A mobile jacking pipe backstop support device and backstop method

A support device, mobile technology, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of unable to meet the requirements of strength and stability, cumbersome installation process, unreliable, etc., to achieve anti-recession The limit process is scientific and efficient, saving construction space, and good anti-recession effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention can be better understood from the following examples.

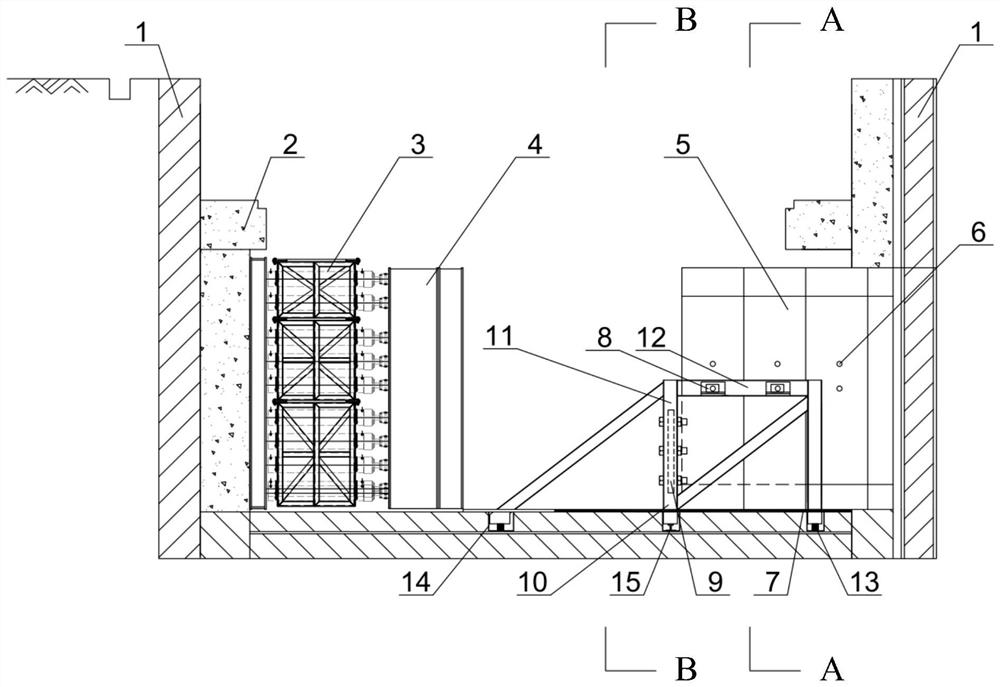

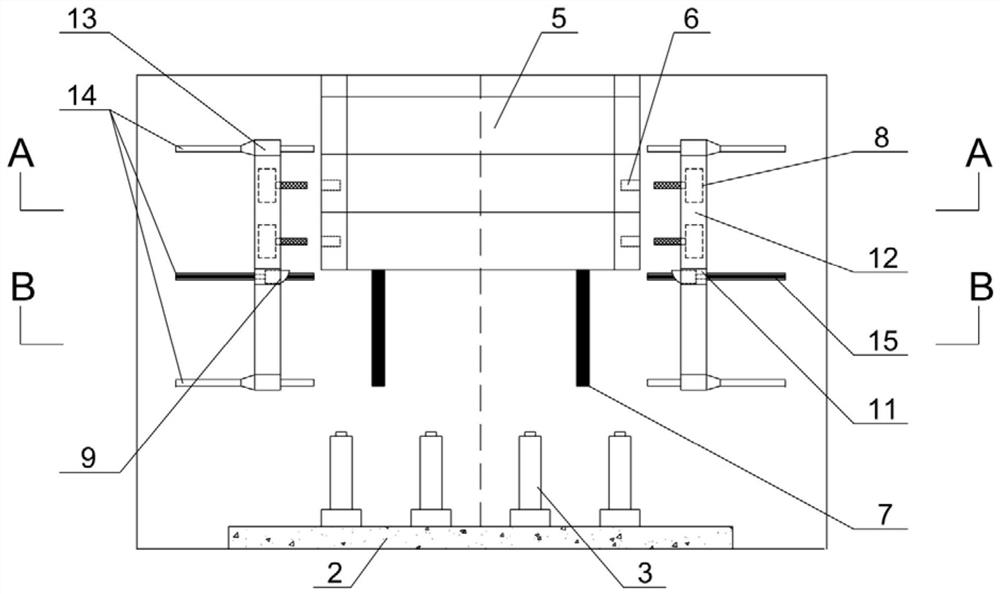

[0046] figure 1 Shown is a schematic elevation view of the backstop device in use. The main structure in the starting well includes a working well 1, a back wall 2, a jacking oil cylinder 3, a top iron 4 and a pipe section guide rail 7, and a cylindrical tubular hoisting hole 6 is arranged at the position of the upper middle side wall of the pipe section 5. The mobile pipe jacking stop support device includes a pair of back stop supports 10 respectively arranged on both sides of the pipe section 5 in the jacking direction, and a support guide rail 15 for the back stop support 10 to move along the jacking direction perpendicular to the pipe section 5;

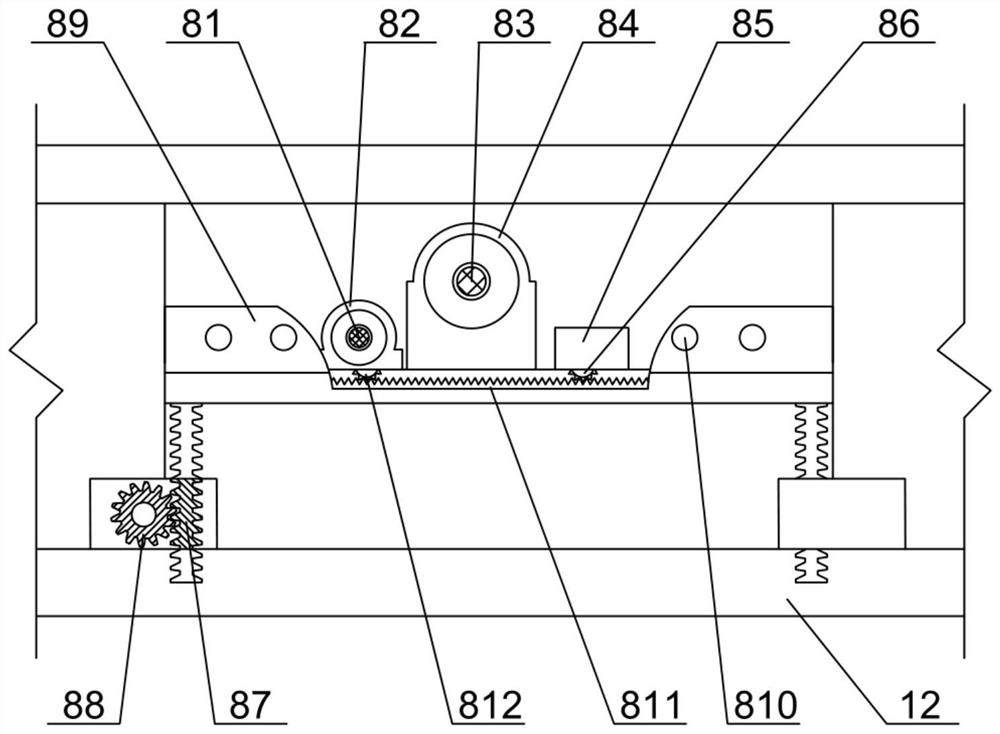

[0047] The inner side of the rear end of the two sides of the backstop brackets 10 are respectively provided with a mechanical locking device 9 for restricting the back of the pipe section 5; Rod device 8; when the pipe section 5 advances in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com