Hydraulic fast forging unit adopting superposed oil supply of hydraulic pumps and high-pressure accumulators

A high-pressure accumulator and hydraulic oil technology, which is applied to the accumulator device, the drive device of the press and the forging press, etc., can solve the problems of no-load energy consumption, large power waste, and unreasonable hydraulic pump configuration. , to achieve the effect of reasonable resource allocation, avoiding energy waste and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

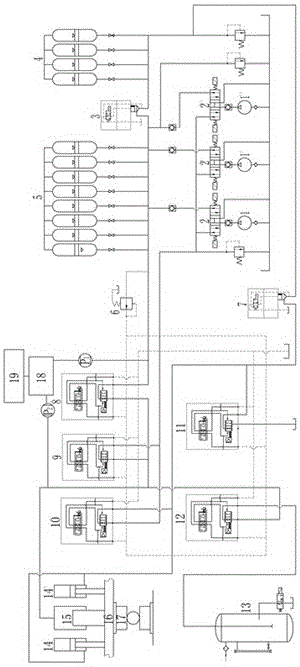

[0048] The present invention will be further explained below in conjunction with accompanying drawing:

[0049] as attached figure 1 As shown, the main hydraulic cylinder 15 is a plunger hydraulic cylinder, and the forging hammer head 17 of the hydraulic fast forging unit is connected to the plunger of the main hydraulic cylinder 15 through the movable beam 16, and when the plunger is filled with hydraulic oil, the forging hammer head 17. Empty stroke descending; the single-out rod return hydraulic cylinders 14, 14' are placed on both sides of the main hydraulic cylinder 15, and the single-out rod in it is linked with the forging hammer head 17 through the movable beam 16. When the rod chamber is filled with hydraulic pressure The forging hammer head 17 realizes the return stroke when the oil is oily; there are multiple high-pressure accumulators, and the multiple accumulators are divided into Group A high-pressure accumulator 5 and Group B high-pressure accumulator 4; the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com