A hydraulic system for associated safety control of front and rear doors of injection molding machine

A technology of safety control and hydraulic system, which is applied in the field of hydraulic circuit safety control system and injection molding equipment. It can solve the problems that the hydraulic safety circuit cannot meet the needs of customers, the high degree of equipment safety requirements, and the failure of the safety insurance of the control oil circuit, etc., to achieve effective stop. The effect of opening and closing mold, improving safety level and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

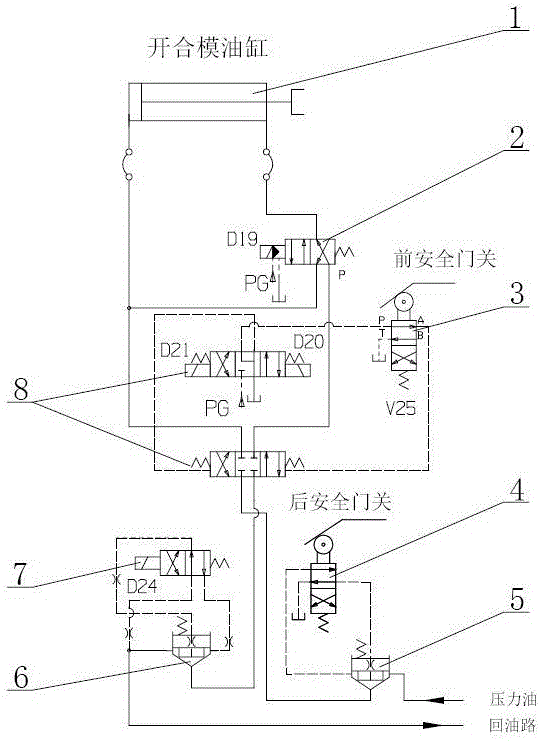

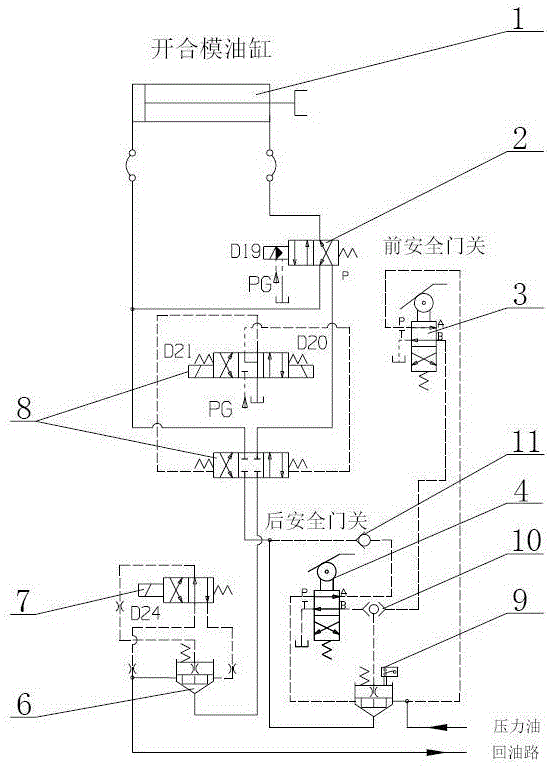

[0012] The implementation mode is to simulate the actual application of the safety control system of the hydraulic circuit of the mold opening and closing of the plastic machine in sequence. In the hydraulic circuit of the safety control, the front safety door touch panel is released, the rear safety door touch panel is released, the front safety door touch panel and the rear door are released. Describe the four working conditions in which the touch panels are all released and the front safety door touch panels are all pressed down.

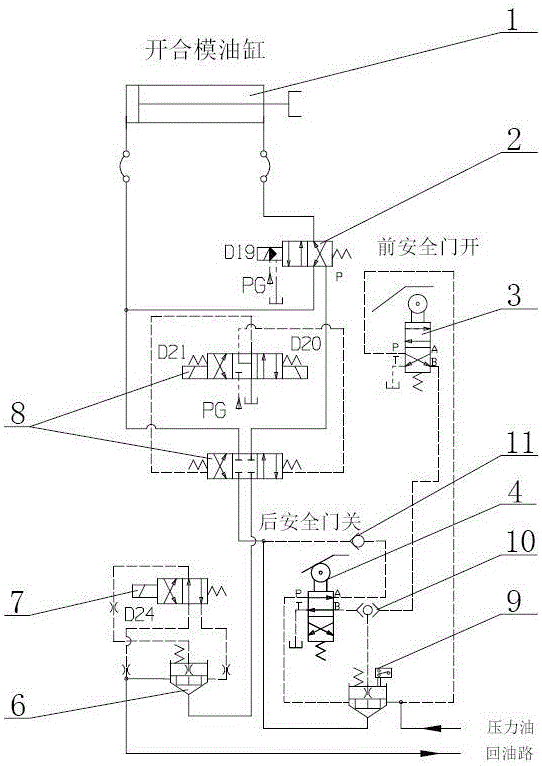

[0013] Only the front safety door touch panel is released: if image 3 As shown, the oil intake of the system communicates with chamber B through chamber P of the front door mechanical directional valve 3, and connects with the upper chamber of the cartridge valve (9) with detection function through the shuttle valve (10), because the area of the upper chamber of the cartridge valve is larger than The area of the lower chamber, the pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com