Method for controlling heating apparatus

A control method, technology of heating device, applied in furnace control device, electrical program control, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

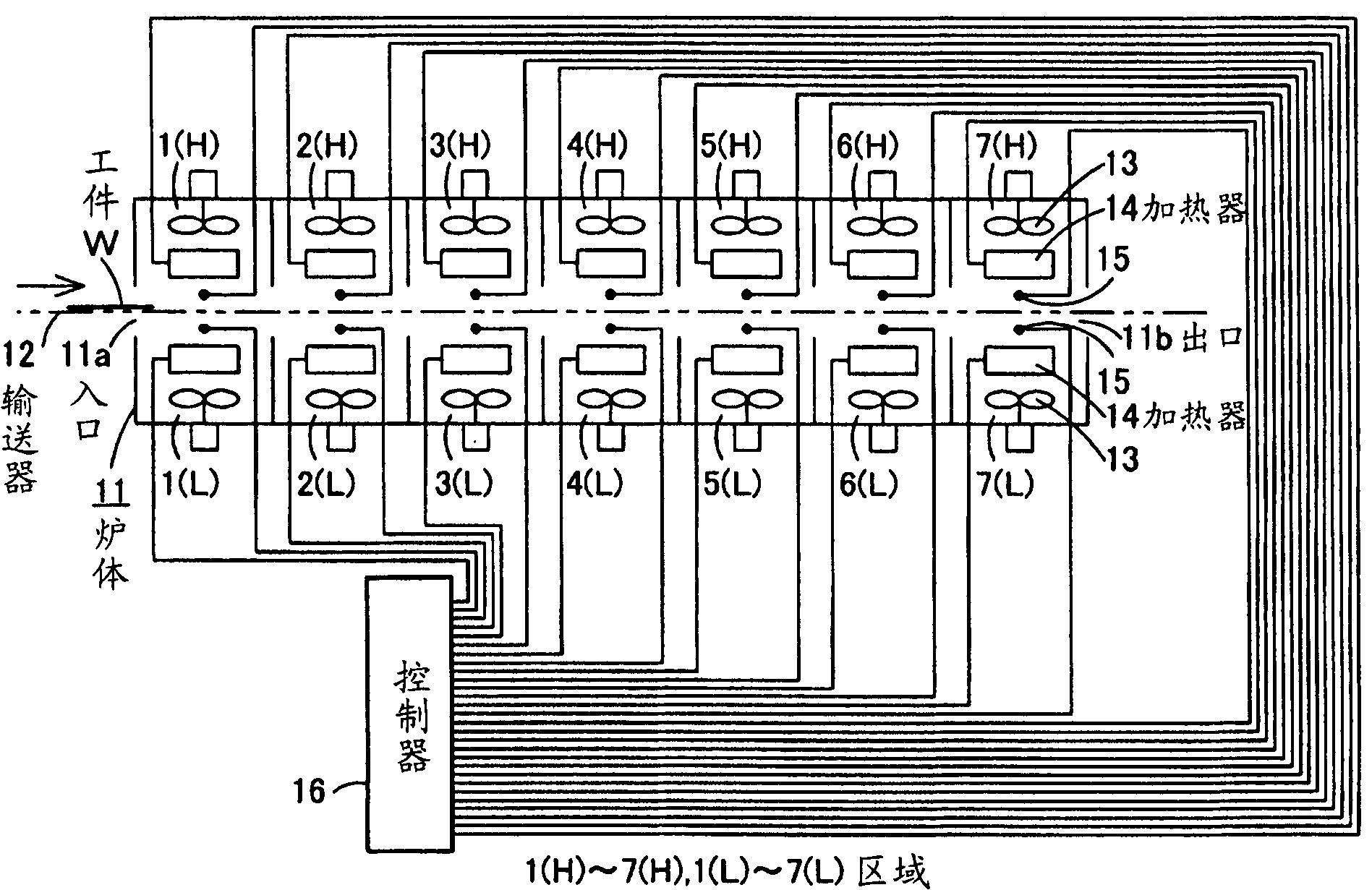

[0038] Each heater 14 and temperature sensor 15 are connected to a controller 16 which controls the power supply to each heater 14 while monitoring the ambient gas temperature in each area. The controller 16 controls the start-up operation for starting the ambient gas temperature in each zone 1 (H) to 7 (H) and 1 (L) to 7 (L) when starting the main heating operation. , control the ambient gas temperature in each area 1(H)~7(H), 1(L)~7(L) to keep it at the prescribed preheating temperature or reflow temperature.

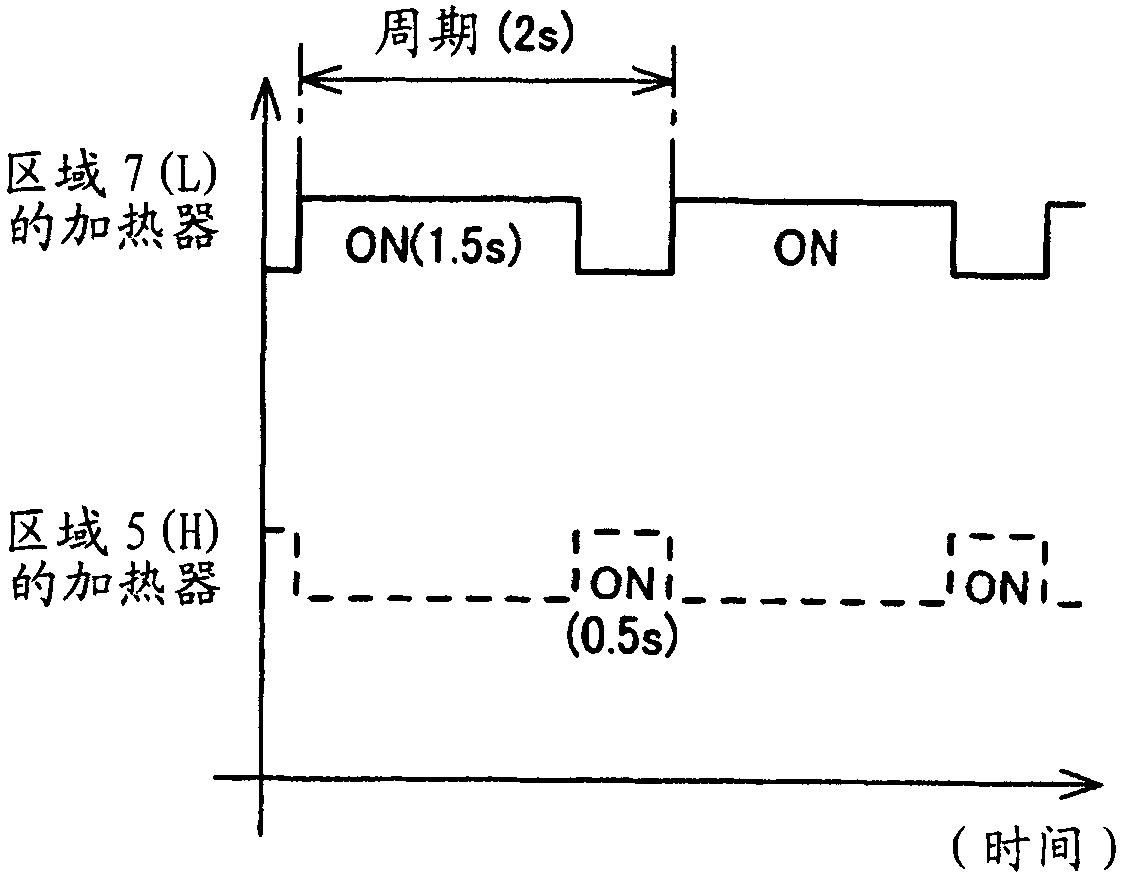

[0039] As the control method for the controller 19 to control each heater 14, the following control method is more suitable: control the switching circuit according to the temperature information from the temperature sensor 15, and control the pulse of the heater on-duty ratio (=on time / switching period). Wide modulation method (so-called PWM method), and switching frequency modulation method (so-called PFM method), etc.

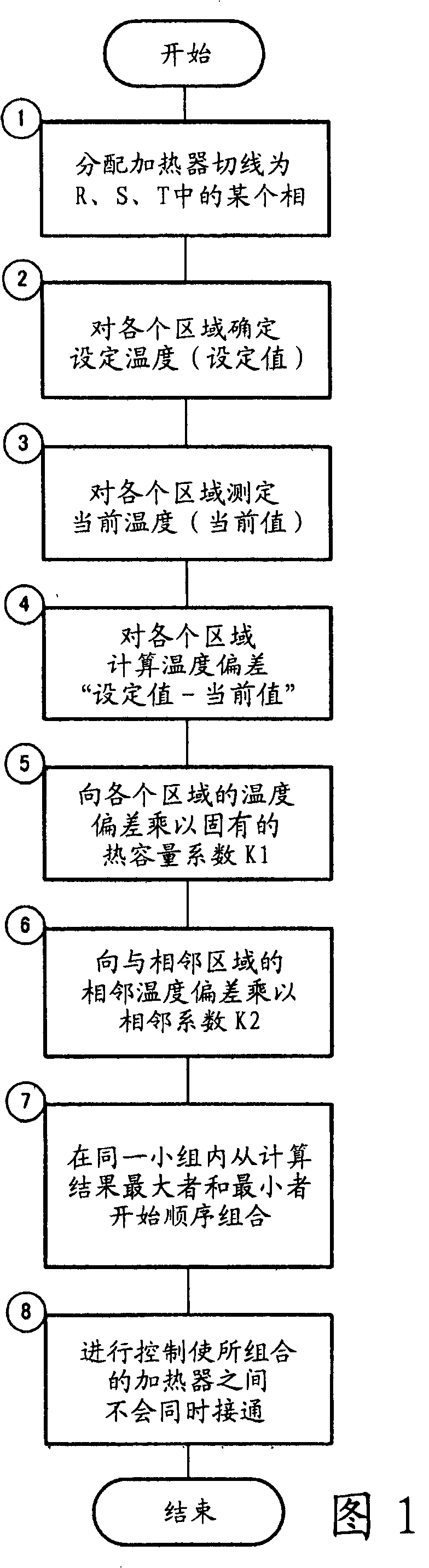

[0040] In this way, refer to figure 1 The sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com