Automatic yarn waxing device of flat knitting machine

A technology for automatic waxing and yarn application in textiles, papermaking, knitting, etc., which can solve the problems of inconvenient installation and operation and large space occupation, and achieve the effects of improving production efficiency, occupying less space and improving the waxing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

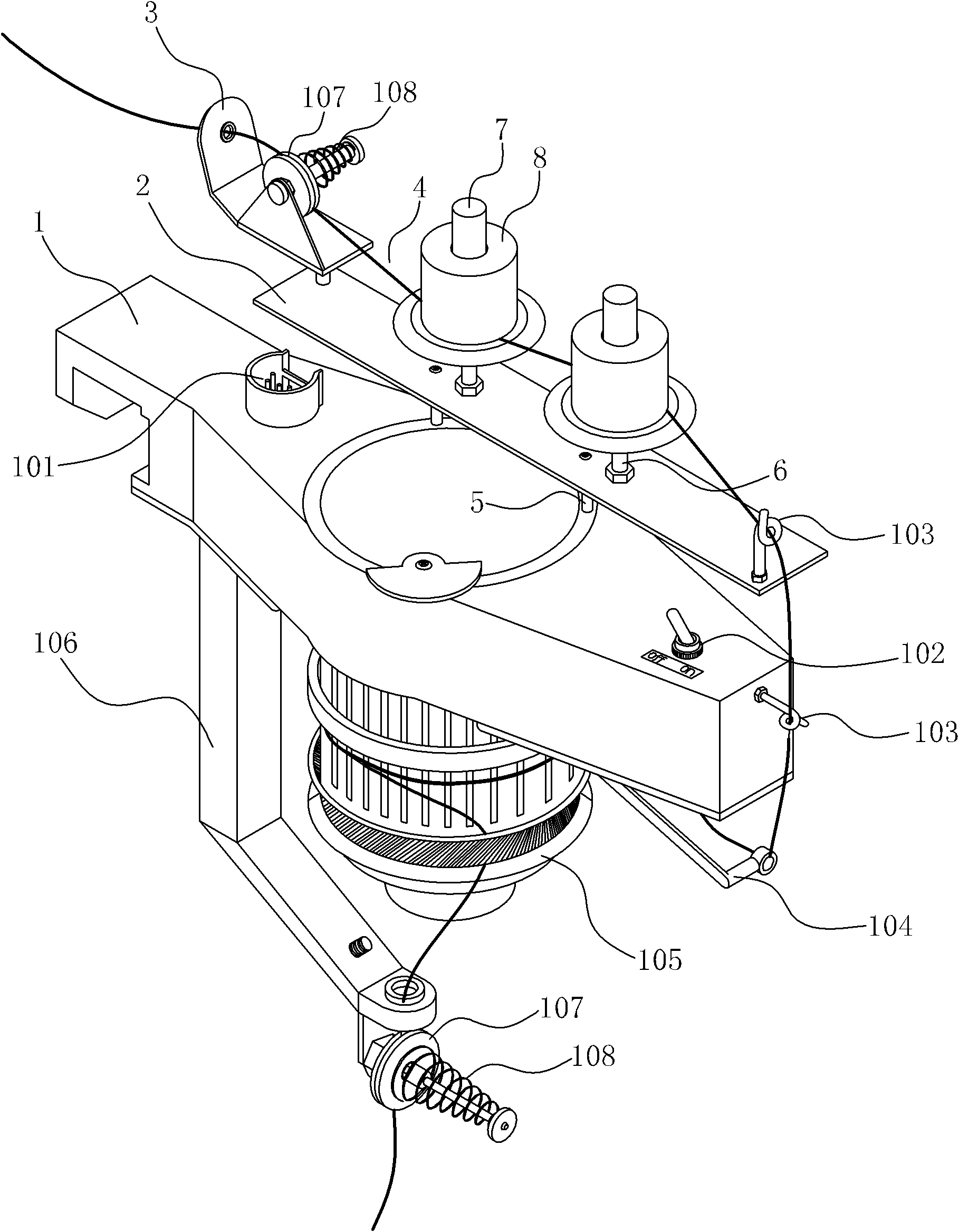

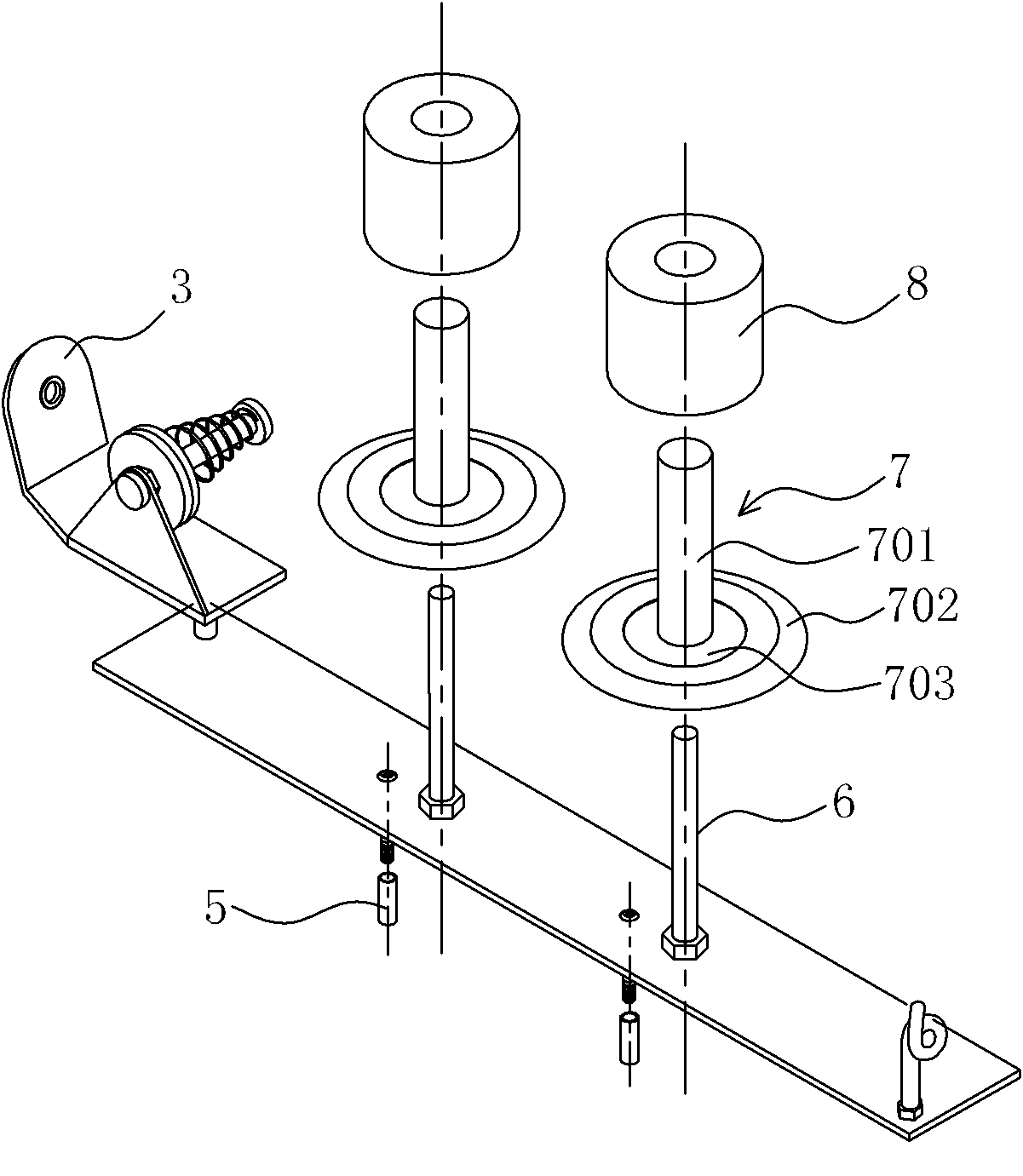

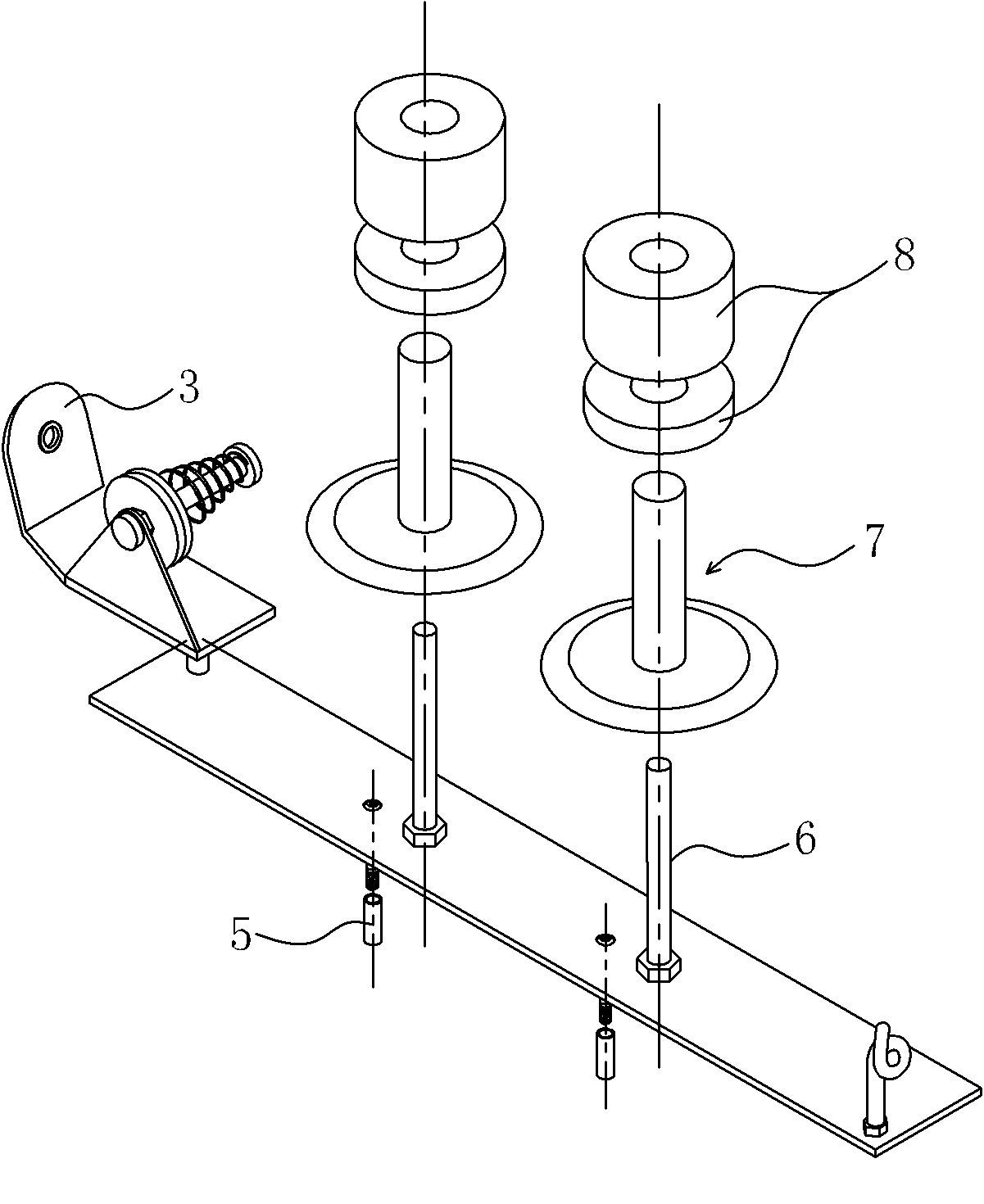

[0016] The present invention will now be further described with reference to the drawings. The names of the serial numbers in the figure are: body 1, power socket 101, switch 102, lead hole 103, pick spring 104, electric yarn wheel assembly 105, outlet bracket 106, wire clamp 107, tension spring 108, frame body 2, wire clamp Bracket 3, yarn 4, bolt sleeve 5, shaft 6, wax ring seat 7, sleeve rod 701, chassis 702, shallow recess 703, wax ring 8, gasket 9, spring 10, adjusting block 11, and adjusting bolt 12.

[0017] Such as figure 1 As shown, the automatic waxing device of the flat knitting machine is composed of a yarn storage and feeder and a waxing component. The yarn storage and feeder is composed of the body 1, the power socket 101, the switch 102, the lead hole 103, the pick spring 104, and the electric yarn The wheel assembly 105 and the thread-out bracket 106 are composed of the existing structure of the yarn storage and feeder, so it will not be described in detail. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com