Patents

Literature

40results about How to "Effective stop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-zone resistance heater

InactiveCN1377568ACool evenlyGuaranteed cooling temperatureHeater elementsTransit-time tubesElectrical resistance and conductanceHelium

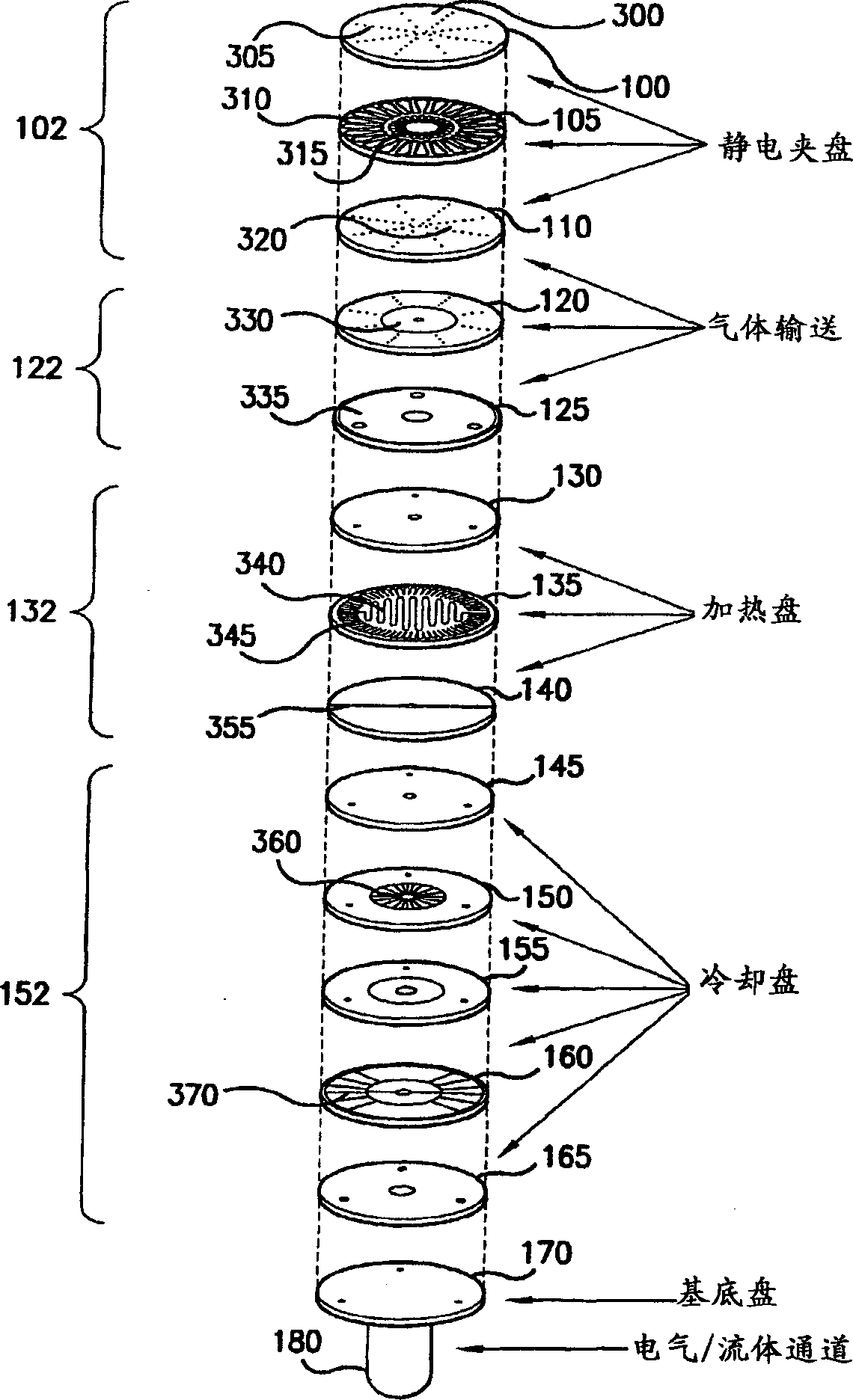

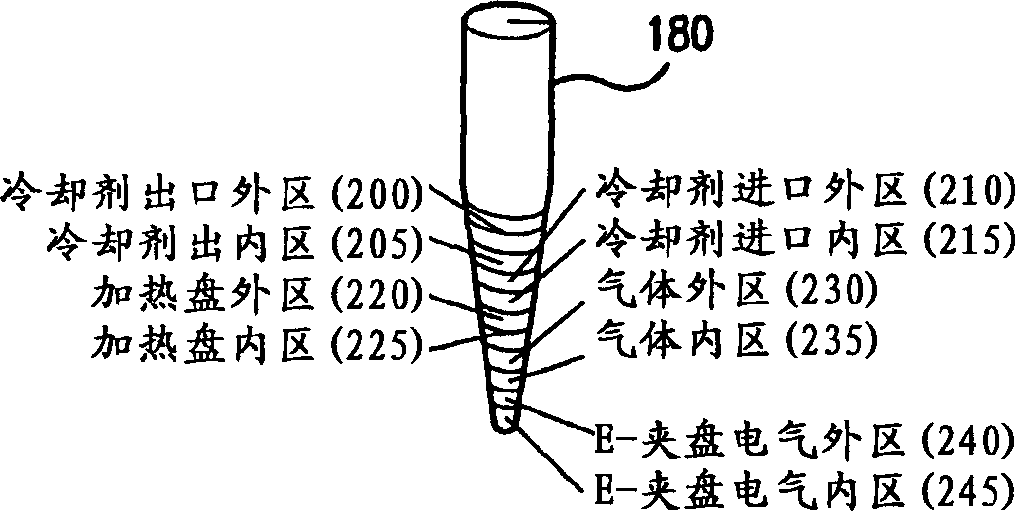

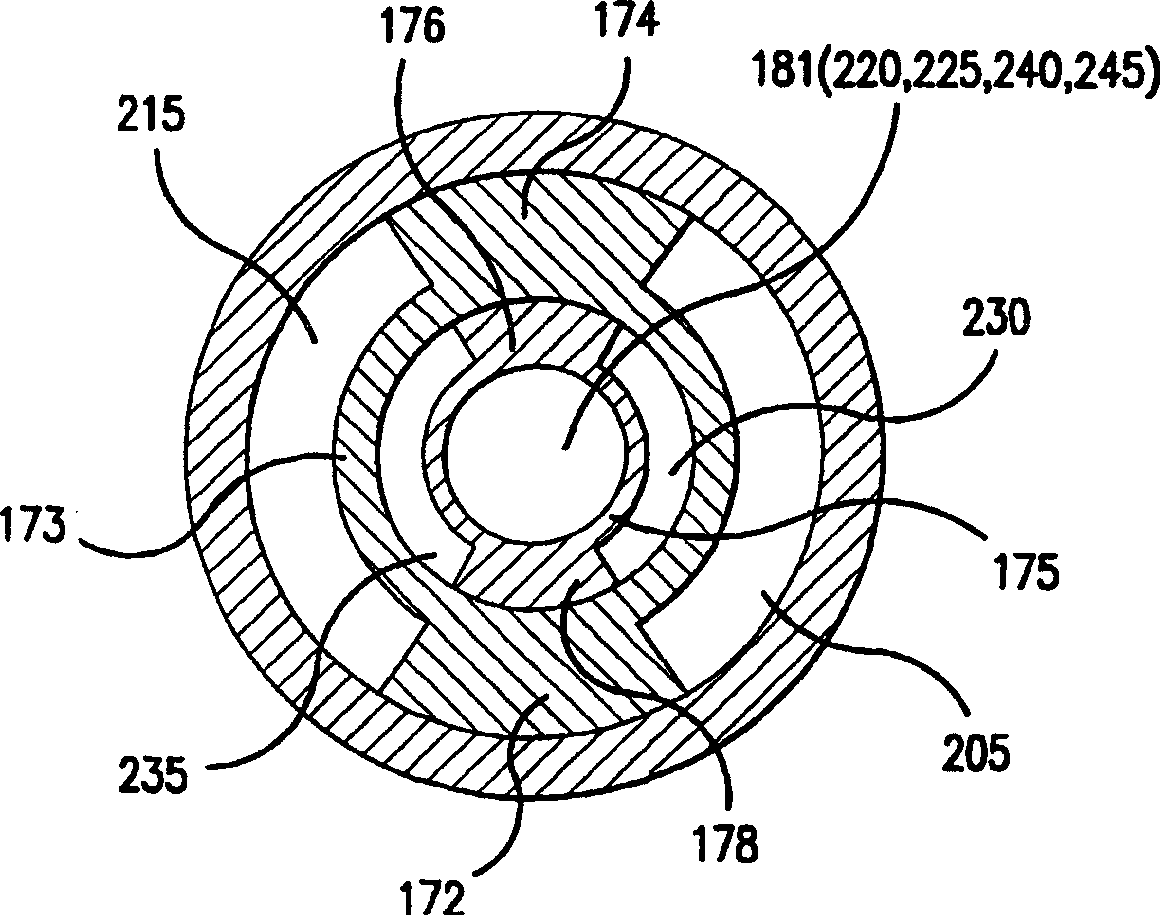

A substrate holder for holding a substrate (e.g., a wafer or an LCD panel) during plasma processing. The substrate holder is a stack of processing elements which each perform at least one function. The elements include an electrostatic chuck (102), an He gas distribution system (122), multi-zone heating plates (132), and multi-zone cooling system (152). Each element is designed to match the characteristic of the processing system, e.g., by applying heat based on a heat loss characteristic of the substrate during normal processing. The integrated design allows for precise control of the operating conditions, including, but not limited to, fast heating and fast cooling of a substrate.

Owner:TOKYO ELECTRON LTD

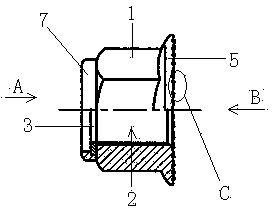

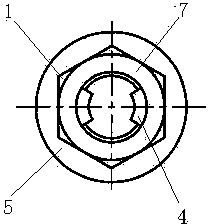

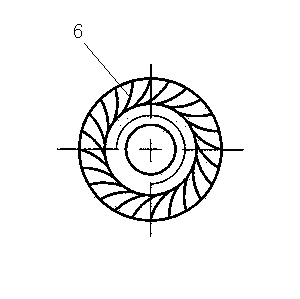

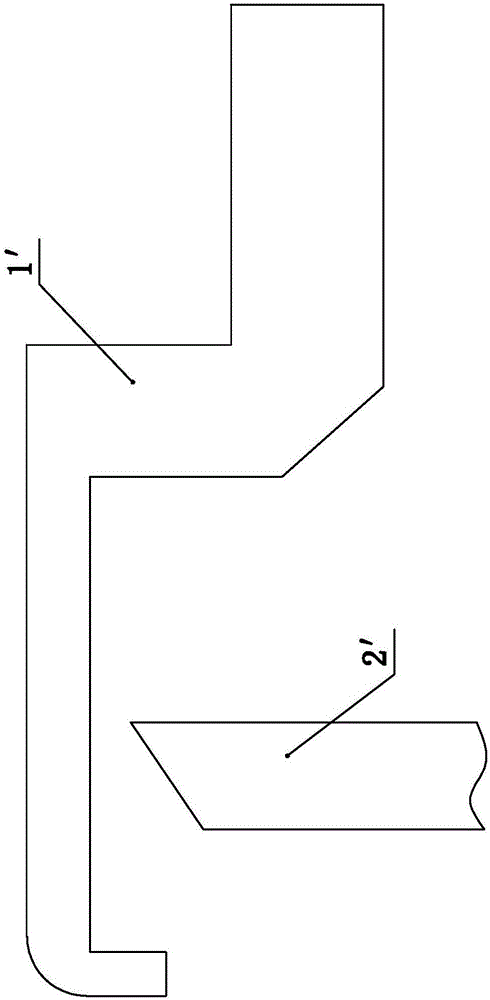

Automatic locking anti-loosening nut

The invention discloses an automatic locking anti-loosening nut which comprises a nut body. The nut body is provided with a threaded hole, an annular boss which extends outwardly is arranged at an end of the nut body, an annular elastic locking plate is fixed into an annular hole of the annular boss, a center hole of the annular elastic locking plate is concentric with the threaded hole, and the inner diameter of the elastic locking plate is smaller than that of the threaded hole. Protrusions which are radially protruded towards a hole center are arranged on the inner surface of the locking plate. A flange is further arranged on the nut body, and continuous radial antislip teeth are arranged on an end surface of the flange. The automatic locking anti-loosening nut has the advantages that the automatic locking anti-loosening nut can be reliably locked, shock-resistant and anti-loosening effects can be realized, the deformation-resistant metal locking plate is excellent in elastic resetting ability and can be reset after being used and detached, accordingly, original functions of the automatic locking anti-loosening nut can be kept, the automatic locking anti-loosening nut is reusable and is convenient to detach, and the cost can be saved; the nut is provided with the flange with the antislip teeth, so that anti-loosening and antislip friction force can be greatly increased, and the automatic locking anti-loosening nut is reliable in anti-loosening performance.

Owner:江苏浩瀚汽车标准件有限公司

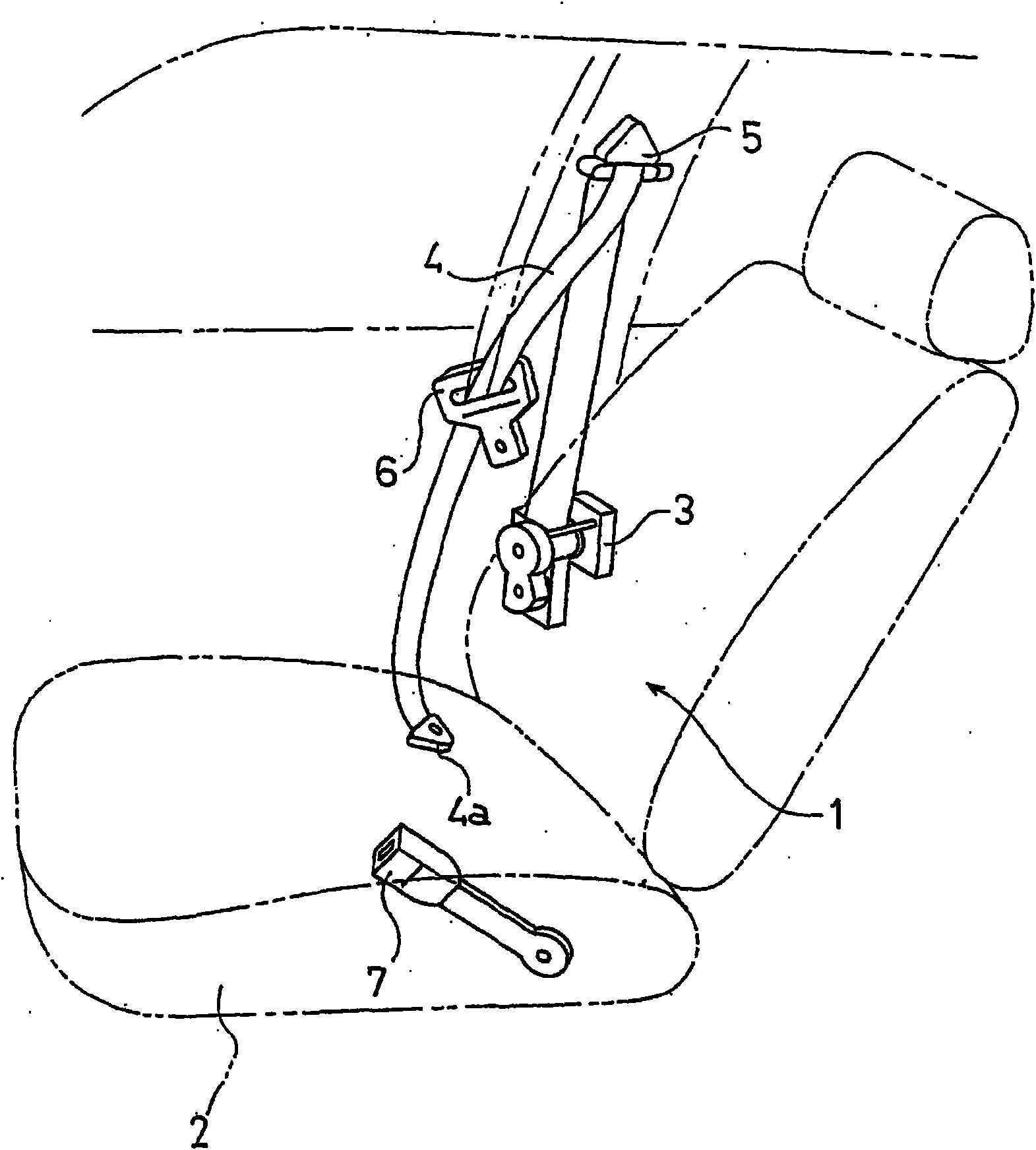

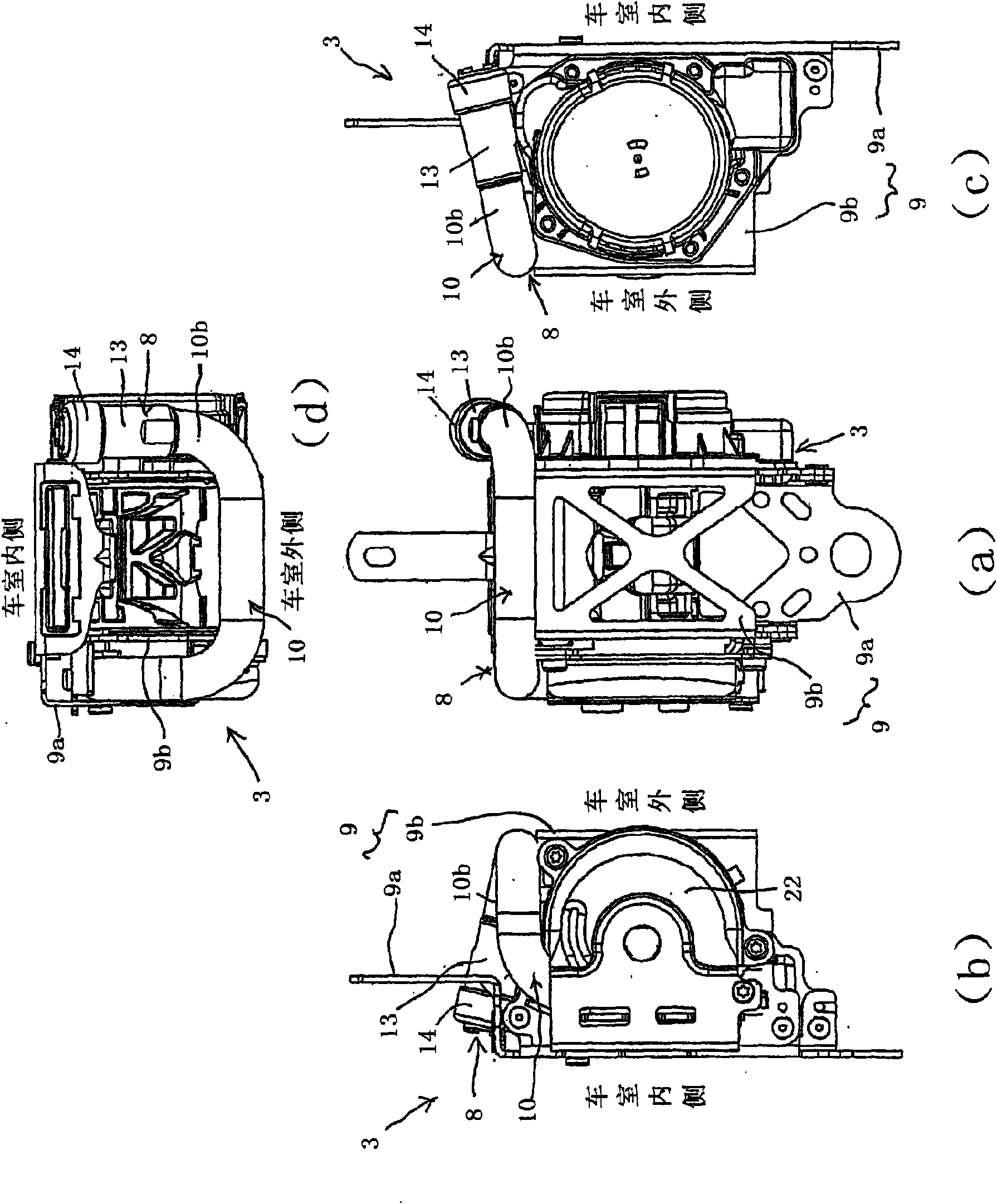

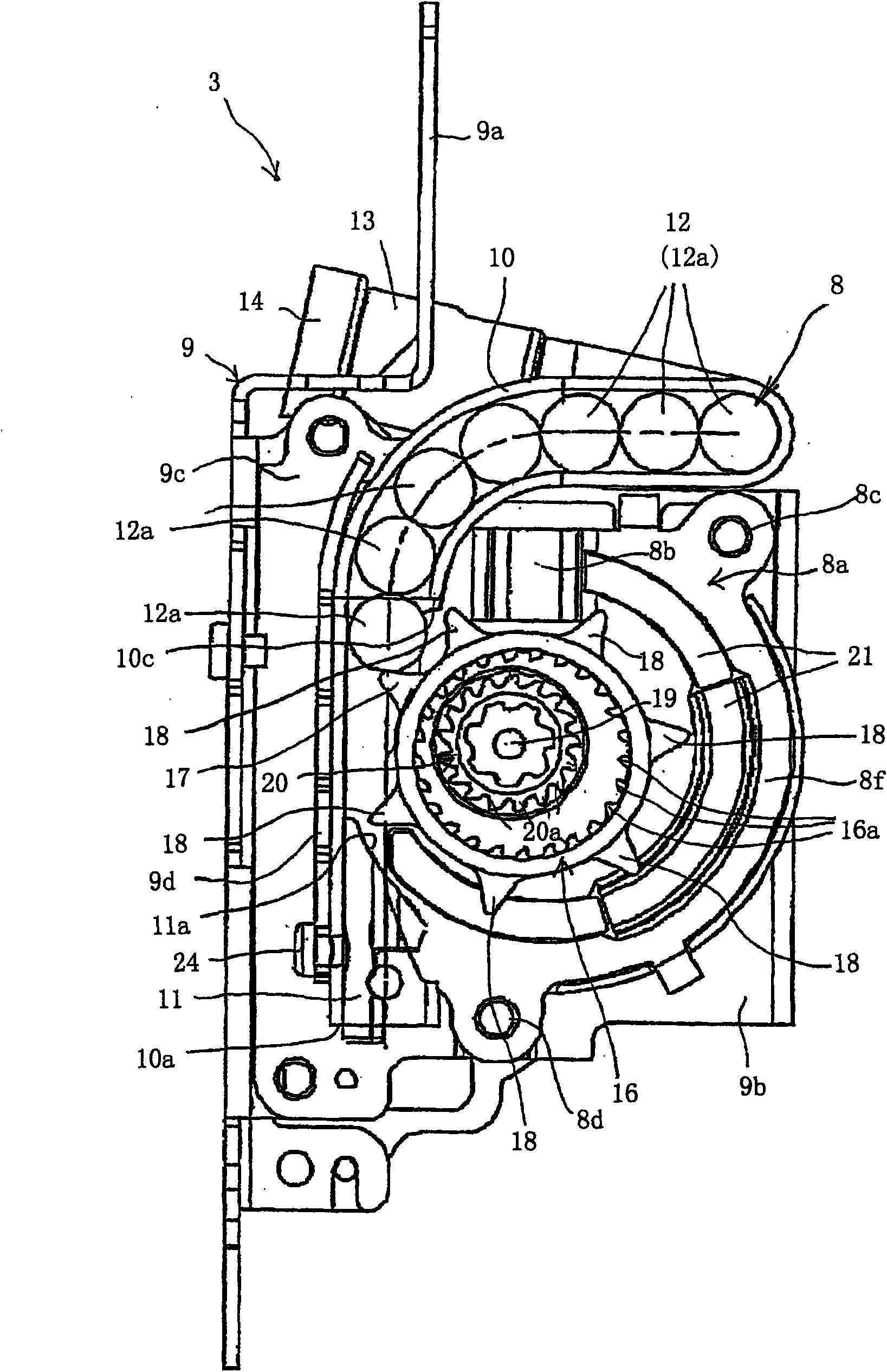

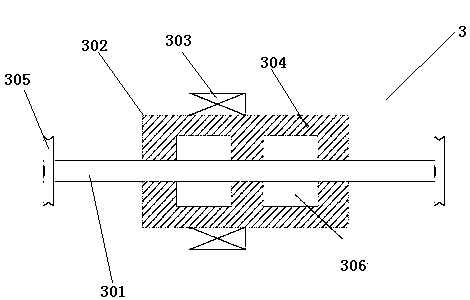

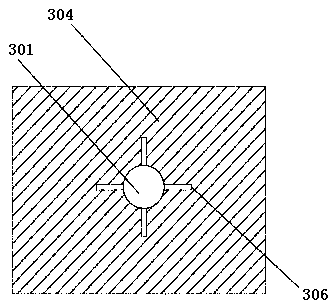

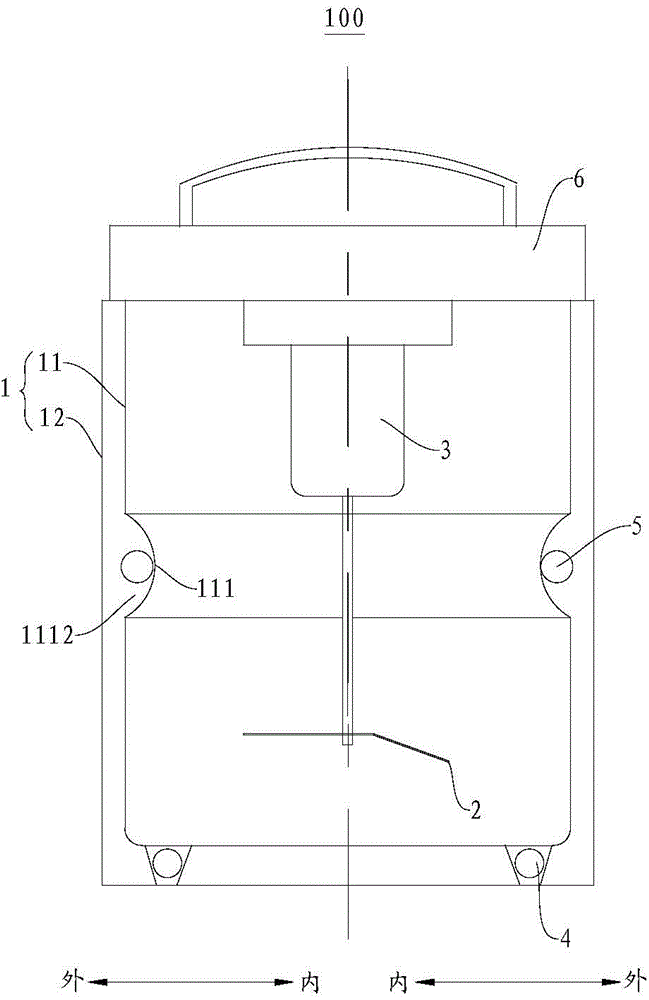

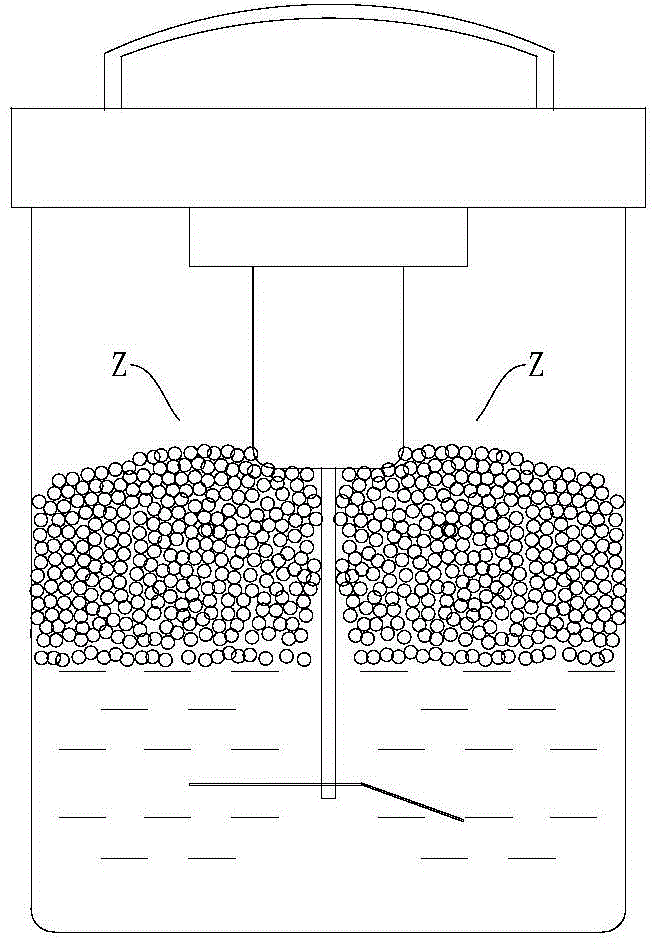

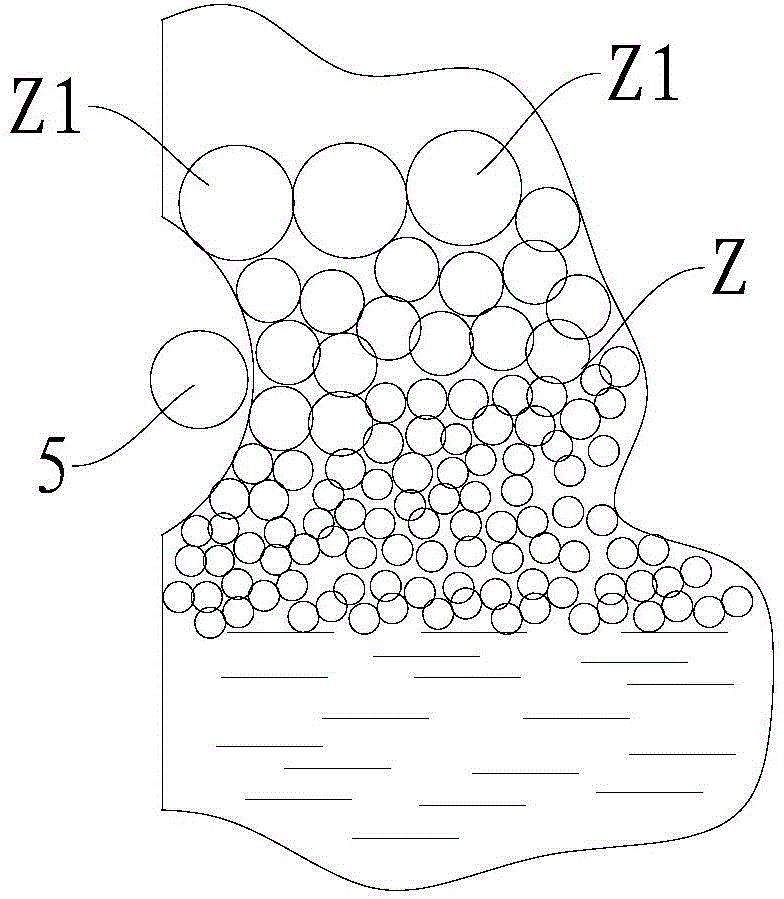

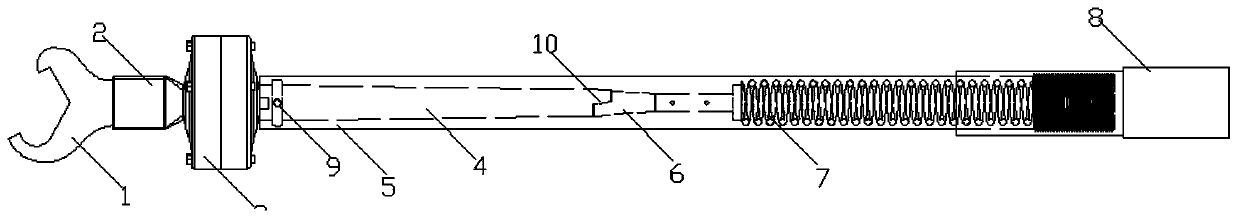

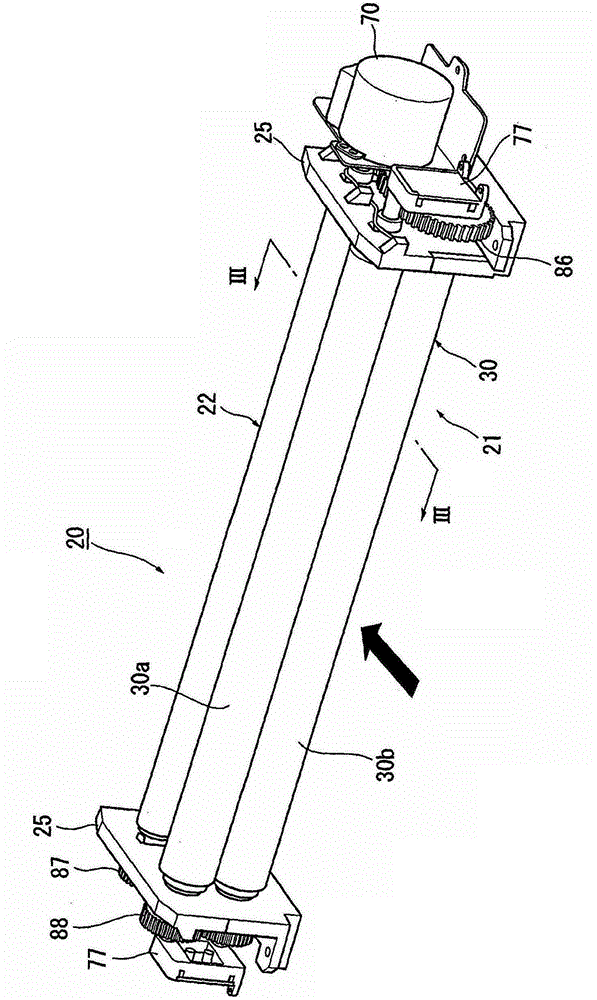

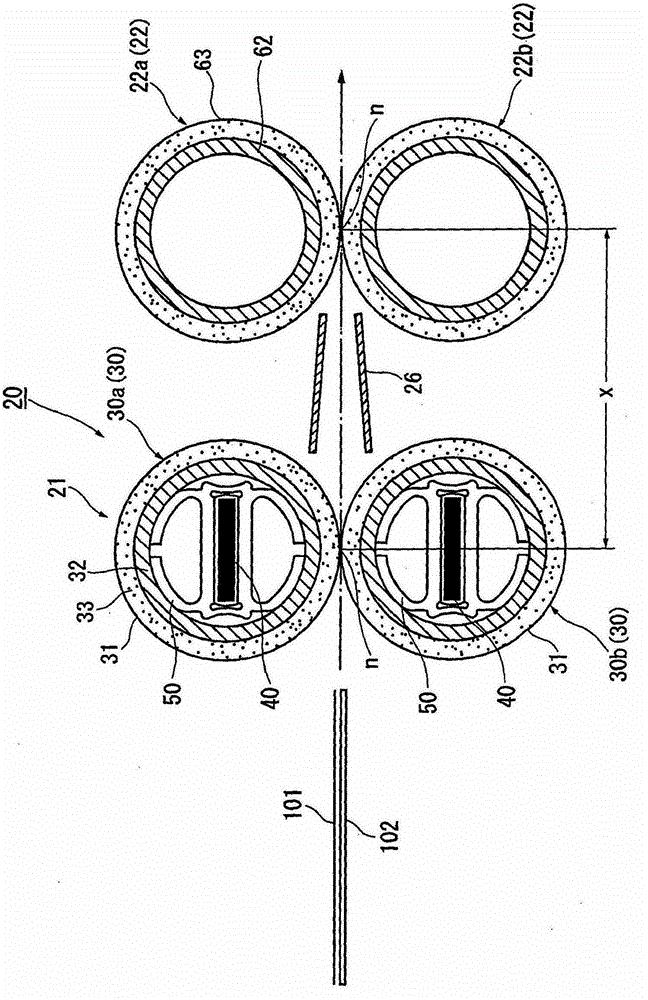

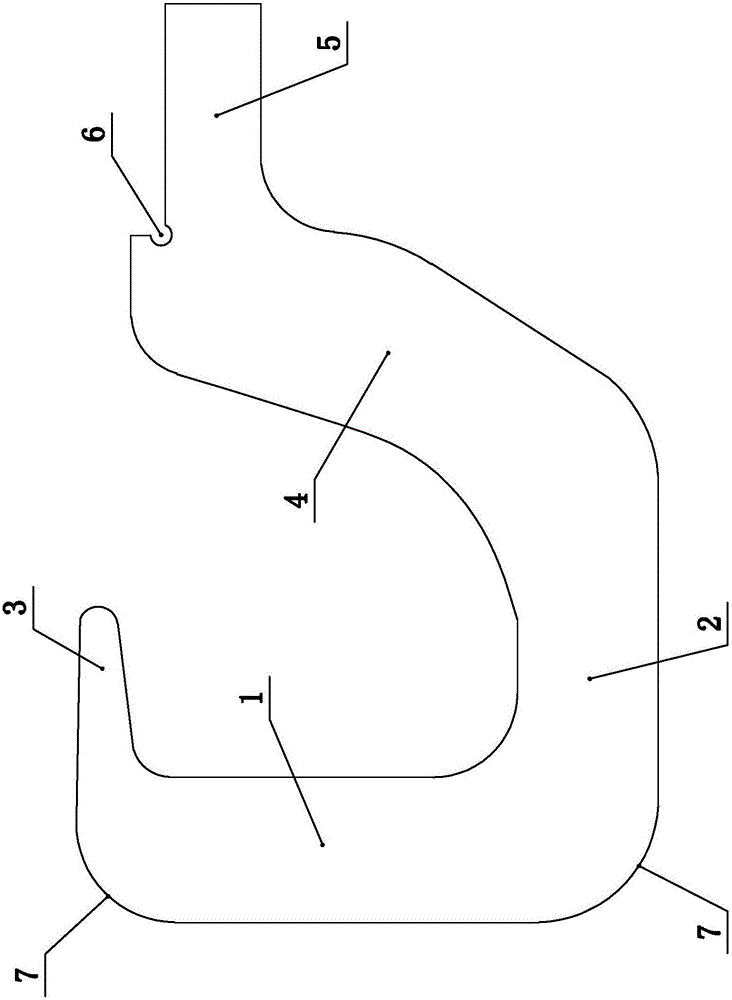

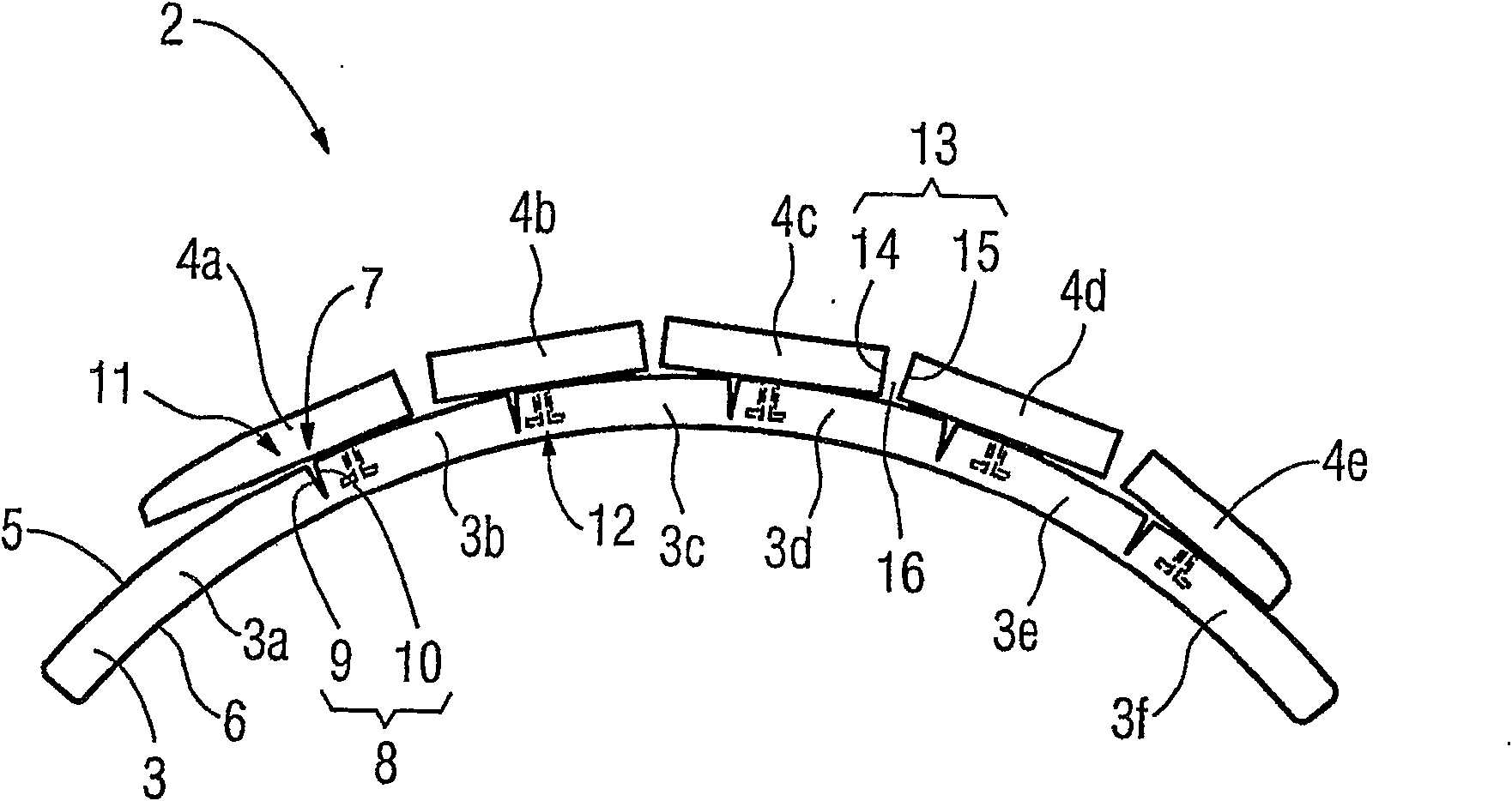

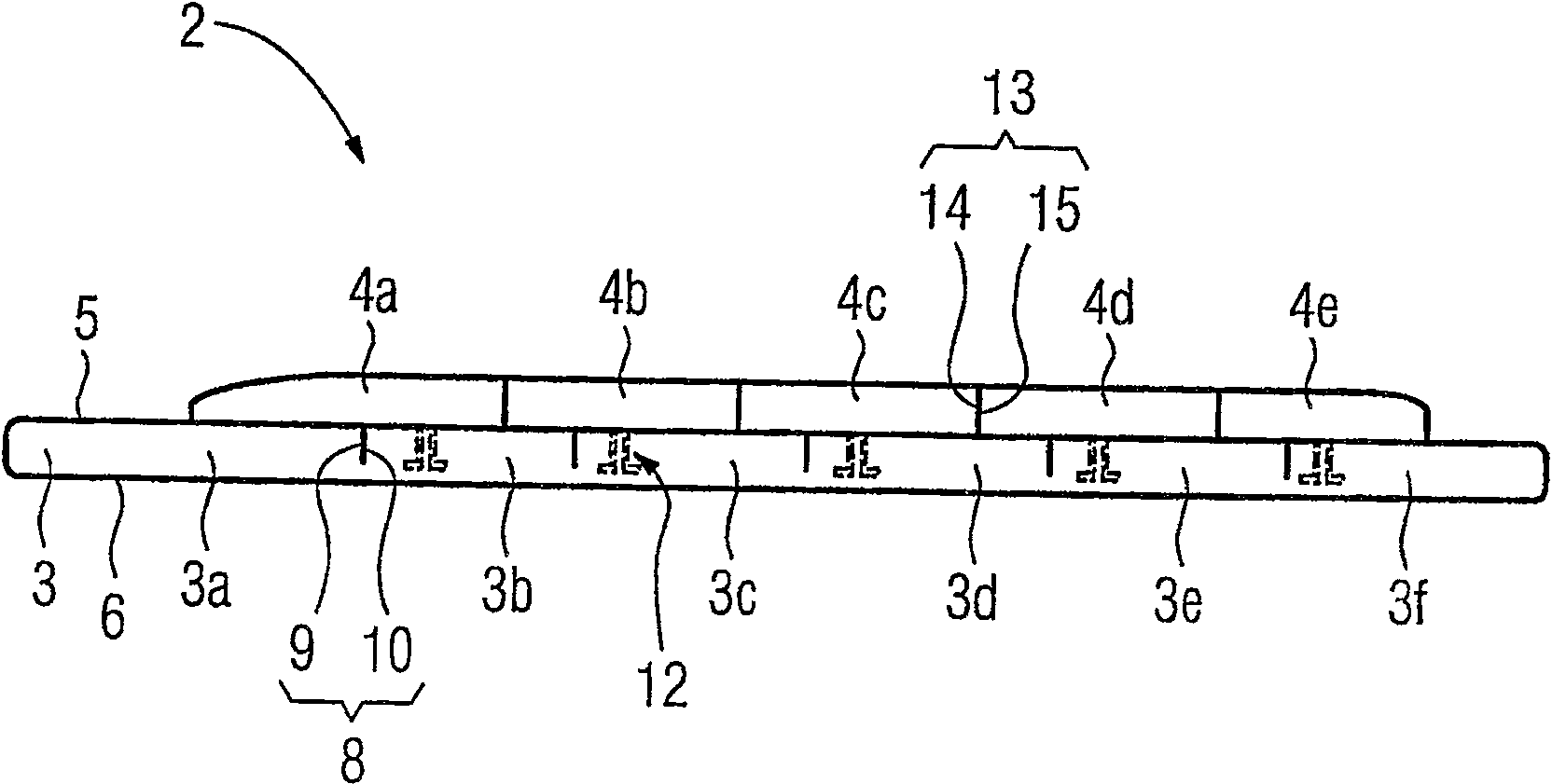

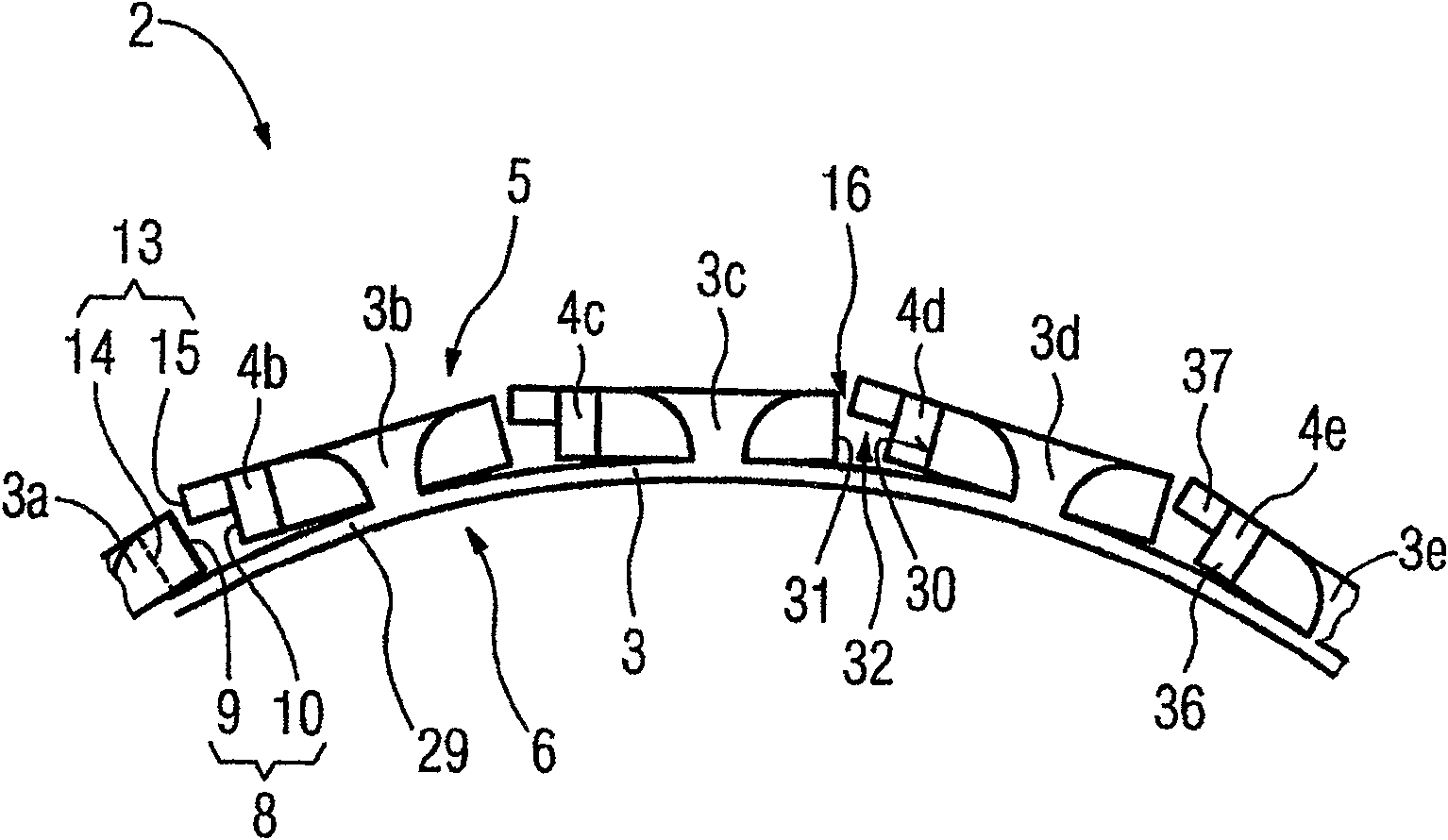

Pretensioner, seatbelt retractor and seatbelt device

The present invention relates to a pretensioner, a seatbelt retractor and a seatbelt device. In order to provide a compact and less expensive pretensioner (8) for improving the work assembly efficiency while effectively transmitting the pressing force of plural force transmission members (12) to a ring gear (16), plural balls (12a) inside a pipe (10) are pressed under the pressure of gas from a gas generator (14) in an emergency. The first ball (12a) presses a lever (17), and the balls (12a) other than the first ball (12a) sequentially press subsequent levers (18) such that the ring gear (16)rotates to move rightward. Internal teeth (16a) of the ring gear (16) are meshed with external teeth (20a) of a pinion (20) attached to a rotary shaft (19) at a side of a spool. The pinion (20) then rotates to allow the spool to retract a seatbelt. The first ball (12a) abuts on a ball stopper portion (10d) of the pipe (10) to stop the rest of the balls (12a) such that most of the balls (12a) are located in a circular movement path.

Owner:JOYSON SAFETY SYST JAPAN GK

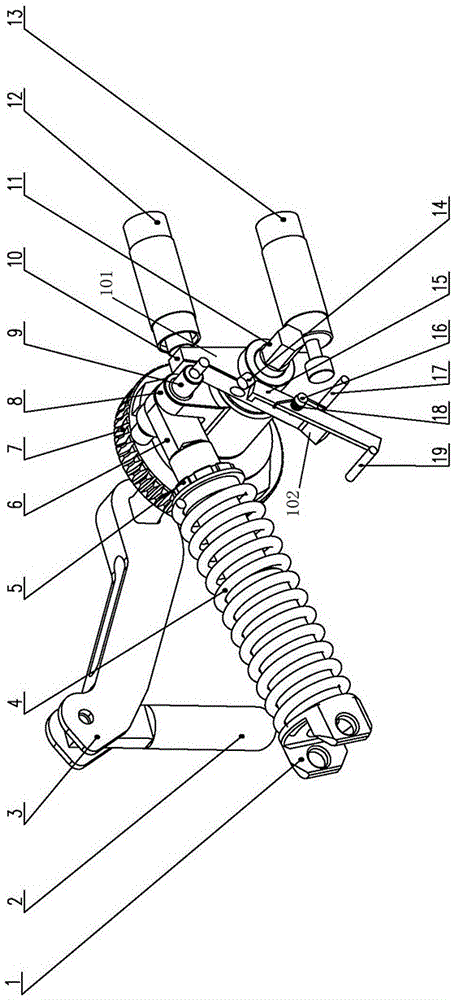

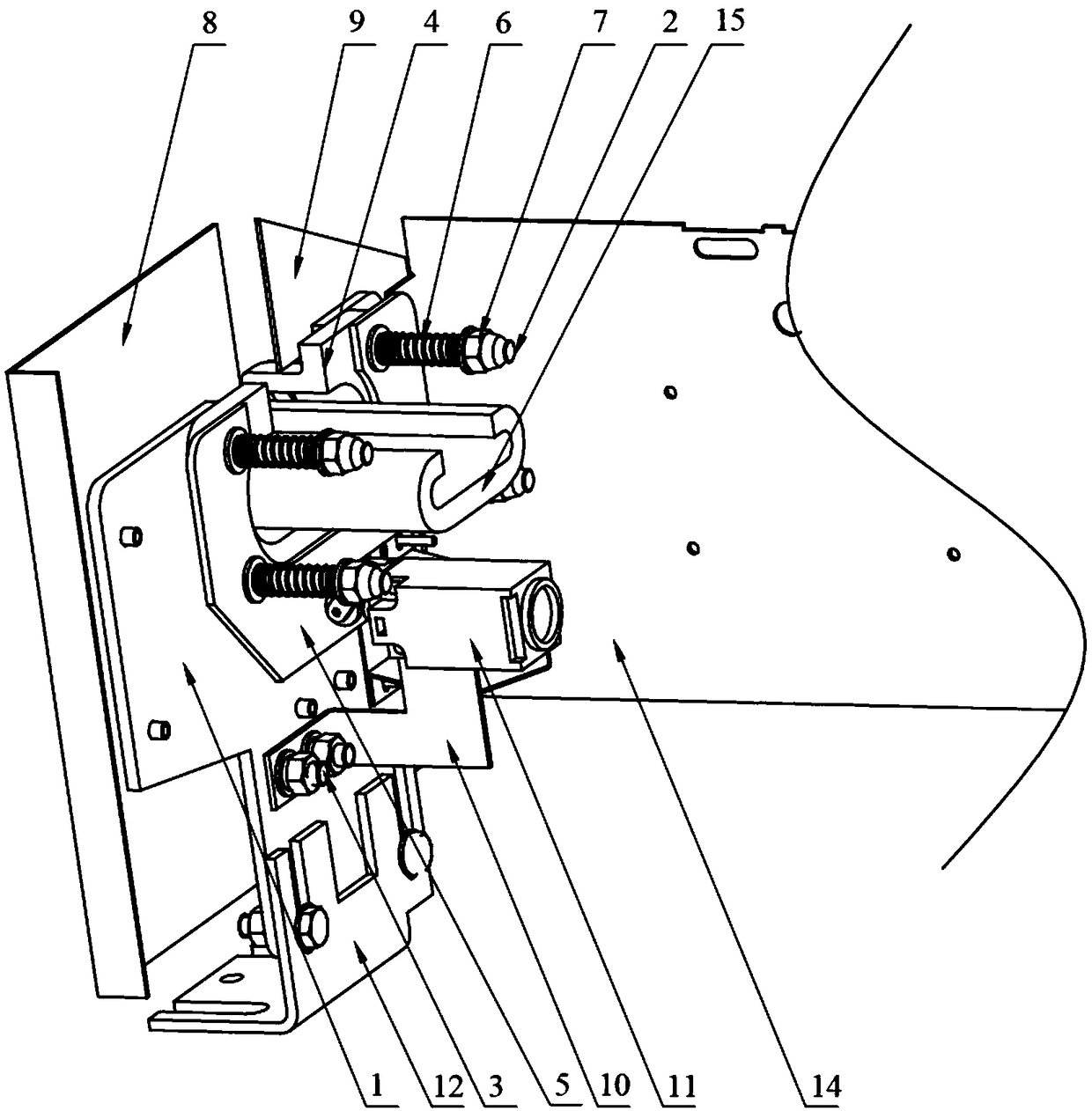

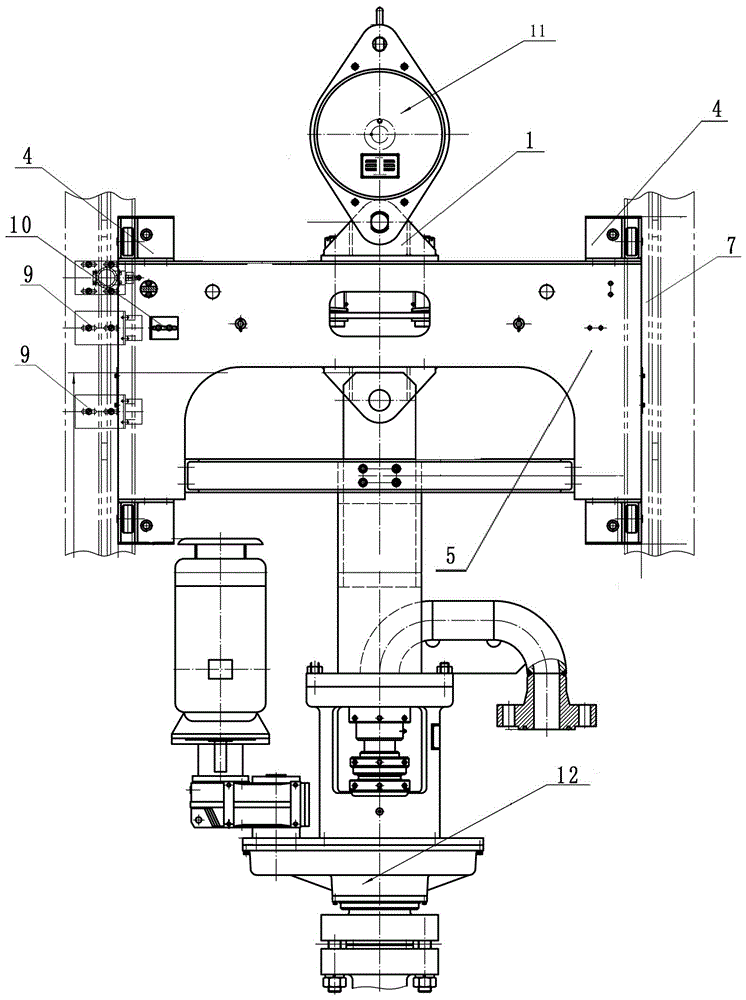

Switching device and spring operation mechanism thereof

ActiveCN106504919AImprove securityAvoid premature actionContact driving mechanismsSwitch power arrangementsElectrical equipment

The invention relates to a switching device and a spring operation mechanism thereof. The spring operation mechanism comprises an installation frame, wherein the installation frame is provided with an output shaft; the output shaft is provided with a closing position and an opening position; a driven connecting lever is fixedly arranged on the output shaft; the output shaft is rotationally sleeved with a driving connecting lever; the driving connecting lever has a release travel in a rotation travel; the output shaft is provided with a stop structure; the installation frame is rotationally provided with a retainer; the retainer is provided with a stop part; the stop part is used for being in stop fit with the stop structure to stop and position the output shaft at the corresponding closing position or opening position before the driving connecting lever strikes the driven connecting lever; the retainer is provided with a locking position for making the stop part and the stop structure in stop fit in the rotation travel; the retainer is also provided with an unlocking part; the unlocking part is struck by the driving connecting lever on the corresponding release travel to compel a retaining bar to rotate away from the locking position. The output shaft is prevented from rotating before the driving connecting lever strikes the driven connecting lever by using stopping and positioning of the retainer on the output shaft, and the safety performance of the switching device is improved.

Owner:PINGGAO GRP +2

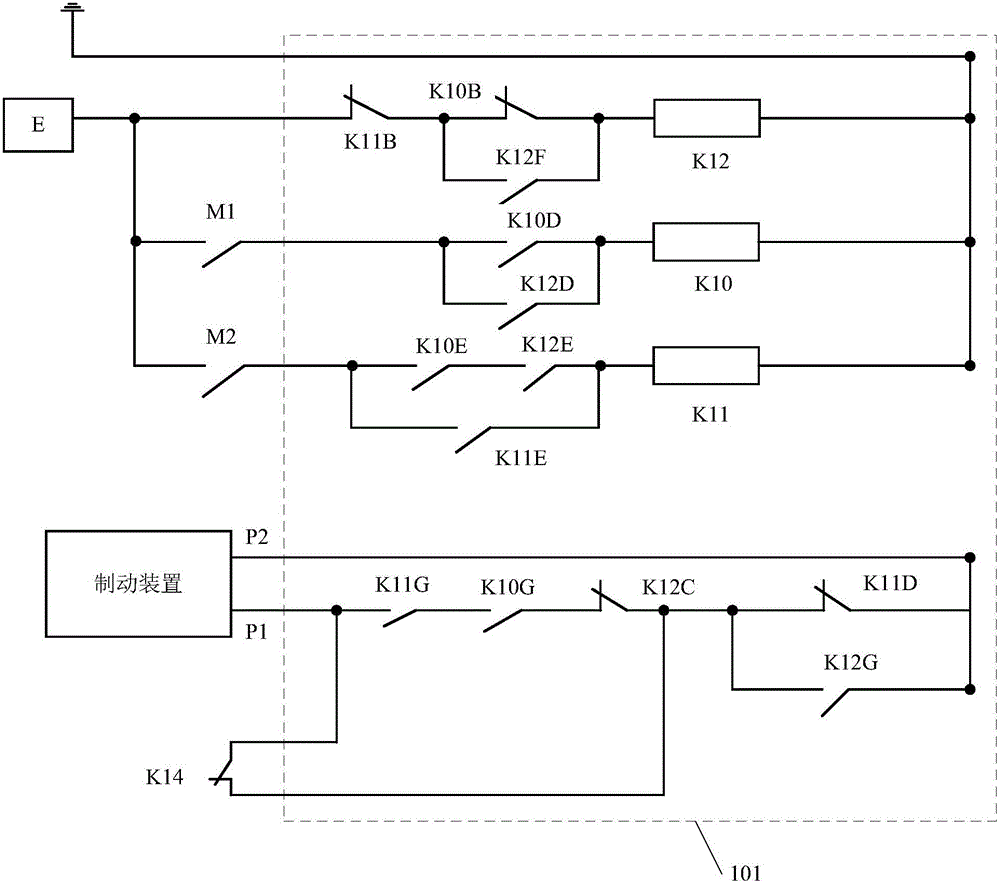

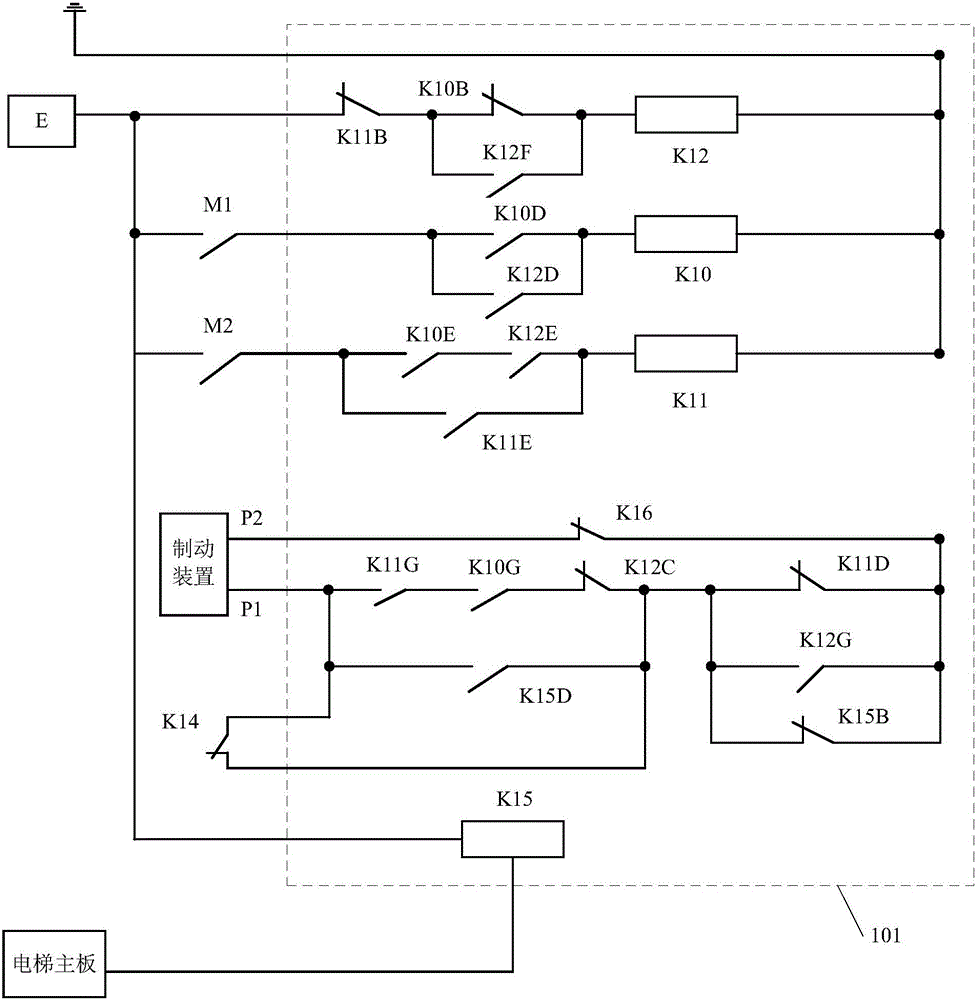

Accidental car movement protection circuit and method

InactiveCN105836585AImprove securityEliminate potential safety hazardsElevatorsBuilding liftsCar door

The invention relates to the technical field of elevators and discloses an accidental car movement protection circuit and a method. The accidental car movement protection circuit is applied to a geared elevator and comprises a control device, a door area switch, a car door switch and a brake device, wherein the door area switch, the car door switch and the brake device are connected with the control device; when an elevator is located in a door area, the door area switch is switched on; when the elevator is located outside the door area, the door area switch is switched off; when a car door of the elevator is closed, the car door switch is switched on; when the car door is opened, the car door switch is switched off; when the car door switch is switched off and the door area switch is switched off, the control device controls the brake device to stop the elevator, so that the car can be effectively braked and maintains the stop state when the car of the geared elevator is subjected to accidental movement; the potential safety hazard caused by the accidental movement of the car of the geared elevator is eliminated; the safety of the geared elevator is improved.

Owner:SHANGHAI STEP ELECTRIC

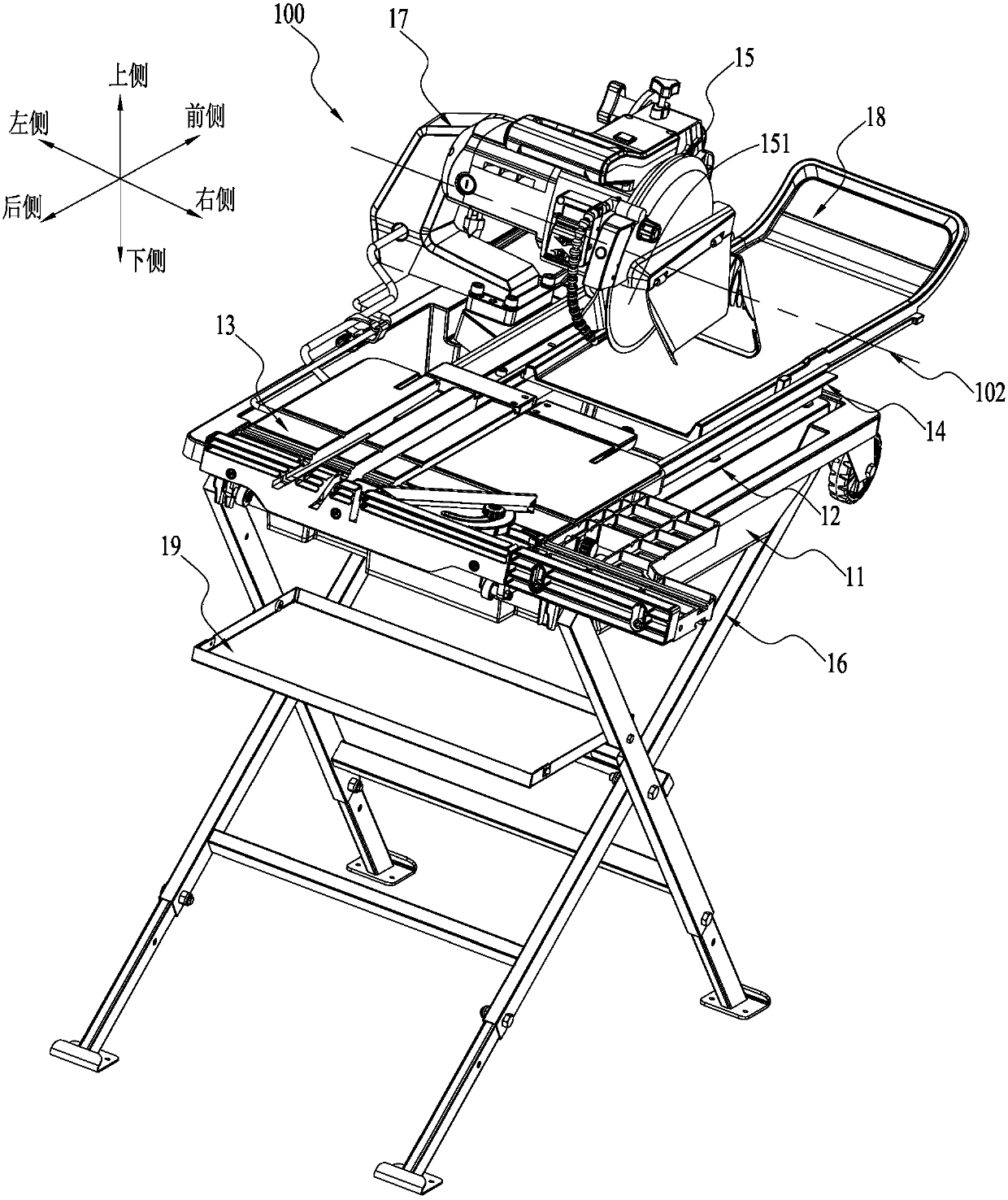

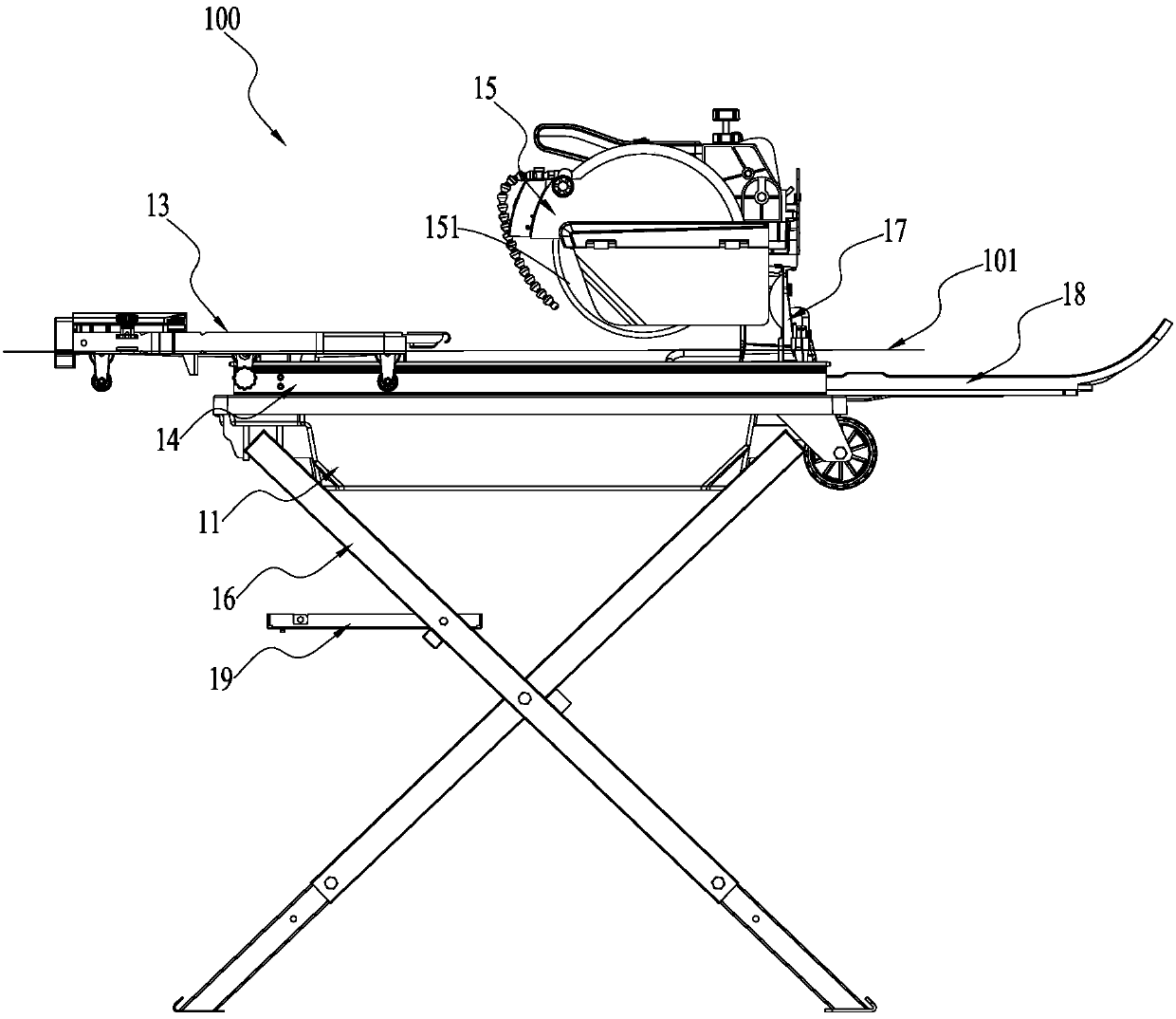

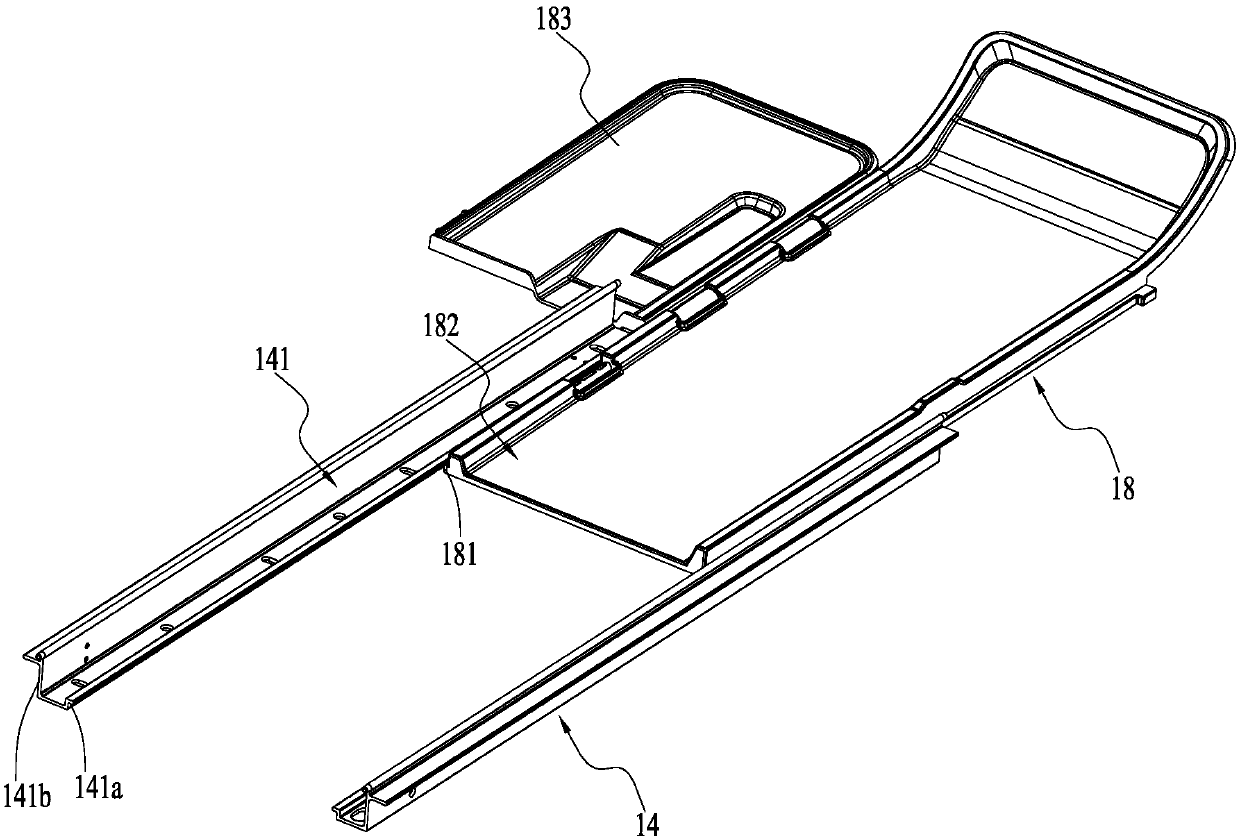

Cutting tool

ActiveCN107553744AEffective stopWorking accessoriesStone-like material working toolsWater storageEngineering

The invention discloses a cutting tool, comprising a water basin, a cutting head, a frame, a guide rail component, a working table and a water pond; and the water pond is used for water storage, the cutting head is used for realizing a cutting function, the frame is used for supporting the cutting head, the guide rail component is mounted to the frame, the working table is slidably mounted to theguide rail component along a first straight line direction, and the water pond is at least partially arranged between the cutting head and the water, wherein the water pond at least partially exceedsthe water basin along the first straight line direction, and the water pond can effectively stop water splattered from the cutting head.

Owner:NANJING CHERVON IND

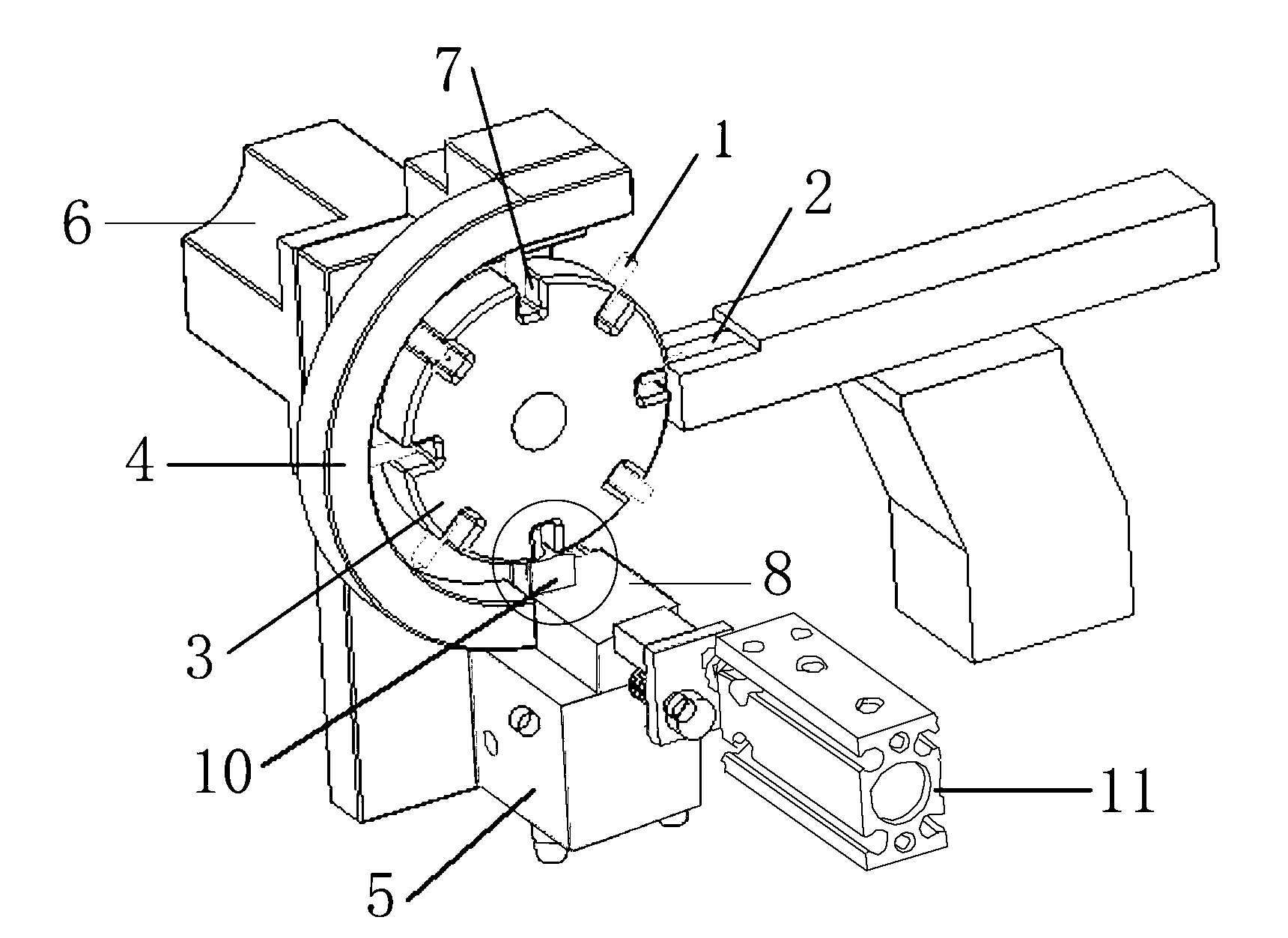

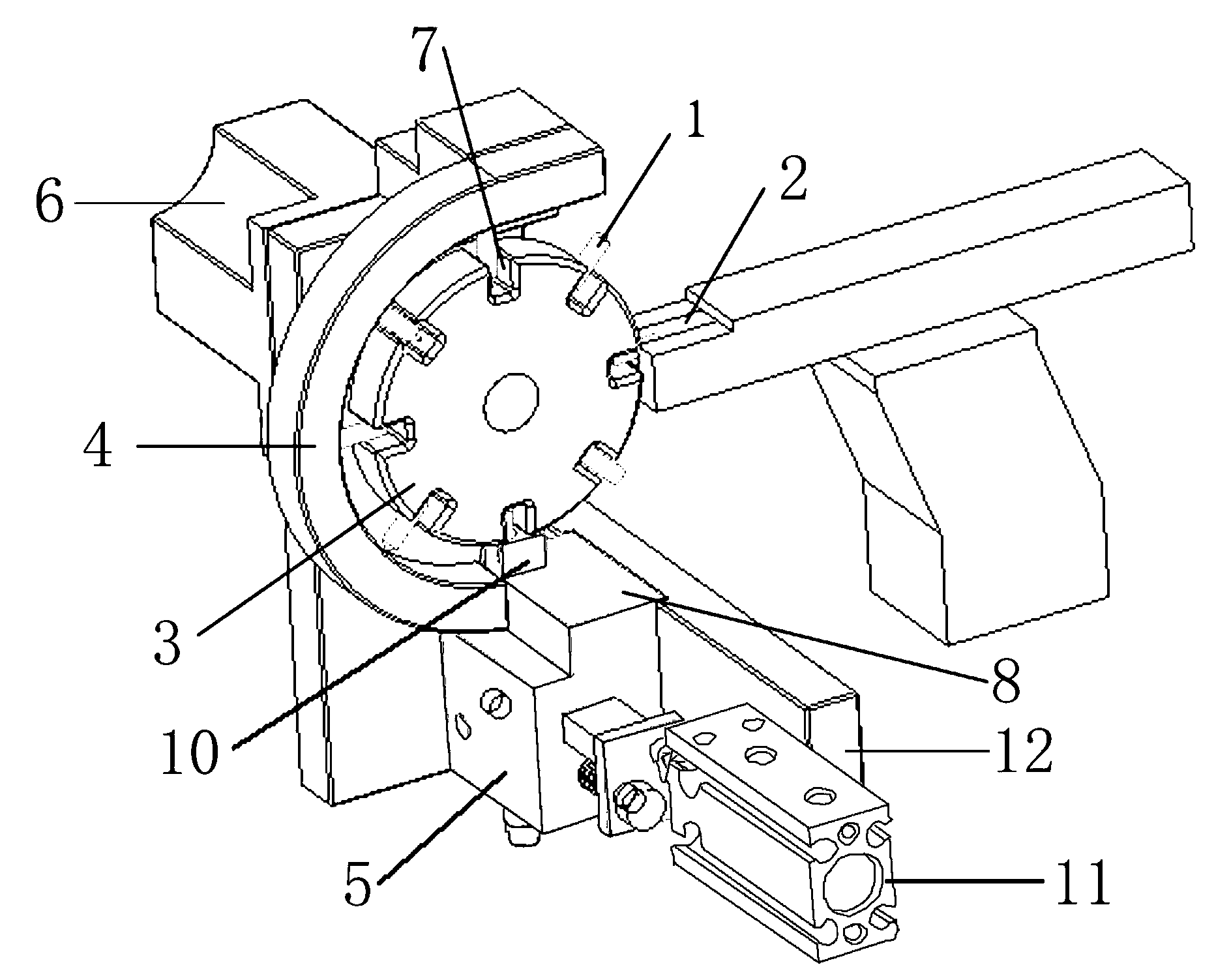

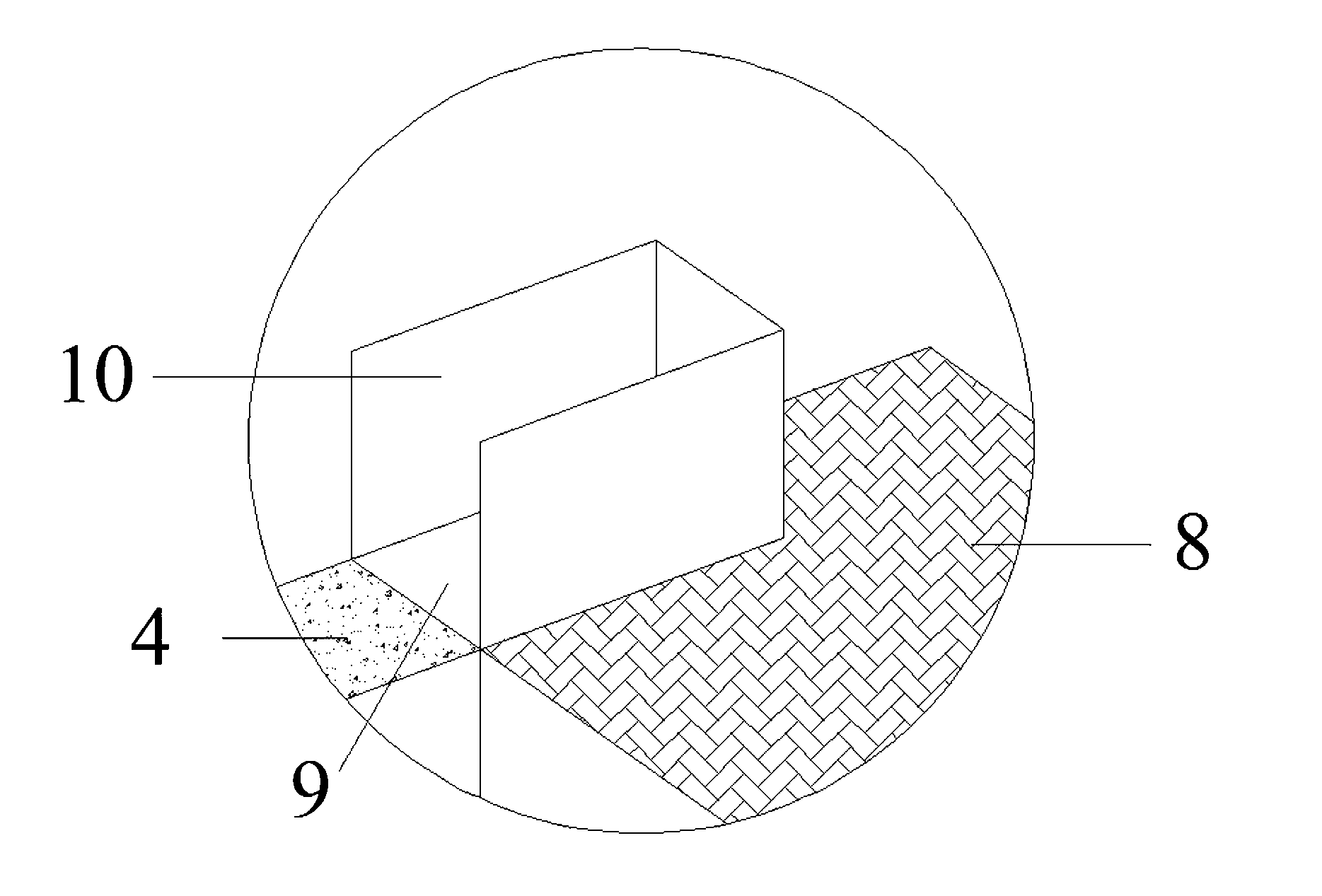

Bolt distribution device

The invention discloses a bolt distribution device which is characterized by comprising a component conveying channel, a distribution disc, a limiting sleeve, a distribution box and a motor, wherein the edge of the distribution disc is concave towards an axis center to form a containing groove; a component containing channel through which a bolt passes to a working station is formed in the distribution box; a guiding plate is arranged on the upper surface of the distribution box and is provided with a guiding hole; and a blocking plate is formed at the edge of the guiding hole. The bolt distribution device has the beneficial effects of being simple in structure and stable in performance; the bolt is transferred from the component conveying channel into the distribution box through the distribution disc so as to fall onto the working station, and the motor drives the distribution disc to work without manual operation, so that the time and the human source are saved and the working efficiency is improved; the relative distance of the two adjacent bolts on the working station can be adjusted by controlling the rotating speed of the distribution disc, so that the application range is wide; and the blocking plate on the guiding plate can effectively block the bolt to enable the bolt to accurately fall into the component containing channel, so that the bolt distribution process is performed orderly.

Owner:SUZHOU ITIS ELECTRON MFG TECH +1

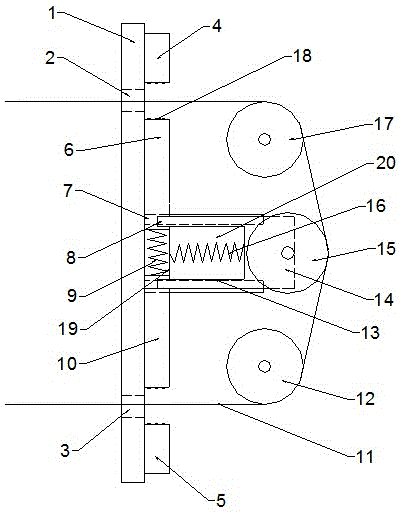

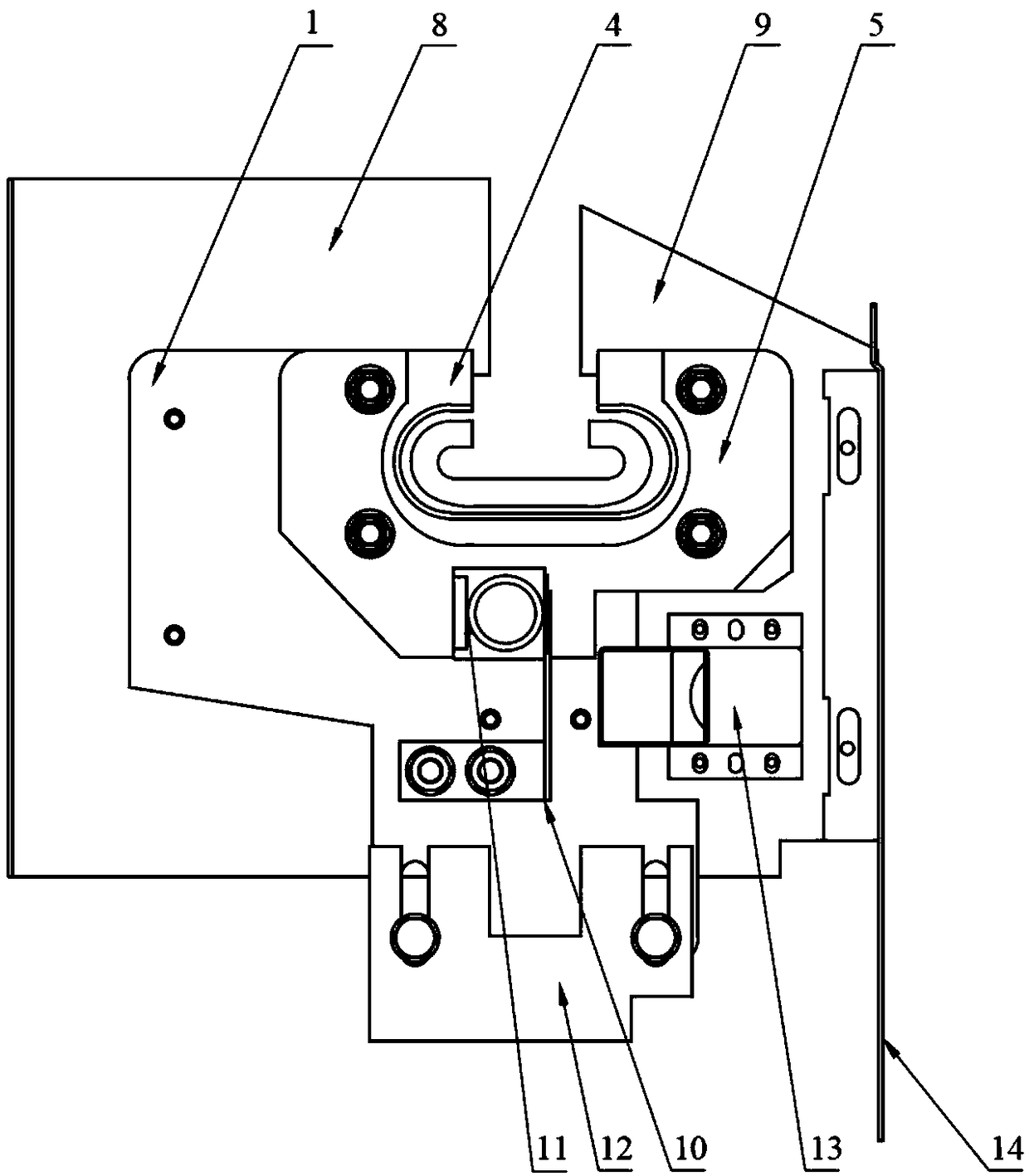

Device for automatic line stopping after yarn breaking

The invention relates to a structure of a device for automatic line stopping after yarn breaking, comprising a frame, a clamping device, an adjusting device, and a guide assembly. The clamping device comprises a fixed block A, a tightening device, and a fixed block B. A compression spring A is arranged in the middle of the tightening device, the two ends of the compression spring A are respectively connected with a tightening block A and a tightening block B, and the side wall of the tightening block A and the side wall of the tightening block B are respectively provided with a groove. The adjusting device comprises a pair of guide rails and a sliding block. The guide rails are respectively arranged at the two ends of the compression spring A, and are fixed to the frame. The sliding block is provided with two pins which are respectively inserted into the grooves of the tightening block A and the tightening block B in a matching manner. A compression spring B is arranged inside a cavity. The device is advantageous in that the means of clamping at both sides is adopted when the device suffers from line breakage under an energized condition, and the problem of winding is not caused even if clamping at one end fails; and under the condition of power outage, the tension between yarns disappears, and line conveying is stopped effectively through clamping at both ends.

Owner:HAIAN QI HONG TEXTILE TECH CO LTD

Safe elevator

InactiveCN108750861AGuaranteed safety and reliabilityUniform and stable forceElevatorsLower limitMicrocontroller

The invention relates to the field of elevator equipment manufacturing, in particular to a safe elevator. The safe elevator is provided with multiple anti-falling devices and comprises an elevator carand an elevator shaft, wherein a rubber bag is arranged on the outer peripheral surface of the elevator car, and a safety air bag is arranged in the rubber bag; an upper limiting groove and a lower limiting groove are formed in the inner wall of the elevator shaft, the elevator car is provided with positioning rods corresponding to the upper limit groove and the lower limit groove respectively, and telescopic mechanisms for allowing the positioning rods to extend and retract are arranged on the elevator car; the safe elevator further comprises a controller composed of a single-chip microcomputer, an auxiliary steel cable, a braking device arranged at the top of the elevator shaft and a detecting device for detecting the descent speed of the elevator car, the output end of the detecting device is connected with the input end of the controller, and the controller is connected with the braking device; and a plurality of hard springs which are uniformly distributed are arranged at the bottom of the elevator car, one ends of the hard springs are fixed at the bottom of the elevator car, and the other ends of the hard springs are fixedly welded to round or square iron plates.

Owner:王天石

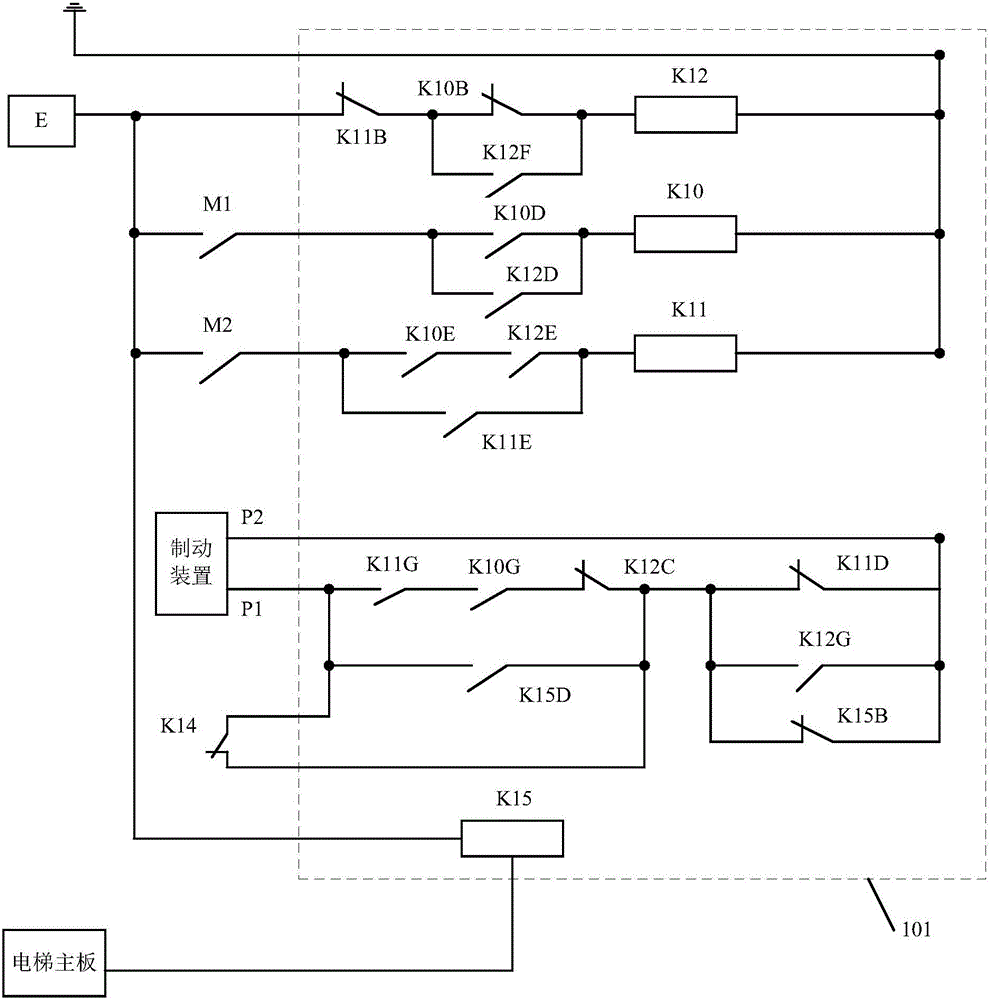

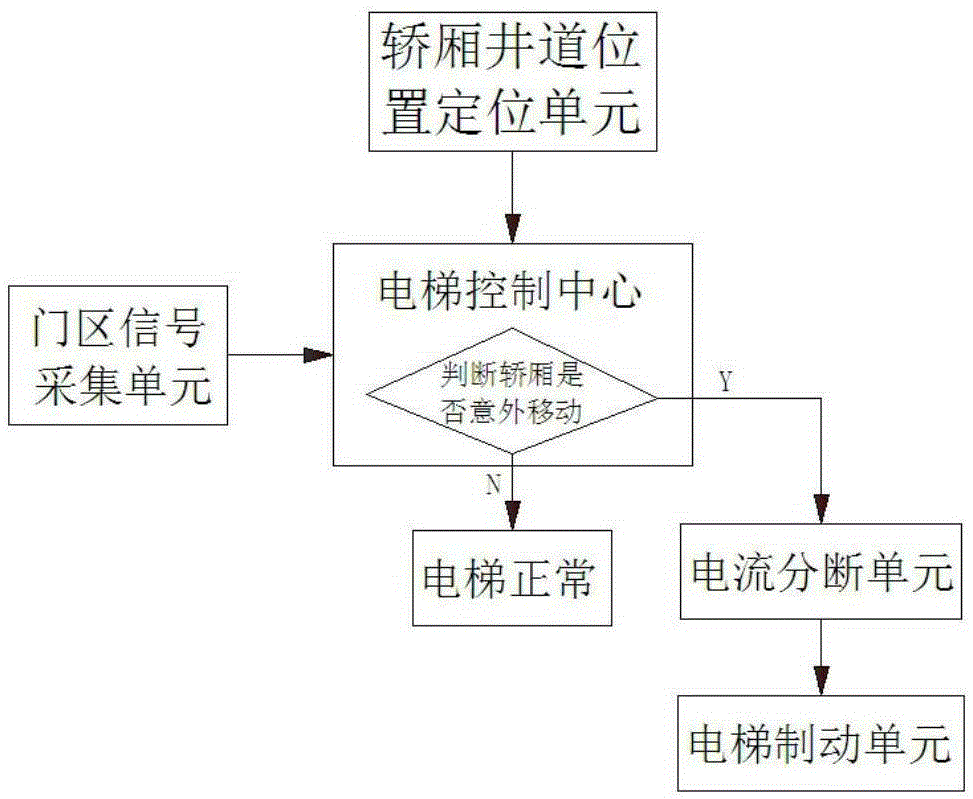

Control system and control method for preventing elevator car from accidentally moving

The invention provides a control system for preventing an elevator car from accidentally moving. The control system comprises a door area signal collecting unit, an elevator car shaft position positioning unit, an elevator control center, a current disjunction unit and an elevator braking unit. The signal output end of the door area signal collecting unit and the signal output end of the elevator car shaft position positioning unit are connected with the signal input end of the elevator control center. The elevator control center output signals to the current disjunction unit to control the elevator braking unit. When the elevator car is not located at the door area position and the elevator car accidentally moves under the door opening state, the elevator car can be effectively stopped, and major safety accidents are avoided. Meanwhile, an existing elevator system does not need to be greatly modified, and elevators in the using process or elevators in the producing process can be conveniently refitted.

Owner:GUIZHOU TIANYI ELEVATOR COMPLETE SET EQUIP

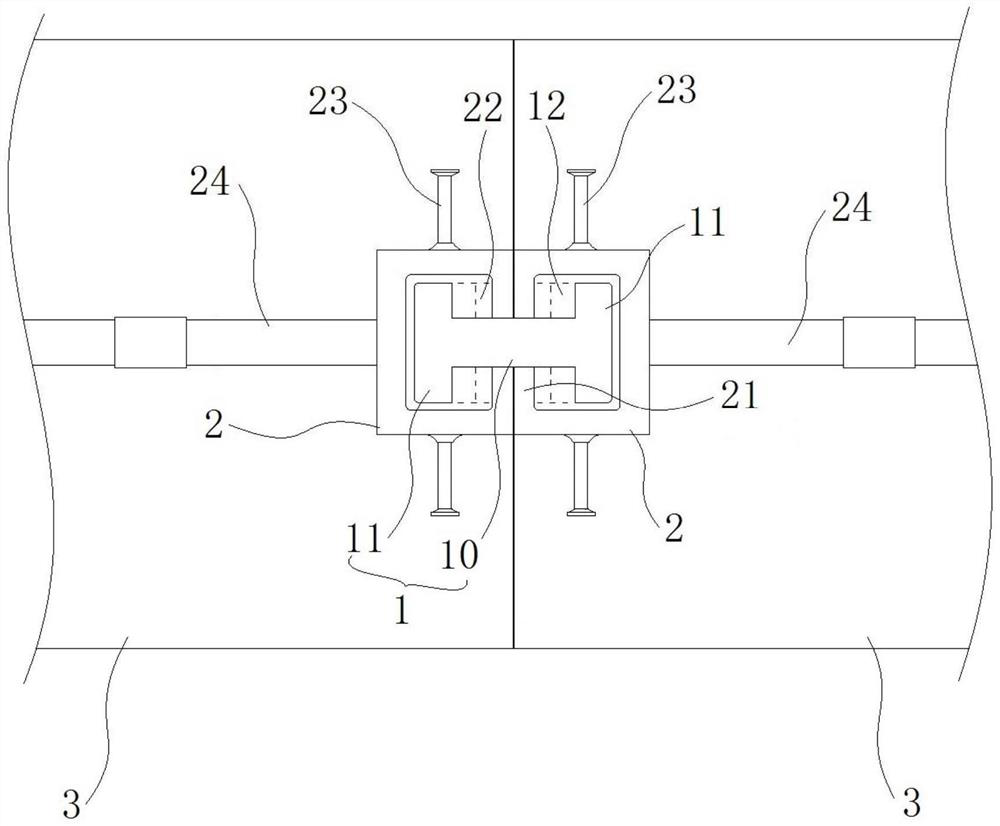

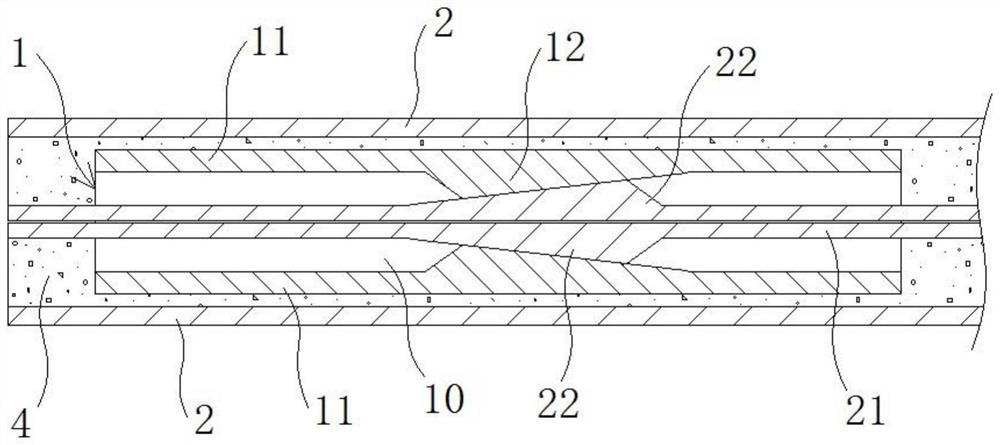

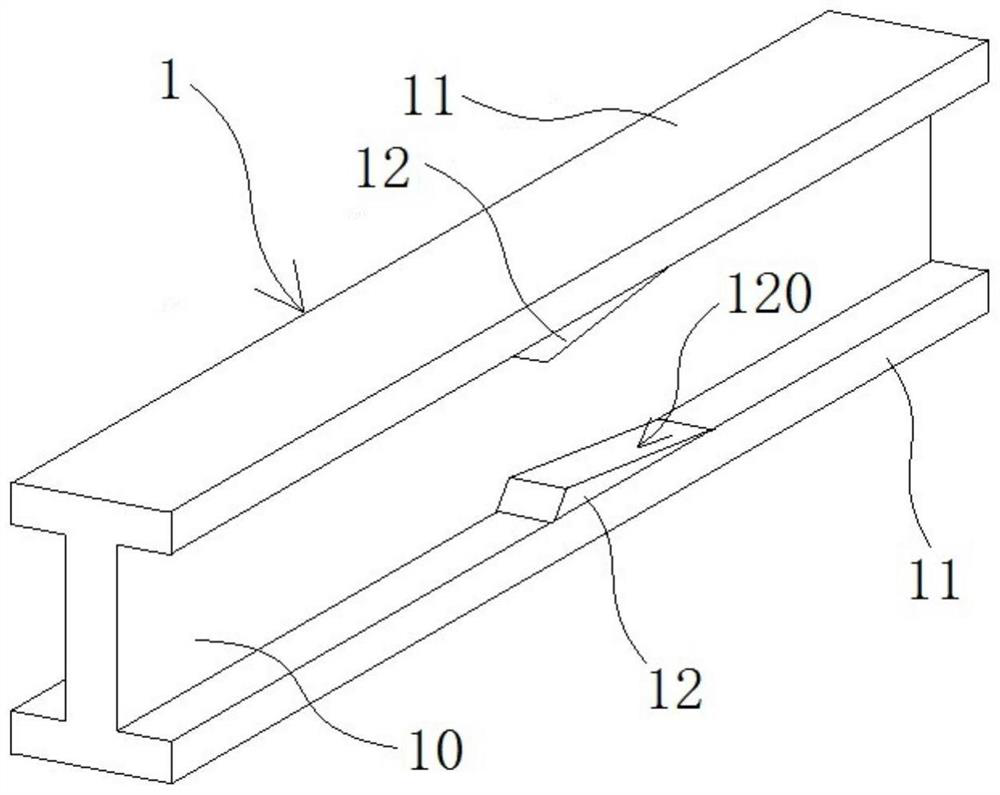

Connecting assembly of assembly type component

PendingCN112459113AHigh strengthFirm fastening forceArtificial islandsSheet joiningMechanical engineeringIndustrial engineering

The invention provides a connecting assembly of an assembly type component, and relates to the field of component connection. The connecting assembly of the assembly type component comprises two C-shaped groove pieces and an I-shaped connecting piece, the C-shaped groove pieces are provided with component connecting parts used for being fixedly connected with the component, the I-shaped connectingpiece comprises a web in the middle and two side flanges, groove openings of the C-shaped groove pieces are in clearance fit with the web, the side flanges are used for being in stop fit with the inward-turned edges of the C-shaped groove pieces when the I-shaped connecting piece is inserted into the C-shaped groove pieces, wedge-shaped structures are further arranged on the C-shaped groove pieces and / or the I-shaped connecting piece, and the wedge-shaped structures are provided with wedge-shaped surfaces used for guiding the two C-shaped groove pieces to be fastened oppositely. The I-shapedconnecting piece gradually goes deep into the two C-shaped groove pieces, and the wedge-shaped surfaces of the wedge-shaped structures convert longitudinal movement into opposite fastening force on the two C-shaped groove pieces, so that the two components form fastening connection; and a plurality of bolts are replaced by the complete I-shaped connecting piece, so that the high-strength connecting requirement is met, the operation is simplified, and the construction efficiency is improved.

Owner:GUANGZHOU METRO DESIGN & RES INST

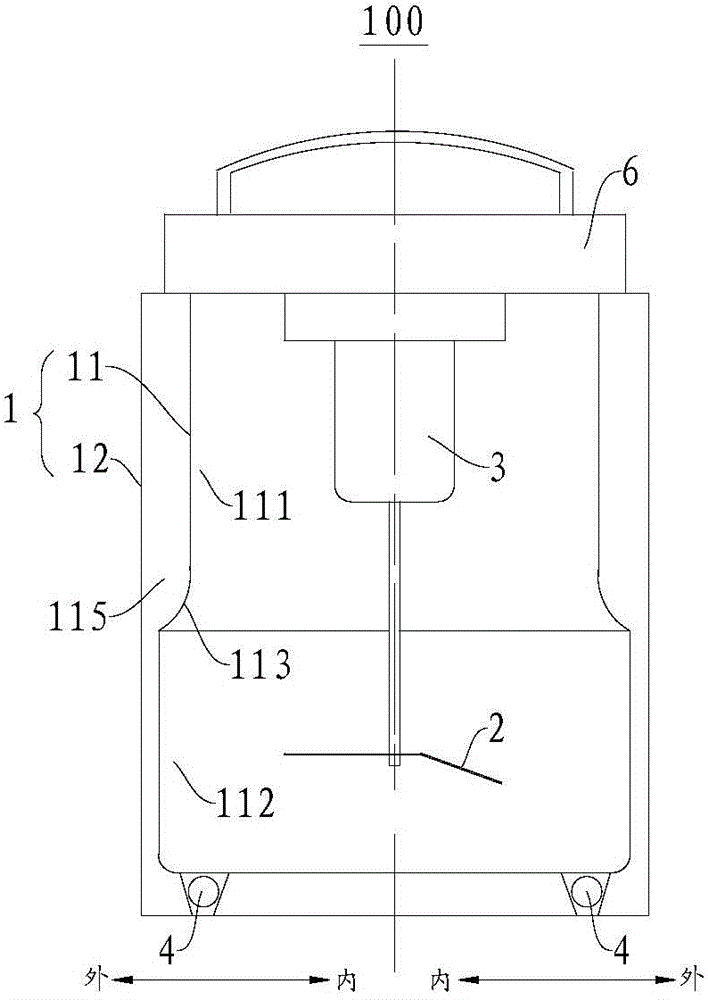

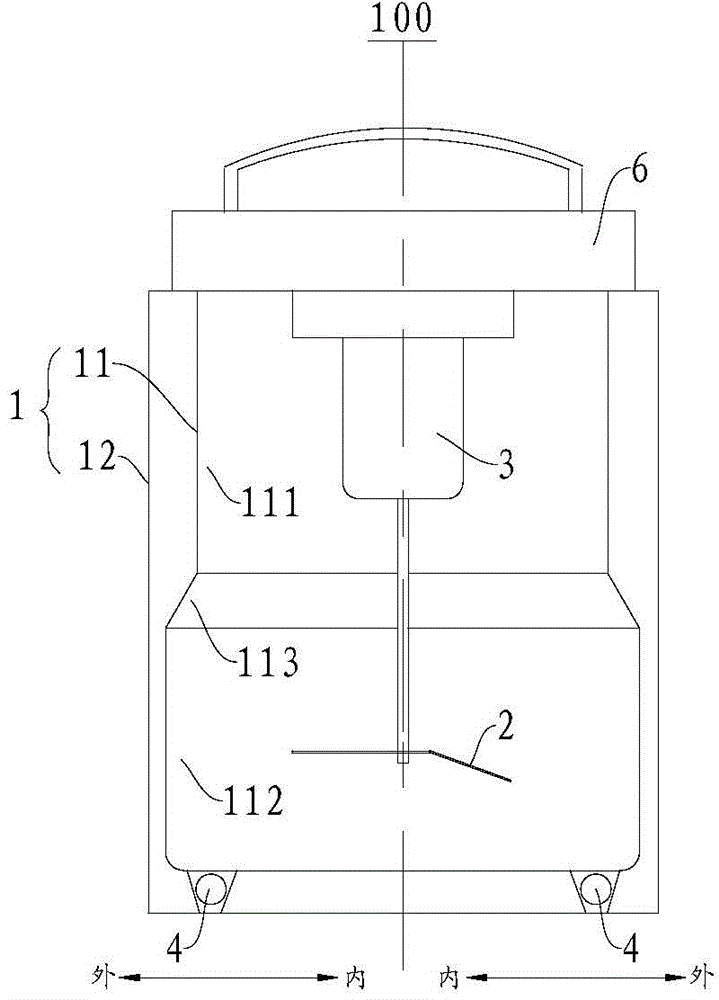

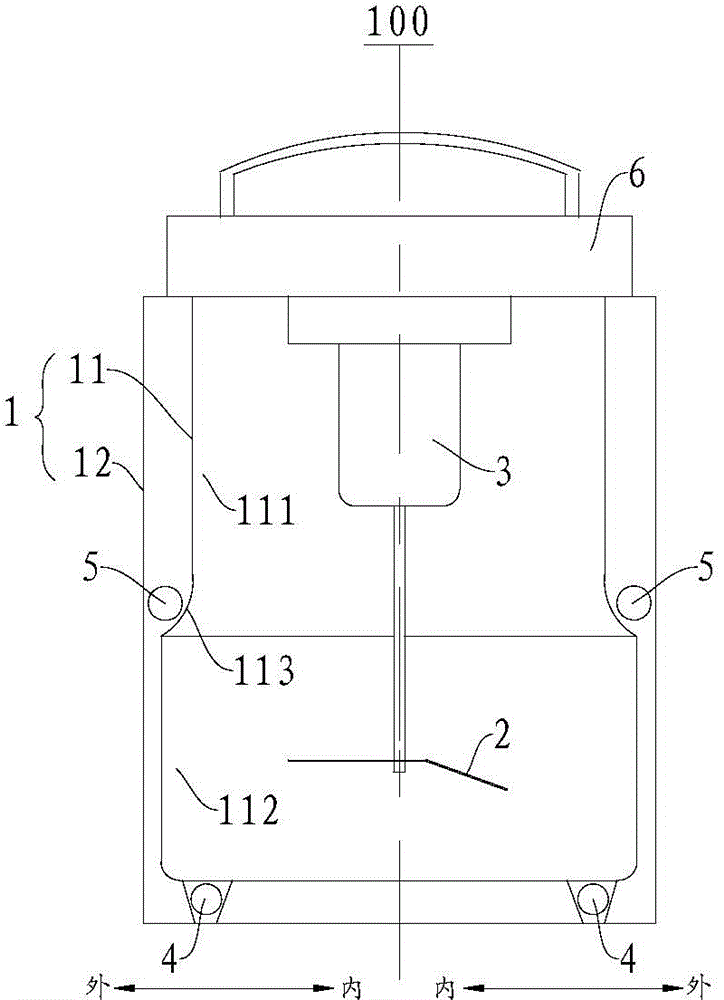

Soybean milk making machine

The invention discloses a soybean milk making machine which comprises a barrel, a crushing device, a crushing motor, a boiling heating component, a foam breaking heating component and an anti-overflowing structure. Annular foam breaking ribs protruding out of the inner wall face of the side wall of the barrel are constructed on the side wall of the barrel. The crushing device is arranged inside the barrel. The crushing motor is connected with the crushing device. The boiling heating component is at least used for heating and boiling raw soybean milk. The foam breaking heating component is not lower than the highest liquid level inside the barrel in the heating and boiling process. The foam breaking ribs are not lower than the highest liquid level. The anti-overflowing structure is arranged inside the barrel and is not lower than the highest liquid level. Due to the fact that the independent foam breaking heating component is arranged on the soybean milk making machine, and foams are broken in a heating mode through the foam breaking heating component, the foam breaking efficiency is improved, and the foam breaking effect is better due to the facts that the foam breaking ribs and the anti-overflowing structure are arranged and the foam breaking heating component is arranged in a matched mode.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

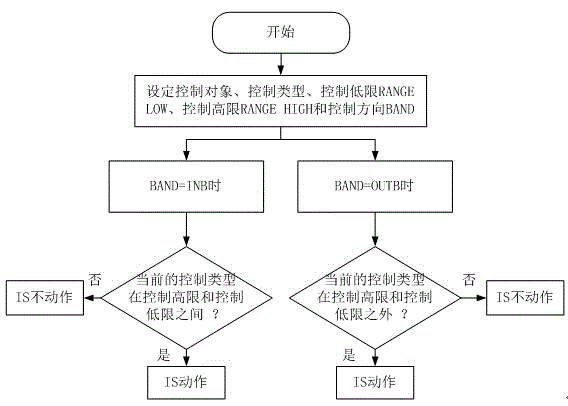

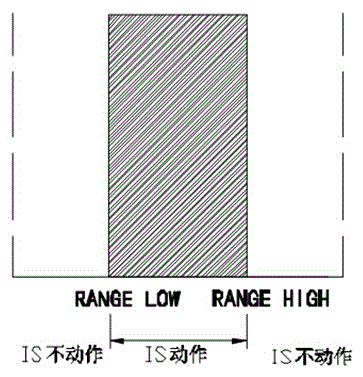

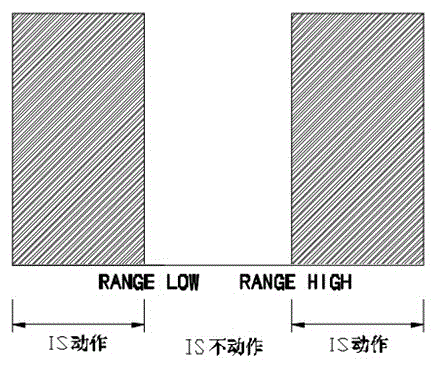

Control method of action units in environment test system

InactiveCN104990860AAvoid volatilityEffective operationWeather/light/corrosion resistanceProgramme control in sequence/logic controllersSocial benefitsEconomic benefits

The invention provides a control method of action units in an environment test system. The units are controlled to act within the range and out of the range, and on-off of the action units is controlled according to the action modes. Control types and the controlled action units are flexible and diverse. The control types include current set values SP, current measuring values PV or current target set values TSP of the temperature, humidity or air pressure and the like, and the control types are independent and do not interfere with one another. A compressor and other working units can be reasonably utilized, the working units can run or stop at the appropriate time, the energy consumption is reduced, and fluctuation of a controlled target is avoided. The control method can be widely applied to the field of temperature and humidity environment control, a large amount of energy consumption can be saved, and huge economic benefits and social benefits are brought to the society.

Owner:广州市庆瑞电子科技有限公司

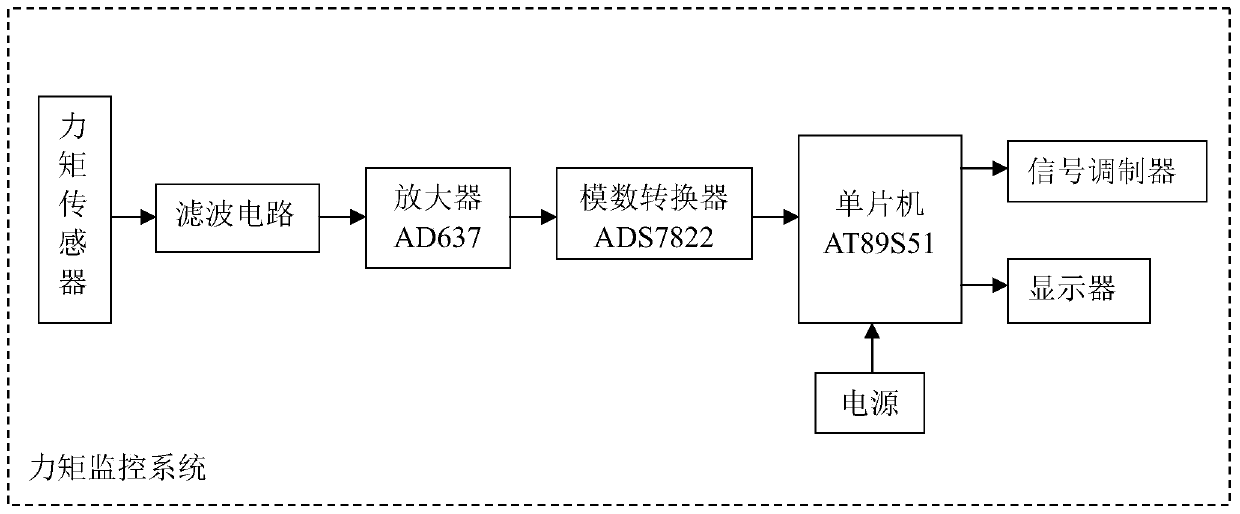

Returnable digital-display intelligent spanner suitable for narrow space

PendingCN110394753AReachable return tripTo achieve the purpose of saving effortSpannersWrenchesData displayMicrocontroller

The invention relates to a returnable digital-display intelligent spanner suitable for narrow space. The returnable digital-display intelligent spanner comprises a spanner main body and a torque display system arranged at the rear end of the spanner main body, wherein the spanner main body comprises a spanner head, a QH main body, a speed reducer, a QH accessory body, a sleeve, a sliding block, aspring and a handle, and the torque display system comprises a single-chip microcomputer, a torque sensor, a filter circuit, an amplifier, an analog-digital converter, a display and a power supply. According to the returnable digital-display intelligent spanner suitable for the narrow space, the torque display system can display the torque numerical value during a working state in real time through the torque display system, a remote transmission system can transmit signals to a computer terminal in real time, the real-time change of torque can be observed in a computer display screen arrangedat a long distance, so that convenience is provided for operators; and the structure is simple, intelligent control over mounting parts is realized through torque data display, and observation is simple, visual, clear and accurate.

Owner:WUYI UNIV

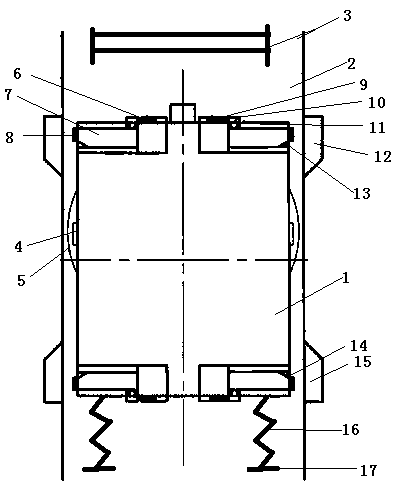

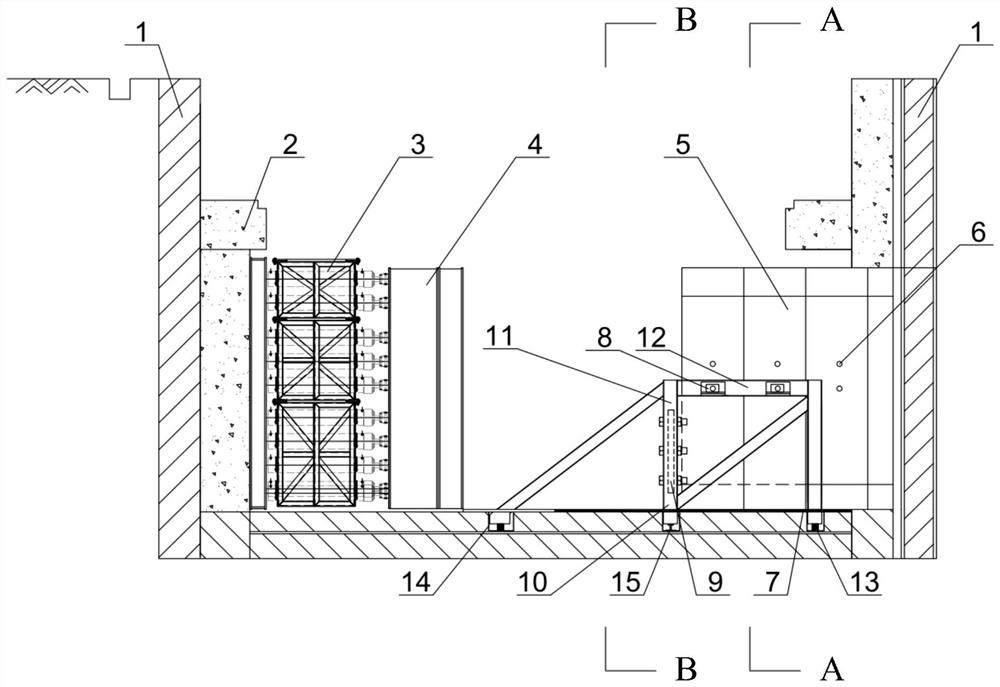

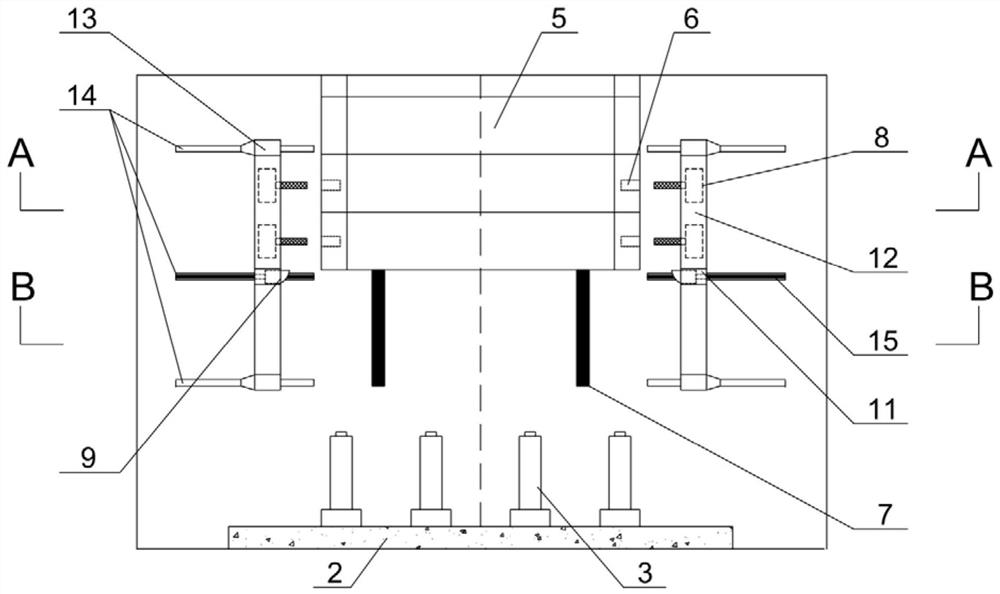

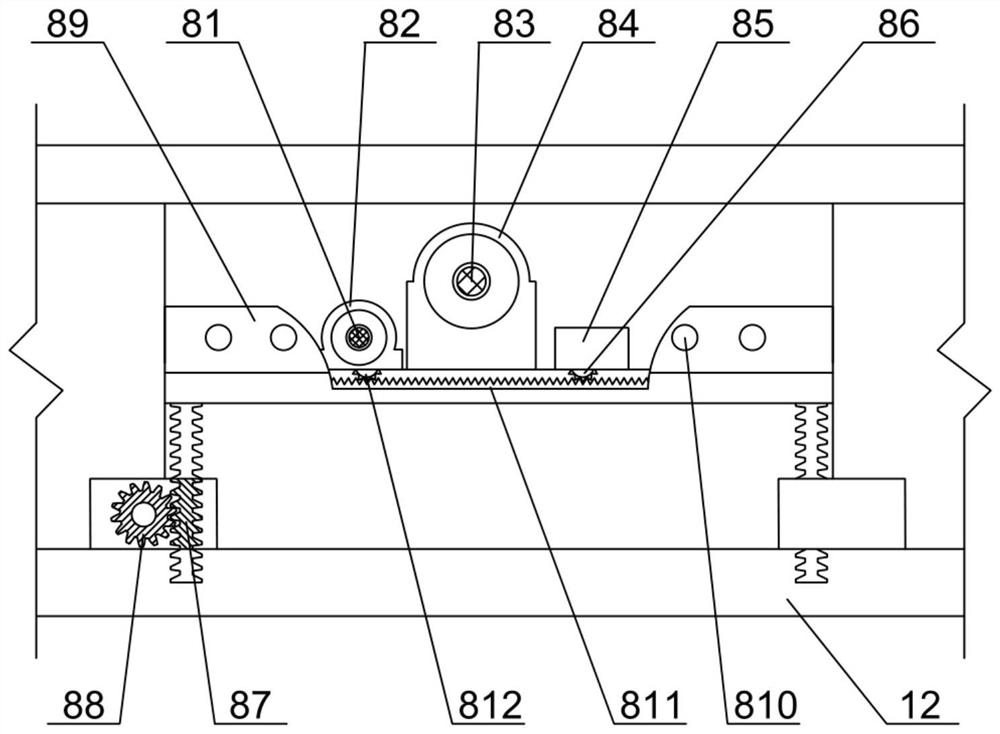

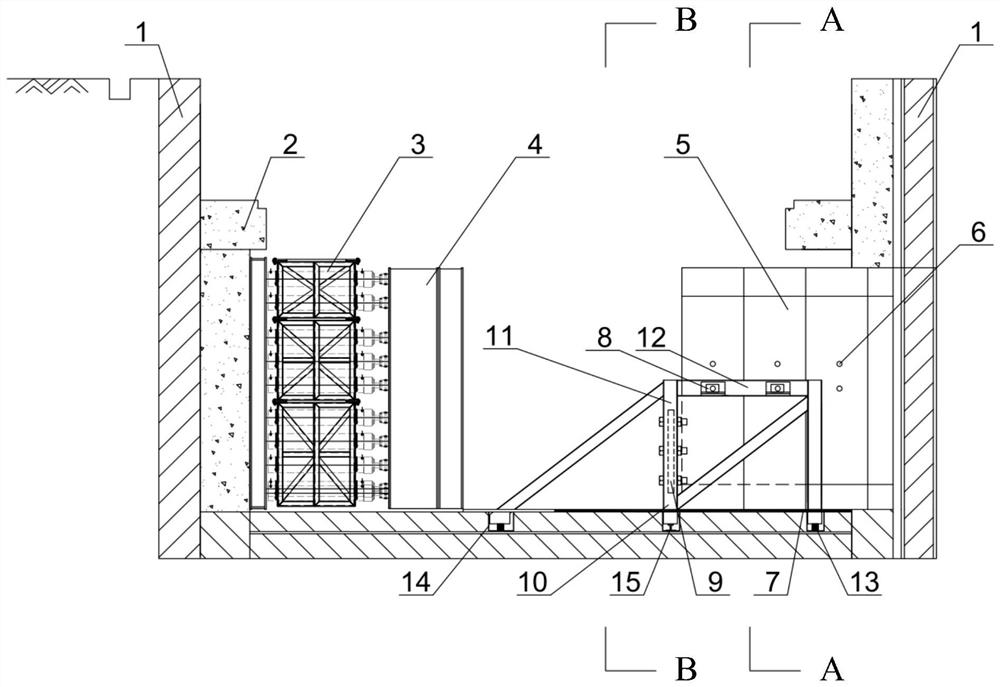

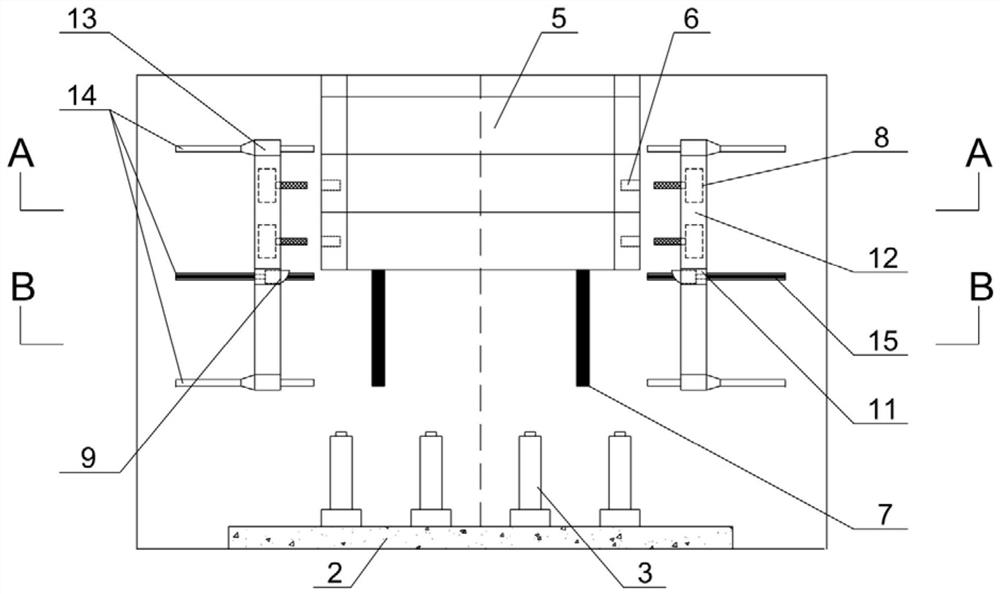

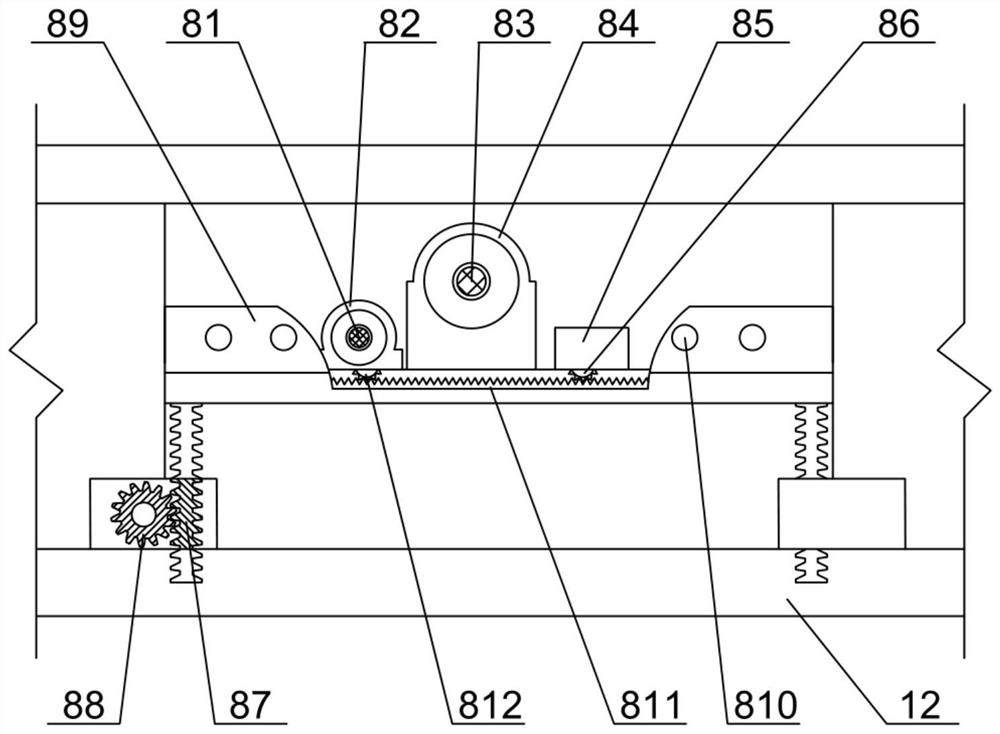

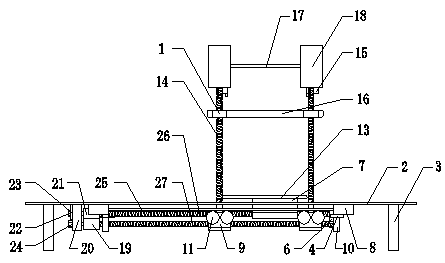

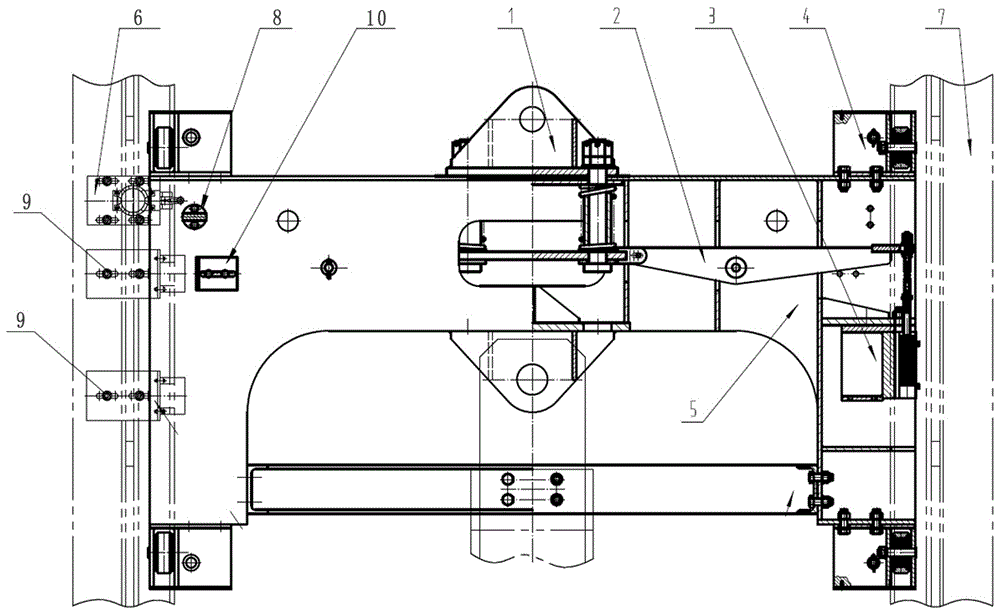

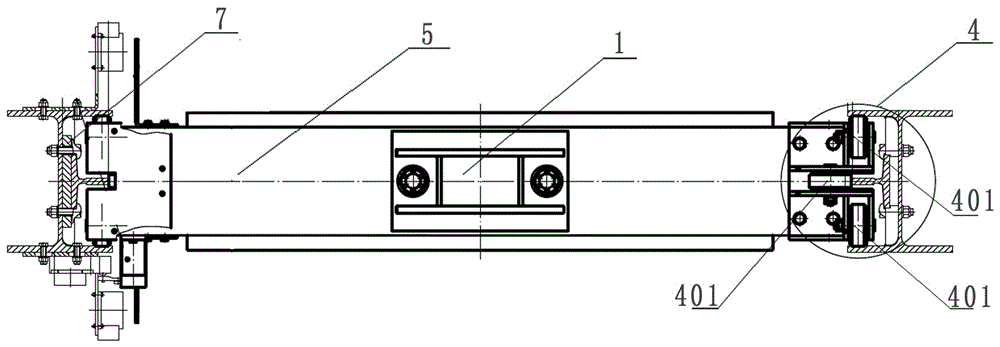

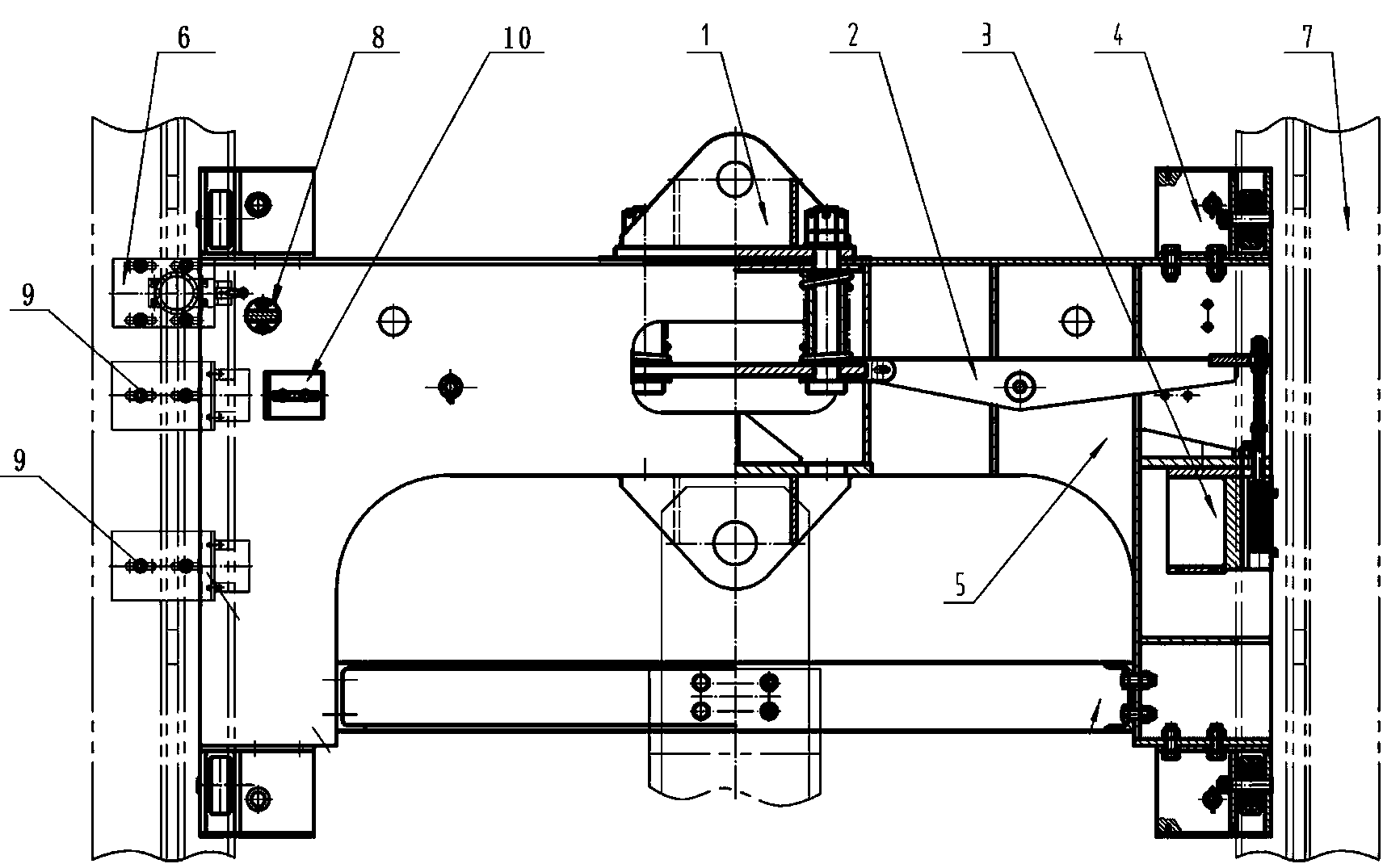

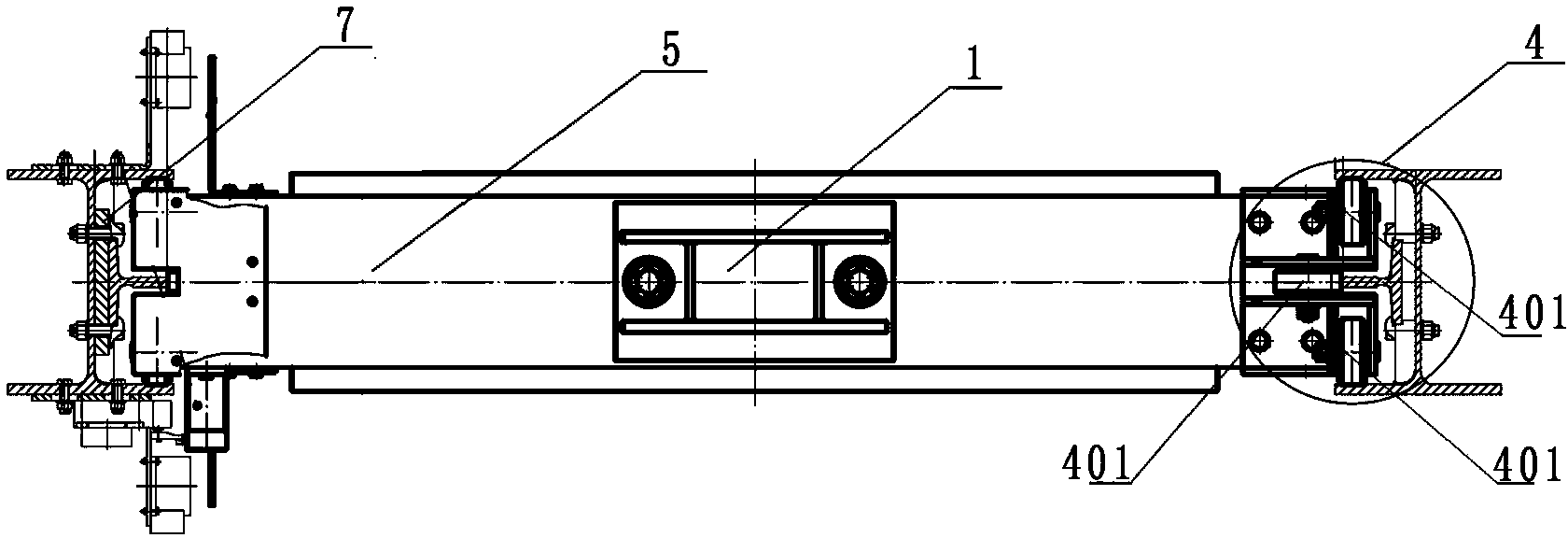

Movable jacking pipe retaining support device and retaining method

ActiveCN113374932AGood effectFlexible moving processPipe laying and repairStructural engineeringHydraulic pressure

The invention discloses a movable jacking pipe retaining support device and a retaining method. The movable jacking pipe retaining support device comprises a pair of retaining supports arranged on the two sides of the jacking direction of a pipe joint correspondingly and a support guide rail used for enabling the retaining supports to move in the direction perpendicular to the jacking direction of the pipe joint. The inner sides of the rear ends of the retaining supports on the two sides are each provided with a mechanical locking and clamping device used for limiting backward retreating of the pipe joint. Movable hydraulic telescopic rod devices used for being clamped into the side wall of the pipe joint are arranged on the inner sides of the top ends of the retaining supports on the two sides correspondingly. When the pipe joint advances in the jacking direction, the pipe joint firstly makes contact with and compresses the mechanical locking and clamping devices on the two sides, and after the whole pipe joint passes, the mechanical locking and clamping devices rebound and abut against the rear end of the pipe joint to limit backward retreating of the pipe joint; and meanwhile, the movable hydraulic telescopic rod devices can move to the positions of hoisting holes reserved in the side wall of the pipe joint, and pin shafts are inserted into the hoisting holes, so that the pipe joint is stopped and limited.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +2

A mobile jacking pipe backstop support device and backstop method

ActiveCN113374932BGood effectFlexible moving processPipe laying and repairStructural engineeringMechanical engineering

The invention discloses a mobile pipe jacking anti-retreat bracket device and a method for preventing retreat, comprising a pair of anti-retreat supports respectively arranged on both sides of the pipe joint jacking direction, and used for the anti-retreat support brackets to be pushed along a direction perpendicular to the pipe joint. The guide rail of the bracket that moves in the direction; the inner side of the rear end of the anti-retraction bracket on both sides is respectively provided with a mechanical locking device for restricting the retreat of the pipe joint; Telescopic rod device; when the pipe joint advances in the direction of jacking, it first contacts and compresses the mechanical locking devices on both sides until the entire pipe joint passes, and the mechanical locking device rebounds and resists the rear end of the pipe joint to limit The pipe joint retreats; at the same time, the mobile hydraulic telescopic rod device can move to the position of the hoisting hole reserved on the side wall of the pipe joint, and insert the pin shaft into the hoisting hole to stop the pipe joint from retreating.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +2

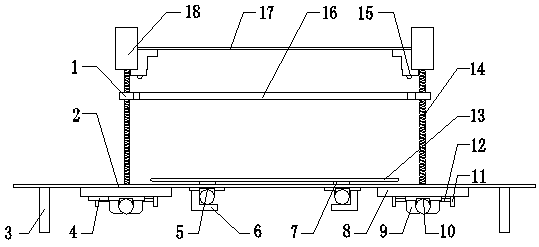

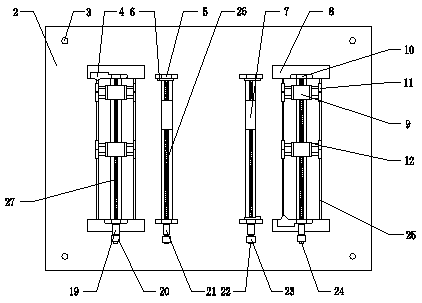

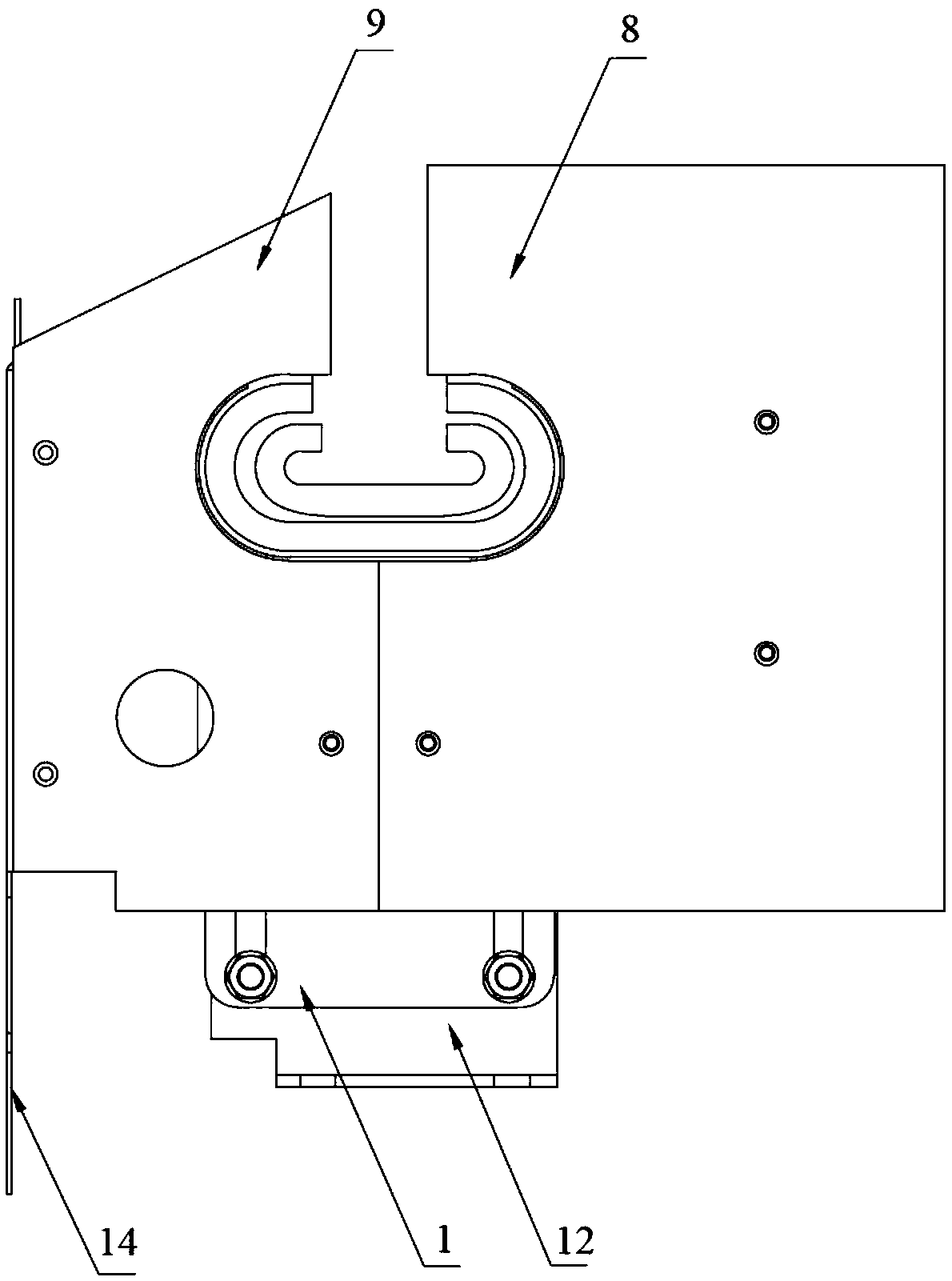

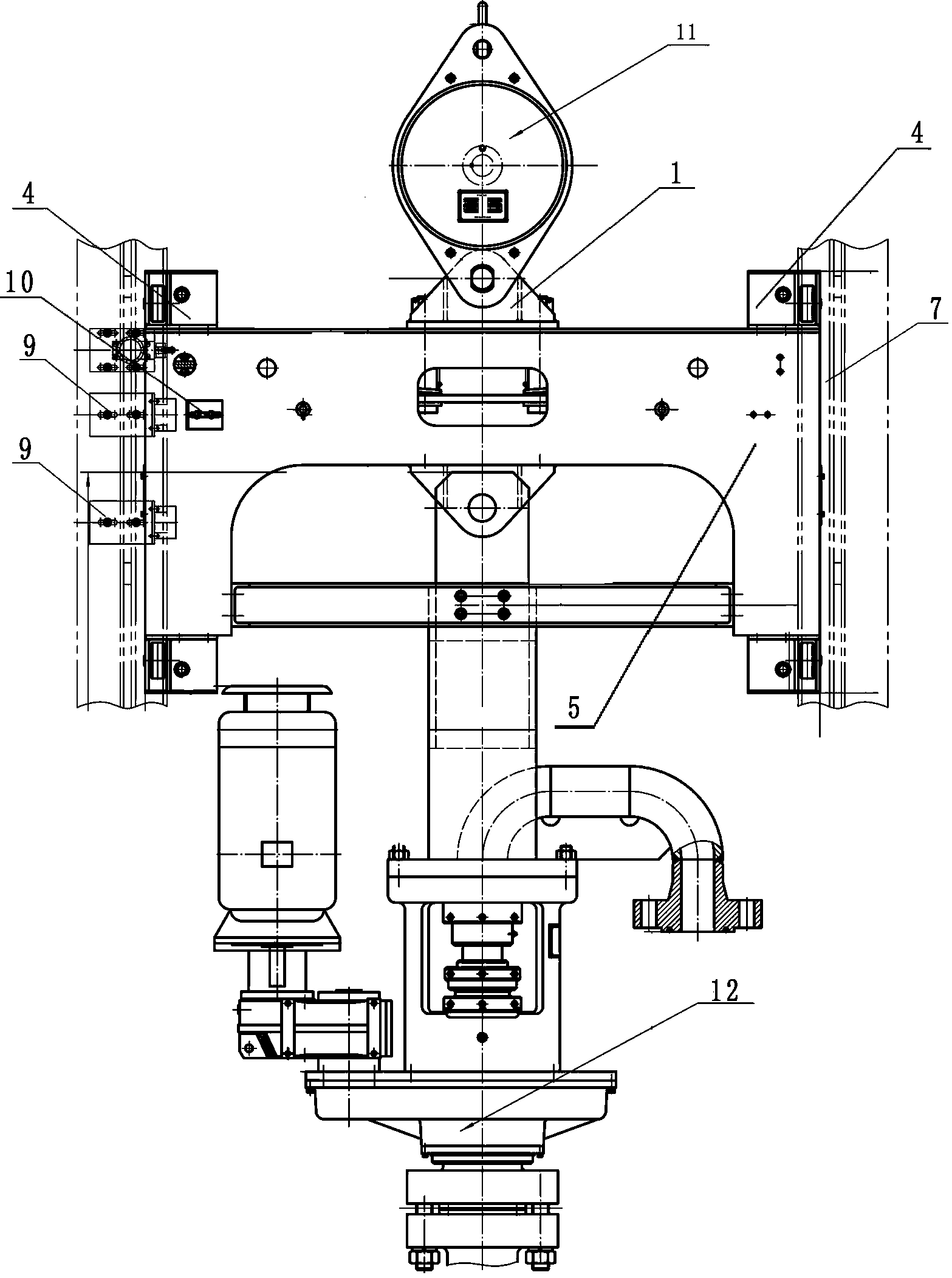

Lateral stereo parking equipment

The invention discloses lateral stereo parking equipment. The lateral stereo parking equipment comprises a main platform module, a first-layer bedplate transverse-moving module, a second-layer bedplate transverse-moving module and a second-layer bedplate lifting module. The first-layer bedplate transverse-moving module is composed of a first-layer bedplate, first lead screw nuts, first-layer bedplate transverse-moving limiting switches, first-layer bedplate connecting blocks, first couplers, first-layer bedplate transverse-moving motors, first-layer bedplate transverse-moving motor sleeves andfirst lead screws. The second-layer bedplate lifting module is composed of a second-layer bedplate, a second-layer bedplate four-corner frame, lifting lead screws, second-layer bedplate lifting limiting switches and lifting motors. The second-layer bedplate transverse-moving module is composed of second-layer bedplate transverse-moving limiting switches, block-up platforms, moving frames, secondlead screw nuts, second couplers, second-layer bedplate transverse-moving motor sleeves, second-layer bedplate transverse-moving motors and second lead screws. The lateral stereo parking equipment issimple in structure, convenient, practical, good in motion stationarity and high in safety coefficient, and the lateral parking problem can be solved effectively.

Owner:董志

Hand strap outlet and inlet device for escalator

The invention discloses a hand strap outlet and inlet device for an escalator. The hand strap outlet and inlet device comprises an inlet supporting plate and a hand strap. A rubber opening is installed in the inner side of the inlet supporting plate. A Y-shaped touch panel is installed on the inner side of the rubber opening. A safety switch is installed on the inner side of the Y-shaped touch panel. The hand strap penetrates through the rubber opening and a notch of the Y-shaped touch panel. The hand strap penetrates through the rubber opening and the gap is smaller than 4mm. A front left wall board and a front right wall board are installed on the outer side of the inlet supporting plate. A self-starting switch hole is formed in the front right wall board, and a microwave sensor is installed on the self-starting switch hole. The safety switch is installed on the inlet supporting plate through a switch support. The distance from a safety switch contact to the Y-shaped touch panel is smaller than 0.5mm. The automatic start-stop function is achieved, and abrasion of escalator parts can be reduced while energy is saved. The gap between the hand strap and the rubber opening is small,the escalator can be effectively stopped and safety is high.

Owner:SHANDONG FUJI ZHIYU ELEVATOR

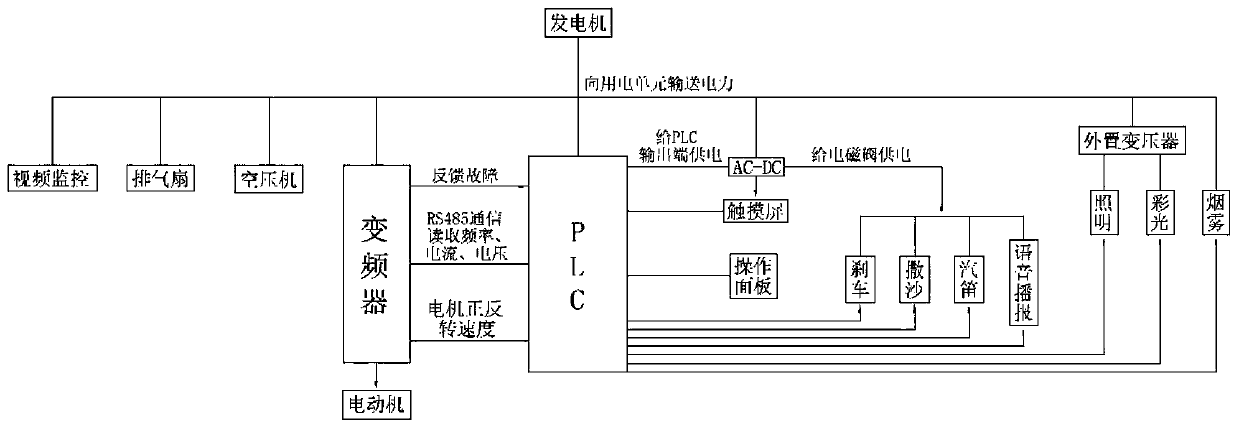

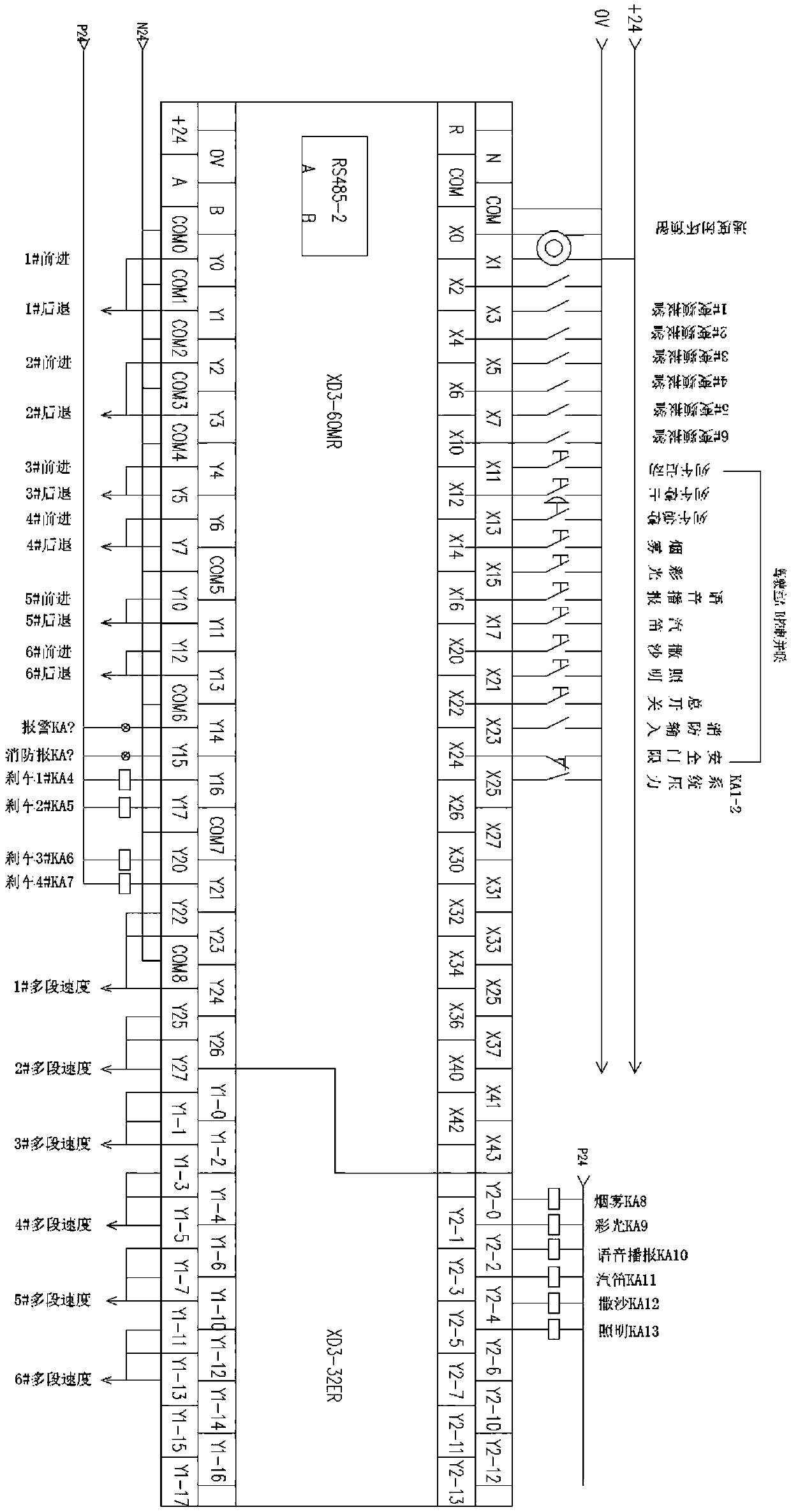

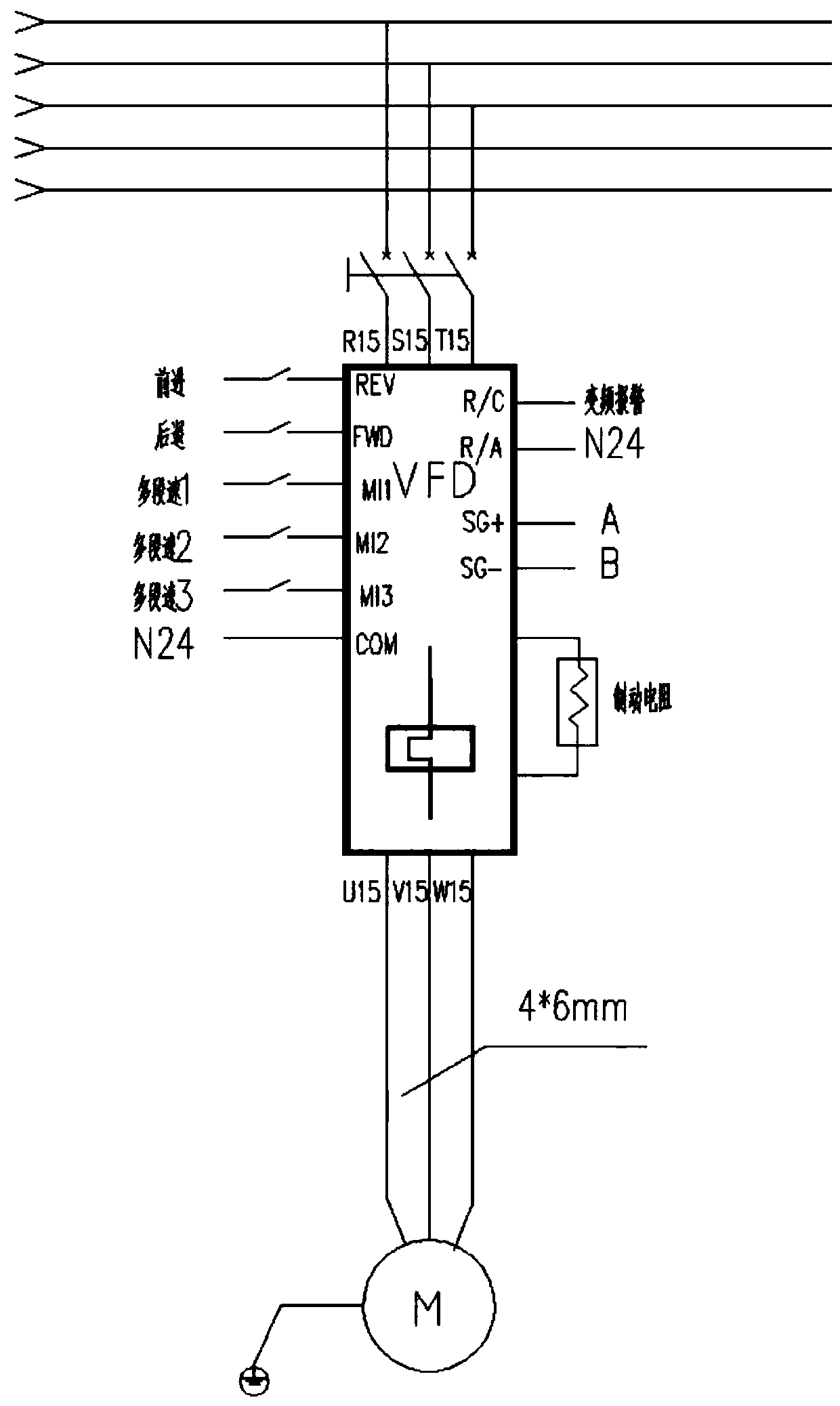

Sightseeing train control system

InactiveCN109814479AEffective startEffective stopProgramme control in sequence/logic controllersFrequency changerControl system

The invention discloses a sightseeing train control system which comprises a programmable logic controller (PLC), a frequency converter, a brake system, an operation panel and a touch screen. The PLCis connected with the frequency converter, the brake system, the operation panel and the touch screen through circuits, instructions are issued to the frequency converter and the brake system throughthe operation panel and the touch screen, and a power system of a sightseeing train is composed of a plurality of motors; each motor is connected with the frequency converter, and advancing, backing and stopping of the sightseeing train and control over the speed of the sightseeing train are realized by the PLC through the frequency converter. According to the sightseeing train control system, based on the PLC, control is accurate, the interface is user-friendly, operation is simple and convenient, running is stable, and the starting, stopping, running speed and running direction of the sightseeing train can be safely, effectively and reasonably controlled.

Owner:重庆艾博瑞威轨道交通设备有限公司

An anti-falling device for a hydraulic decoking system

ActiveCN104019352BAccurateRapid responseThermal non-catalytic crackingSelf acting brakesInsertion stentLocking mechanism

An anti-falling device for a hydraulic decoking system, comprising a lifting mechanism, a lever mechanism, a locking mechanism, a guiding mechanism and a bracket, the two sides of the bracket are provided with locking guide rails for guiding the vertical movement of the bracket, and the bracket is provided with The guide mechanism matched with the locking guide rail, the lifting mechanism is arranged on the top of the bracket, the lifting mechanism is provided with a lifting rod, and the lifting rod passes through the through hole set on the bracket downwards, and passes through the lever mechanism fixed on the bracket and the lock. The tension mechanism is connected, and the lifting rod is located between the lever mechanism and the bracket, and a return spring is sleeved. The return spring can push the lever mechanism to move when the lifting mechanism falls, and make the locking mechanism contact the locking guide rail. The invention has the advantages of simple structure, reasonable design, low manufacturing cost, long continuous trouble-free operation period, high safety reliability, and low device cost, effectively preventing accidental injuries to operators due to equipment falling.

Owner:LUOYANG JIANGUANG SPECIAL EQUIP

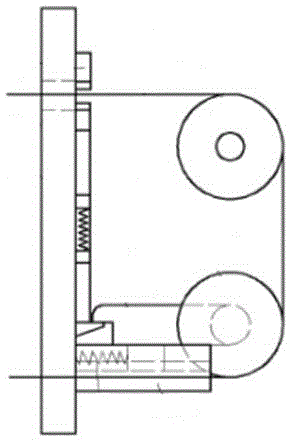

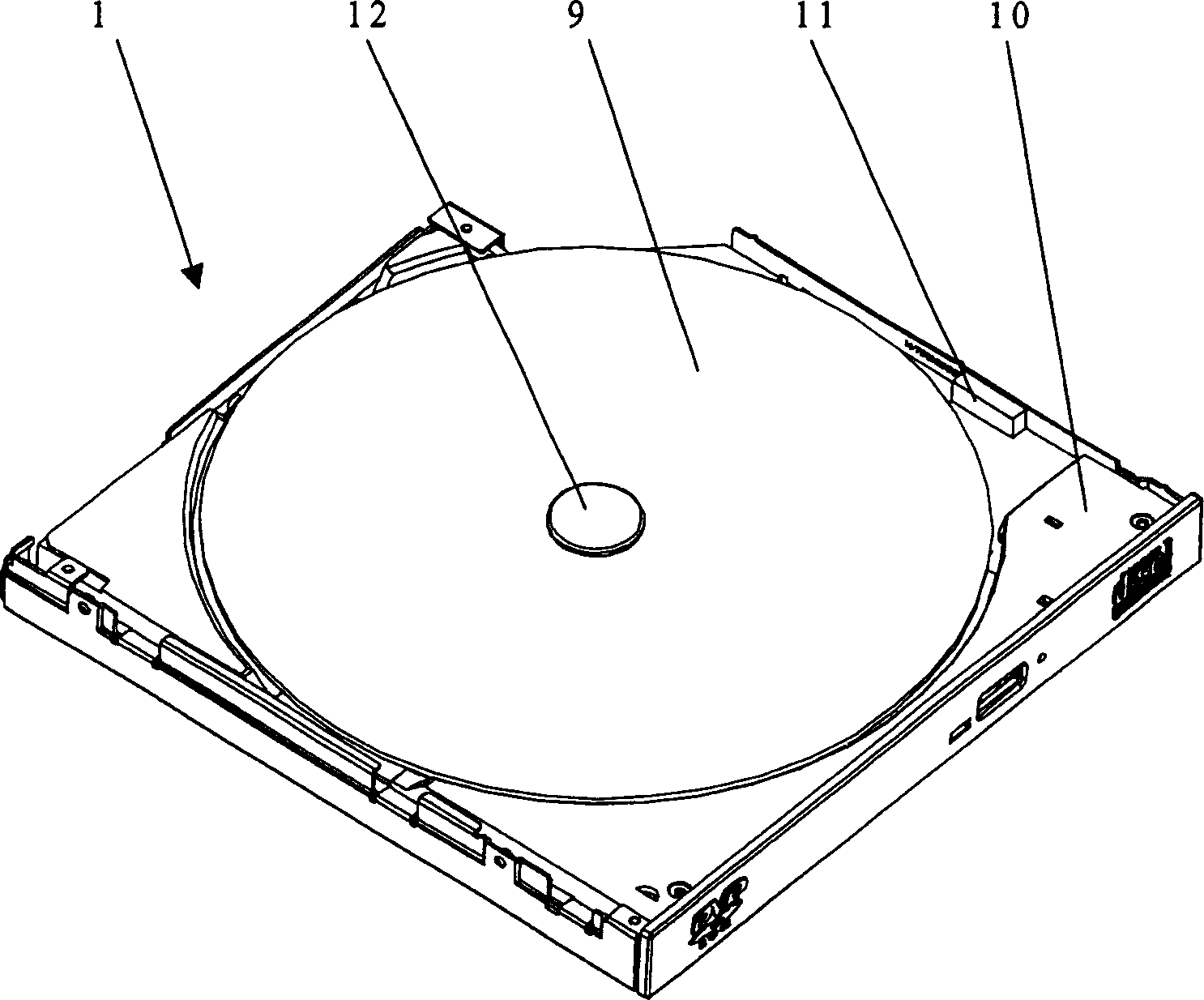

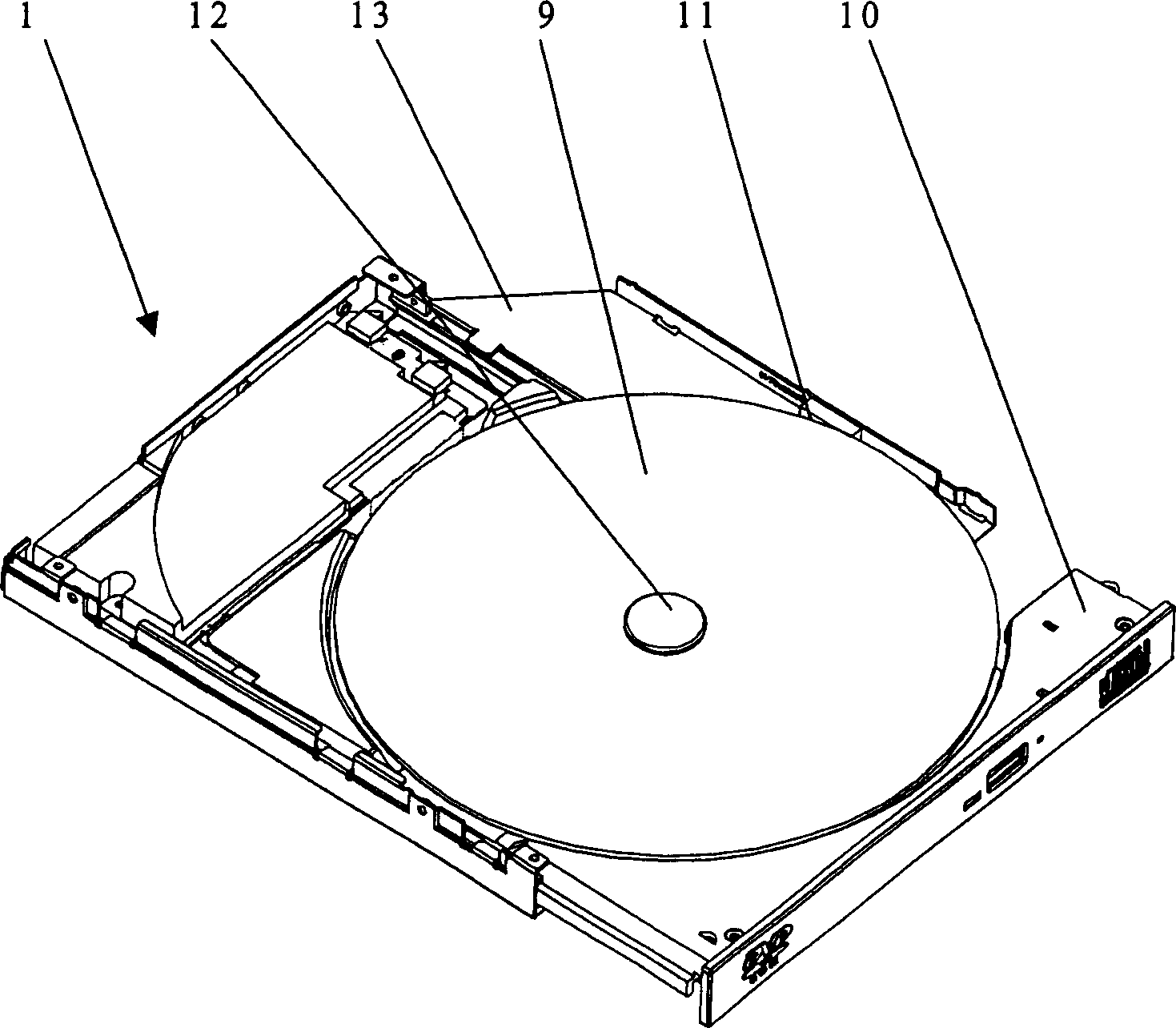

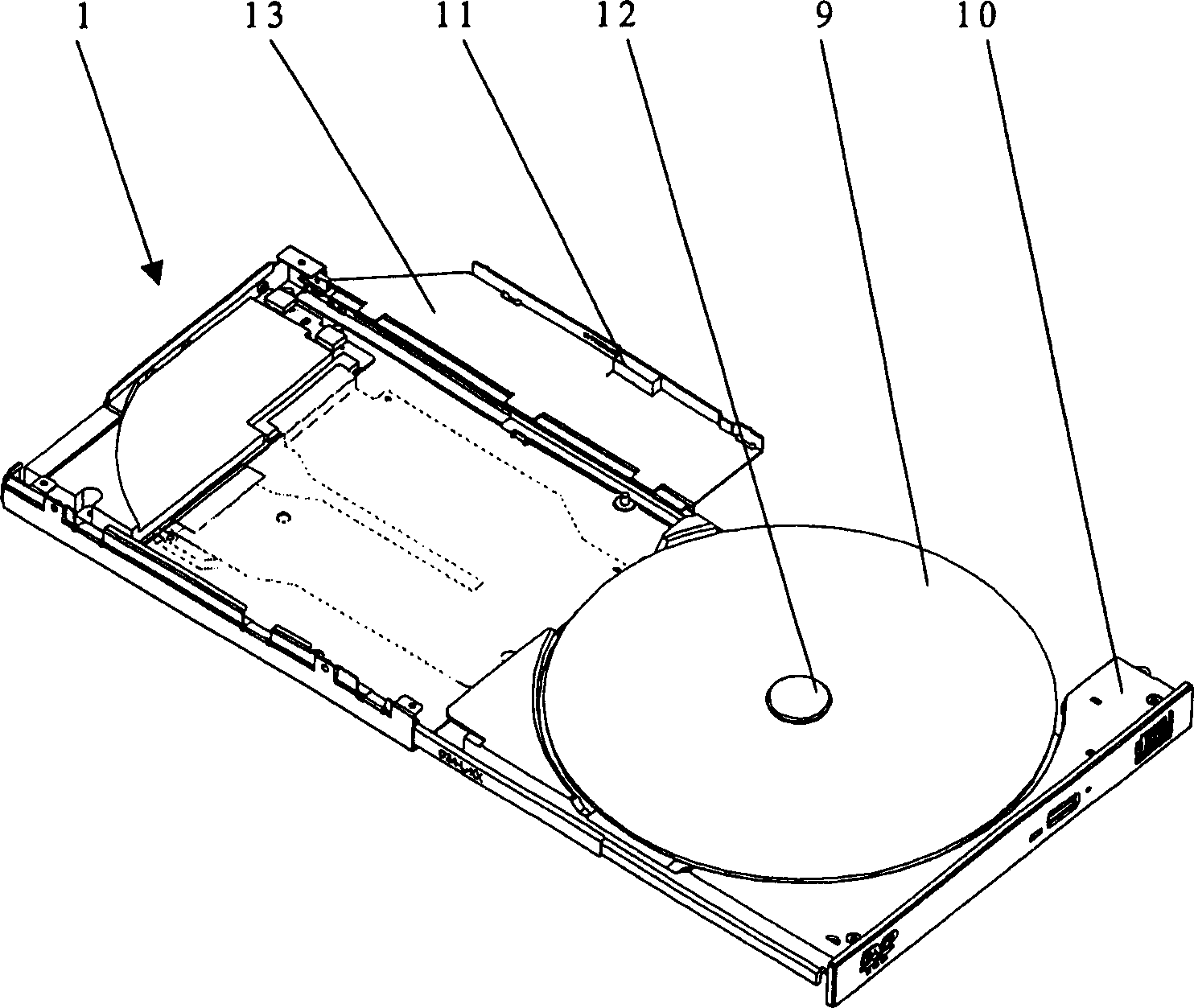

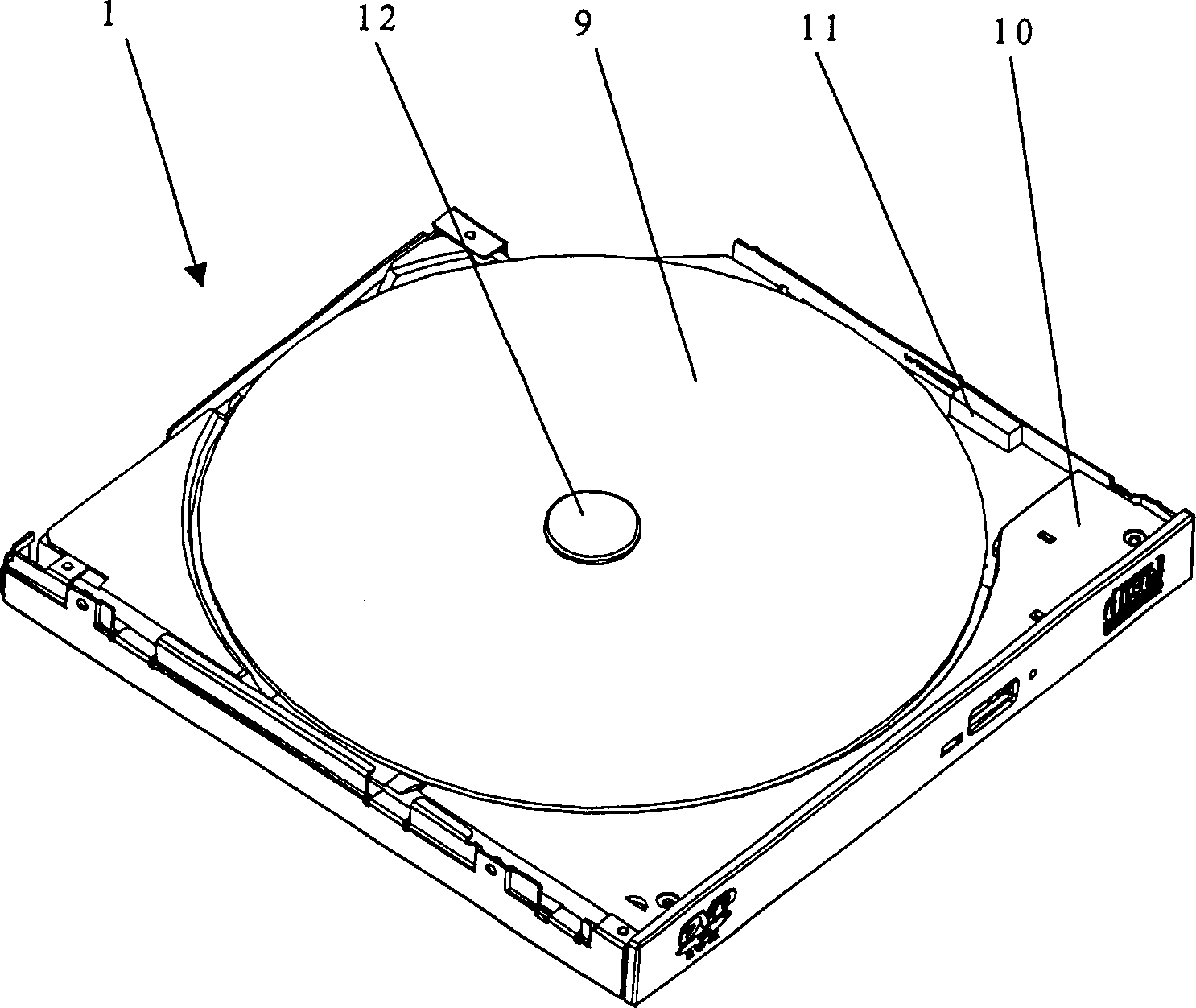

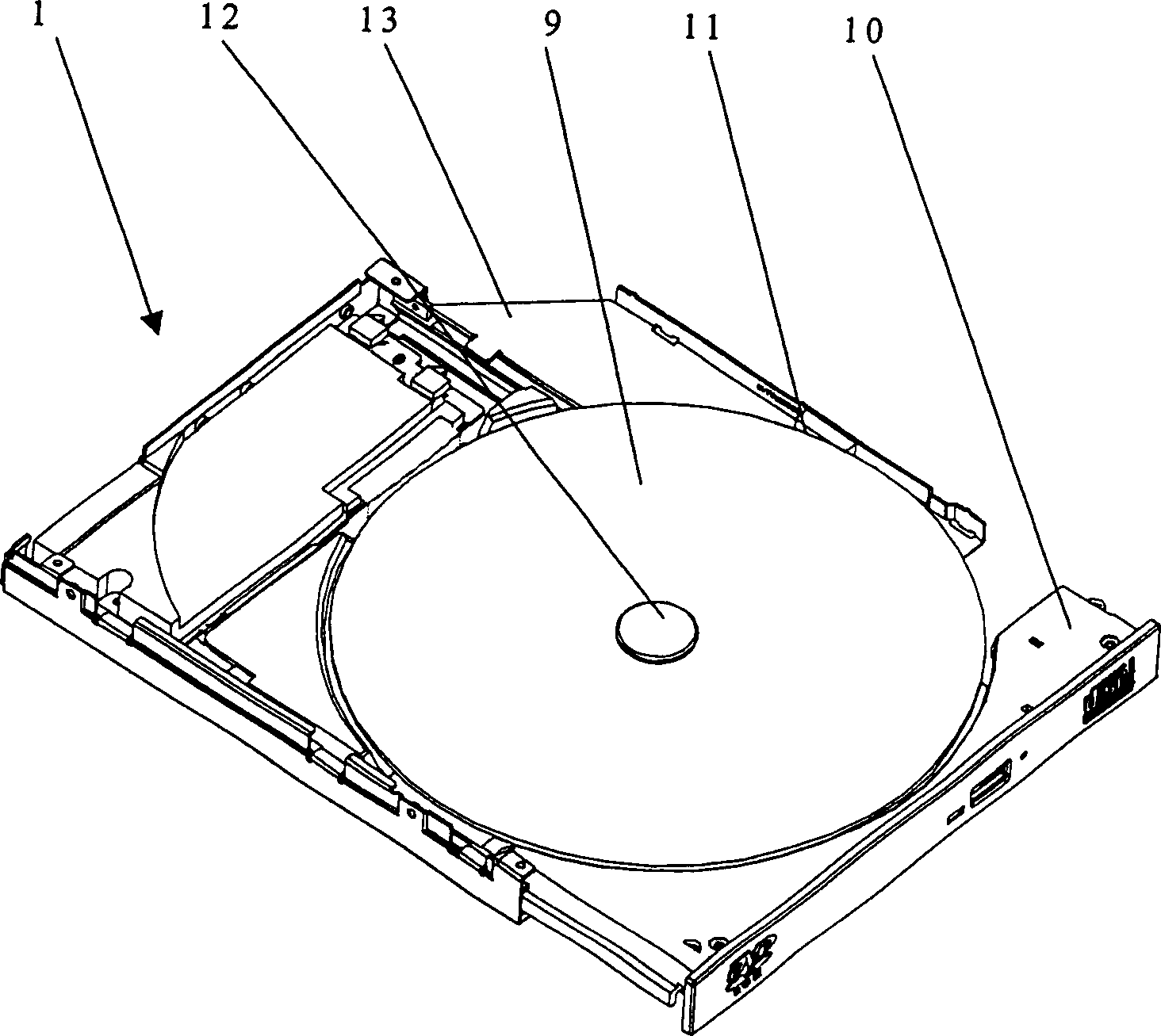

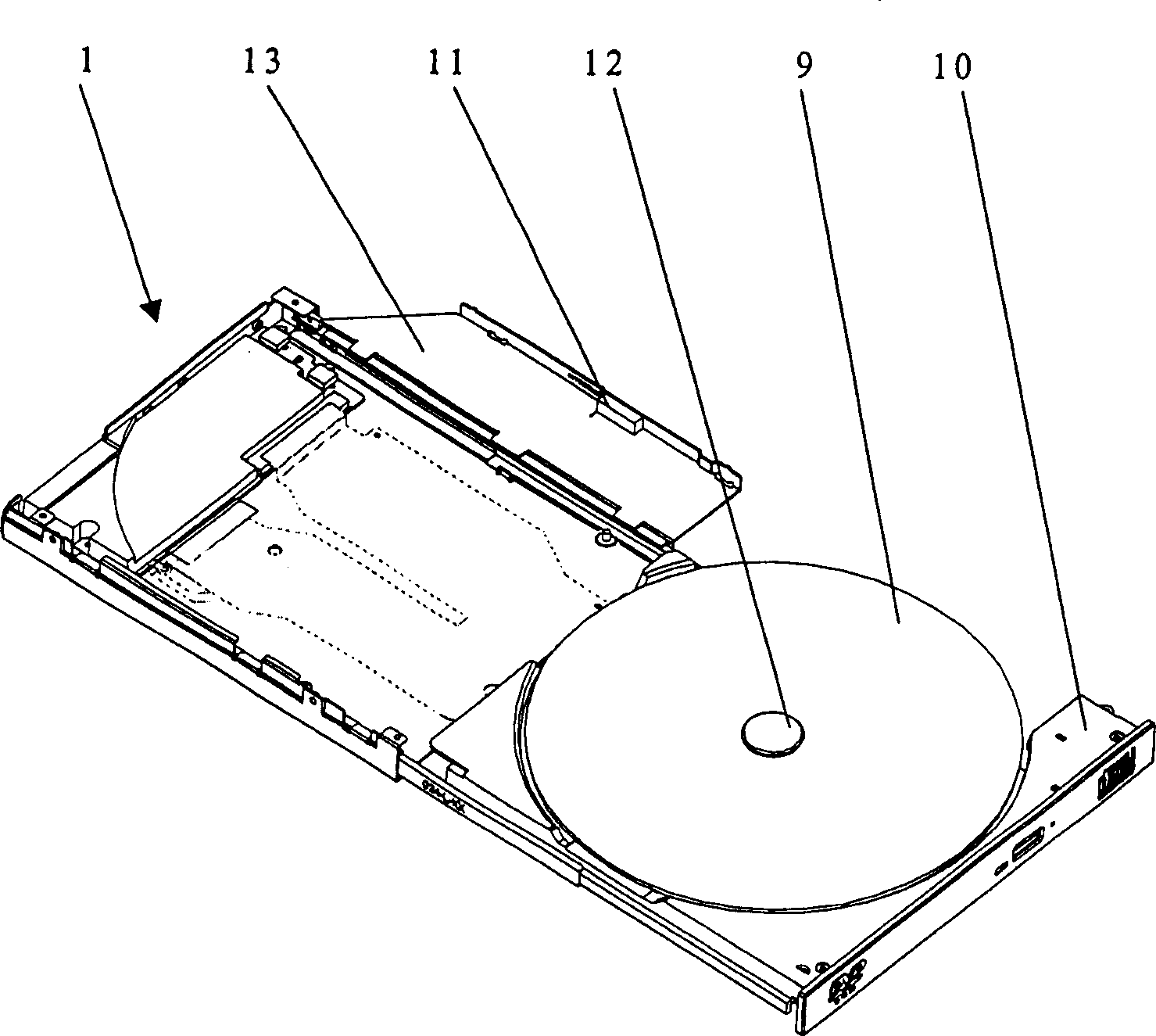

Pallet disc brake mechanism of thin disc apparatus

InactiveCN1553448AEffective stopDoes not affect the braking functionRecord information storageRecording on magnetic disksEngineeringDisc brake

Owner:LITE ON IT

Anti-dropping device for hydraulic decoking system

ActiveCN104019352AAccurateRapid responseThermal non-catalytic crackingSelf acting brakesLocking mechanismEngineering

An anti-dropping device for a hydraulic decoking system comprises a lifting mechanism, a lever mechanism, a locking mechanism, a guide mechanism and a support. Locking guide rails for guiding the support to perform vertical motion are arranged on two sides of the support, the support is provided with the guide mechanism matched with the locking mechanism, the lifting mechanism is arranged at the top end of the support and provided with a lifting rod, the lifting rod penetrates a through hole in the support downwards and is connected with the locking mechanism through the lever mechanism fixed on the support, the part of the lifting rod located between the lever mechanism and the support is sleeved with a returning spring, the returning spring can push the lever mechanism to move when the lifting mechanism drops, and the returning spring enables the locking mechanism to be in contact with the locking guide rails. The anti-dropping device is simple in structure, reasonable in design, low in processing and manufacturing cost, long in continuous failure-free running cycle, high in safety reliability and low in device cost, and accidental injury accidents caused to operators due and caused by device dropping are effectively avoided.

Owner:LUOYANG JIANGUANG SPECIAL EQUIP

Soybean milk machine

The invention discloses a soybean milk machine, comprising a barrel, a disintegrator, a crushing motor, and a cooking heating component. The barrel comprises an inner container. The internal diameter dimension of the lower end face of an upper section part of the inner container side wall is smaller than the internal diameter dimension of the upper end face of the lower section part of the side wall, so as to form a transition part between the upper section part and the lower section part, the transition part being narrowed relative to the lower section part. The disintegrator is arranged in the barrel. The crushing motor is connected with the disintegrator. The cooking heating component is at least used to cook and heat raw soybean milk. The upper edge of the transition part is higher than the highest liquid level in the barrel in a heating cooking process. Through arranging the transition part with the narrowed structure, the soybean milk machine can effectively extrude and stop foam generated on liquid surface, and through the transition part, foam would extrude each other, so the foam is easier to break, defoaming effect is improved, and soybean milk making time is effectively shortened.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

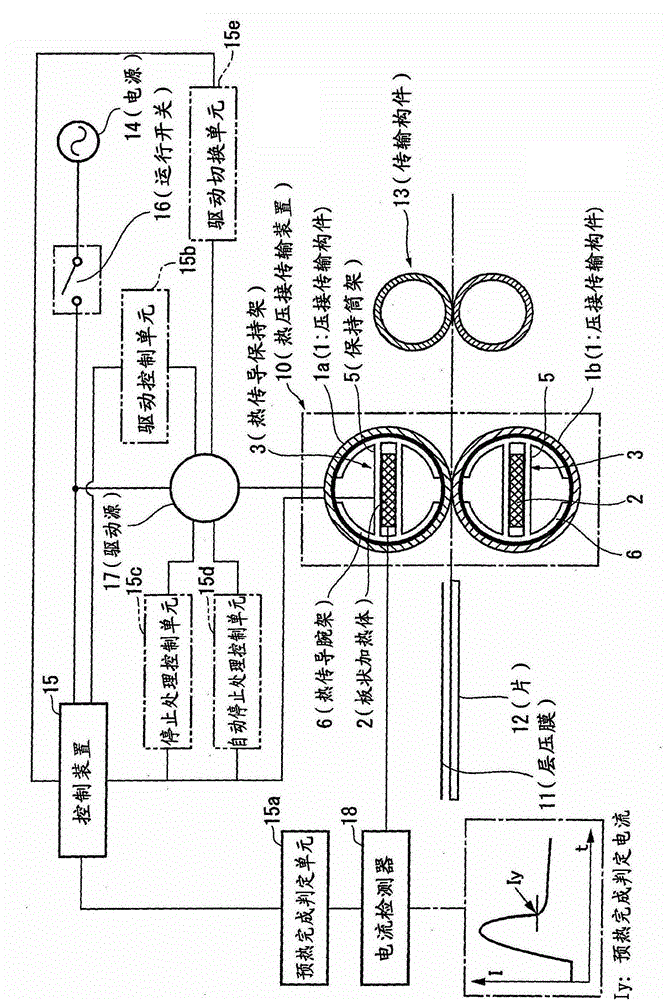

Lamination device

InactiveCN103085439BIncrease ascent speedMaintain stabilityControlling laminationLaminationElectrical resistance and conductancePower flow

A laminating device increases raising speed of laminating speed without a temperature detector and stably sustains the laminating temperature. The laminating device is provided with the following components: a thermal compression bonding transmission device (10) which at least performs overlapped transmission on laminating films (11) and sheets (12) and thermal compression bonding; a control device (15) which controls the thermal compression bonding transmission device (10); an operation switch (16) which supplies power from a power supply (14) in operation. The thermal compression bonding transmission device (10) is provided with a plate-shaped heater (2) which comprises a PCT thermistor on at least one of compression transmission components (1) in pairs. The control device (15) is provided with the following components: a current detector (18) which detects the current value along with energization to the PCT thermistor in operation; and a preheating complement determination unit (15a) which determines whether the surface temperature of the compression bonding transmission component (1) reaches the preheating complement state with a temperature at which the laminating can be performed on condition that reduction change of the current value detected by the current detector (18) after peak of increase change reaches a preset value.

Owner:SAKAE CO LTD

Pallet disc brake mechanism of thin disc apparatus

InactiveCN1272789CEffective stopDoes not affect the braking functionRecord information storageRecording on magnetic disksDisc brakePallet

Owner:LITE ON IT

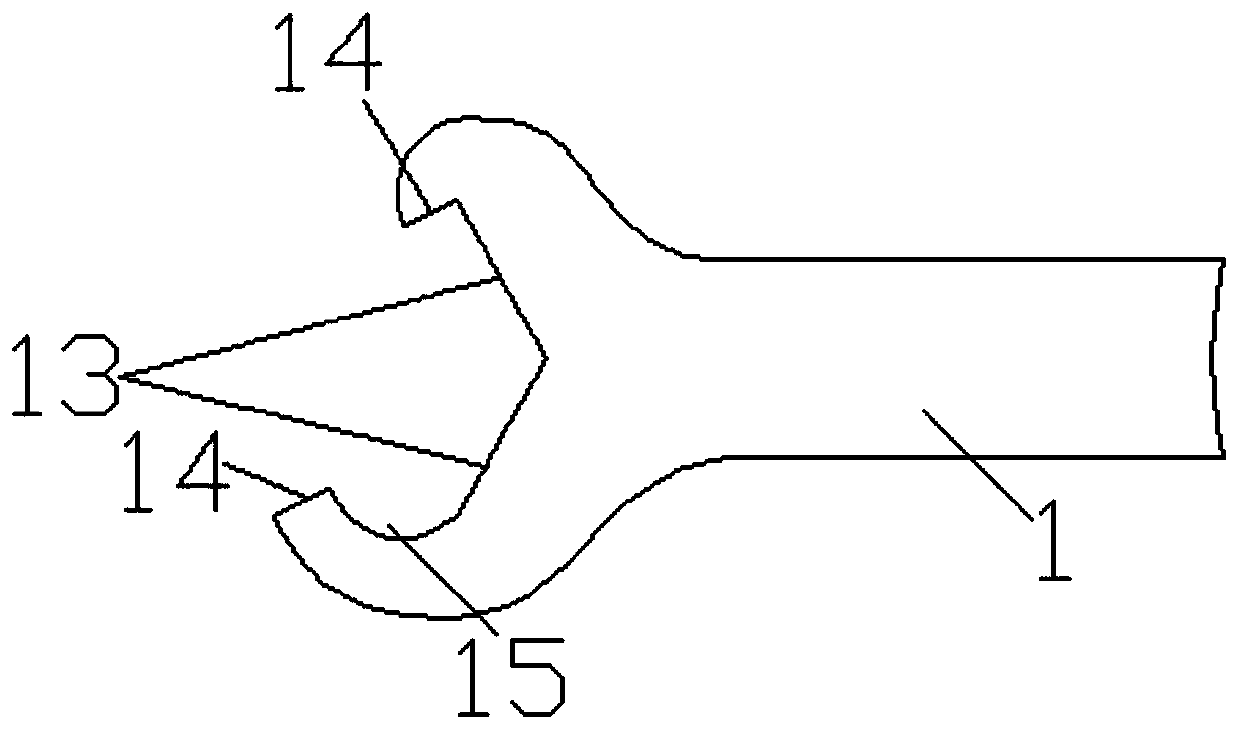

Lint hooking tool of tufting machine

InactiveCN105887377ARealize hooking operationEffective stopTufting apparatusEngineeringMechanical engineering

The invention discloses a lint hooking tool of a tufting machine. The lint hooking tool comprises a tool beam, wherein the tool beam is provided with a vertical section and a transverse section; the upper end part of the vertical section is bent backward and extends to form a reversed hook part; the lower end part of the vertical section is connected with the front end part of the transverse section; the rear end part of the transverse section is connected with a smooth section which extends upward obliquely; and the smooth section is connected with an inserting tail part which is backward bent and extends. By virtue of the lint hooking tool disclosed by the invention, after the reversed hook part moves backward to hook a lint loop and moves frontward again to hook the next lint loop, the hooked lint loop is released from the reversed hook part and slides out upward along the smooth section, so that people can realize lint hooking operation under the condition that the lint loop is not cut by people.

Owner:ZHEJIANG DADA HOMETEXTILE

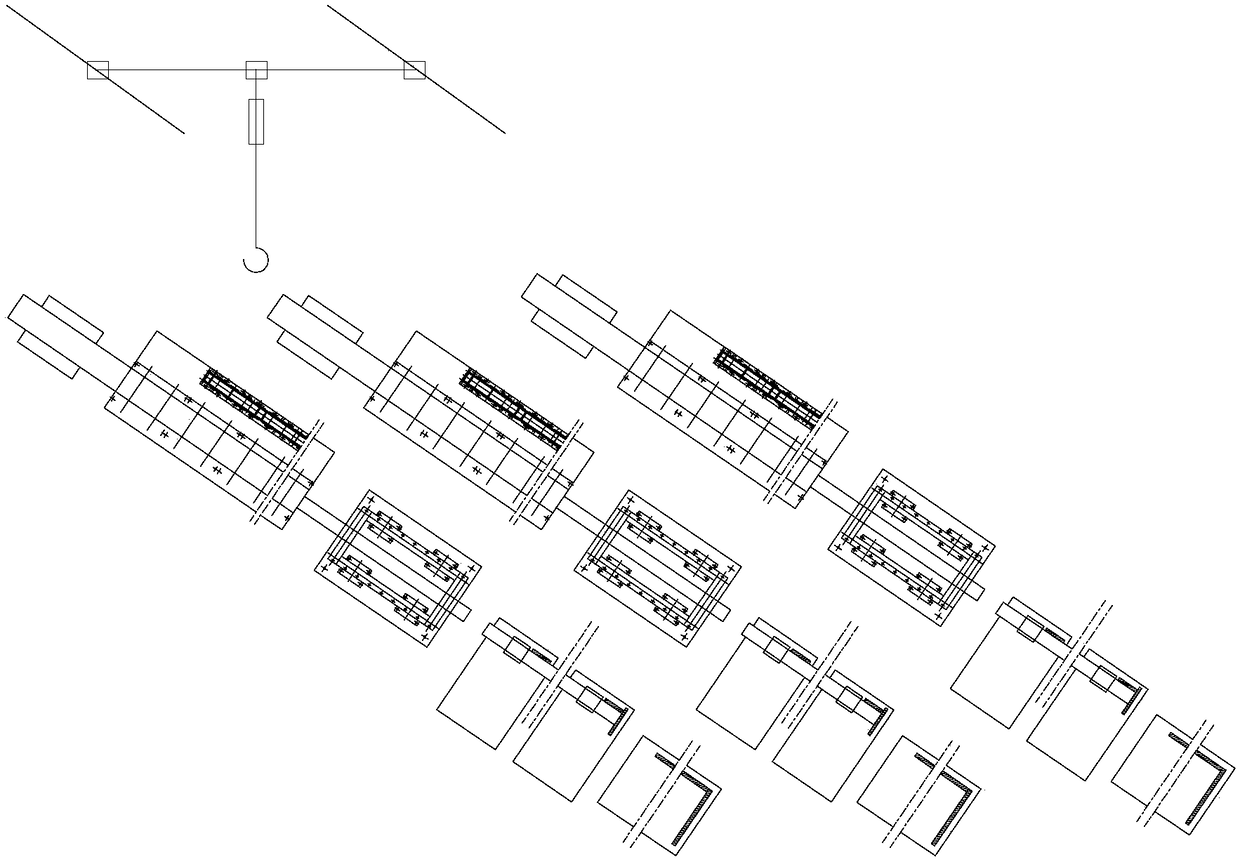

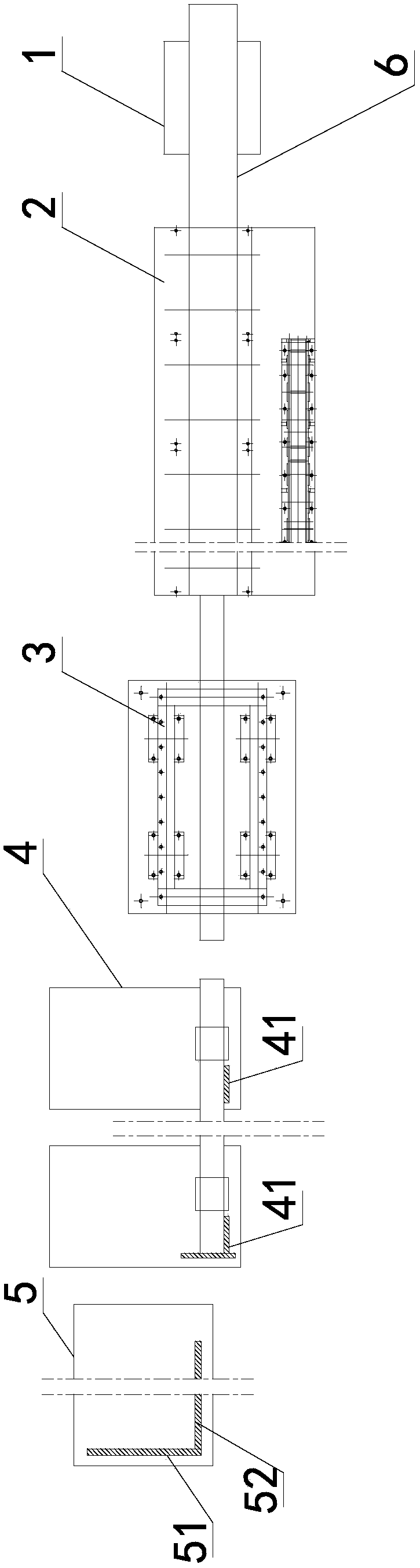

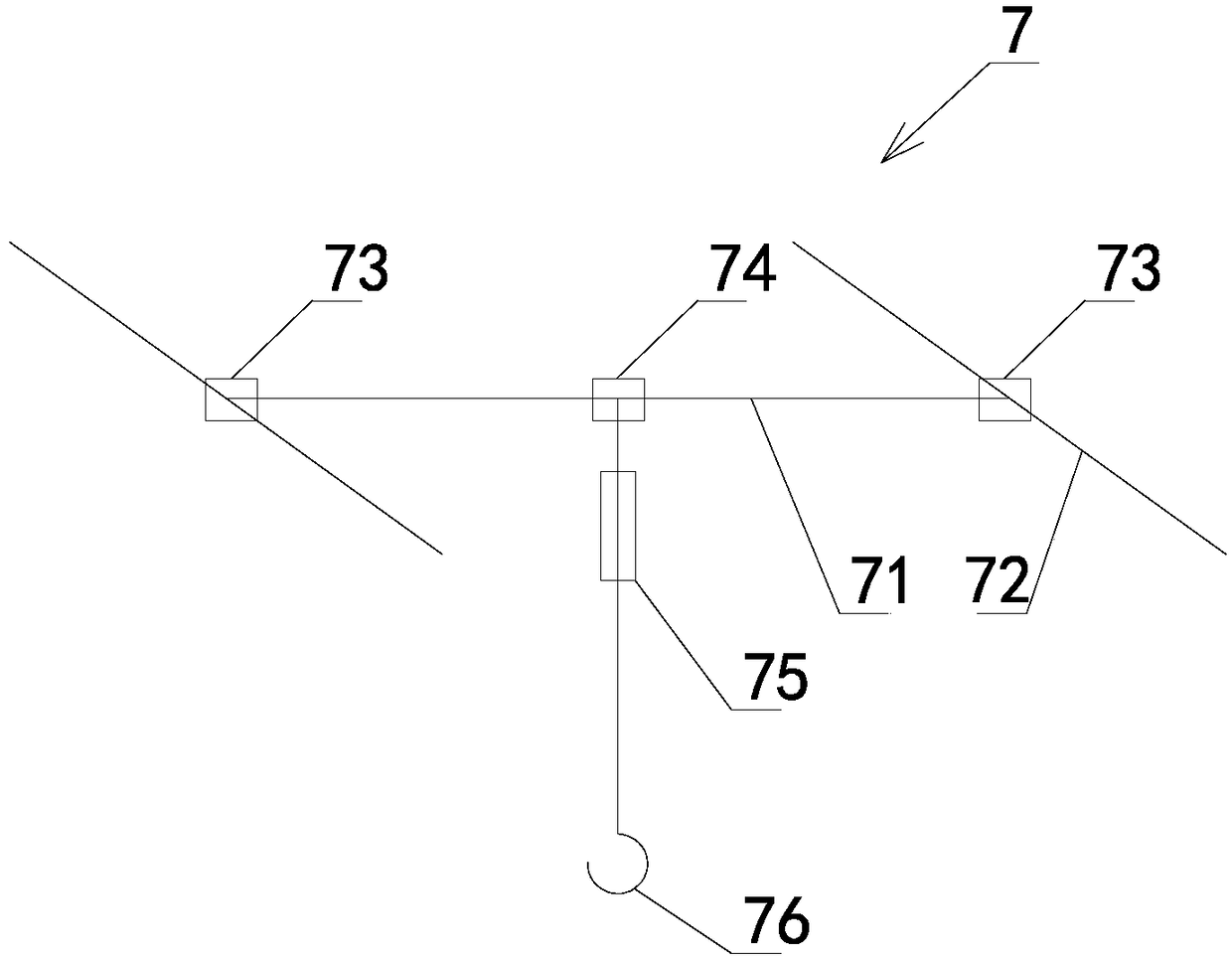

Keel production system

InactiveCN108860763AEliminate channelSmall footprintOther manufacturing equipments/toolsBundling machine detailsEngineeringUtilization rate

The invention discloses a keel production system. The keel production system comprises a travelling crane and multiple keel production devices which are arranged side by side, wherein each keel production device comprises a feeding mechanism, a bending mechanism, a shearing mechanism, a packaging mechanism and a stacking mechanism which are arranged in sequence; the travelling crane comprises a supporting beam, a moving mechanism, a lifting mechanism and a pothook; the moving mechanism is connected to the supporting beam; one end of the lifting mechanism is connected to the moving mechanism; the other end of the lifting mechanism is connected to the pothook; an installing frame is arranged at a feeding port side of the bending mechanism; and the shearing mechanism is arranged at a discharging port side of the bending mechanism. The keel production system can be applied to the technical field of a production device, can effectively overcome the defects in the prior art and can effectively improve the production efficiency; further, the floor space required can also be reduced; and the utilization rate of plants is increased.

Owner:BEIJING NEW BUILDING MATERIAL

Glove and glove reinforcement

InactiveCN100581626CEasy to makeGuaranteed bending performanceGlovesBall sportsEngineeringClassical mechanics

Owner:赫尔姆特·胡森欧德

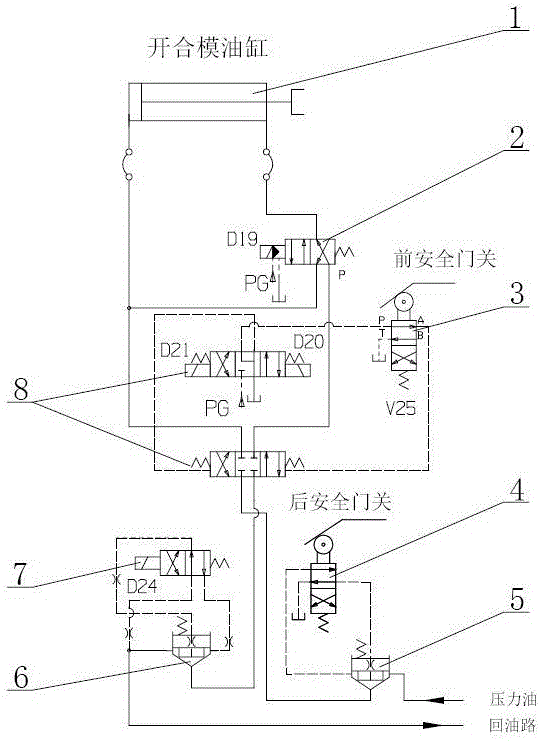

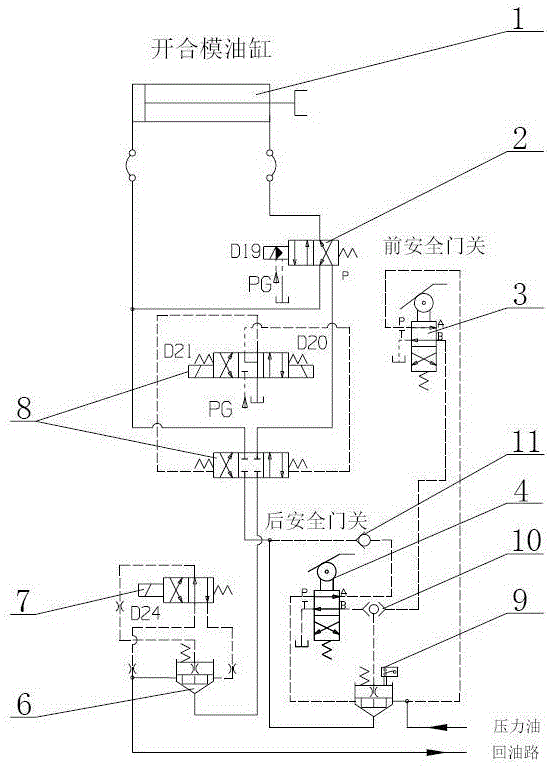

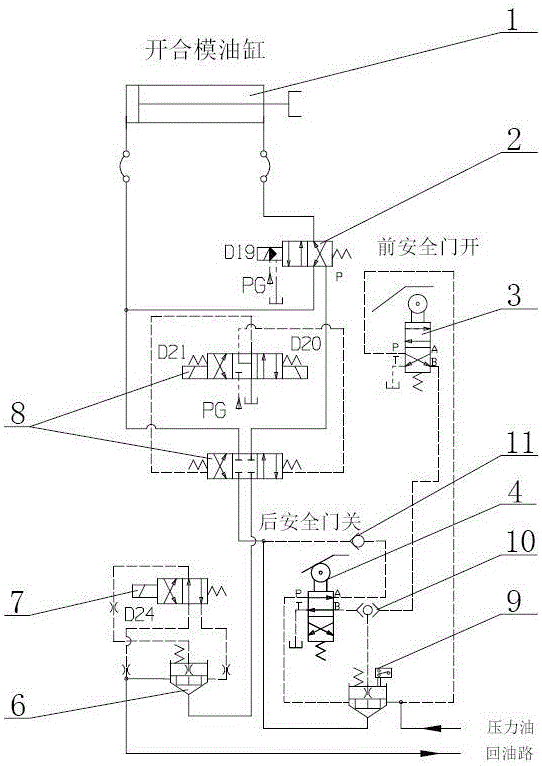

A hydraulic system for associated safety control of front and rear doors of injection molding machine

Owner:江门顺兴吸塑厂有限公司

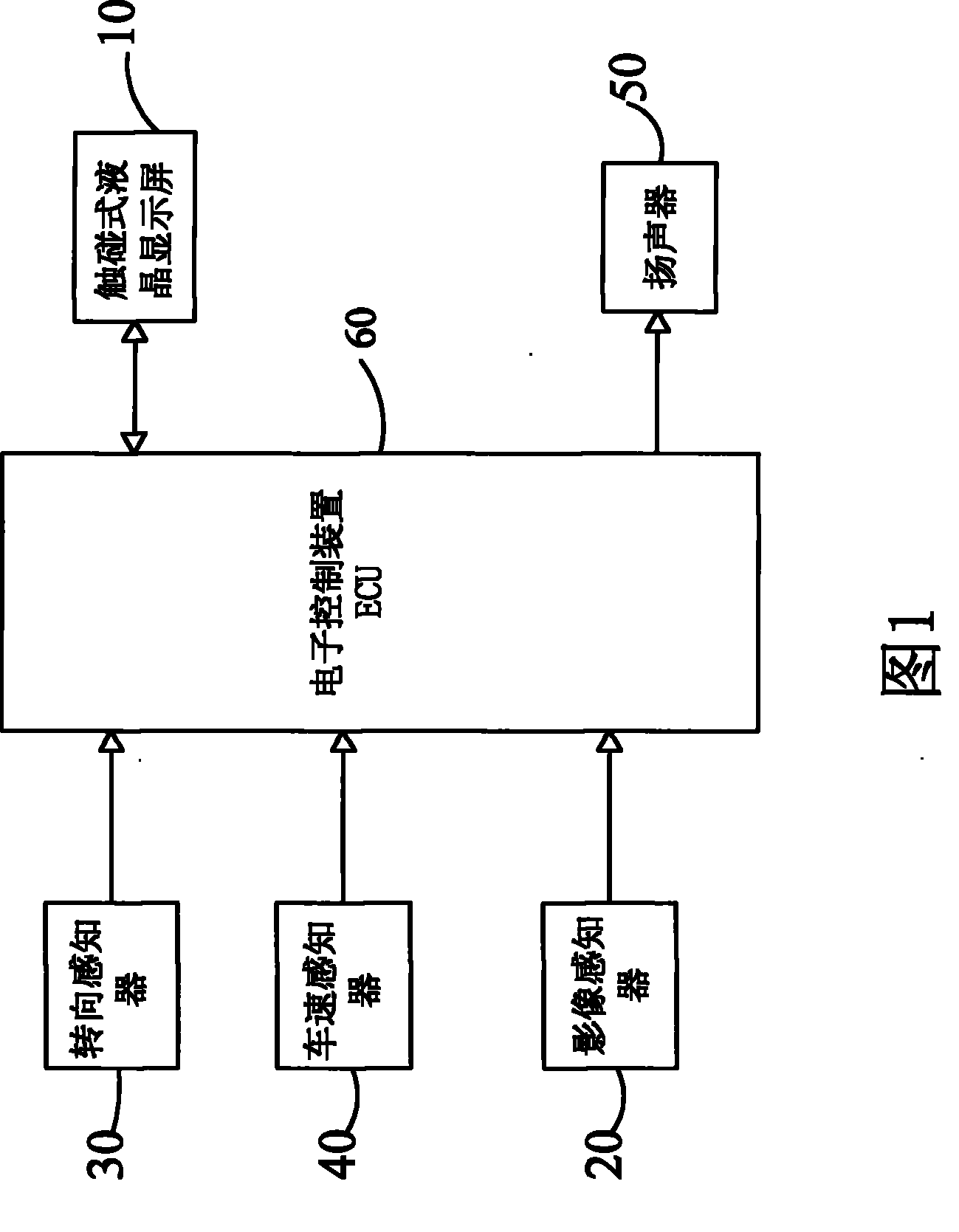

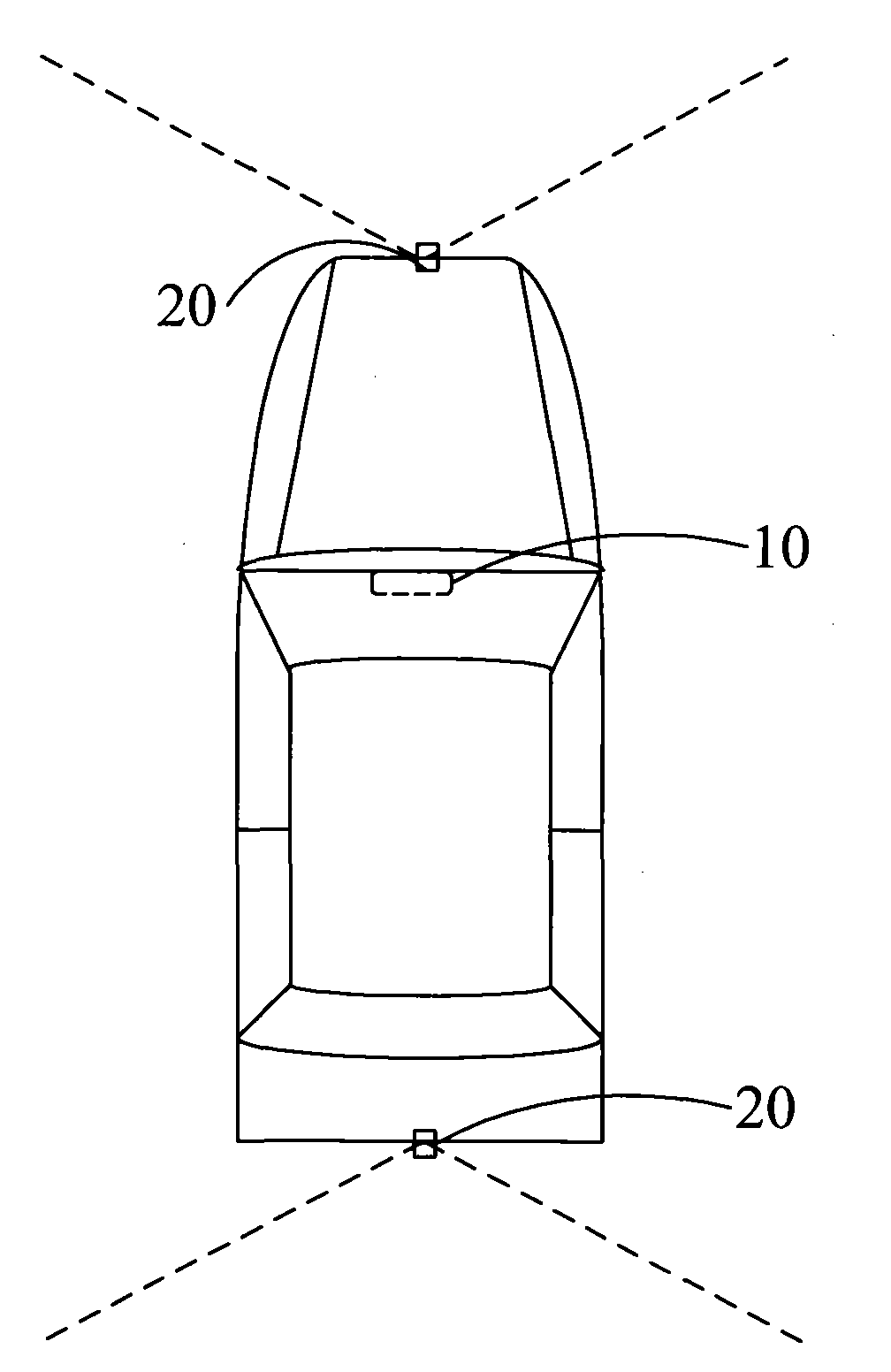

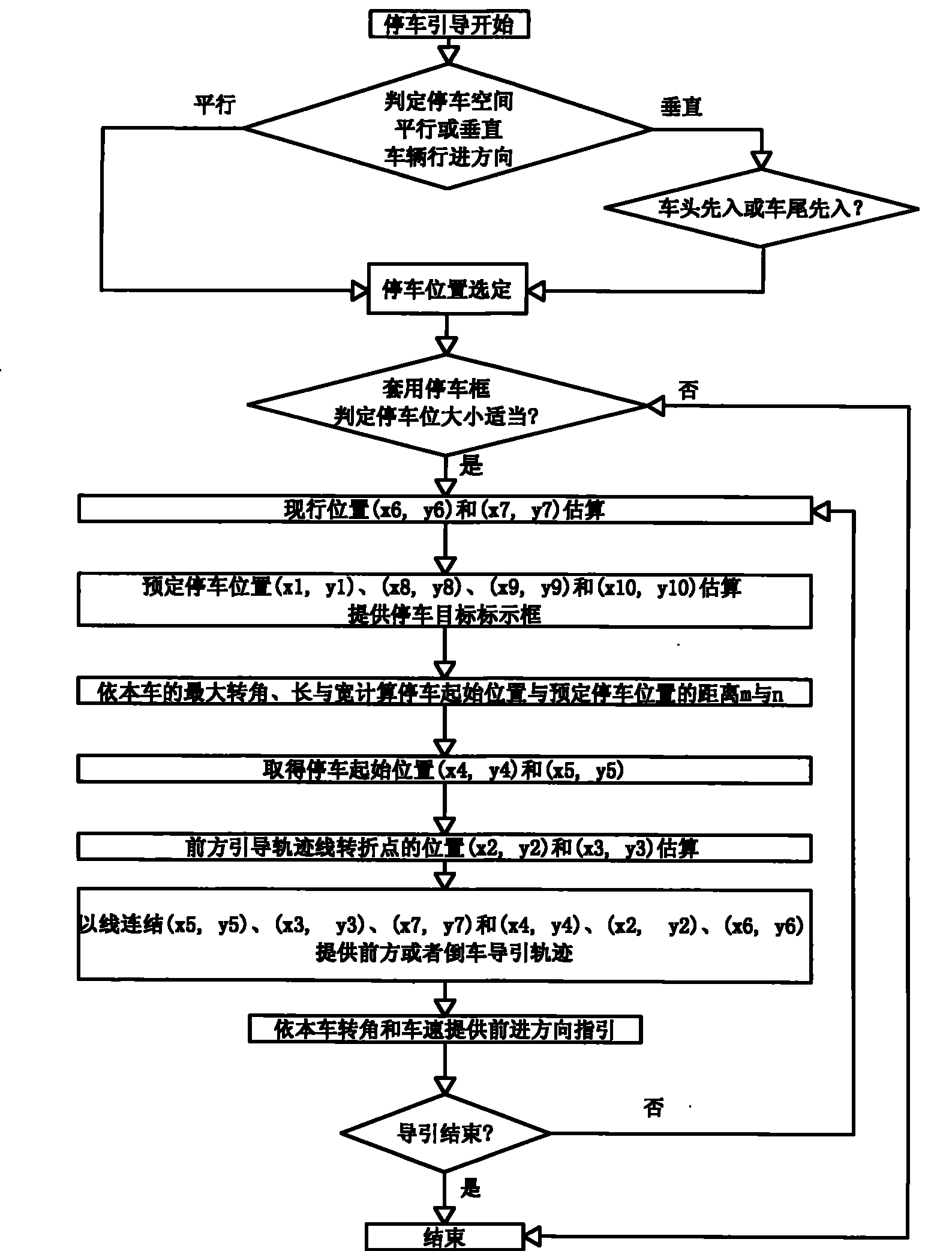

Parking guiding system and guiding method thereof

ActiveCN101727754BQuick stopEffective stopIndication of parksing free spacesAnti-collision systemsReal-time computingImage sensor

Owner:AUTOMOTIVE RES & TESTING CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com