Lamination device

A lamination device and lamination film technology, applied in the direction of lamination device, lamination, lamination control, etc., can solve the problems of inspection abnormality, heating operation out of control, etc., to prevent misoperation, accelerate the rising speed, and suppress the influence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

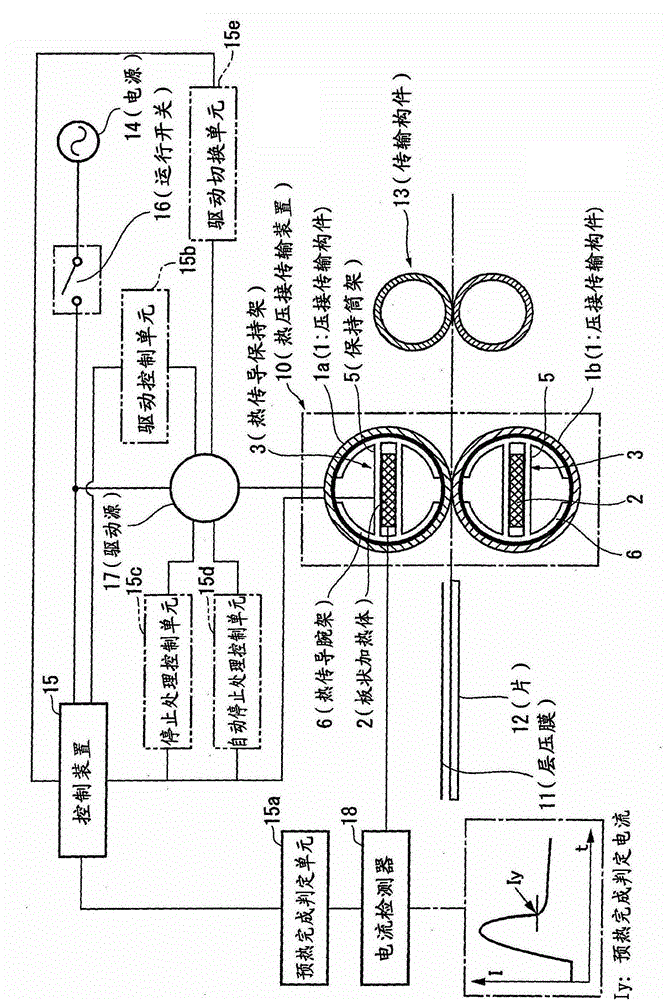

[0094] — Lamination device —

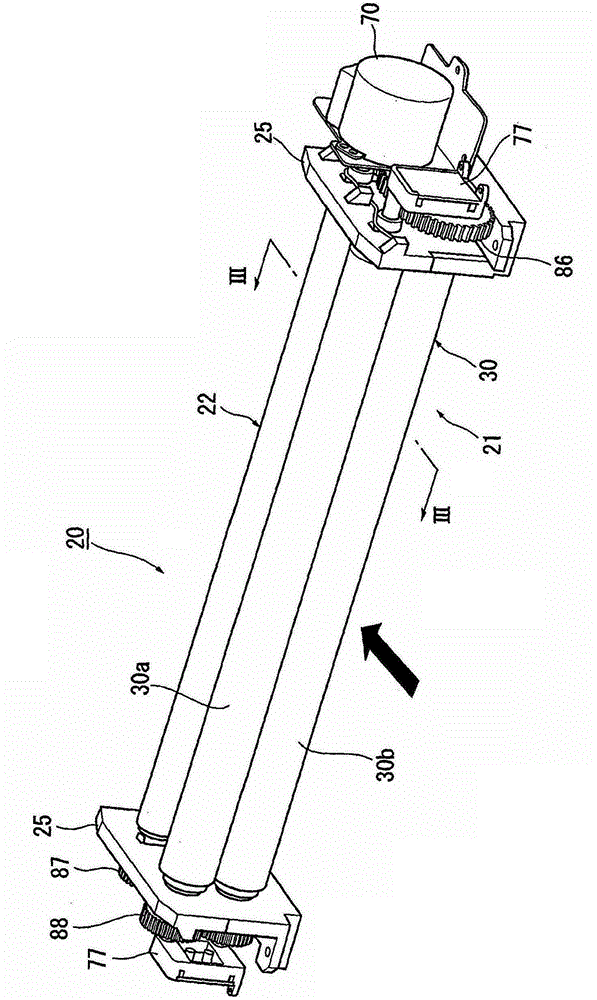

[0095] figure 2 as well as image 3 Embodiment 1 of the laminator to which the present invention is applied is shown.

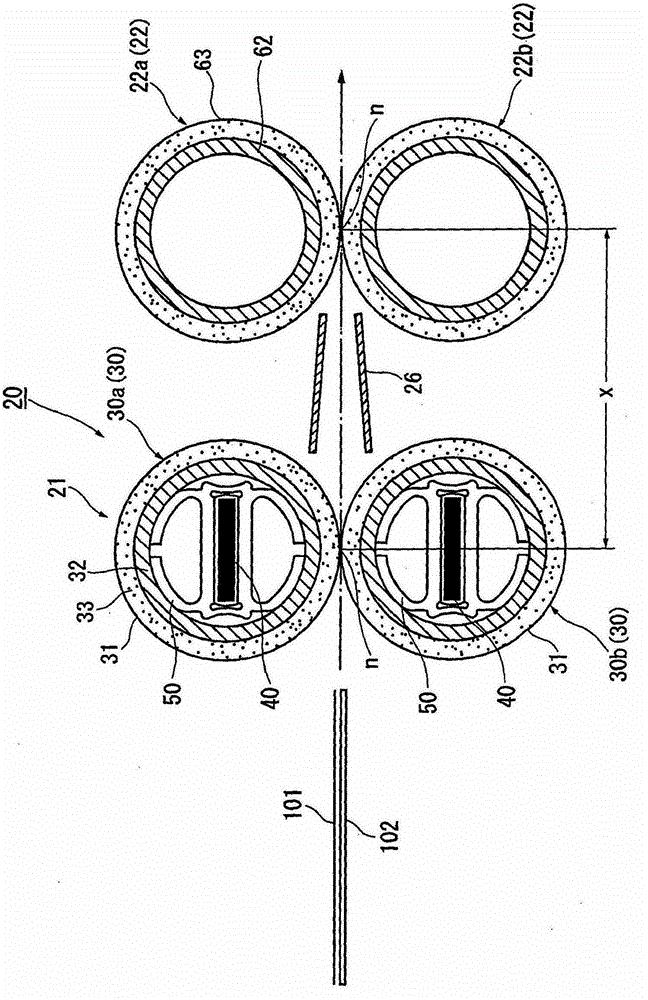

[0096] In this figure, the laminator 20 includes a thermocompression bonding transfer device 21 that is thermocompression-bonded while conveying a lamination film 101 and a sheet 102 in a superimposed manner, and is disposed on the downstream side of the thermocompression bonding transfer device 21 in the sheet transfer direction. The paired transport rollers 22 on the top are supported by the supporting side plates 25 of the housing.

[0097] In the present embodiment, the thermocompression bonding transfer device 21 is constituted by a pair of thermocompression bonding transfer rollers 30 (specifically, 30a, 30b).

[0098] The pair of thermocompression transfer rollers 30 includes: a pair of crimp transfer rollers 31 that are both formed in a hollow roll shape and conveyed with the lamination film 101 and sheet 102 sandwic...

Embodiment approach 2

[0219] Figure 22 The outline of Embodiment 2 of the laminator to which the present invention is applied is shown.

[0220] In this figure, the laminating device 20 is equipped with multiple sets (3 groups in this example) of pairs of thermocompression transfer rollers 30 (specifically 30(1), 30(2) as the thermocompression transfer device 21. ), 30 (3)), and a pair of transport rollers 22 for pulling and transporting the laminated sheet 102 are arranged on the downstream side of the sheet transport direction.

[0221] Here, the configuration of each thermocompression transfer roller 30 is the same as in Embodiment 1, and a guide member 26 for guiding the laminated sheet 102 is provided between each thermocompression transfer roller 30 and transfer roller 22 as necessary. . In addition, the same symbols as those in Embodiment 1 are assigned to the same components as those in Embodiment 1, and detailed description thereof will be omitted here.

[0222] According to this embod...

Embodiment approach 3

[0224] Figure 23 The outline of Embodiment 3 of the laminator to which the present invention is applied is shown.

[0225] In this figure, the lamination device 20 differs from Embodiments 1 and 2 in that, for example, both have a pair of upstream pressure-contacting transfer rollers 91 formed in a hollow roller shape and conveyed with the lamination film 101 and sheet 102 sandwiched between them (specifically, Said to be 91a, 91b); Provided on the downstream side thereof are formed in a roll shape and sandwich the laminated film 101 and the sheet 102 conveyed paired downstream side crimping transfer rollers 92 (specifically, 92a, 92b ); the belt members 93 (specifically 93a, 93b) such as polyimide resin, etc., which are respectively installed between these pairs of upstream and downstream pressure contact rollers 91, 92, for example, in the paired upstream The heater assembly 40 is held on one side crimping transfer roller 91 via the heat transfer holder 50 .

[0226] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com