Metal halide lamp and UV bubble structure thereof

A metal sheet and metal wire technology, applied in the field of metal halide lamps, can solve the problems of UV bubble bursting and other problems, and achieve the effect of not easy to burst, reduce pollution, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

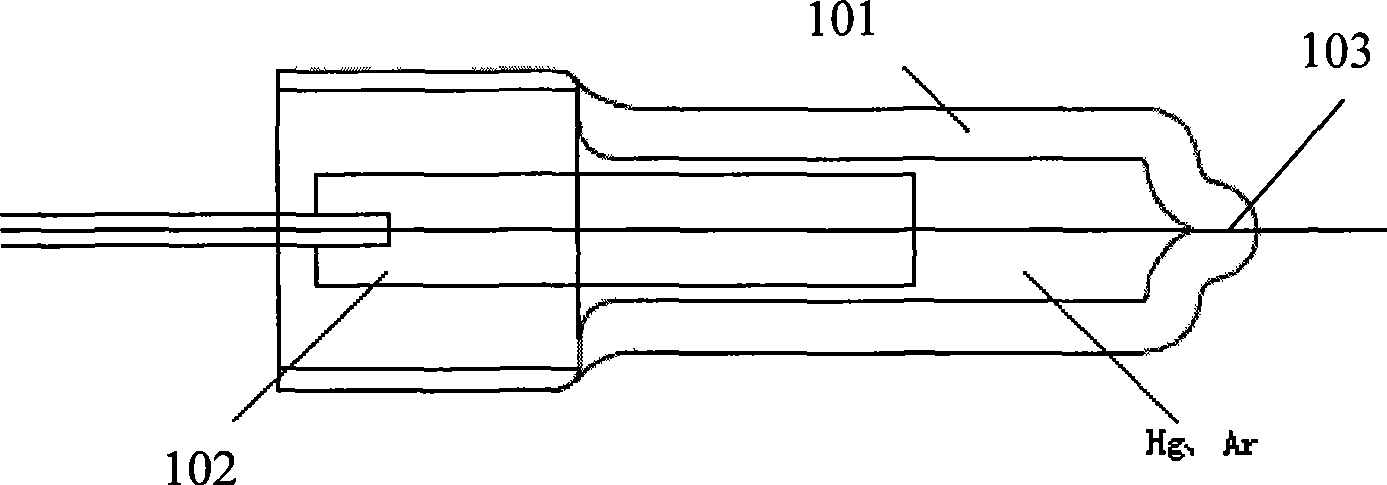

[0015] first as figure 1 As shown, a UV bubble of the present invention includes a housing 101 of quartz glass, a molybdenum sheet 102 and a mixed gas of Hg and Ar filled in the housing, wherein the housing 101 is cylindrical, with a diameter ≤ 3.5mm, and the bottom of the housing is provided with Protrusion 103 . During manufacture, the molybdenum rod and the molybdenum sheet 102 are spot-welded first, the connected molybdenum sheet 102 is submerged in the quartz tube shell 101, and the flame is heated and hermetically sealed. After the other end of the shell is fed with argon and mercury, it is vacuumed and then filled with argon, and the filling and pumping process is repeated several times before being sealed off. During the sealing and separation process, appropriate technological means are adopted to minimize the presence of liquid mercury in the UV bulb, and the mercury content can be less than 0.5mg, and more optimally, the mercury content can be less than 0.3mg.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com