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0031] The cable forming process of the fiber grating array sensing optical cable of the present invention (taking embodiment 3 as an example) is as follows:

[0032] During the cabling process, the optical fiber is released in the form of active pay-off with small tension. First, a reinforcement is longitudinally wrapped around the optical fiber, with a diameter of preferably 2-5mm, and then the steel wire is released. The sheath is made of polyvinyl chloride, and then the sheath is stretched in the cold water tank by selecting the appropriate speed of the traction wheel. At this time, the longitudinal package reinforcement is stretched together, and the optical fiber is in the loose sleeve structure without traction. round effect, accumulating longer fibers in the sheath. Then wait for the sheath to pass through the traction wheel, the longitudinal sheath reinforcement and the sheath recover elastically, and the length is shortened, so that the optical fiber in the loose she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com