Method for operating hybrid drive system of hybrid vehicle and control device

A hybrid vehicle and hybrid drive technology, which is applied in the arrangement and engine control of multiple different prime movers of hybrid vehicles and general power units, can solve problems such as discarding, and achieve the effect of high starting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

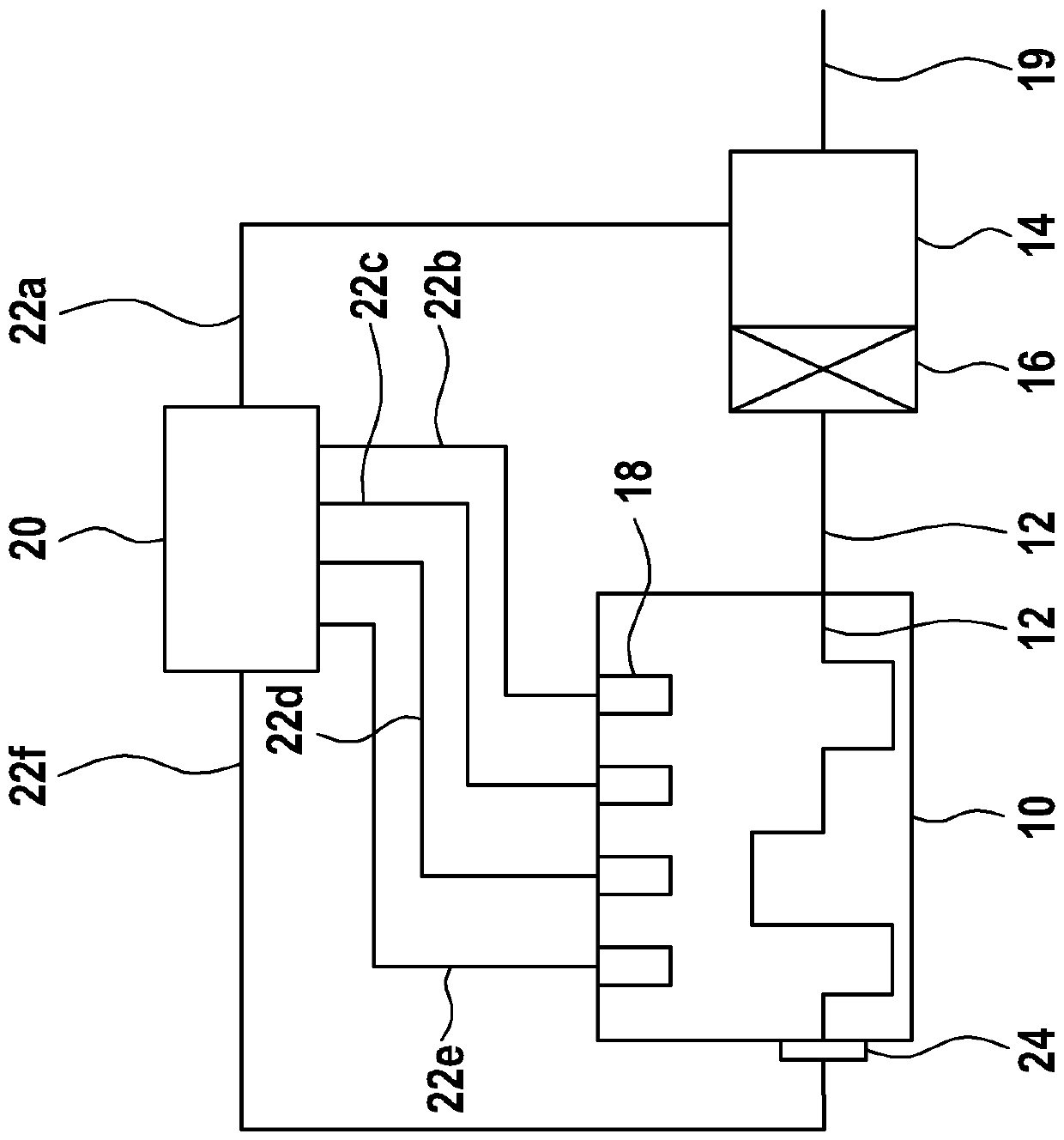

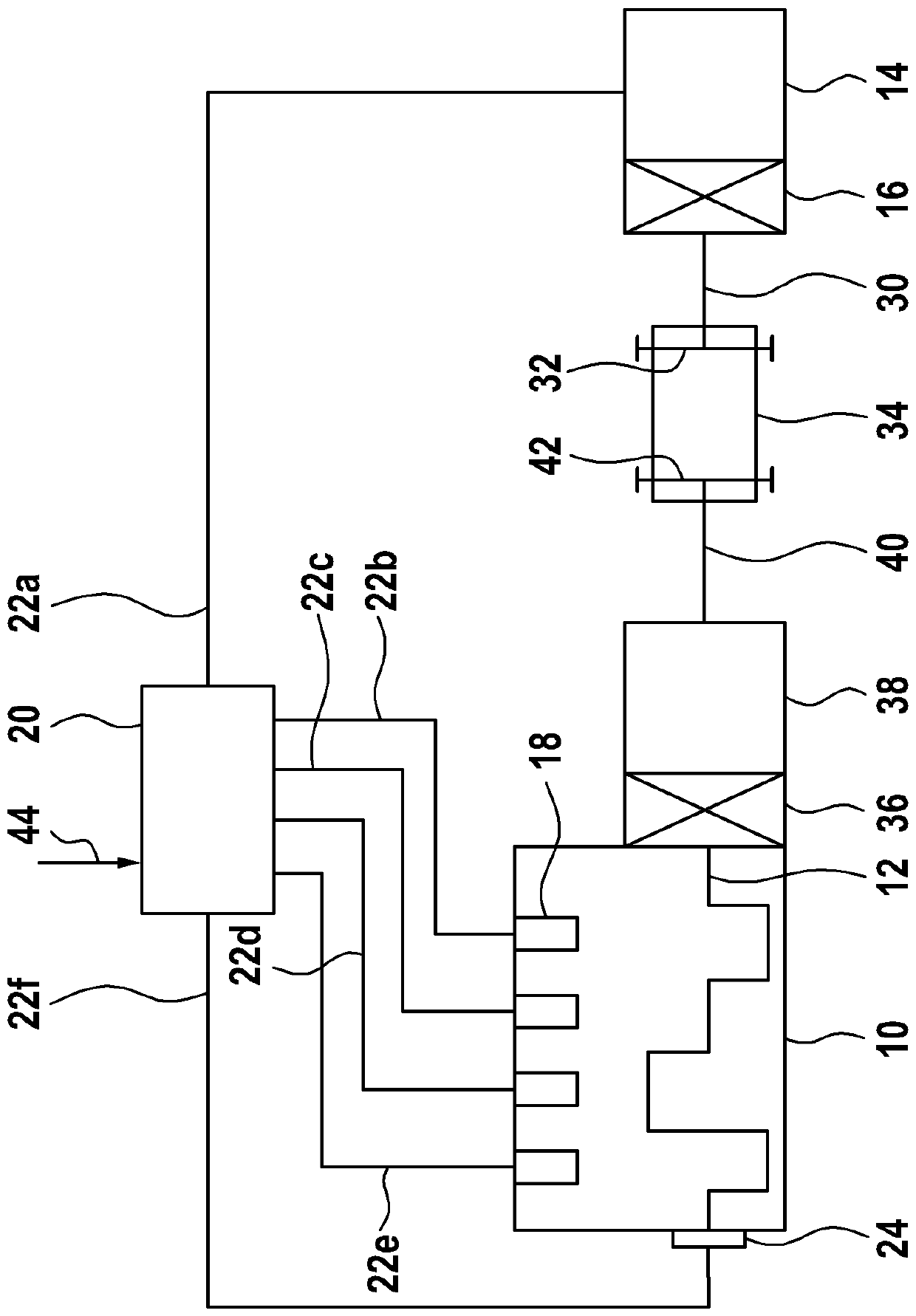

[0017] figure 1 A schematic diagram of a first hybrid drive system is shown for explaining an embodiment of a method for operating such a hybrid drive system.

[0018] exist figure 1 The hybrid drive system shown schematically in FIG. 2 comprises a combustion motor 10 with a cooperating crankshaft 12 and a drive electric machine 14 . Combustion motor 10 also has injection valves and ignition coils, not shown. By way of example only, the drive motor 14 is connected to the crankshaft 12 via a clutch 16 and / or a transmission, so that the crankshaft 12 can be rotated by means of the drive motor 14 and without the combustion motor 10 running. figure 1 The topology of the hybrid drive system can therefore also be referred to as the P2 topology. The rotation of the crankshaft 12 solely by means of the drive motor 14 is often also referred to as non-igniting rotation of the crankshaft 12 .

[0019] It is expressly pointed out, however, that the method described subsequently can al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com